Effectiveness of Direct Bonding of Gas Piping in Mitigating Damage

advertisement

Effectiveness of Direct Bonding of Gas Piping

in Mitigating Damage from an Indirect Lightning Flash

Prepared By:

Brian Kraft

Rising Tide Consulting LLC

Palmer, MA

Robert Torbin

Cutting Edge Solutions LLC

Framingham, MA

August 2007

© Kraft/Torbin 2007

Reproduction of this document, in whole or in part, without express, written consent is strictly prohibited.

Effectiveness of Direct Bonding of Gas Piping

in Mitigating Damage from an Indirect Lightning Flash

Brian Kraft and Robert Torbin

i

Executive Summary

Damage to gas piping systems during a lightning event may occur due to arcing between the gas

piping and some other conductive metallic pathway that is in close proximity. The presence of

different levels of electrical potential in these pathways creates the impetus for the arc to occur.

The different levels of potential are directly attributable to unequal or non-bonding of the

individual pathways to the premise grounding system. A series of physical tests were performed

by Lightning Technologies Incorporated for the Titeflex Corporation to simulate a corrugated

stainless steel tubing (CSST) gas piping system that has been energized by an indirect lightning

flash. This paper summarizes the interpretation of this data and presents recommendations

concerning the direct bonding of gas piping systems.1 For testing purposes, a standard

residential building was modeled including the bonding (and non-bonding) of the gas piping

system after being energized by an indirect lightning flash. The evaluation of the testing data

indicates that the risk of damage to the gas piping system due to arcing is significantly reduced

when the system is directly bonded to the premise electrical grounding system. A non-bonded

piping system would be subject to 97 percent of the charge from an indirect lightning strike,

while a direct bonded piping system would be subject to only 20 percent or less of the same

charge. Based on the data and the experience of the authors, a set of installation guidelines for

the direct bonding of CSST systems was developed. The recommended direct bonding should

not be considered a definitive protective measure against all lightning strikes nor construed as an

optimum level of bonding.

1.0

Study Objectives

The objective of this reported study was to perform an independent engineering evaluation of

data collected during an experimental test program to evaluate the effectiveness of direct

bonding of the gas piping system to the grounding system of the premise electrical system used

in typical residential construction. The product of this evaluation was the development of

installation guidelines for an effective bonding method.

1 The testing results discussed herein are copyrighted by Titeflex Corporation. Reproduction of information covered by

Titeflex’s copyright without the express, written consent of Titeflex Corporation is strictly prohibited.

© Kraft/Torbin 2007

1

2.0

Background

2.1

Piping Systems and Conductive Metallic Pathways

A residential gas system is composed of several distinct parts including the gas utility service,

the piping system within the building and the pipe and fittings connecting these two parts. The

gas utility service is generally comprised of underground polyethylene (PE) piping leading from

the distribution network/main in the street to the exterior of the building where the piping is

brought above ground via a gas meter riser that connects to the utility gas meter. The meter riser,

which provides the transition from underground PE piping to above ground metal piping, is

almost always electrically conductive. However, these risers have only a minimum length of

steel pipe in direct contact with the earth and are not considered part of the grounding electrode

system. Section 250.52 (B) of the NEC prohibits the use of any underground metallic gas piping

as a grounding electrode.

In the past, the utility underground gas service piping was commonly all steel pipe, and was

often cathodically protected. For this reason, and to prevent inadvertently creating a second

electrical ground point, a dielectric union has been traditionally placed by the utility in the gas

line prior to the connection point with the gas meter. The dielectric union essentially electrically

isolates the underground portion of the gas delivery network from the interior gas piping system.

Even though non-conductive polyethylene piping is now used underground in virtually all new

construction, the dielectric union continues to be installed for protection from stray currents. The

meter riser, regulator and meter are commonly installed outdoors on the side of the building for

protection and other practical considerations. Other meter locations were not considered as part

of the study, nor were the service connections for LP systems.

House gas piping may consist of rigid steel pipe, copper tubing, corrugated stainless steel tubing

or a combination of these three materials. Routing within the building varies greatly depending

on the floor plan, gas appliances installed, and installation methods employed by the piping

installer. Depending on when the gas piping is installed during the construction schedule and

given the limited space available to install utilities, it is not unusual for interferences to occur

between different utilities. Therefore, it is not uncommon for gas piping to be routed in close

proximity to, or even in direct contact with electrical wiring, heating/cooling ducts, water piping,

steel structural supports and appliance exhaust vents. This proximity can have a contributory

effect on the impact of lightning strikes to these various metallic pathways.

All gas piping systems (regardless of material) are required by the electrical and fuel gas code to

be electrically continuous. All gas piping is installed per the requirements of the locally adopted

fuel gas code, most commonly the National Fuel Gas Code (NFPA54), International Fuel Gas

Code (IFGC) and the Uniform Plumbing Code (UPC) and, in the case of CSST, in accordance

with the manufacturer’s instructions. Gas piping systems must also be bonded to the grounding

system in accordance with both Section 250.4(A) (4) and Section 250.104(B) of the NEC.

Traditionally, the means for bonding of gas piping has been the equipment grounding conductor

when the piping is attached to equipment that is electrically powered. However, the requirement

for bonding when the gas equipment is not electrically powered is not clearly stated in the NEC.

© Kraft/Torbin 2007

2

Similar to the gas utility service, a residential electrical system consists of the utility electrical

service mains, the house wiring within the building and an electrical panel/enclosure that forms

the interface between the two. Utility mains are generally run via overhead power lines.

However, newer housing developments often employ underground distribution systems. Both

overhead and underground systems are locally earth-grounded to provide protection from stray

voltage, voltage imposed by lightning, line surges and unintentional contact with higher voltage

lines as stated in Section 250.4 (A) (1) of the NEC. The premise electrical panel also

incorporates a grounding system, commonly through a grounding electrode conductor and buried

electrodes/rods. This provides the electrical ground specific to that building, and is referred to as

the house ground.

Other than a three-foot minimum spacing that may be required in some areas, few requirements

exist for the location of the gas and electric utility service entrances in relation to each other. It

is generally left up to the two utilities to determine the placement of their facilities based on their

own requirements and other considerations. While it is most common for the two utility

entrances to be located in close proximity, installations resulting in the electrical panel being on

the opposite side of the building from the gas meter are not uncommon. The separation distance

between the electric panel and/or the grounding electrode system and the gas meter is an

important factor in the design of an effective bonding connection.

In the event of an electrical fault, stray voltage or fault current could be imposed onto any

conductive metallic pathway within the structure. If there is no effective path to ground, a

significant electrical hazard to the occupants of the building would exist. This hazard is largely

negated by the bonding of these pathways to the electrical ground system of the building. This

bond provides a safe low-impedance path to neutral earth. When the equipment grounding

conductor is used as the bonding means, no additional effort is required by the piping installer or

the electrical contractor to achieve this condition. Thus, we refer to this as “self-bonding”. In a

situation where the gas piping system is not connected to a permanently wired gas appliance, it is

unlikely that the system is bonded to the electrical system ground at all based on conventional

plumbing/electrical construction practices. An un-bonded metallic system increases the potential

for a hazard (to the building occupants) to exist.

2.2

Direct Bonding

It is not uncommon for piping systems, including steel gas piping, to be bonded to the electrical

ground system through the use of a dedicated wire and clamp. As this method provides a direct

connection between the piping system and the electrical ground system, it is referred to as “direct

bonding”. For direct bonding, the clamp is attached to a single location on the piping system to

provide electrical contact. The wire is then connected to the clamp and routed to either the

electrical panel ground or directly to the grounding electrode system.

There are numerous advantages to this method. First, it provides the safety of bonding without

reliance on the connection of the gas piping system to a grounded appliance where bonding

could be compromised if the appliance is taken out of service, replaced with a differently fueled

© Kraft/Torbin 2007

3

unit, or there is a wiring system modification. Additionally, the direct bond method can be

visually inspected for continuity, as the clamp and wire connections must be visible. A self-bond

connection requires the use of a continuity tester to verify a proper connection at the appliance.

Finally, the direct method of bonding provides a low impedance electrical path to ground that is

significantly shorter, less electrically resistive, and therefore, more effective than is a self-bond at

safely conveying stray voltages and ground-faults to ground.

Direct bonding of all metallic supply lines entering a building is a critical but often overlooked

approach when considering protection of a building and its contents during an electrical storm.

Lightning strikes near buildings (with ground current transfer distances of up to 1 to 3-km from

the strike center) can induce differences in potential between the electrical system and any nonbonded mechanical system. Direct bonding of these systems (using a 6 AWG copper wire) to

the building grounding electrode system allows the mechanical systems to be energized at (or

near) the same rate as the electrical system and in unison with the voltage wave induced by the

lightning strike.

Use of the equipment grounding conductor (EGC) as the bonding means does not achieve the

same effect. The EGC (which is typically a 12 or 14 AWG copper wire) does not allow that

mechanical system to be energized at the same rate as the electrical system. The path to ground

through the EGC is typically much longer (and with greater impedance) than the direct bonding

distance (near the service entrance) between each mechanical system and the grounding

electrode system. When energized by lightning, this situation permits the electrical potential in

the many conductive pathways to become unbalanced, and thus arcing is more likely to occur.

Bonding through the equipment grounding conductor is only intended for personnel safety in the

event of an electrical fault occurring in the premise wiring system, and has been shown to be

inadequate when dealing with lightning energy. That being said, it should be noted that the NEC

does not require direct bonding for all metallic systems, nor does it effectively address lightning

protection which is considered out-of-scope.

2.3

Lightning Energy

Lightning is, by its very nature, a massively powerful natural phenomenon, capricious and

impossible to predict. While significant research has been performed on the lightning

phenomenon, general engineering solutions to mitigate its impact have not been widely

implemented in the residential market. The occurrence of lightning varies from intense (2

million strikes per year) to light (2,000 strikes per year) on a state-by-state basis. Given that the

magnitude, frequency and duration of the energy involved with each lightning strike varies

widely, the design of the most effective protection should take local conditions into

consideration. Lightning energy is transferred to a structure whether the strike is directly to the

building or indirectly through another medium (such as the earth). A direct strike involves both

direct hits to the structure or strikes from a branch off of the main bolt. An indirect strike occurs

when the energy from the main bolt enters the structure through another pathway such as the

overhead power line or through the ground under the house.

© Kraft/Torbin 2007

4

Due to the high levels of electrical power inherent in a lightning flash, no single point or path can

provide it with an adequate connection to the earth which it seeks. Practically speaking, this

means that a direct lightning flash to the ground or to a structure will saturate its immediate path

to ground at the object struck. The lightning strike will proceed to conduct its overflow energy

indirectly to ground by generating very high voltages and currents in the surrounding earth,

objects and structures, commonly to very large distances. In this way, lightning will use all

available paths to disperse this electrical energy to neutral earth. In the case of a direct strike to a

structure, energy will travel indiscriminately through all of the conductive systems within the

building including electrical wiring, communications cables, ventilation ducts, water piping, gas

piping, steel structural members and exhaust vents, and often with a destructive effect.

In the case of an indirect flash near to the structure, lightning energy will travel into the structure

and through the aforementioned systems if they provide a significant path to neutral earth. The

energy level in this situation is such that systems or objects that would not normally be

considered electrically continuous and/or conductive can and are used as paths to ground. For

example, water in trees or wooden framing members can provide lightning with a path to ground,

but with significant damage to the insulating cellulose. Re-bar in unburied footings will respond

in the same fashion, with similar explosive damage to the surrounding concrete. The dielectric

insulator at the gas service entrance is commonly arced over during a lightning event, with the

lighting using the underground riser as a ground point. Any of the conductive systems within the

residence that pass near a steel structural support, such as a Lally column in a New England

basement, will provide a potential path to ground, even if a short arc through air is required to

make the connection.

Under certain circumstances (such as close proximity), CSST can be damaged by arcing to/from

other conductors as they are energized by a lightning strike. This arc causes localized heating at

the arc termination points, sometimes creating enough heat to melt through the steel pipe wall.

This effect is similar to damage caused to aircraft skins by direct lightning flashes. The existing

research shows that this type of damage is most closely related to charge delivered, that is, the

amount of charge transferred by the arc/flash and the duration over which the arc is active.

Charge delivered, or the area under the curve of amperes-versus-seconds, is highly predictive of

material damage. Lightning testing commonly utilizes current-versus-time wave shapes

identified by values for time-to-peak current amplitude and time-to-current decay of 50-percent

peak amplitude (as measured in microseconds) to model both direct and indirect lightning

flashes.

© Kraft/Torbin 2007

5

3.0

Laboratory Evaluation Program

3.1

Test Objectives

A testing protocol was developed, in consultation with Lightning Technologies Incorporated

(LTI), to model an indirect lightning flash striking near the house and the associated energy

entering the premise (and the gas piping system) through a pathway provided by the electrical

service entrance.2 LTI (Pittsfield, MA) is a leading developer of, and test facility for, lightning

protection systems, and was under contract with the Titeflex Corporation to perform these tests.

The testing program was designed to evaluate different bonding approaches and techniques for

gas piping systems consistent with the requirements of the NEC and the National Fuel Gas Code.

The laboratory testing program was conducted using so-called “typical” lightning profiles, and

was only intended to allow relative comparisons of alternative bonding techniques. The results

from the testing program provide general guidance on improving the performance of bonding as

it affects the ability of the gas piping to absorb lightning energy without damage and to divert

this energy safely to ground. However, the recommended bonding technique should not be

considered a definitive protective measure against all lightning strikes nor construed as an

optimum level of bonding.

3.2

Simulation of Physical Piping System

In order to develop a test method to achieve the stated objective, the complex physical system

represented by a residential building (including the nearby lightning strike) had to be analyzed

and simplified to allow for laboratory simulation. Factors that were considered in the

development of the laboratory model and testing procedure included:

•

Basic residential wood-framed construction

•

Low-pressure metallic gas piping systems and their installation configurations

•

Premise electrical wiring systems and their configurations

•

Electrically conductive connections between the electrical and gas piping systems

•

Lightning, its behavior and typical energy profiles as determined by industry sources

The model used for the evaluation program represented a standard residential building of wood

construction with the gas and electrical service entrances of varying distances apart and

energized under the following conditions:

•

Lighting striking a nearby utility pole and entering through the electrical service mains

and saturating the premise electrical grounding system

2 The testing results discussed herein are copyrighted by Titeflex Corporation. Reproduction of information covered by

Titeflex’s copyright without the express, written consent of Titeflex Corporation is strictly prohibited.

© Kraft/Torbin 2007

6

3.3

•

Lightning energy traveling through the building via the gas piping and electrical wiring

with the gas service entrance as a primary path to neutral earth via a “failed” dielectric

fitting

•

Polyethylene jacket of the CSST in direct contact with the house wiring

•

Polyethylene jacket of the CSST scuffed through normal installation techniques

•

Either a non-bonded or direct bonded piping system installed

Model of Physical System

In order to model the physical system comprising a gas piping system installed in a typical

single-family residential structure, test samples were setup as shown in Figure 1. A hole was

made in the polyethylene jacket (using a standard soldering iron) to represent damage caused to

the jacket during installation. This hole was placed over the crown of a corrugation to expose the

stainless steel beneath. The electrode was then placed in contact with the PE jacket, entirely

covering, but not touching, the exposed stainless steel. If an arc was developed during the test, a

new hole was prepared and the electrode moved to this new location before the next test was

conducted. New coating holes were spaced approximately one inch apart.

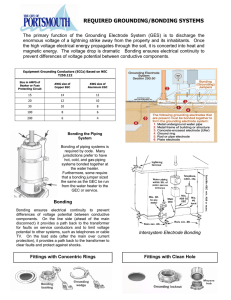

Figure 1: Test Sample Assembly

The generator consisted of a large bank of capacitors connected in parallel, with a

resistor/inductor assembly at the capacitor bank output to control output wave shape. The

generator was then connected to the sample assembly via a switch. The generator was also

connected to the facility ground plane to provide a full circuit. Firing of the generator consisted

of applying power to the capacitor bank (switch open) to develop a charge across this bank.

When the desired voltage across the bank was reached, the power cycle was discontinued. The

switch was then closed, thus subjecting the test sample assembly to the stored charge.

© Kraft/Torbin 2007

7

Two current probes and one voltage probe were connected to an oscilloscope to record current

output of the generator, current passing into the electrode via an arc to the CSST, and voltage in

the CSST. Data time plots allowed the calculation of charge output from the generator and

charge traveling down the electrode via an arc from the CSST. Various generator charges were

used to explore the relationship between the measured values, arc generation, and the generation

of a hole in the CSST for various bonding configurations. Tests were performed for the

following direct bond configurations:

•

10 feet of 6 AWG copper wire

•

20 feet of 6 AWG copper wire

•

40 feet of 6 AWG copper wire

•

20 feet of 8 AWG copper wire

•

40 feet of 8 AWG copper wire

Tests were also performed with no direct bond in order to generate some baseline data. A

resistor bank, highly resistive relative to the wiring in the sample assembly, was supplied as a

direct path to ground for the generator charge in order to model other available, low quality

ground paths. This direct path to ground was also necessary for equipment and personnel safety.

3.4

Lightning Profile

Due to the chaotic nature of lightning, it is impossible to re-create in an experimental setting.

Natural lightning displays an extremely wide range of electrical characteristics for which modern

physics is incapable of providing a definitive model. However, simplified models of the

electrical impulse from a lightning strike have been developed and can be found in various

technical papers and standards. The model chosen for the evaluation of lightning mitigation

techniques and materials must be determined by the researcher based on the physical system

being studied. The model used for this testing was based on lightning current traveling via the

overhead utility wires and internal conductors to the test site (a residential house). This resulted

in the selection of an impulse model intended for indirect effects as the most appropriate.

There are commonly used current impulse models for indirect lightning effects found in both the

aircraft and surge suppressor industries. An example of one of these waveforms can be seen in

Figure 2. Further details and examples of these waveforms can be found in SAE ARP-5412 [ref

1] and various IEEE standards. The majority of these waveforms are similar in shape with the

greatest variation found in the magnitude and duration of the lightning energy. These values are

expressed in time to rise to peak current and time to fall to 50 percent of peak current.

© Kraft/Torbin 2007

8

Figure 2: Waveform Example [ref 1]

A review of surge suppressor specifications found three common waveform durations: 8µs x

20µs, 10µs x 300µs and 10µs x1000µs. Preliminary testing was performed using all three of

these waveforms. This testing determined that the 10µs x 300µs waveform caused damage at

significantly lower charge levels than the other forms. In order to provide the most conservative

results, the 10µs x 300µs waveform was selected for all subsequent testing.

3.5

Testing Results

Using the test protocol previously described, 40 generator firings were performed on non-bonded

test samples. Generator settings were selected to explore the conditions required to create an arc

to the test sample, and thus firings were performed at settings where arcing was only

intermittent. Arcing was generated in only 12 firings. Arcing occurred intermittently at voltages

of 2.35 kV to the maximum setting of 4.75 kV. All data was collected to provide a baseline for

subsequent testing of bonded test samples. A summary of this data can be found in the Test

Results Summary, Table 1 and Table 2, as well as in Appendix C.

Based on the same test protocol, 49 generator firings were performed on bonded test samples.

Generator settings were selected to initiate arcing so as to explore current and charge transfer to

the test sample while in a bonded assembly. Arcing was generated in 37 firings. A summary of

this data can be found in the Test Results Summary, Table 1 and Table 2, as well as in Appendix

C.

© Kraft/Torbin 2007

9

Table 1: Test Results Summary, Generator Output

Test

Set-Up

No Bond

10-ft, 6AWG

20-ft, 6AWG

40-ft, 6AWG

20-ft, 8AWG

40-ft, 8AWG

Generator Current (kA)

Min

Max

0.28

4.85

2.00

9.50

3.05

9.15

1.95

13.30

5.15

9.25

5.10

10.00

Generator Charge (C)

Min

Max

0.78

1.90

0.75

3.70

1.20

3.80

0.61

3.20

2.10

3.40

2.10

3.45

CSST Voltage (kV)

Min

Max

0.47

4.75

1.30

5.25

4.00

8.20

2.40

8.50

4.65

6.95

4.70

5.60

©Titeflex Corporation 2007 (reproduced herein by consent of Titeflex Corporation)

Table 2: Test Results Summary, Test Sample

Test

Set-Up

No Bond

10-ft, 6AWG

20-ft, 6AWG

40-ft, 6AWG

20-ft, 8AWG

40-ft, 8AWG

Results

Arced

Hole

i

No

i

i

Yes

Yes

Yes

No

No

No

No

No

CSST Current (kA)

Min

Max

% of

Generator

2.30

4.65

96

------1.40

3.95

40

1.15

7.80

57

2.30

4.25

45

3.10

5.60

60

CSST Charge (C)

Min

Max

% of

Generator

1.10

1.95

98

------0.08

0.37

8

0.10

0.88

21

0.25

0.49

13

0.37

0.77

20

Legend: i: intermittent

©Titeflex Corporation 2007 (reproduced herein by consent of Titeflex Corporation)

© Kraft/Torbin 2007

10

4.0

Analysis

4.1

Interpretation of Results

From the test data (see Appendix C) it is clear that the correlation between arc initiation and

voltage at the CSST is poor. Arc initiation occurred and did not occur within the range of

2.35kV to 4.75kV. Conversely, the bond configuration of 10-ft of 6 AWG showed no arcing at

voltages as high as 5.25kV. As would be expected of a phenomenon as complex as arcing, the

data shows that more factors (than were measured during these tests) are significant to arc

initiation. Some of these factors may be the size of the hole in the PE jacket, distance from the

electrode to the stainless steel of the CSST, time versus voltage, and the condition of the

electrode. While further research could be done into these factors, the wide variation in

construction techniques would seem to minimize the relevance. The only conclusion that can be

reached is that fairly high voltage levels, in the order of thousands of volts, are required to

initiate an arc.

It is clear from the non-bonded configuration results that when a poor quality connection to

ground is present, an initiated arc to a well grounded conductor will carry the majority of the

current and charge. Lightning entering a building through the electrical system decreases the

efficacy of the electrical grounding system via charge saturation and travels to neutral earth

through the gas service entrance via an arc-over of the dielectric union. The non-bonded

configuration was the only configuration examined where the arc generated perforations through

the tubing wall.

It is very interesting to note the total lack of arcing with the 10-ft of 6 AWG bond configuration.

This bond configuration presented the lowest impedance path to ground of any of the

configurations examined in this study. This allowed the discharge to occur in a significantly

shorter time period, thus minimizing the exposure of the sample to peak voltages. It can be

inferred that insufficient time was available at peak voltage for the intervening dielectric, in this

case air, to breakdown and allow an arc to initiate. This effect is of great interest in the

prevention of damage to the piping and further studies are recommended.

The most significant finding of an analysis of the testing performed to date is the fraction of

generator current and charge that is conducted by the gas piping via an initiated arc and the total

lack of arc generated perforations due to this decrease. Each configuration shows a fairly stable

percentage regardless of generator settings or output. Table 3 summarizes these percentages.

While the variation in charge transfer due to generator waveform appears to be significant, there

is insufficient data at this point to come to a firm conclusion. Further research could be

undertaken to examine this variation. Contrasting the data between bonding configurations

shows a good correlation between resistance of the bond wire and percent charge transferred.

Doubling the length of the bond wire effectively doubles its resistance. This doubling effect is

shown in an equivalent doubling of percent charge transfer for the same wire gauge.

© Kraft/Torbin 2007

11

Table 3: Percentage of Electrical Impulse Transmitted via Arcing

Bonding Configuration

Peak Current

Charge Transfer

92%

97%

10-ft, 6 AWG

No Arcing

No Arcing

20-ft, 6 AWG

No Bond

40%

8%

1

57%

21%

2

40-ft, 6 AWG

56%

18%

20-ft, 8 AWG

45%

13%

40-ft, 8 AWG

60%

20%

40-ft, 6 AWG

©Titeflex Corporation 2007 (reproduced herein by consent of Titeflex Corporation)

1: Generator waveform 18μs x 215μs rather than normal 13μs x 300μs.

2: Single data point.

The various direct bond configurations modeled represented a variation in distance from the gas

service entrance to the electrical service entrance typical of residential construction. Other

pathway lengths are possible, but have not been studied at this time. The selection of either a 6

or 8 AWG copper bond wire has its precedence in the NEC based on several factors and

operating conditions as discussed in Section 4.2. The implementation of direct bonding of gas

piping for lightning mitigation places additional requirements on the bonding conductor and

connection that exceed the conventional bonding practices for the electrical protection of the gas

service.

4.2

Review of NEC Requirements

Ultimately, the effectiveness of a direct bond connection between the gas piping system and the

grounding electrode system will depend on many inter-related factors. Some of these factors

include the size and ampacity of the bonding jumper; the bonding jumper material; the location

of the gas piping relative to the grounding electrode system; the attachment method; and the

point of attachment to the gas piping system. The electrical system grounding system is assumed

to be designed and installed in accordance with the 2005 Edition of the National Electrical Code

(NEC). The NEC permits the gas piping to be bonded to either the service equipment enclosure,

the grounded conductor at the service, the grounding electrode conductor (if of sufficient size) or

to the one or more grounding electrodes used. The NEC under Section 250.4 (A) (4) requires

that all electrically conductive materials (which potentially includes all metallic piping, ducts,

vents, coax cable etc.) be bonded together in a manner that establishes an effective (lowimpedance) ground-fault current path.

© Kraft/Torbin 2007

12

The National Electrical Code contains many references to the requirements for bonding of

electrically conductive materials which include wiring, piping, ducts, vents and structural steel.

These requirements are specified throughout Section 250 of the NEC and all have the common

goal of protecting the public safety from electrical faults within the premise wiring system by

establishing an effective ground-fault current path. The objectives of this study were focused on

establishing more effective bonding of gas piping systems that may become energized by

indirect lightning strikes near the building. Towards that end, the authors conducted a study of

the NEC to review its coverage for the use and type of bonding for other conductive materials

and pathways to ground, and to compare those requirements with the conventional bonding

practices used for gas piping. Appendix B contains a listing of references within the NEC for

use of direct bonding and the application of a 6 AWG copper wire as the bonding means. It is

quite clear that the use of a 6 AWG copper bond wire is a well established approach for other,

similar conductive metallic systems; that a 6 AWG copper wire will be an effective means for

diverting (to ground) much of the energy associated with an indirect lightning strike; and the use

of direct bonding should be a familiar and straightforward solution to implement in the field by

electrical contractors.

4.3

Installation Instructions for Direct Bonding

Based, in part, on the testing results and subsequent analysis, and the general practice of bonding

established through the NEC, a separate set of installation instructions has been developed for

direct bonding of gas piping systems. These generic instructions have been included as

Appendix A. In essence, the instructions require the installation of a 6 AWG copper wire from a

single attachment point on the gas piping system near the service entrance of the building

directly to the grounding electrode system. All of the recommended practices and sizing criteria

are consistent with the requirements of Section 250 of the NEC and the National Fuel Gas Code.

When approved by each CSST manufacturer, these bonding practices will become part of their

published installation instructions, and a mandatory requirement for all new installations. In

accordance with NEC Section 110.3(B), listed equipment shall be installed and used in

accordance with the manufacturer’s instructions and the terms of the listing. In some

jurisdictions, the manufacturer’s instructions are permitted to take precedent over the affected

code when they are more conservative or restrictive in practice.

© Kraft/Torbin 2007

13

5.0

Conclusions and Recommendations

5.1

Conclusion

A test assembly and testing protocol were developed that represented a typical residential piping

system subjected to an indirect lightning flash via the electrical power lines. This model did

incorporate various configurations of bonding including no bonding and direct bonding with

copper conductors of varying lengths and gauges. The test results show a good correlation

between bonding configuration and percent charge transferred via an initiated arc to the gas

piping. Based on a subsequent review of the test results, it is estimated that a non-bonded system

would be subject to 97 percent of the charge from an indirect lightning flash entering the

building. By comparison, any of the direct bond configurations studied would only be subjected

to 20 percent or less of the same charge. In the case of a direct bond supplying a sufficiently low

impedance path to ground, there is a distinct possibility that arc initiation can be halted all

together. This effect requires further confirmation.

In conclusion, it is clear that the use of direct bonding with a gas piping system, specifically

CSST, can significantly decrease the risk of damage and increase the safety of the gas

installation. This conclusion leads to the recommendation that direct bonding be required for all

new gas installations. To implement direct bonding methods in the field, a set of installation

instructions have been developed and will be used to provide guidance to electrical contractors

who generally install the bonding means and to electrical inspectors who are responsible for

insuring that the bonding is properly installed.

5.2

Recommendations

Based on the results of the testing and the analyses of that data, the appropriate fuel gas and

electrical codes should be amended to require the direct boding of all metallic piping in

residential construction. This process has been initiated with a proposal to the National Fuel Gas

Code. The code change process is long and complex, and it is recommended that a committee of

interested parties be formed to monitor the process to its conclusion. Many advantages have

been highlighted in this report including ease of inspection, robustness (avoiding appliance and

wiring changes), and a significant improvement in providing a low impedance path to ground.

The testing and analyses also highlight a compelling reason to require direct bonding: There is a

significant reduction in the level of imposed current and a lower potential for arcing in the event

of an indirect lightning flash near the building. Further research is required to fully evaluate the

effects of direct bonding conductor length and gauge, and the ability of this bond configuration

to mitigate or eliminate arcing damage. However, there is sufficient evidence to recommend the

adoption of direct bonding by the code community without any further delay.

© Kraft/Torbin 2007

14

6.0

Bibliography and References

1.

----. ARP5412, Aircraft Lightning Environment and Related Test Waveforms,

Warrendale, PA: SAE, 2005.

2.

----. NFPA 54, National Fuel Gas Code, National Fire Protection Association, Quincy,

MA 1999, 2002, 2006.

3.

----. NFPA 70, National Electrical Code, National Fire Protection Association, Quincy,

MA 1999, 2005.

4.

----. NFPA 780, Standard for the Installation of Lightning Protection Systems, National

Fire Protection Association, Quincy, MA 2000, 2004.

5.

Anderson, R.B. and Eriksson, A.J., Lightning Parameters for Engineering Applications,

Suceava, Roumania: Colloquium and Study Committee Meeting, Cigre Study

Committee 33, 1979.

6.

Cianos, N. and Pierce, E.T., A Ground-Lightning Environment for Engineering Usage,

Menlo Park, California: Stanford Research Institute, 1972. Figure 25, pp. 66.

7.

Crouch, K.E., Lightning Technologies Incorporated, Pittsfield, MA 2007.

8.

Kithil, R., Lightning Protection for Engineers, Louisville, CO: National Lightning

Safety Institute, 2005.

9.

Martzloff, F. D. and Crouch, K. E., “Coordination de la Protection Contre les

Surtensions dans les Reseaux Basse Tension Residentiels”, Proceedings 1978 IEEE

Canadian Conference on Communications and Power, 78CH1373-0, pp. 451-454.

10.

Rupke, E., Lightning Technologies Incorporated, Pittsfield, MA 2004-2007.

© Kraft/Torbin 2007

15

APPENDIX A

GUIDELINES FOR DIRECT (ELECTRICAL) BONDING OF CSST SYSTEMS

This guideline document describes the requirements for the direct bonding of corrugated

stainless steel tubing (CSST) gas piping systems. The bonding of CSST shall be installed by a

licensed contractor recognized by the local jurisdiction as capable of performing such work.

Direct bonding is required for all CSST natural and LP gas piping systems whether or not the

connected gas equipment is electrically powered. These guidelines are applicable to all new

CSST installations as well as partial retrofits of CSST to existing steel pipe and copper tubing

systems. These guidelines are applicable for typical single-family and multi-family dwellings

and certain commercial buildings. An engineer knowledgeable in electrical system design and

the local electrical code should review the bonding requirements for each commercial application

to determine if additional bonding and/or larger conductor sizes are required.

CSST installed inside or attached to the exterior of a building or structure shall be electrically

continuous and directly bonded to an effective ground-fault current path. The gas piping system

shall be considered to be directly bonded when installed in accordance with the following:

•

A bonding jumper is permanently and directly connected to the electrical service

grounding system. This shall be achieved through a connection to the electrical service

equipment enclosure, the grounded conductor at the electrical service, the grounding

electrode conductor (where of sufficient size) or to the one or more grounding electrodes

used. (NEC Section 250.104 B)

•

A single bond connection shall be made to the building gas piping downstream of the

utility meter, but near the service entrance (either outdoors or indoors) of the structure, or

downstream of the gas meter of each individual housing unit within a multi-family

structure. A “daisy chain” configuration of the bonding conductor shall be permitted for

multi-meter installations. A bonding connection shall not be made to the underground,

natural gas utility service line.

•

The bonding conductor shall not be smaller than a 6 AWG copper wire. The bonding

conductor shall be installed and protected in accordance with the NEC Section 250.64.

•

The bonding conductor shall be attached in an approved manner in accordance with NEC

Article 250.70 and the point of attachment for the bonding conductor shall be accessible.

•

Bonding/grounding clamps shall be listed to UL 467 or other acceptable national

standards.

© Kraft/Torbin 2007

16

•

The bonding clamp shall be attached at only one point within the piping system to either

the CSST brass fitting (if so listed) or to a rigid steel pipe component located between the

meter and the first downstream CSST fitting. See Figures 1, 2 and 3 for guidance. The

corrugated stainless steel tubing portion of the gas piping system shall not be used as the

point of attachment of the bonding clamp at any location along its length. The bonding

clamp shall be attached such that metal to metal contact is achieved with the steel pipe

component or CSST fitting.

The National Electrical Code recommends the bonding of all metallic piping systems and

metallic air ducts within the premise as a means for providing additional safety. Avoiding direct

contact between these metallic pathways has also been shown to reduce the possibility for arcing

between systems with different levels of electric potential.

Bond wire

Bond wire

Clamp

Clamp

Steel pipe

Figure 1: Bonding Attachment to Pipe

© Kraft/Torbin 2007

CSST fitting

Figure2: Bonding Attachment to CSST Fitting

17

Bond wire

Clamp

Manifold

Figure 3: Bonding Attachment to Uncoated (Customer-Owned) Manifold

© Kraft/Torbin 2007

18

APPENDIX B

NEC REFERENCES FOR THE USE OF 6 AWG COPPER BOND JUMPER

NFPA 70-2005 Edition of the National Electrical Code

250.53: Grounding Electrode System Installation.

(C) Bonding Jumper. The bonding jumper(s) used to connect the grounding electrodes together

to form the grounding electrode system shall be installed in accordance with 250.64(A), (B), and

(E) shall be sized in accordance with 250.66, and shall be connected in the manner specified in

250.70.

250.66: Size of Alternating-Current Grounding Electrode Conductor. The size of the

grounding electrode conductor of a grounded or ungrounded ac system shall not be less than

given in Table 250.66, except as permitted in 250.66(A) through (C).

(A) Connections to Rod, Pipe, or Plate Electrodes. Where the grounding electrode conductor

is connected to rod, pipe, or plate electrodes as permitted in 250.52(A)(5) or (A)(6), that portion

of the conductor that is the sole connection to the grounding electrode shall not be required to be

larger than 6 AWG copper wire or 4 AWG aluminum wire.

Table 250.66: Grounding Electrode Conductor for A-C Systems:

Size of Service Entrance Conductor:

2 or smaller => 8 AWG Copper

1 or 1/0

=> 6 AWG Copper

2/0 or 3/0

=> 4 AWG Copper

250.64: Grounding Electrode Conductor Installation. Grounding Electrode Conductors shall

be installed as specified in 250.64(A) through (F).

250.64(B): Securing and Protection Against Physical Damage. When exposed, a grounding

electrode conductor or its enclosure shall be securely fastened to the surface on which it is

carried. A 4 AWG or larger copper or aluminum grounding electrode conductor shall be

protected where exposed to physical damage. A 6 AWG grounding electrode conductor that is

free from exposure to physical damage shall be permitted to be run along the surface of the

building construction without metal covering or protection where it is securely fastened to the

construction; otherwise it shall be in rigid metal conduit, intermediate metal conduit, rigid

nonmetallic conduit, electrical metallic tubing, or cable armor. Grounding electrode conductors

smaller than 6 AWG shall be in rigid metal conduit, intermediate metal conduit, rigid

nonmetallic conduit, electrical metallic tubing, or cable armor.

© Kraft/Torbin 2007

19

250.104 Bonding of Piping Systems and Exposed Structural Steel

(A) Metal Water Piping. The metal water piping system shall be bonded as required in (A)(1),

(A)(2), or (A)(3) of this section. The bonding jumper(s) shall be installed in accordance with

250.64(A), (B), and (E). The points of attachment of the bonding jumper(s) shall be accessible.

(1) General. Metal water piping systems(s) installed in or attached to a building or structure

shall be bonded to the service equipment enclosure, the grounded conductor at the service, the

grounding electrode conductor where of sufficient size, or to the one or more grounding

electrodes used. The bonding jumper(s) shall be sized in accordance with Table 250.66 except

as permitted in 250.104(A)(2) and (A)(3). {(A)(2): Buildings of Multiple Occupancy; (A)(3):

Multiple Buildings or Structures Supplied by a Feeder(s) or Branch Circuit(s).}

(B) Other Metal Piping. Where installed in or attached to a building or structure, metal piping

system(s), including gas piping, that is likely to become energized shall be bonded to the service

equipment enclosure, the grounded conductor at the service, the grounding electrode conductor

where of sufficient size, or to one or more grounding electrodes used. The bonding jumper(s)

shall be sized in accordance with 250.122, using the rating of the circuit that is likely to energize

the piping system(s). The equipment grounding conductor for the circuit that is likely to

energize the piping shall be permitted to serve as the bonding means. The points of attachment

of the bonding jumper(s) shall be accessible.

FPN: Bonding all piping and metal air ducts within the premises will provide additional safety.

250.122: Sizing of Equipment Grounding Conductors.

(A) General. Copper, aluminum, or copper-clad aluminum equipment grounding conductors of

the wire type shall not be smaller than shown in Table 250.122 but shall not be required to be

larger than the circuit conductors supplying the equipment.

Table 250.122: Minimum Size Equipment Grounding Conductors for Grounding

Raceways and Equipment:

100 AMP => 8 AWG Copper

200 AMP => 6 AWG Copper

250.120: Equipment Grounding Conductor Installation. An equipment grounding conductor

shall be installed in accordance with 250.120(A), (B) and (C).

(C) Equipment Grounding Conductors Smaller Than 6 AWG. Equipment Grounding

Conductors Smaller Than 6 AWG shall be protected from physical damage by a raceway or

cable armor except where run in hollow spaces of walls or partitions, where not subject to

physical damage, or where protected from physical damage.

© Kraft/Torbin 2007

20

800.100: Cable and Primary Protector Grounding (Communications)

(D) Bonding Electrodes. A bonding jumper not smaller than 6 AWG copper or equivalent shall

be connected between the communications grounding electrode and power grounding electrode

system at the building or structure served where separate electrodes are used.

810.21: Grounding Conductors – Receiving Stations (Radio and Television Equipment)

(J) Bonding of Electrodes. A bonding jumper not smaller than 6 AWG copper or equivalent

shall be connected between the radio and television equipment grounding electrode and power

grounding electrode system at the building or structure served where separate electrodes are

used.

820.100: Cable Grounding (Community Antenna Television and Radio Distribution

Systems)

(D) Bonding of Electrodes. A bonding jumper not smaller than 6 AWG copper or equivalent

shall be connected between the community antenna television system’s grounding electrode and

power grounding electrode system at the building or structure served where separate electrodes

are used.

830.100: Cable, Network Interface Unit, and Primary Protector Grounding (NetworkPowered Broadband Communications Systems)

(D) Bonding of Electrodes. A bonding jumper not smaller than 6 AWG copper or equivalent

shall be connected between the network-powered broadband communications system grounding

electrode and power grounding electrode system at the building or structure served where

separate electrodes are used.

NFPA 780-2004 Standard for the Installation of Lightning Protection Systems

4.19.2.2: Conductors used for the bonding of grounded metal bodies or isolated metal bodies

requiring connection to the lightning protection system shall be sized in accordance with bonding

conductor requirements in Table 4.1.1.1 (A) and Table 4.1.1.1 (B).

4.1.1.1 (A): Ordinary structures not exceeding 23-m (75ft) in height shall be protected with

Class I materials as shown in Table 4.1.1.1 (A).

Table 4.1.1.1 (A) Minimum Class I Material Requirements: Bonding Conductor, cable (solid

or stranded): Cross section area = 26,240 cir mils.

NOTE: 6 AWG wire has a cross sectional area of 26,251 cir mils.

© Kraft/Torbin 2007

21

APPENDIX C

TEST RESULTS FROM LABORATORY PROGRAM

No Bond

Generator

CSST

Charge Level

Current

Charge

Voltage

Current

Charge

(kV)

(kA)

(C)

(kV)

(kA)

(C)

1

0.28

NM

0.47

No Arc

2

0.56

NM

0.86

No Arc

3

0.86

NM

1.40

No Arc

4

1.15

NM

1.80

No Arc

5

1.30

0.78

2.35

No Arc

5

1.30

0.78

2.35

No Arc

5

1.30

0.78

2.35

No Arc

6

1.60

0.98

2.80

No Arc

6

1.60

1.00

2.80

No Arc

32

6

1.64

1.04

2.80

No Arc

37

6

1.64

1.04

2.85

No Arc

43

6

1.64

1.04

2.85

No Arc

48

6

1.65

1.15

2.85

No Arc

13

6

1.70

NM

2.80

No Arc

54

7

1.85

1.15

3.25

No Arc

62

7

1.85

1.15

3.25

No Arc

33

7

1.88

1.20

3.30

No Arc

36

7

1.88

1.20

3.00

3.25

1.30

38

7

1.88

1.20

3.30

No Arc

44

7

1.88

1.20

3.30

No Arc

50

7

1.95

1.30

3.25

No Arc

55

8

2.15

1.35

3.75

No Arc

63

8

2.15

1.35

3.75

No Arc

34

8

2.18

1.40

3.80

No Arc

35

8

2.18

1.40

3.80

No Arc

39

8

2.18

1.40

3.75

No Arc

51

8

2.25

1.50

3.75

No Arc

56

9

2.45

1.55

4.20

No Arc

40

9

2.45

1.55

4.25

No Arc

42

6

2.80

1.22

2.35

2.70

1.10

47

6

2.85

1.20

2.85

2.70

1.15

46

6

2.95

1.25

2.85

NM

NM

14

8

3.85

1.65

3.75

2.30

31

8

3.85

1.65

2.45

3.70

1.50

45

8

3.85

1.65

3.55

3.60

1.50

52

9

4.25

1.80

4.10

4.20

NM

53

9

4.35

1.70

3.50

4.20

1.70

64

9

4.35

1.75

3.95

4.25

1.75

57

10

4.85

1.90

4.60

4.65

1.95

41

10

4.85

1.90

4.75

4.45

1.85

©Titeflex Corporation 2007 (reproduced herein by consent of Titeflex Corporation)

Test

No.

9

10

11

12

58

59

60

61

© Kraft/Torbin 2007

22

Direct-Bond: 20 feet of 8 AWG

Generator

CSST

Test

Charge Level

Current

Charge

Voltage

Current

Charge

No.

(kV)

(kA)

(C)

(kV)

(kA)

(C)

80

10

5.15

2.10

4.65

2.30

0.25

81

12

6.15

2.50

4.75

2.75

0.28

82

14

7.25

2.95

5.70

3.30

0.37

83

16

8.20

3.30

6.30

3.75

0.40

85

18

9.25

3.35

6.95

4.20

0.45

86

18

9.25

3.35

6.95

4.20

0.43

84

18

9.25

3.40

5.85

4.25

0.49

©Titeflex Corporation 2007 (reproduced herein by consent of Titeflex Corporation)

Direct-Bond: 40 feet of 8 AWG

Generator

CSST

Test

Charge Level

Current

Charge

Voltage

Current

Charge

No.

(kV)

(kA)

(C)

(kV)

(kA)

(C)

87

10

5.1

2.1

4.9

3.1

0.37

89

12

6.1

2.5

4.7

3.65

0.45

90

14

7.15

2.9

6.85

4.35

0.58

91

16

8.1

3.15

6.85

4.95

0.64

94

18

9.1

3.45

7.35

5.6

0.73

93

18

9.15

3.45

7.8

5.6

0.73

92

18

10

3.35

7.8

5.6

0.77

©Titeflex Corporation 2007 (reproduced herein by consent of Titeflex Corporation)

Direct-Bond: 10 feet of 6 AWG

Test

No.

Charge Level

(kV)

Generator

Current

(kA)

Charge

(C)

Voltage

(kV)

CSST

Current

(kA)

Charge

(C)

2

4

2.00

0.75

1.30

No Arc

3

4

2.10

0.70

1.70

No Arc

4

5.75

3.00

1.00

2.30

No Arc

5

8

4.30

1.40

3.40

No Arc

6

10

5.30

1.80

3.30

No Arc

7

14

7.25

2.40

4.75

No Arc

8

18

9.50

3.70

5.25

No Arc

©Titeflex Corporation 2007 (reproduced herein by consent of Titeflex Corporation)

© Kraft/Torbin 2007

23

Direct-Bond: 20 feet of 6 AWG

Generator

CSST

Test

Charge Level

Current

Charge

Voltage

Current

Charge

No.

(kV)

(kA)

(C)

(kV)

(kA)

(C)

22

6

3.05

1.30

4.25

No Arc

28

6

3.15

1.20

4.00

No Arc

27

6

3.20

1.20

4.05

No Arc

25

7

3.65

1.40

4.50

1.40

0.09

26

7

3.65

1.45

4.15

1.40

0.08

24

7

3.70

1.50

4.25

1.45

0.10

23

8

4.20

1.70

5.35

1.65

0.12

21

10

5.30

2.15

5.80

2.05

0.15

20

12

6.30

2.55

7.05

2.50

0.21

17

14

7.20

2.85

7.30

3.05

0.25

19

14

7.25

2.95

7.25

3.05

0.25

16

14

7.25

NM

6.25

NM

NM

18

18

9.15

3.80

8.20

3.95

0.37

©Titeflex Corporation 2007 (reproduced herein by consent of Titeflex Corporation)

Direct-Bond: 40 feet of 6 AWG

Generator

CSST

Charge Level

Current

Charge

Voltage

Current

Charge

(kV)

(kA)

(C)

(kV)

(kA)

(C)

4

1.95

0.70

3.40

No Arc

3

2.15

0.61

2.75

1.15

0.10

3

2.15

0.62

2.90

No Arc

4

3.00

0.85

3.25

1.65

0.16

4

3.00

0.85

2.40

1.65

0.17

5

3.70

1.05

3.45

2.15

0.20

5

3.75

1.05

3.25

2.15

0.20

6

4.50

1.60

5.20

2.35

0.25

8

5.95

1.65

4.45

3.45

0.35

10

7.50

NM

4.50

4.40

0.47

12

8.80

2.30

5.70

5.20

0.55

14

10.45

2.85

6.95

6.10

0.67

16

11.80

3.10

6.30

6.90

0.76

18

13.30

3.20

8.50

7.80

0.88

Change of Generator Output viz. Waveform

79

18

9.15

3.30

8.10

5.10

0.60

©Titeflex Corporation 2007 (reproduced herein by consent of Titeflex Corporation)

Test

No.

65

71

72

69

70

68

67

66

73

74

75

76

77

78

© Kraft/Torbin 2007

24