(1) Operations must be carried out in such a manner that no more

advertisement

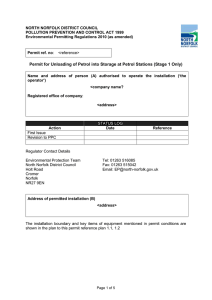

London Borough of Camden Environmental Permit To Operate An Unloading of Petrol Into Storage Activity Pollution Prevention and Control Act 1999 Environmental Permitting (England and Wales) Regulations 2007 Installation Name BP Euston Filling Station Installation Address 142 Hampstead Road, London NW1 2PT Environmental Permit Reference Number: PPC17/08 Environmental Permit - BP Euston Filling Station- PPC17/08 INTRODUCTORY NOTE This does not form a part of the Environmental Permit. The following Environmental Permit is issued under the Environmental Permitting (England and Wales) Regulations 2007, (SI2007/3538) to operate an installation carrying out an unloading of petrol into storage at petrol stations activity listed in 1.2 Part B (d) of Part 2 of those Regulations, to the extent of the Environmental Permit. The emissions to air that require control are volatile organic compounds in particular benzene. The Environmental Permit specifies conditions that must be complied with. The Operator shall use the “best available techniques” (BAT) for preventing or, where that is not practical, reducing emissions from the installation. Techniques include both the technology used and the way in which the installation is designed, built, maintained and operated. The Environmental Permit has been prepared in accordance with the best available techniques stipulated in the Secretary of State’s Process Guidance Note 1/14 (06) ‘Unloading of Petrol into Storage at Petrol Stations.’ Description of Environmental Permitted Installation BP Euston is permitted to unload petrol into five petrol storage tanks, equipped with a vapour recovery system (Stage 1) to control displaced vapours during petrol filling operations. The key air emissions from this activity that warrant control are petrol vapours including benzene. General Statutory Requirements Proposed change in the operation of the installation If the Operator proposes to make a change in the operation of the installation, the London Borough of Camden shall be notified within 14 days prior to making the change. If the proposed change requires any Environmental Permit conditions to be varied, an application for variation will have to be made to the London Borough of Camden, in accordance with Regulation 20 of the Environmental Permitting Regulations (EP Regulations). Surrender of the Environmental Permit Where an Operator intends to cease the operation of an installation (in whole or in part) the London Borough of Camden shall be informed in writing, such notification must include the information specified in Regulation 24 of the EP Regulations. Revoke of Environmental Permit The London Borough of Camden may revoke the Environmental Permit in part or in whole. In accordance with Regulation 22 the Environmental Permit ceases to have effect on the date specified in the notice. Transfer of the Environmental Permit or part of the Environmental Permit Before the Environmental Permit can be wholly or partially transferred to another person, a joint application to transfer the Environmental Permit has to be made by both the existing and proposed holders, in accordance with Regulation 21 of the EP Regulations. A transfer will not be allowed where the Regulator considers that the proposed holder will not be the person who will have control over the operation of the installation or will not ensure compliance 1 London Borough of Camden Environmental Permit - BP Euston Filling Station- PPC17/08 with the conditions of the transferred Environmental Permit. The London Borough of Camden shall be notified in writing 14 days prior to any change in the Operator’s trading name, registered name or registered company address. If an operator fails to apply for an Environmental Permit transfer the London Borough of Camden can take enforcement action against that operator for operating without an Environmental Permit. Enforcement and Offences If the London Borough of Camden are of the opinion that you have contravened, or are contravening or likely to contravene a Condition of the Environmental Permit it may serve an Enforcement Notice; in accordance with Regulation 36 of the EP Regulations. If the London Borough of Camden are of the opinion that the operation of an installation or mobile plant involves a risk of serious pollution it must, in certain circumstances, serve a Suspension Notice; in accordance with Regulation 37 of the EP Regulations. The offences detailed in Regulation 38 of the EP Regulations include failing to comply with or to contravene a Condition in a Environmental Permit, failing to comply with an enforcement or suspension notice, intentionally making a false entry in any records to be kept under a condition of a Environmental Permit. A person guilty of an offence, upon summary conviction, could be liable (i) to the maximum penalty of a fine not exceeding £20,000 and six months imprisonment, or (ii) upon conviction to a fine not exceeding the statutory maximum or two years imprisonments. Responsibility under workplace health and safety legislation This Environmental Permit is given in relation to the requirements of the EP Regulations. It must not be taken to replace any responsibilities you may have under the Health and Safety at Work Act 1974. Subsistence Fee The holder of the Environmental Permit is required to pay an annual subsistence charge. The charge is set by the Secretary of State and is payable to the London Borough of Camden on the 1st of April of each year. The London Borough of Camden may revoke the Environmental Permit upon non-payment of the subsistence charge. Appeal against Environmental Permit conditions Anyone who is aggrieved by the conditions attached to an Environmental Permit can appeal to the Secretary of State for the Environment, Food and Rural Affairs. Appeals must be made in accordance with the requirements of Regulation 31 of the EP Regulations. Appeals should be sent to the Secretary of State for Environment, Food and Rural Affairs. The address is as follows: The Planning Inspectorate, Environmental Pollution Appeals, Room 4/19 Temple Quay House, 2 The Square, Temple Quay, Bristol, BS1 6PN 2 London Borough of Camden Environmental Permit - BP Euston Filling Station- PPC17/08 Useful References Secretary of State’s Process Guidance Note 1/14(06) ‘Unloading of Petrol into Storage at Petrol Stations”. Contacting the London Borough of Camden If you wish to contact the local authority regarding any matters related to this Environmental Permit please contact: Colin Stapleton, Specialist Technical Officer London Borough of Camden, Town Hall, Argyle Street, London, WC1H 8EQ Tel: 020 7974 2638 Fax: 0207 974 6955 Email: env.health@camden.gov.uk 3 London Borough of Camden Environmental Permit - BP Euston Filling Station- PPC17/08 ENVIRONMENTAL PERMIT TO OPERATE AN ULOADING OF PETROL INTO STORAGE ACTIVITY Pollution Prevention and Control Act 1999 Environmental Permitting (England and Wales) Regulations 2007 (SI2007/3538) Environmental Permit Number: PPC17/08 London Borough of Camden (“the Regulator”) in exercise of the powers under Regulation 13 of the Environmental Permitting (England and Wales) Regulations 2007 hereby authorises: BP (“the Operator”) whose registered office address is BP Express Shopping Limited 500 Witan Gate Milton Keynes MK9 1ES to operate an unloading of petrol into storage activity at BP Euston Filling Station 142 Hampstead Road London NW1 2PT to the extent authorised by and subject to the conditions of this Environmental Permit. Signed ………………………………………………………………………… Authorised Officer of the London Borough of Camden Date …………………………………………………………………………. 4 London Borough of Camden Environmental Permit - BP Euston Filling Station- PPC17/08 CONDITIONS General Conditions 1) The permitted installation shall be limited within the installation boundary as outlined in red on the site plan. 2) The Environmental Permitted Installation shall be managed in an efficient and effective manner that facilitates the reduction and prevention of emissions to air. 3) The Operator shall follow the procedures for safe operation for petrol unloading prescribed in the petroleum licence conditions and in the Carriage of Dangerous Goods by Road Regulations 1996. 4) Staff at all levels need the necessary supervision, training and instruction in their duties relating to control of the process and emissions to air. Training of all staff with responsibility for operating the process shall include: (a) awareness of their responsibilities under the Environmental Permit; in particular supervising and performing unloading operations of tankers (b) how to minimise emission during abnormal conditions such as incidences of vapour leaks. (c) inspection and maintenance associated with vapour recovery systems 5) The operator shall maintain a statement of training requirements for each operational post and keep a record of the training received by each person whose actions may have an impact on the environment. These documents shall be made available to the regulator on request. 6) All staff, in particular those who supervise the installation, shall be fully conversant with the requirements of the Environmental Permit. A copy of this Environmental Permit shall be made available at all times for reference by all staff carrying out work subject to the requirements of the Environmental Permit. 7) All equipment and technical means shall be used in operating the installation shall be maintained in good operational condition and in accordance with a preventative maintenance schedule. The vapour recovery system shall be associated with the following maintenance arrangements: (a) the Stage 1 vapour recovery system shall be serviced annually, with the certificate of testing kept in the site register. (b) pressure vacuum relief valves or other similar devices on fixed tank vents shall be checked for correct functioning, including extraneous matter, seating and corrosion at least once every three years. (c) vapour containment integrity, associated with Stage II vapour recovery system, shall be tested at least once every three years, and always following substantial 5 London Borough of Camden Environmental Permit - BP Euston Filling Station- PPC17/08 changes or significant events that lead to the removal or replacement of any of the components required to ensure the integrity of the containment system. (d) effectiveness of the Stage II vapour recovery system shall be inspected at least once every three years where an automatic monitoring system is in place and every year in other cases. A record of inspection and maintenance work shall be kept in the site register. 8) The operator shall maintain a log book at the permitted installation incorporating details of all maintenance, examination and testing, inventory checking, installation and repair work carried out, along with details of training given to operating staff at the service station. The register required to be kept by the Petroleum Licensing Authority shall suffice for this purpose. 9) Vapours displaced by the delivery of petrol into storage facilities at the permitted installation shall be returned through a vapour tight connection line to the mobile container delivering the petrol. Unloading operations may not take place unless the arrangements are in place and properly functioning. 10) Petrol delivery and vapour return lines shall be tested prior to commissioning and periodically for vapour containment integrity. 11) A competent person shall remain near the tanker and keep a constant watch on hoses and connections during unloading. A competent person is one who has received training for deliveries in accordance with Conditions. Delivery drivers may be trained as the competent person. 12) Instances of vapour lock shall be recorded in the site register. If such incidences persist, the operator shall inform the local authority of the corrective measures taken and timescales over which they will be implemented in order to mitigate the vapour lock. 13) All reasonably practicable steps shall be taken to prevent uncontrolled leaks of vapour from vents, pipes and connectors from occurring. 14) Instances of vapour leaks shall be dealt with promptly. Petrol unloading activities shall cease until remedial action has been carried. A record shall be made of all incidences of vapour leaks and details of the corrective measures taken in accordance with Condition 8. 15) The London Borough of Camden shall be advised without delay of the circumstances of such a vapour leak if there is likely to be an effect on the local community. The operator shall advise the local authority of the corrective measures to be taken and the timescales over which they will be implemented. 16) Vapour collection systems shall be sized and designed to minimise vapour emission occurring during the maximum petrol and vapour flow. 17) In the case of existing vapour collection systems, an assessment shall be made of the maximum number of tanker compartments which can be discharged whilst still maintaining the integrity of the vapour collection system. The design or assessment shall 6 London Borough of Camden Environmental Permit - BP Euston Filling Station- PPC17/08 not account for diesel if the storage tank is separately vented, but shall be included if it utilises the same vent pipe as the petrol storage tanks. 18) The connection points on the tank filling pipes and vapour return pipe shall be fitted with secure seals to reduce vapour leaks when not in active use. Similarly, if apertures are provided on storage tanks for the use of a dipstick, these shall also be securely sealed when not in active use. 19) The fittings for delivery and vapour return pipes shall be different to prevent misconnection. 20) Adjacent to each vapour return connection point, there shall be a clearly legible sign instructing "Connect vapour return line before off loading" or similar wording. In the case of direct fill operations where the filling points are underground, the sign may be located nearby above ground provided it is easily visible from the fill points. In addition a sign shall: (a) refer to the maximum number of tanker compartments which may be unloaded simultaneously, or (b) a clear system of the maximum number of tanker compartments which may be unloaded simultaneously shall be included in the Petroleum Delivery Certificate. 21) Storage tank vent pipes shall be fitted with a pressure vacuum relief valve to reduce vapour loss or a similar device, which is at least as effective in minimising emissions during unloading and storage. Orifice plates shall not be permitted. Pressure vacuum relief valves shall be sized and weighted to prevent vapour loss and potentially hazardous pressurisation. Operators shall note that the sizing, seating and safety features associated with fitting pressure vacuum relief valves may be subject to health and safety legislation. 22) Vent pipes shall normally discharge not less than 3 metres above the ground, or within 3 metres of any opening windows or ventilation air inlets. 23) Venting of the petrol vapour shall be though the vent pipes marked on the attached site plan. 24) When connecting hoses prior to delivery, the vapour return hose shall be connected before the delivery hoses. The vapour return hose shall be connected by the road tanker end first, and then at the storage tank end. If diesel only is delivered to storage tanks, which are not manifolded with petrol tanks, then a vapour recovery line is not required. 25) All road tanker compartment vent and discharge valves shall be closed on completion of the delivery. 26) On completion of unloading, the vapour hose shall not be disconnected until the delivery hoses have been discharged and disconnected. The delivery hoses shall be disconnected at the road tanker end first, whilst the vapour return hose shall be disconnected at the storage tank end first. 27) All connection points shall be securely sealed after delivery. 7 London Borough of Camden Environmental Permit - BP Euston Filling Station- PPC17/08 28) Manhole entry points to storage tanks shall be kept securely sealed except when maintenance and testing are being carried out which require entry to the tanks. 29) Road tanker compartment dip testing shall not be performed whilst the vapour hose is connected, except in the case of split compartment deliveries where dip testing is carried out, which can be safely undertaken to the satisfaction of the Petroleum Licensing Authority. 30) Stage II controls shall be installed to existing service stations by 1 January 2010 where the throughput of petrol exceeds 3500m3 in any 12 month period. Prior to installation the local authority shall receive the technical specification of the Stage II controls (see Explanatory Note 1), the certification to confirm ‘type approval’(in accordance with Condition 32) and the method of monitoring the control system (in accordance with Condition 34) in order to approve proposed vapour recovery system. 31) Vapours displaced by the filling of petrol into vehicle petrol tanks at service stations shall be recovered through a vapour recovery system to a storage installation, which shall include the service station’s underground storage tank or other appropriate vessel. (See Explanatory Note 1). Filling of vehicle petrol tanks shall not take place unless such a vapour recovery system is in place and fully functioning. 32) The Stage II vapour recovery system shall be approved for use under the regulatory regime of at least one European Union or European Free Trade Association country (“type approval”). A certificate to confirm such compliance shall be retained at the petrol station with the log book. The vapour recovery system shall be certified by the manufacturer to have a hydrocarbon capture efficiency of not less than 85%, determined through the aforementioned type approval test. 33) All vapour recovery equipment used shall be designed, installed and tested in accordance with the relevant British, European and international standards or national methods in place at the time that the equipment was installed. 34) Operators shall install an automatic monitoring system or ensure a greater frequency of manual testing (see Explanatory Note 2). The frequency of monitoring shall be undertaken in accordance with Table 1. Table 1: Frequency of Monitoring for Different Vapour Recovery Systems Type of System Active system with automatic monitoring Active system without automatic monitoring Other systems Tests Required (post-commissioning) Vapour containment integrity = 3 years Vapour recovery effectiveness (V/P ratio) = 3 years Vapour containment integrity = 3 years Vapour recovery effectiveness (V/P ratio) = 1 year Vapour containment integrity = 3 years Vapour recovery effectiveness = 1 year (according to manufacturer’s specification) 8 London Borough of Camden Environmental Permit - BP Euston Filling Station- PPC17/08 35) A record shall be kept of all maintenance, examination and testing, installation and repair work carried out for Stage II controls in accordance with Condition 8. 36) Weekly checks to verify functionality of the Stage II controls shall be carried out where an automatic monitoring system is not employed. Such checks shall include: (a) a test of functionality of the vapour recovery system using appropriate equipment; (b) an inspection for torn, flattened or kinked hoses and damaged seals on vapour return lines; (c) an entry of the checks and findings in the station log book 37) Where weekly functionality checks are required, operators shall ensure that all relevant staff is trained to perform the checks in accordance with the manufacturers instructions. In all cases, relevant staff shall be trained in the use of preventative maintenance for vapour recovery systems to the manufacturers instructions in accordance with Condition 4. 38) Adverse results from any monitoring activity shall be investigated in accordance with the following procedure: (a) identify the cause and take corrective action (b) record as much detail as possible regarding the cause and extent of the problem, and the action taken by the operator to rectify the situation (c) re-test to demonstrate compliance as soon as possible; and (d) notify the regulator End of Conditions 9 London Borough of Camden Environmental Permit - BP Euston Filling Station- PPC17/08 Interpretation of Terms For the purpose of this Environmental Permit the following definitions shall apply. “Authorised officer” - any person authorised by the London Borough of Camden under section 108(1) of the Environment Act 1995 to exercise, in accordance with the terms of any such authorisation, powers specified in Section 108(4) of the Act. “VOC” – any organic compound having at 293.15 a vapour pressure of 0.01 kPa or more, or having a corresponding volatility under the particular conditions of use. Explanatory Notes Explanatory Note 1 With regards to Condition 30 the following types vapour recovery system can be installed: A- Open Active Vapour Recovery with Return of Vapours to Underground Storage Tank When petrol enters the vehicle tank, an active vapour recovery system (open active petrol vapour recovery system) uses a vacuum pump to suck a corresponding volume of vapours back into a storage tank. Components of an open active petrol vapour recovery system may include: • A vapour recovery nozzle; • A hose through which vapours are collected (coaxial or similar) and a pipe through which the vapours are returned (this may be separate from the fuel line or may be inserted into the fuel line); • A vacuum pump; • A system to control the ratio of the volume of vapour recovered to the volume of petroldispensed into the vehicle tank; • A vapour storage tank (i.e. the petrol storage tank). The control of the ratio of the volume can be achieved by • A proportional valve controlled either hydraulically or electronically; or • Controlling the speed of the vacuum pump B - Active recovery of vapours as petrol at the dispenser Alternative vapour recovery systems may be used, in which petrol vapours are recovered at the dispenser and returned direct for re-sale. Such equipment may include: • • • Standard nozzles and hoses designed for petrol vapour recovery as used where the vapours are returned to the underground storage tank; A vacuum pump which sucks the vapour through the nozzle and hose; A heat exchanger which condenses the petrol vapours and a tank in which water is separated and the recovered petrol stored. The recovered petrol is then passed to the dispenser petrol lines during refilling. 10 London Borough of Camden Environmental Permit - BP Euston Filling Station- PPC17/08 C - Passive vapour recovery ‘Passive’ or ‘balance’ vapour recovery systems do not include a vacuum pump. Instead, the pressure exerted by the displaced petrol vapours is used to drive the vapours back into the storage tank. In such a system, a rubber bellows/boot is required in order to ensure that there is a seal between the vehicle and the nozzle. These systems require greater control on the part of the vehicle owner in ensuring an adequate seal and are generally seen as being more unwieldy than the techniques referred to above. Explanatory Note 2 The automatic monitoring system referred to in Condition 34 shall: a) Automatically detect faults in the proper functioning of the petrol vapour recovery system including the automatic monitoring system itself and indicate faults to the operator. A fault should be deemed to be present where continuous monitoring during filling of vehicle petrol tanks indicates that the V/P ratio averaged over the duration of filling has fallen below 85% or has exceeded 115% for ten consecutive filling operations. This only applies to filling operations of at least 20 seconds duration and where the rate of petrol dispensed reaches at least 25 litres per minute. b) Automatically cut off the flow of fuel on the faulty delivery system if the fault is not rectified within 1 week. c) Be approved for use under the regulatory regime of at least one European Union or European Free Trade Association country. 11 London Borough of Camden Environmental Permit - BP Euston Filling Station- PPC17/08 Appendix 1 - Site Plan A BP Euston Filling Station 12 London Borough of Camden