Ground Grid Integrity

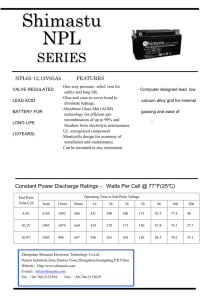

advertisement

Tech Tips Ground Grid Integrity by Jeff Jowett Megger T he testing of grounding electrodes…grids, meshes, and the like…is most often considered in terms of a resistance test. That is to say, the resistance of the surrounding environment to current flow to some arbitrary or carefully plotted point typically referred to as remote earth or infinite earth. The ground grid is intended to serve the dual purpose of carrying currents into the earth without exceeding the operating tolerances of any protected equipment while assuring that personnel in the vicinity are not exposed to electric shock as would result from excessive step or touch potentials. Resistance tests indicate the overall capability of the grid in this regard: its electrical relationship to its environment. But there remains the question of the internal condition of the grid itself. Out of sight, out of mind? Buried under ground, the grounding electrode doesn’t call attention by mere visual inspection, which is the first step in most electrical maintenance. Though they may seem inert, grounding electrodes are subject to their own unique set of stresses, just like other electrical equipment. Fault clearance and lightning protection can severely damage a grid or mesh, separating individual elements, interrupting continuity, and introducing high resistance across bonds. But in the meantime, the electrode may have cleared the fault perfectly well, leaving no obvious indication that it has been compromised. A subsequent event may not be afforded the same level of protection. Furthermore, a less dramatic but more persistent force of deterioration is the incessant process of corrosion and weather. Freezing and expansion exert pressures that can break apart a grid. Ironically, the best grounding soils are also the most corrosive. Low resistivity soil that facilitates the flow of fault current also promotes electrolytic current that eats away at the metallic structure of a grounding electrode. Use of dissimilar metals hastens the process. Rods have been known to last as little as two years, with typically a risk of at least some corrosion effects being present after four.1 A standard ground resistance test just looks at voltage drop across the surrounding soil and gives no measure of the physical condition of the electrode itself. www.netaworld.org The grounding electrode typically is carrying only noise, but must be able to accommodate worst case conditions of high current flow when called on line during an event. Therefore, to test grid integrity, the tester must be able to produce high current. A grid tester works similarly to a ground tester in that it supplies current and measures voltage drop across the test item. In this case, the test item is the grid, whereas in a ground test, it includes the surrounding soil. It is dissimilar in that the grid tester typically employs an industry standard of 300 amperes, whereas a ground tester operates on the milliampere level. Rather than calculating and displaying resistance, the grid tester evaluates the change in current flow. Test equipment consists of a variable current source requiring on the order of a 10.5 kVA capability, operated from a 50 ampere, 240 Vac source. Test leads can range anywhere from 10 to 100 feet of 2/0 welding cable. A reference ground is first established, preferably a transformer neutral. The leads are connected, one to the test ground and the other to the reference ground below any bonding connections (Fig. 1). The tester is then energized and adjusted to pass 300 amperes via the reference ground through the grid under test for a duration of three minutes. Fall 2008 NETA WORLD C A D B Measurements after Test Hook-Up Figure 1 A clamp-on ammeter is then used to measure current at critical points around this system: through the reference ground above (A) and below (B) the attachment of the test lead and on the opposite side of the system through the test ground both above (C) and below (D) the lead connection. Current readings are recorded, and the tester indicates voltage drop across the system. Voltage drop of the leads themselves is also measured. This is done by disconnecting from the test item, shorting the leads together, and passing 300 amperes for three minutes, noting the voltage. This value is then subtracted from the voltage drop taken during the test to isolate voltage drop across the grid from the lead contribution. For an indication of acceptable continuity, a value of no more than 1.5 volts per 50 feet of straight line ground path should be measured. The straight line ground path is the distance between the two lead connections. Though valuable, this method is not rigorously precise, and so a redundant system of evaluation exists based on current return. For single driven electrodes, at least 200 amperes should return to the source via the ground path. For mats and grids, at least half of the current must return via the ground path. If not, it indicates a potentially bad connection and should be dug up for repair. What is the method that makes this procedure successful? What happened to Kirchhoff ’s laws? Kirchhoff ’s first law states that the sum of the currents flowing from a point in a circuit equals the current flowing to that point, i.e., current is a precisely measurable quantity that doesn’t just “disappear into thin air.” Operation of the high-current grid tester is based on an application of Kirchhoff ’s first law to NETA WORLD Fall 2008 account for all the current that is injected into the system. By injecting a substantial amount of current, it becomes comparatively easy to note its division along stress lines. It is expected that most of the current will follow the shortest, straightest path (least resistance) between the two test points. The ammeter readings indicate to what extent this is occurring. Discontinuity or high resistance connections anywhere between the test points will divert proportionate amounts of current through the rest of the system. Substations are multiply-bonded into a Faraday cage configuration, and other facilities with complex or extensive grids are also typically connected to the electrical system at multiple points. Therefore, it cannot be presumed that all current is flowing in a particular path. Current flowing from the tester must first be measured for any diversion into the system (point A, Fig. 1), and to determine the amount flowing into the grid (B). This value is then compared to the amount returning through the test ground (D), and that which is diverted through parallel paths into the rest of the system (C). To illustrate, an example of an acceptable test is shown in Fig. 2. Pretest conditions indicate typical values of current flowing on the system. The distance between the test connections is measured, and the voltage drop across the leads is taken from the tester. Performance of the test then indicates 270 amperes flowing into the grid, with some diversion through the reference ground back into the electrical system. The ground connection being measured then shows 280 amperes returning (test current enhanced by some “noise” on system). Since this is a grid, the industry standard calls for at least a 150 ampere return, so this is well exceeded. Voltage drop across the test was measured at 7.9, but as 7.5 of this was lead resistance, only 0.4 volt is across the tested path. This falls within the allowance for 1.5 volts per 50 feet (1.5/50 x 15 = 0.45). The tested ground path passes both criteria with acceptable values. A failed test is outlined in Fig. 3. Here, only a negligible amount of current returns through the tested ground connection, while 280 amperes flow through building structure via a parallel connection. Voltage drop calculates to 8.1 (15.6 – 7.5), which fails the requisite criterion (100 feet allows 2 x 1.5 = 3 volts). If the test setup were switched to the other leg of the structure, results would be essentially reversed, so the ground connection on the left would have to be dug up and inspected for a fault in continuity. Similarly, ground cables, clamps and ferrules can be tested prior to installation using the same equipment and parameters. Cable manufacturer’s specifications should provide proper voltage drop. For instance, 300 amperes on 100 feet of cable yields 30,000 ampere-feet. For 4/0 bare copper, the voltage drop should be 4.1 volts. For a 10 foot section, therefore, the voltage drop would be 0.41. If manufacturer’s guidelines are not available, the following www.netaworld.org 1. 2. 3. 4. Measurements before Test Hook-Up Hook-Up and Connections Figure 2 Figure 3 Measurements before Test Hook-Up Current in transformer neutral (reference) = 82 amperes Current in the post ground wire = 6 amperes Distance between reference ground and post ground = 15 feet Voltage drop in test leads with 300 amperes = 7.5 volts Measurements after Test Hook-Up and with 300 Amperes Flowing in the Test Circuit (i.e., test set meter reading) 1. 2. 3. 4. 5. Current flow in reference ground to grid = 270 amperes Current flow in reference ground to T(X) = 50 amperes Current flow from grid to post ground = 280 amperes Current flow from the structure to post ground = 1 ampere Voltage reading at the test set meter = 7.9 volts formula can be used to get an approximation of voltage drop, bearing in mind that manufacturer’s specifications are always preferable: V = (2 x I x L x R)/1000 where, I = test current L = length R = resistance per 1000 feet Specific code requirements are not in effect, but standards exist that provide guidelines for grid testing. Notably, NFPA70E-1983, Part I, Chapter 2, Section F, Item 4 outlines low-impedance continuity, and Part III, Chapter I, Section B, Item 1 calls for continuous maintenance. OSHA has adopted this as a safety requirement, and IEEE 81 references testing of grid structure. By this method, each ground connection around a substation or other facility can be tested. Faults are not precisely pinpointed, but by isolating www.netaworld.org 1. 2. 3. 4. Measurement before Test Hook-Up Current in transformer neutral (reference) = 82 amperes Current in frame ground = none Distance between reference ground and frame ground = 100 feet Voltage drop of the test leads with 300 amperes = 7.5 volts Measurement after Test Hook-Up and with 300 Amperes Flowing in the Test Circuit (i.e., test set meter reading) 1. 2. 3. 4. 5. Current flow in reference ground to grid = 270 amperes Current flow in reference ground to T(X) = 50 amperes Current in frame ground from grid = 2.5 amperes Current flow in frame ground from the structure = 280 amperes Voltage reading at the test set meter = 15.6 volts a faulty current path, the work of excavation and repair is markedly reduced. Lyncole XIT Grounding Electrical Equipment Testing and Maintenance, A. S. Gill, Prentice Hall 1 Jeffrey R. Jowett is Senior Applications Engineer for Megger in Valley Forge, Pennsylvania, serving the manufacturing lines of Biddle®, Megger®, and Multi-Amp® for electrical test and measurement instrumentation. He holds a BS in Biology and Chemistry from Ursinus College. He was employed for 22 years with James G. Biddle Co. which became Biddle Instruments and is now Megger. Fall 2008 NETA WORLD