water tank coatings guide - Induron Protective Coatings

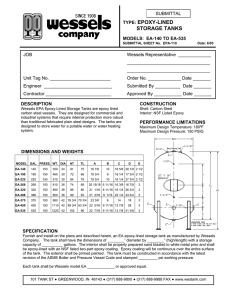

advertisement

WATE R TAN K COATI NG S G U I DE WATER TANK COATINGS GUIDE PRODUCT TYPE COMMENTS VOL SOLIDS VOC RECOMMENDED FILM THICKNESS AC 403 Acrylic Elastomeric Acrylic coating which will bridge small cracks and reduce freeze-thaw damage. 44% <75 g/l 6.0-12.0 Aquanaut Primer Acrylic Rust Inhibitive Primer 37% <110 g/l 1.5-3.0 Aquanaut II Acrylic Enamel Gloss Finishes in a unique high performance, user-friendly water based system. 36% <192 g/l 2.0-4.0 Armorlux Aluminum Aluminum Alkyd Uniform Metallic Finish 43% <450 g/l 1.0-2.0 Armorlux Color Chrome Aluminum Aluminum Alkyd Uniform Colored Metallic Finish 32% <540 g/l 1.0-1.5 Ceramapure TL70 Polyamide Epoxy A unique high build NSF Std 61 Certified Tank Lining. Incorporates ceramic pigment for maximum corrosion protection of immersed substrates. 70% < 255 g/l 10.0-15.0 Induraguard Polyamidoamine Epoxy High Solids, Surface Tolerant Epoxy that meets OTC/VOC restrictions that is available in a wide range of colors. 75% <240 g/l 3.0-7.0 Induramastic 85 Epoxy Mastic Surface Tolerant Epoxy available in Tan or Off White. 73% <240 g/l 3.0-7.0 Indurazinc MC67 Zinc Rich MCU NSF Std 61 Certified Tank Lining. Zinc provides galvanic protection, MCU provides durability, toughness and quick cure. 67% <238 g/l 2.5-3.5 Indurazinc DF 67 Zinc Rich MCU Zinc provides galvanic protection, MCU provides durability, toughness, quick dry times and dry fall characteristics. 67% <238 g/l 2.5-3.5 Indurethane 6600 Plus Acrylic Polyurethane High Solids, High Gloss polyurethane that meets OTC requirements for VOC and provides up to 50% extended protection from ultra-violet light 64% <336 g/l 2.0-3.0 Indurethane 6700 Flat Urethane Acrylic Polyurethane High Solids, Flat polyurethane that meets OTC requirements for VOC 67% <324 g/l 2.0-3.0 Indurethane 5000 Clear Coat Acrylic Polyurethane Excellent roller application properties. Significantly extends the color retention of darker colors. 45% <440 g/l 1.0-2.0 P-30 Universal Primer Phenolic Alkyd Primer Excellent one package corrosion protection and may be recoated with most Induron finishes including, alkyds, acrylics, polyurethanes and epoxies. 51% <380 g/l 2.0-3.5 PE-70 Polyamide Epoxy NSF Std 61 Certified Tank Lining. Available in Tan, Gray or Aqua White. 70% <252 g/l 3.0-6.0 RC-70 Polyamide Epoxy NSF Std 61 Certified Tank Lining for rapid cure applications. Available in Tan, Gray or Aqua White. 70% <264 g/l 3.0-6.0 Perma-Clean 100 Ceramic Epoxy Amine Epoxy NSF Std 61 Certified Tank Lining. A solvent free, ZERO VOC immersion grade lining incorporating ceramic pigment for maximum corrosion protection of immersed substrates. 100% 0.0 g/l Perma-Clear Fluorourethane Fluorourethane Provides extended color and gloss retention beyond the normal life of conventional polyurethane, clear urethanes and even fluorourethane finishes. 52% <300 g/l 15.0-30.0 2.0-3.0 SYSTEM FIRST COAT MILS SECOND COAT MILS THIRD COAT MILS TOTAL DFT –––––– 20.0-30.0 7.0-11.0 7.0-11.0 STEEL INTERIOR, WET-SURFACE PREPARATION SSPC-SP10 Ceramapure TL70 PE-70 RC-70 10.0-15.0 3.0-5.0 3.0-5.0 Ceramapure TL70 PE-70 RC-70 10.0-15.0 4.0-6.0 4.0-6.0 N/A Epoxy: ICS-2 PE-70 RC-70 3.0-5.0 PE-70 RC-70 3.0-5.0 PE-70 RC-70 3.0-5.0 9.0-15.0 Epoxy: ICS-3 Perma-Clean 100 20.0-25.0 N/A –––––– N/A –––––– 20.0-25.0 Zinc/Epoxy: ICS-5 Indurazinc MC67 2.5-3.5 PE-70 RC-70 3.0-5.0 PE-70 RC-70 3.0-5.0 8.5-13.5 Epoxy: ICS-1 STEEL INTERIOR, DRY - SURFACE PREPARATION SSPC-SP6 Epoxy PE-70 RC-70 3.0-5.0 Induraguard 4.0-6.0 N/A –––––– 7.0-11.0 Zinc/Epoxy Indurazinc MC67 or DF67 2.5-3.5 Induraguard 4.0-6.0 N/A –––––– 6.5-9.5 STEEL EXTERIOR, BLASTED - SURFACE PREPARATION SSPC-SP6 Alkyd: OCS-1A P30 Universal Primer 2.0-3.0 Armorlux Aluminum 1.0-2.0 Armorlux Aluminum 1.0-2.0 4.0-7.0 Alkyd: OCS-1B P30 Universal Primer 2.0-3.0 Armorlux Color Chrome 1.0-1.5 Armorlux Color Chrome 1.0-1.5 4.0-6.0 Zinc/Acrylic: OCS-3 Indurazinc MC67 or DF67 2.5-3.5 Aquanaut Primer 2.0-4.0 Aquanaut II 2.0-4.0 6.5-11.5 Zinc/Fluorourethane: OCS-4 Indurazinc MC 67 or DF67 2.5-3.5 Indurethane 6700 Flat Urethane 2.0-3.0 Perma-Clear Fluorourethane 2.0-3.0 6.5-9.5 Epoxy/Urethane: OCS-5 PE-70 or RC-70 Induraguard 3.0-5.0 Induraguard 3.0-5.0 Indurethane 6600 Plus Indurethane 6700 Flat 2.0-3.0 8.0-13.0 Zinc/Epoxy/Urethane: OCS-6 Indurazinc MC 67 or DF67 2.5-3.5 Induraguard 3.0-5.0 Indurethane 6600 Plus Indurethane 6700 Flat 2.0-3.0 7.5-11.5 STEEL EXTERIOR, OVERCOATING - SURFACE PREPARATION DEPENDS ON CONDITION OF SURFACE Acrylic Aquanaut II 2.0-4.0 Aquanaut II 2.0-4.0 N/A –––––– 4.0-8.0 Epoxy Mastic/ Urethane Induramastic 85 Induraguard 3.0-5.0 Indurethane 6600 Plus Indurethane 6700 Flat 2.0-3.0 N/A –––––– 5.0-8.0 Aluminum Armorlux Aluminum 1.0-2.0 Armorlux Aluminum 1.0-2.0 N/A –––––– 2.0-4.0 Color Chrome Aluminum Armorlux Color Chrome 1.0-1.5 Armorlux Color Chrome 1.0-1.5 N/A –––––– 2.0-3.0 Penetrating Epoxy Spot: Induramastic 85 E-Bond 100 1.0-2.0 Optional: Induraguard PE-70 RC-70 Aquanaut II 3.0-4.0 Indurethane 6600 Plus Aquanaut II 2.0-3.0 6.0-9.0 CONCRETE - SURFACE PREPARATION CLEAN, FULLY CURED AND DRY Interior PE-70 RC-70 3.0-5.0 PE-70 RC-70 3.0-5.0 PE-70 RC-70 3.0-5.0 9.0-15.0 Interior Ceramapure TL70 10.0-15.0 Ceramapure TL70 10.0-15.0 N/A –––––– 20.0-30.0 Interior Perma-Clean 100 20.0-25.0 N/A –––––– N/A –––––– 20.0-25.0 Exterior AC403 Acrylic Elastomeric 6.0-12.0 AC403 Acrylic Elastomeric 6.0-12.0 N/A –––––– 12.0-24.0 NOTES: 1. Brush or roller application may require additional coat(s) to achieve recommended film thickness and/or complete hiding. 2. When using heavily pigmented colors it is recommended to use Perma-Clear Fluorourethane over Indurethane 6700 Flat to maximize color and gloss retention. 3. All ICS and OCS designated systems correspond with the ANSI/AWWA D102 Latest Version System Number. WATER TANK COATINGS GUIDE ESTIMATING TANK SURFACE AREAS ELEVATED TANKS Capacity (Gals.) 50,000 100,000 150,000 200,000 250,000 500,000 750,000 1,000,000 Riser Diameter 4 ft. 4 ft. 5 ft. 6 ft. 7 ft. 5 ft. Dry 8 ft. Dry 8 ft. Inside Area (Sq.Ft.) 3,150 4,300 5,100 5,900 6,700 10,000 13,600 17,000 Outside Area (Sq. Ft.) 6,500 8,000 9,900 11,100 12,700 19,600 29,100 36,900 Inside Area (Sq. Ft.) PEDESTAL COLUMN SPHERICAL TANKS Capacity (Gals.) Wet 50,000 2,200 100,000 3,350 150,000 4,150 200,000 5,000 250,000 5,700 500,000 9,000 750,000 11,750 1,000,000 14,750 Dry 2,700 2,950 3,450 4,100 4,500 5,500 7,100 8,900 Outside Area (Sq. Ft.) 3,950 5,350 6,500 7,750 8,700 12,750 16,500 20,450 Inside Area (Sq. Ft.) SINGLE FLUTED COLUMN TANKS SINGLE PEDESTAL COLUMN TANK Capacity (Gals.) Wet 500,000 12,000 750,000 15,900 1,000,000 19,850 1,500,000 27,850 2,000,000 31,000 Dry 17,500 26,750 31,850 35,975 54,250 Outside Area (Sq. Ft.) 19,300 27,675 33,250 39,750 47,750 Inside Area (Sq. Ft.) COMPOSITE ELEVATED TANK Capacity (Gals.) Wet 500,000 11,000 1,000,000 18,000 1,500,000 25,000 2,000,000 30,900 2,500,000 35,100 Dry 1,400 1,600 1,900 2,000 2,300 Outside Area (Sq. Ft.) 9,500 15,200 20,200 25,100 28,500 STANDPIPES AND RESERVOIRS Flat Roof or Floor Area = .7854 x diameter² Roof and Framing Area = 1.22 x diameter² Cone Roof Area = .85 x diameter² Shell Area = 3.1416 x diameter x height