IS (Intrinsic safety) - Ex (Epsilon x)– ATEX – CENELEC

advertisement

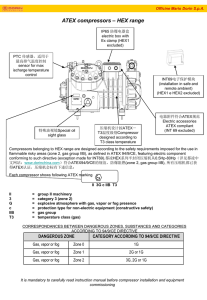

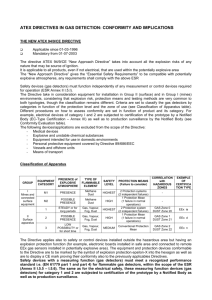

MAY 2002 IS (Intrinsic safety) - Ex (Epsilon x)– ATEX – CENELEC By: Helge Knudsen, Test&Approval, Niros Telecommunication A/S You may have heard those expressions concerning Transceivers and other electric equipment in Europe. Do you need an ATEX IS certified Transceiver? In general an ATEX IS certified Transceiver should be used at locations, plants and production sites, with hazardous areas with potential risks of explosive gasses and/or dust. The following list points out some locations where an ATEX IS certified Transceiver may be needed. Note the list is not exhaustive. • • • • • • • Off-shore, meaning oil rigs and oil/gas production platforms Off-shore, meaning tankers for gas and oil Off-shore, meaning all ships or vessels engaged in this business On-shore, meaning refineries and oil/gas productions plants Transportation and filling up of oil and gas Petro-chemical industries Fire Brigades, for operation in hazardous areas with potential risks of explosive gasses and/or dust. The term IS indicates the equipment is certified according to the requirements in Directive 76/117/EEC or the new Directive 95/9/EC (ATEX Directive). The used standards are: Cenelec EN 50014 Electrical apparatus for potentially explosive atmospheres – General requirements and Cenelec EN 50020 Electrical apparatus for potentially explosive atmospheres - Intrinsic safety "i". CENELEC or Ex certified is often synonymous for certification according to the requirements in Directive 76/117/ECC. Intrinsically Safe Transceivers, in our terms, are for use in areas where there is a potentially risk of explosive gas/dust is or could be present. The new ATEX Directive 94/9/EC shall be used for such products after 30th June 2003 Information on the issue new / old Directive can be found on the EU commission homepage http://www.europa.eu.int/comm/enterprise/atex/ And on UL-Europe Homepage “Overview of Potentially Explosive Atmospheres Directives” http://www.ul.com/hazloc/potential.html Hirsemarken 5 DK-3520 Farum Tel.: +45 4499 2800 Fax: +45 4499 2808 www.niros.com Page 1 of 6 MAY 2002 Which technical differences are there between normal handheld transceiver and an ATEX IS certified transceiver. All components and parts of the transceiver must not generate high temperatures and high energy sparks in normal operation or with a fault present. There are different levels of protection given by different temperature and energy classes. The battery shall have a circuit that makes the battery short circuit proof without overheating and limits spark energy. The Transceiver has limitations on capacitor and inductor values or other protective means to limit energy from reactive and non-reactive components. High temperatures shall be limited by extensive use of heatsinks, heat conduction and power limiting. Accessory connector for external microphone etc shall have a build in protective circuits to limit energy on the connector. The ATEX certificate specifies the important data for the connector interface. It is important only to use accessories that are certified for use with the specific “IS” Transceiver, otherwise safety can not be guaranteed. Chargers and other accessories, which are used outside the area with potentially explosive atmosphere, need a certification as 'Associated Apparatus' to the specific Transceiver. This ensures that a fault in for example a charger do not harm the “IS” protection in the Transceiver or in the battery. Hirsemarken 5 DK-3520 Farum Tel.: +45 4499 2800 Fax: +45 4499 2808 www.niros.com Page 2 of 6 MAY 2002 Description of classes and different marking The local authorities will decide class and Zone for a particular location. The illustrative figures in this part and other figures can be downloaded from http://www.ul-europe.com/default.asp?ID=70 Electrical equipment are divided into the following Groups and Categories: Group I: Mining, category 1 Group II: Surface, category 1, 2 and 3. Hirsemarken 5 DK-3520 Farum Tel.: +45 4499 2800 Fax: +45 4499 2808 www.niros.com Page 3 of 6 MAY 2002 Marking A example of marking of certified electric equipment is shown below Additional marking Because of the special importance for safety of products intended for use in potentially explosive atmospheres and in order to avoid any misunderstandings directive 94/9/EC provides for additional markings. The European standard series EN 50014 for electrical products for potentially explosive atmospheres foresees a supplementary marking. For detailed and complete information about marking according to the requirements of the European standards for electrical products it is necessary to use this standard series, which contain a number of useful examples. Most important are: • the symbol EEx to indicate that the product is in compliance with one or more standards of this series • the symbol for each type of protection used (o, p, q, d, e, ia, ib, m, etc.) • explosion groups I, IIA, IIB, or IIC in case of type of protection d, i or q • the symbol indicating the temperature class or the maximum surface temperature Hirsemarken 5 DK-3520 Farum Tel.: +45 4499 2800 Fax: +45 4499 2808 www.niros.com Page 4 of 6 MAY 2002 For protection of electrical equipment used in potentially explosive gas atmospheres standard EN 50014 gives the general requirements. The standard for each different type of protection is symbolised by a letter as follows: • « o » for oil immersion according EN 50015; • « p » for pressurisation according EN 50016; • « q » for powder filling according EN 50017; • « d » for flameproof enclosure according EN 50018; • « e » for increased safety according EN 50019; • « ia » or « ib » for intrinsic safety according EN 50020; • « m » for encapsulation according EN 50028. Electrical equipment shall conform to EN 50014 and one or more types of protection. Example on additional marking EEx ib IIC T5 • • • • EEx indicate compliance with one ore more standard in the EN 50014 series. “ib” means compliance with Level of protection “ib”, intrinsic safety according to EN 50020. IIC indicate apparatus group IIC. T5 means Temperature class 5, i.e. maximum surface temperature is 100 °C at specified maximum ambient temperature. Temperature class Maximum surface temperature (°C) T1 450 T2 300 T3 200 T4 135 T5 100 T6 85 Classification of maximum surface temperatures for Group II electrical apparatus (EN 50014 @ ambient temperature -20°C to +40°C) More guides on marking can be found in the ATEX Guidelines, which may be downloaded from the EU commission homepage: http://www.europa.eu.int/comm/enterprise/atex/guide/index.htm Hirsemarken 5 DK-3520 Farum Tel.: +45 4499 2800 Fax: +45 4499 2808 www.niros.com Page 5 of 6 MAY 2002 References: DIRECTIVE 94/9/EC OF THE EUROPEAN PARLIAMENT AND THE COUNCIL of 23 March 1994 on the approximation of the laws of the Member States concerning equipment and protective systems intended for use in potentially explosive atmospheres ATEX GUIDELINES (FIRST EDITION) Guidelines on the application of council directive 94/9/EC of 23 March 1994 on the approximation of the laws of the Member States concerning equipment and protective systems intended for use in potentially explosive atmospheres Folder from UL-Demko ATEX Equipment for Hazardous Locations – a Short Introduction in Terminology Hirsemarken 5 DK-3520 Farum Tel.: +45 4499 2800 Fax: +45 4499 2808 www.niros.com Page 6 of 6