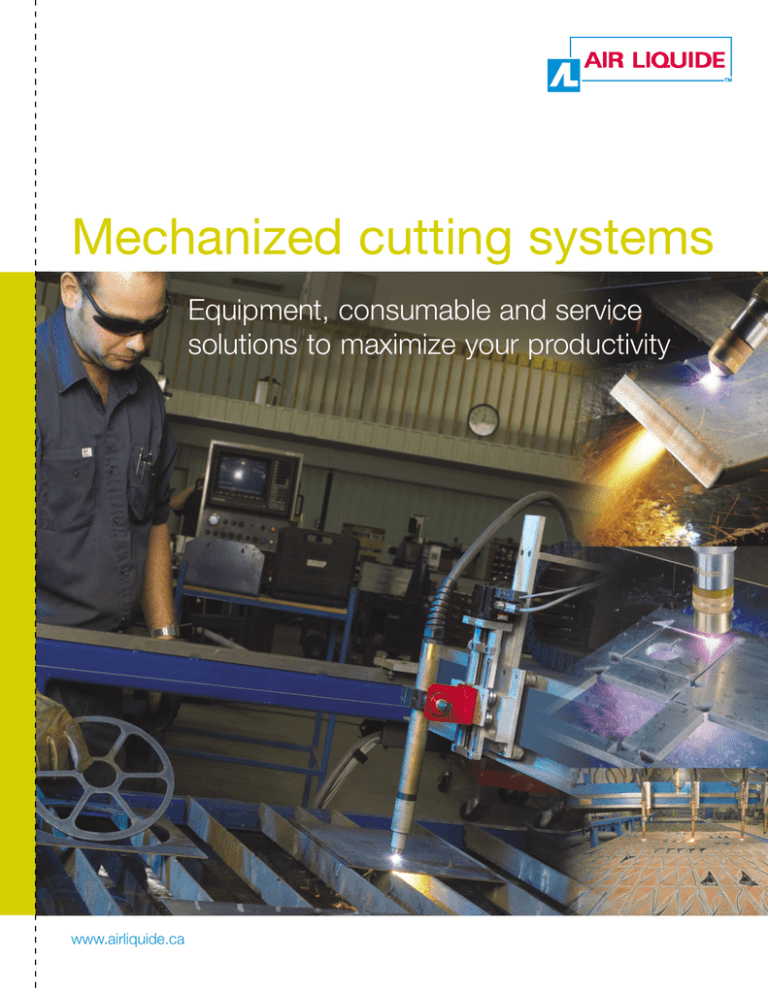

Mechanized cutting systems

advertisement

Mechanized cutting systems Equipment, consumable and service solutions to maximize your productivity www.airliquide.ca You can rely on Air Liquide’s knowledge and experience to improve your cutting operations . . . we’ve been doing it for more than 100 years. Total systems from a single source When your metal fabrication business needs to reach the next level of productivity, our experience is at your service. Whether you are flame cutting heavy steel sections or plasma cutting stainless steel or aluminum plate, Air Liquide can provide everything you need to optimize your process: • Evaluation of your current operation and recommendations for process improvements that will save you money, expand your capabilities or increase your productivity . . . whatever your objective is. • State-of-the-art profile cutting machines to suit any budget, from compact 4’x4’ economy models to the largest of powerful CNC machines required in heavy industrial situations. • HyPerformance™ mechanized plasma systems for superior HyDefinition® cut quality and low operating cost. • A variety of optional controls, software, cutting tables and other components to complete your system. • Retrofit or upgrade of existing machines to current technology standards to get better performance from older assets. • Full line of OEM consumable parts to guarantee your cut quality. • Process gases and gas supply systems to suit any application. Air Liquide is the world leader in industrial gases and can tailor each installation to your specific requirements. • Training on machine operation & maintenance, cutting processes, workplace safety or a host of other topics that concern your employees. • Services such as management of your gas and hardgoods supply so that you can concentrate on growing your business. 2 To achieve the highest quality and performance levels in your cutting operations you need to have equipment with the most advanced and reliable technology available. The keys to quality and operating cost reduction are reliability, consistency and efficiency. Air Liquide provides you the latest, most advanced HyPerformance HPR260’s operating cost is less than half the cost of the competition 10 mm (3/8”) 12 mm (1/2”) 20 mm (3/4”) RELATIVE COST OF CUT NOZZLE AND ELECTRODE COST The next generation of mechanized plasma metal cutting technology from Hypertherm®, the world’s foremost manufacturer of plasma arc cutting equipment. HyPerformance (130 A) HD3070 (100 A) Competitor A Competitor B HyPerformance (100 A) (130 A) (200 A) HD4070 (200 A) Competitor A Competitor B HyPerformance (200 A) (160 A) (260 A) HT4400 (400 A) Competitor C (250 A) HyPerformance™ systems • Designed to cut a wide range of thicknesses of mild steel, stainless steel and aluminum • Increased cut speeds • Lower cut angle variability than any “precision” competitor tested • HyDefinition® cut quality at half the operating cost • Patented LongLife® system design for extended parts life • Consistent, repeatable cutting performance • Virtually dross-free cutting reduces the need for secondary operations • Marking and cutting performed with the same consumables Controls and accessory products • CNC shape cutting controls • Torch height controls • Drive systems • Marking, scoring and punching systems • Thermal cutting software Hypertherm, HyPerformance, HyDefinition and LongLife are trademarks of Hypertherm Inc. 3 No matter what the size of your metal fabrication business there’s a cutting machine to suit your needs. Affordable metal cutting solutions Many fabrication shops do not do their own plate cutting because they think the cost of purchasing a cutting machine is beyond their means, they are too complicated to operate, or that they don’t have the space required to install one. Others may feel they do not have enough continuous work to justify an in-house machine, so they outsource their cutting operations. Today’s technology has put an end to all these concerns. Job shop Signs & lettering Ornamental Air Liquide can supply a flame or plasma cutting machine that will meet your every expectation in terms of affordability, ease of use, cut quality, reliability and floor space requirement. Let us help you make the step up to higher productivity. Art & hobby Light fabrication HVAC Features • User-friendly software installs on a standard computer, allowing you Kitchen & restaurant equipment to get up and running in a minimum of time. • Flexibility to cut custom “one-off” parts or production series runs. • Durable construction and simplicity of design provide years of trouble-free use. • Standard spare parts readily available from local industrial supply houses. • Smallest units can be rolled away to save space when not in use. 4 Large industrial fabricators and metal service centres require cutting machines that can handle their tough demands. Cutting machines for industrial service The acquisition of a large cutting machine is a major investment that has to be carefully undertaken. It is not advisable to make such a purchase without a full analysis of your current and future needs. Air Liquide’s process and product specialists will work with you to make that analysis and offer you a variety of solutions to meet your technical and financial expectations. Each customer is different and one size does not fit all. One may be looking to reduce their existing cost per cut part, whereas another needs increased cutting capacity to handle a new order. Air Liquide has the resources and experience to help you make the right choice. Service centres Shipyards Transportation Features • Variety of machine design configurations available to meet any particular need. Heavy equipment Fabrication • Machine specifications developed to suit the specific requirements of each customer. • Designed and fabricated in Canada. Local manufacture and support can avoid many of the problems associated with out-of-country sourcing. • Proven, reliable, heavy-duty construction backed by a full training and Tank manufacture Structural metal Steel works support package. 5 Air Liquide, the world’s largest producer of industrial gases, offers its customers a full range of cutting gases and gas supply modes to meet their requirements. From single cylinder to bulk supply . . . we can service your gas needs Oxy-fuel cutting of steel When it comes to flame cutting, nobody knows the process better than Air Liquide: after all, our engineers invented it over 100 years ago. From our FLAMAL™ line of flame process gases we can provide you oxygen and a variety of fuel gases to get the best quality and productivity from your mechanized cutting machine installation. Whatever fuel gas you select we have the equipment and consumables to match. Plasma cutting Depending on what materials you are cutting and the quality requirements you have, you will need a reliable source for one or more different cutting gases. From clean, dry compressed air to oxygen, nitrogen, argon or hydrogen, Air Liquide can design and install a delivery system to suit your needs and supply you the gases. Compressed air Acetylene Oxygen MAPP ™ • Single or manifolded cylinders • BulkPaks of 16 cylinders framed in a steel cage • Single or manifolded liquid cylinders Hydrogen • Micro Bulk or Bulk liquid Nitrogen • FLOXAL™ purified air Argon 6 Gas supply modes Business has changed in the 21st century. Customers expect more than just a good product and a good price. Air Liquide creates partnerships with their customers to develop technical solutions that bring them value and profitable growth. Complete service offer In addition to the cutting machines, equipment, gases and consumables you require to implement your process improvements, Air Liquide can provide a wide range of services to ensure you achieve the business efficiencies you seek. Training • Cutting processes • Machine operation • Mechanical systems • Electrical/electronic systems • Preventive maintenance • Process safety Quality/Productivity • Omniweld™ Performance quality, efficiency and cost reduction programs. Supply chain • ManageAL™ productivity, inventory and procurement management programs. Gas distribution • Servigas™ engineering, design, installation and maintenance of gas distribution systems. 7 DISTRIBUTED BY: www.airliquide.ca 1-800-817-7697 Note: This brochure is intended for general information purposes only and is not intended as a representation or warranty of any kind, or as a statement of any terms or conditions of sale. The information herein is believed to be correct, but is not warranted for correctness or completeness, or for applicability to any particular customer or situation. The terms and conditions of any sales transactions that may occur between Air Liquide and any customer shall be set forth in the agreement signed by the parties. 1140-272E (05-11) REL Contact your Air Liquide representative for more information.