COLOUR GUIDE - NU-CORE

advertisement

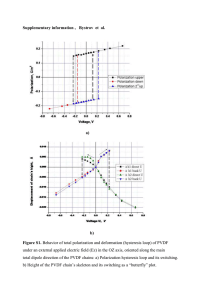

COLOUR GUIDE A2 FIRE RESISTANT Zero fire spread and or droplets when fire tested. Certified EN13501-1:2007 SUSTAINABLE Inorganic Core Composition. First of its kind. ADVANCED COLOUR TECHNOLOGY Let your imagination be our guide PANEL PHYSICAL PROPERTIES PANEL PROPERTIES MEASUREMENT Total Panel Thickness 3mm, 4mm, 5mm, 6mm Aluminium Alloy Thicknesses 0.12mm, 0.15mm, 0.18mm, 0.21mm, 0.31mm, 0.40mm, 0.45mm, 0.50mm Aluminium Grade AA1100, AA3003, AA3105, AA5005 Standard Panel Size Width: 1250mm, 1550mm Length: 2440mm, 2850mm, 3050mm, 3200mm, 4000mm Maximum Custom Panel Size Width: 1575mm Length: 6000mm Panel Weight Custom width and length available upon request. Subject to minimum quantities. 8.12 kg/m2 for 4mm (0.50mm skin front and back) APPLICATIONS CORE MATERIAL CUSTOM COLOUR BY NU-CORE® iD High rise and low rise facades, external and internal feature walls. The standard core is made up of inorganic geo-composite material which is both non-flammable and non-combustible (Fire resistant core tested in accordance to EN13501-1:2007, GB/T17748, GB8624-2006 A2-S1.d0.t0) Building material and product burning performance classification. For colour matching we require one of the following: + Sample (Minimum 25mm x 25mm) + Pantone®/RAL colour reference + PPG or Beckers® code reference All areas which may require a decorative application to the face area. FEATURES + + + + + + + A2 Fire rated inorganic core Non-flammable Non-combustible Sustainable natural core Unlimited range of finishes and textures, PE, PVDF Pre-finished Aluminium, Anodised Aluminium, Stainless Steel, Pre-weathered Zinc, Natural or Pre-weathered Copper Highest quality raw materials used STANDARD FINISHES: PVDF/PE Three coat system, consisting of a primer, topcoat and clear coat with a minimum thickness of 28 microns. Reverse side can either be a milled aluminium finish or a polyester base coat finish. Nano PVDF application available. Specialty finishes available upon request. BENEFITS + + + + + + + Superior fire proof Fixed with smartfix® Fixing System Highly decorative and eye catching Long lasting in all finishes Low maintenance Fast and easy to install using smartfix® Fixing system Nu-core® Sustainable A2FR is available as a bundled product with smartfix® Fixing System METAL FINISHES + + + + + + Aluminium Anodised Stainless Steel – Brushed or Mirror Pre-weathered Zinc Copper - Natural or Pre-weathered Brass - Natural or Pre-weathered Bronze - Natural or Pre-weathered Please send color samples to: Nu-core® iD Custom Colour Department Suite 3, 50 Stanley Street East Sydney, NSW 2010 Australia Kindly provide your name, company name, physical address, email address, project name, project location and the type of finish required. Nu-core® A2FR fills the gap for composite panel applications where traditional FR ACP products were limited. Strict Fire requirements are increasing in many regions and are phasing out the use of traditional FR pre-finished composite panels due to poor fire performance characteristics under extreme heat. Nu-core® A2FR has passed A2 s1 d0 - zero fire spread and or droplets when exposed to fire, proving that the safe performance of Nu-core® A2FR is the new generation in composite panel technology. FLUOROCARBON PAINTS TECHNICAL SPECIFICATION TEST ITEM PERFORMANCE REQUIREMENT (AAMA 2605 - 05) BECKER TEST RESULTS Gloss ASTM D523@60°C Low Normal High Gloss Range (25-35 unit) Pencil Hardness ASTM D3363 >=F Pass Dry Film (AAMA 2605 - 05 7.4.1.1) Adhesive Attraction 100% Excellent, No Change Wet Film (AAMA 2605 - 05 7.4.1.2) Adhesive Attraction 100% Excellent, No Change Pochieren (AAMA 2605 - 05 7.4.1.3) Adhesive Attraction 100% Excellent, No Change Backside Impact (AAMA 2605 - 05 7.5.1) No Crack, Adhesive Attraction 100% @ 3mm ± 0.3mm Excellent, No Change Abrasion Resistance Test (AAMA D968) 40kgs/25µm Pass or Surpass Hydrochloric Acid (AAMA 2605 - 05 7.7.1) No Bubble, No Change by Eye Pass or Surpass Cement (AAMA 2605 - 05 7.7.2) No Change Pass or Surpass GRINDING TEST (1MM) CHEMICAL RESISTANCE Nitric Acid (AAMA 2605 - 05 7.7.3) E<5 Pass or Surpass Detergent(AAMA 2605 - 05 7.7.4) No Change Pass or Surpass Window Detergent (AAMA 2605 - 05 7.7.5) No Change Pass or Surpass Moisture Test, 400hrs x 100% RH x 38°C (ASTM D2247 or ASTM D 4585) No Bubbling (ASTM D 714) Pass or Surpass Salt Spray Test, 400hrs x 5% NaCI (ASTM B117) Average Side Corrosion 7 Grade, Bubble 8 Grade (ASTM D1654) Pass or Surpass CORROSION RESISTANCE WEATHER RESISTANCE (Florida, 10 years) E<=5 Pass or Surpass Pulverization (ASTM D4214) ≤ 8 Grade Pass or Surpass Gloss Retention Rate(ASTM D523) ≥ 50% Pass or Surpass Corrosion(ASTM D244) Paint Film Drop < 10% Pass or Surpass Aberration (ASTM D2244) PVDF/PE Glittering Silver - NU001 PVDF / PE True Silver - NU002 PVDF / PE Ash Silver - NU003 PVDF / PE Moon Light Silver - NU004 PVDF / PE Slate Silver - NU005 PVDF / PE Dark Champagne - NU006 PVDF / PE Silver Grey - NU007 PVDF / PE Charcoal Silver - NU008 PVDF / PE Dark Pearl - NU009 PVDF / PE True Red - NU010 PVDF / PE Bright Red - NU011 PVDF / PE Firebrick Red - NU012 PVDF / PE Golden - NU013 PVDF / PE Golden Brass - NU014 PVDF / PE Golden Champagne - NU015 PVDF / PE Goldfinch - NU016 PVDF / PE Sugar Bronze - NU017 PVDF / PE True White - NU018 PVDF / PE Dark White - NU019 PVDF / PE Ivory White - NU020 PVDF / PE Milk White - NU021 PVDF / PE Milk Yellow - NU022 PVDF / PE True Yellow - NU023 PVDF / PE Dim Grey - NU024 PVDF / PE Slate Grey - NU025 PVDF / PE Dark Grey - NU026 PVDF / PE Catalina Blue - NU027 PVDF / PE Deep Blue - NU028 PVDF / PE Cadmium Green - NU029 PVDF / PE Tin Silver - NU030 Nano PVDF Champagne Silver - NU031 Nano PVDF Silver Mink - NU033 Nano PVDF Gold Lame Gloss - NU034 Nano PVDF NANO PVDF Pure White - NU032 Nano PVDF White Gloss - NU035 PE Gloss White Ivory - NU036 PE Silver Gloss - NU037 PE Bright Honey Gloss - NU038 PE Fern Gloss - NU039 PE Traditional Green Gloss - NU040 PE Light Blue Gloss - NU041 PE Bluebonnet Gloss - NU042 PE Jet Black Gloss - NU043 PE Valencia Orange Gloss - NU044 PE Poppy Red Gloss - NU045 PE Ruddy Aubergine Gloss - NU046 PE Pearl Red - NU047 PE Pearl Blue - NU048 PE Pearl Green - NU049 PE Diamond Black - NU050 PE Pearl Black - NU051 PE Silver Brushed - NU052 PE Gold Brushed - NU053 PE Steel Brushed - NU054 Anodized Silver Mirror - NU055 Anodized Gold Mirror - NU056 Anodized Hammerton Nature - NU057 Anodized Topaz - NU058 PVDF / PE Jewel - NU059 PVDF / PE Silver Quartz - NU061 PVDF / PE Lapis - NU062 PVDF / PE Dark Teak - NU063 PVDF / PE Light Walnut - NU064 PVDF / PE Dark Coffee Vein - NU066 PVDF / PE Western Red - NU067 PVDF / PE Spectra Colour Garnet - NU060 PVDF / PE Granite & Wood Grain Oriental White - NU065 PVDF / PE NU-CORE® THE LEADING BRAND IN FIRE RETARDANT DECORATIVE COMPOSITE PANELS Suite 3 50 Stanley Street East Sydney, NSW 2010 Sydney Australia P: +61 2 9331 4065 F: +61 2 9331 8295 P.O. Box 152 Darlinghurst NSW 2010 nu-core.com.au