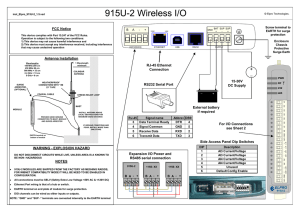

Ground (0V) +24 V Power connections

advertisement

Power connections 3) Power from 2024 to Control box (The valve harness connected) The voltage between pins 1 & 2 in JPT# 123 connector should be +24V. 4) Power from 2024 to Control box The voltage between pins 1 & 2 in M12 connector should be +24V. If 24V, check that the polarity is correct. If 0V, check/replace the valve harness. If 24V, check that the polarity is correct. : 1= +24V (red) 2= gnd (blue/white) 2) Power from 2024 to Control box (The valve harness disconnected) 1 = ground (0 V) (white) 2 = +24V (brown) Male M12 The voltage between pins 11 & 23 in grey 23-pin connector should be +24V. Female M12 If 0V, there isn’t any program inside the module or the module is defected. Ground (0V) +24 V 1) Power from the Truck to 2024 The voltage between pins 1 & 4 in AMP 8 connector should be +24V. If 0V, check the connection in the vehicle or the power supply cable. Please check also the polarity! 1 = gnd 4 = +24V Power connections 4) Power from 2024 to Control box and Receiver 3) Power from 2024 to Control box (The valve harness connected) The voltage between pins 1 & 2 in JPT# 123 connector should be +24V. If 0V, check/replace the valve harness. If 24V, check that the polarity is correct. : 1= +24V (red) 2= gnd (blue/white) The voltage between pins 1 & 2 in M12 connector should be +24V. If 24V, check that the polarity is correct. 2) Power from 2024 to Control box (The valve harness disconnected) The voltage between pins 11 & 23 in grey 23-pin connector should be +24V. The pin numbers in receiver are 1.01 (+24V) and 1.05 (GND) If 0V, there isn’t any program inside the module or the module is defected. M12 & LEMO 1 = ground (0 V) (white) 2 = +24V (brown) Male M12 Female M12 1) Power from the Truck to 2024 The voltage between pins 1 & 4 in AMP 8 connector should be +24V. LEMO Female Ground (0V) +24 V If 0V, check the connection in the vehicle or the power supply cable. Please check also the polarity! 1 = gnd 4 = +24V CAN connections 2) CAN High & Low in M12 connector CAN H: Voltage between GND & CAN H should be a little bit over 2,5V. CAN L: Voltage between GND & CAN L should be a little bit below 2,5V. Check also that CAN aren’t connected to each other. CAN1 H (yellow) CAN1 L (green) 1 = GND (white) 2 = +24 V (brown) 3 = CAN1 H (yellow) 4 = CAN1 L (green) Male M12 1) CAN High & Low in AMP 8-pin connector Check that the pins are inserted in correct way and in correct places. Female M12 CAN connections 3) CAN High & Low in LEMO Female (CB) 1 = GND (white) 2 = +24 V (brown) 3 = CAN1 H (yellow) 4 = CAN1 L (green) 5 = CAN EN (grey) 6 = Case GND (grey) 2) CAN High & Low in M12 connector CAN H: Voltage between GND & CAN H should be a little bit over 2,5V. CAN L: Voltage between GND & CAN L should be a little bit below 2,5V. 1 = GND (white) 2 = +24 V (brown) 3 = CAN1 H (yellow) 4 = CAN1 L (green) Male M12 Female M12 1) CAN High & Low in AMP 14-pin connector Check that the pins are inserted in correct way and in correct places. 2 = CAN 1 H (2024) 3 = CAN 1 L (2024) 6 = CAN 2 H (CABIN) 7 = CAN 2 L (CABIN) 2) CAN High & Low in LEMO 1 = GND (white) 2 = +24 V (brown) 3 = CAN1 H (blue) 4 = CAN1 L (black) 5 = CAN EN (grey), link 5-6 and Rubber Gaiter GND 6 = Case GND (grey) , link 5-6 CAN1 H (yellow) CAN1 L (green) 1) CAN High & Low in AMP 8-pin connector Check that the pins are inserted in correct way and in correct places. 2 = CAN 1 H (yellow) 6 = CAN 1 L Check also that CAN aren’t connected to each other. Control Box V1 LED in control box Red Green Description ON ON CAN Wires from left: 1) Brown (+24V) 2) White (GND) 3) Green (CAN L) 4) Yellow (CAN H) The processor hasn’t been able to start. The problem can be caused by a loose display cable (grey flat cable from PCB to display card) or damaged PCB (processor). Check the display cable or replace the PCB/control box. Blinking 1 Hz OFF The control box is in test state. During start there has been connection between test pins. Check that wires aren’t connected together. OFF Blinking 4 Hz The control box is ok and CAN is working. OFF Blinking 1 Hz The control box is ok but CAN isn’t working. Check the CANwires. or Blinking 1 Hz Blinking 1 Hz Control Box CB V2 1) Normal Control Box - Check that there is a jumper in dead man switch - CAN Enable is free - GND wire from Rubber Gaiter is connected to Case GND CAN Enable (grey) CAN1 H (yellow) (M12 pin 3) CAN1 L (green) (M12 pin 4) Case GND (grey) (Rubber Gaiter) GND (white) (M12 pin 1) +24 V (brown) (M12 pin 2) 2) Remote Control Box - Check that all 6 wires are connected - Check that connector is tightened and wires aren’t twisted and connected together. CAN Enable (grey) (LEMO pin 5) CAN1 H (yellow) (LEMO pin 3) CAN1 L (green) (LEMO pin 4) Case GND (grey) (2 wires, Rubber Gaiter & LEMO pin 6) GND (white) (LEMO pin 1) +24 V (brown) (LEMO pin 2) Control Box PCB V2 LED in control box Red Green Description OFF OFF - Supply voltage is missing -Power save mode active (remote controls) - Software or bootloader is missing ON OFF - Downloading software - software is missing OFF ON Software is running ok Control box is connected to receiver but connection between receiver and 2024 is missing (GND and +24V are ok but CAN H&L aren’t) Software When Service Tool (PC or Service Display) is connected to the system, Software & Runtime versions can be seen in Main window. If 2024 row is empty, Service Tool isn’t connected to the system - CAN interface (Kvaser) isn’t installed - CAN line is damaged or there is a short circuit - the system isn’t powered up. The combination of the software & runtime versions is also important. SW 1.04 & RT 2.15 are compatible with each other but 1.04 & 2.13 aren’t.