Principles of Automotive OEM Coatings

advertisement

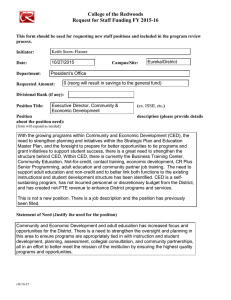

Principles of Automotive OEM Coatings Dr. Ulrike KUTTLER ALLNEX AUSTRIA GmbH - Our R&D Center in Graz Allnex at a Glance A 1.5 Billion $ private equity owned company with a strong market position in 4 different business lines: Sales 2012 by Product Line Liquid Resins and Additives (LRA) Radiation Curable Resins (RAD) Powder Resins (PCR) Crosslinkers (XLR) Different market segments: Automotive Industrial Packaging coatings and inks Protective Industrial plastics Specialty architectural Sales 2012 by Segment Allnex – Our global footprint 2,000 people dedicated to Coating Resins Allnex – Our Technologies for Automotive OEM Coatings RESYDROL® : Waterdilutable Alkyd- and modified Alkyd resins Waterdilutable Polyester- and modified Polyester resins DAOTAN ® : Waterdilutable Polyurethane dispersions VIACRYL ® : Water- and solventdilutable Acrylic resins MACRYNAL ® : Isocyanate crosslinkable Acrylic resins (s/b & w/b) CYMEL ® : Melamine Aminoplast Crosslinkers (methylated, butylated as well as mixed alcohols range) CYCAT ® : Catalysts for Melamine Amino Crosslinkers ADDITOL ® : Additives for Pigment wetting Stabilizing aluminum pigments in waterborne Basecoats Leveling & flow Substrate wetting Degassing & defoaming Automotive OEM Layers Clearcoat DFT: approx. 50 - 60µm Topcoat DFT: approx. 50 - 60µm Basecoat DFT: approx. 10 - 30µm Primer Surfacer DFT: approx. 25 - 35µm Cathodic Electrodeposition „CED“ DFT: approx. 20µm Metal & Pretreatment Automotive OEM Layers - their main responsibilities Cathodic Electrodeposition „CED“ Corrossion protection (together with pretreatment layer) of the car body Primer Surfacer – the „damping- and preparation“ layer Protection against mechanical impacts (stone chip protection ) Leveling of unevenness and irregularities (sanding marks, poor leveling / high roughness of CED) Basecoat – the „style / emotion“ layer Providing color and effect – also of high importance for supporting the shape of the car body Clearcoat – the „appearance and protection“ layer Appearance: Excellent leveling (smooth surface) High gloss and body Protection: UV radiation (causes degradation of the polymers) Chemicals (gasoline, acids, tree gum, bird droppings,……) Mechanical impacts (scratches, car wash brushes,…..) Cathodic Electrodeposition A short introduction CED History Basics Coating composition Tank Adjustments CED - History Anodic Electrodeposition Since 1961 (FORD-Patent) Heyday: 1965 till approx. 1978 Cathodic Electrodeposition Starting in 1975 State-of-the-art technology till today CED - Basics What do we need for CED? A conductive object to be coated (all kinds of metal or metalized substrates) Electric power (DC) generated by a rectifier The CED bath with anode cells as counter electrodes An oven (150 – 190°C) for the stoving process CED - Basics Advantages of CED Fully automated No limitation for the shapes of objects Good penetration into holes (throwing power) No overspray and other losses (except loss of the isocyanate blocking agent) Best corrosion resistance of all coating systems Disadvantages Rather high investments for the coating line Curing temperature >140°C CED - Basics Principle of CED - + Water/e-Coat Elektrolyse Electrolysis Anode: Formation of H+-ions (acid) Coagulation Koagulation Cathode: Formation of OH--Ions (Base) The resin coagulates by the pH-shift CED – The Coating Composition 1. Cationic resin dispersion (also containing the crosslinker) 2. Pigments 3. Cosolvents 4. Additives 5. Curing catalyst 6. Deionised Water 1. Cationic Resin Dispersion for Primer: A. Backbone resin OH OH N Epoxy resin B. Crosslinker: blocked aromatic Isocyanates C. Catalyst: metal catalyst H+ N RCOOOrganic acids like Formic, acetic, lactic,…. Cationic Resin Dispersion for Monocoats: A. Backbone resin OH OH N H+ polyacrylate OH B. Crosslinker: blocked aliphatic Isocyanates N RCOO- Performance Comparison Epoxy - CED Acrylic - CED Corrosion resistance +++ - UV - resistance --- ++ Feasible color range --- ++ Stoving temperature > 160°C > 170°C Salt Spray Test ASTM (500 hrs) Infiltration [mm] 6,5 aromatic aliphatic acrylic/30% EP 5 acrylic/15% EP Epoxy 5 4 3 1 0 1 2 3 4 5 240 hrs Accelerated Weathering (QUV - B) Loss of gloss 100 aromatic 100 aliphatic acrylic/30% EP 68 50 22 15 4 0 1 2 3 4 5 acrylic/15% EP epoxy 2. Colors/Pigments Epoxy CED for car bodies: grey TiO2, carbon black, (extenders) Epoxy CED for small parts: black Carbon black, extenders Acrylic CED for Monocoat systems: different colors Organic pigments 2. Colors/Pigments For the pigment grinding a separate grinding resin is used! The CED system consists of 2 components the CED dispersion (clear, not pigmented) the pigment paste Both components are fed into the tank separately 3. Role of the Cosolvents: Influencing film forming: The higher the solvent content, the softer the film in the deposition stage: the lower the film resistance the higher the flow of electricity the higher the film build increase of the bath temperature has same effect Well established cosolvents are Texanol, Hexylglycol, Phenoxypropanol and Butylglycol (as carrier for the others) 4. Additives Anti crater agents (incompatible with the ecoat): Edge protection additives Zinc pinhole additives (use of cosolvents is also possible) Dispersing additive: for preparing the water dilutable catalyst dispersion 5. Curing Catalysts Blocked aromatic isocyanates need a metal catalyst for deblocking and crosslinking Catalysts in use are DBTO, DOTO, Bismuth compounds All catalysts need a special preparation to bring them into a water dilutable form, which cannot be hydrolised in the waterborne ecoat E- Coat characteristics (CED) Solids content 15 – 20 % pH 4-6 Conductivity 800 – 1500 µSi MEQ-value 25 - 40 (milliequivalent acid/ 100 g solid resin) Pigment binder ratio 0,15 : 1 (black) < 0,1 : 1 (organic) < 0,5 : 1 (grey) General Parameters 1. Voltage 30 – 420 Volt DC 2. Current (Ampere) depending on film resistance 3. Deposition time (sec) 4. Bath temperature (°C) 5. Electric charge (As, Cb) 6. Deposition equivalent (Cb/g deposited ecoat) Minimum Coalescing Temperature MCT (Constant voltage) µm 40 35 irregular deposition regular deposition 30 25 20 15 10 20 22 24 26 28 30 32 Bath temperature °C Cosolvent addition: moves the MCT and µm to the right CED - Process: Deposition time 2 - 4 minutes Loss of solid material is compensated by addition of new material (dispersion as well as pigment paste) ANODE: Formation of the neutralisation acid (removed by the anolyte) Formation of oxygen CATHODE: Deposition, coating formation of hydrogen Film Forming During the Electrodeposition The amount of deposited material decreases with the time of deposition, as the film forms a layer with strongly reduced conductivity Depending on the softness of the E- coat (Tg of the resin), normal film thickness (15 – 25 µm) up to high film build (25 – 50 µm) can be generated Throwing power: the ability of the E- coat to penetrate into holes The film is almost dry after deposition (<2% water) after rinsing Circulation of Anolyte, Ultrafiltration: ANOLYTE = liquid phase in the anode, which absorbs the acid which is generated by the deposition ULTRAFILTRATION = additional removal of waterborne components from the coatings system. Turnover Is the time for full consumption of the material in the tank Depends on coated surface/time Typical turnover is 2-5 weeks, but can go up to 1 year (stability challenge!) Tank size and turnover define the consumption of the material; tank size can go up to 500 m³ (bigger cars, buses) Metal Substrates/Pretreatments Blank steel (only used for testing purposes) Iron phosphated steel (low end substrates) Zinc phosphated steel (most common substrates for Automotive and GI, gives highest performance – depending on dotation and rinsing; Cr free rinse is a must in EU) Sandblasted steel (very seldom) Other metal substrates Mg, Al, …. deliver different deposition performance and have to be evaluated individually Challenges: Cratering (external contaminations) Leveling Pinholes (MCT – behaviour) Coagulation in the tank (too low neutralisation, bacteria ?) Redissolution (too low pH in CED) New metal pretreatments (e.g. Zirconium- based) Primer Surfacer A Short Introduction Primer Surfacer History Basics Coating composition Trends Primer Surfacer - History Only solventbased (s/b) chemistry till late 1980 / early 1990s Worldwide first waterborne (w/b) Primer Surfacer at Opel in Germany early 1990s Other OEM‘s (VW- Group, Volvo, Daimler, BMW,…..) followed within the next decade Today w/b Primer Surfacer is „state of the art“ but still a high amount of s/b technology in use (Fiat, Renault, PSA, OEM‘s in US and Asia,……) 36 Technology Segmentation Primer Surfacer: Development from 2004 to 2010 100% 100% 90% 90% 80% 80% 70% 70% 60% 60% 50% 50% 40% 40% 30% 30% 20% 20% 10% 10% 0% 0% Europe Eastern&Central E. w/b Primer Surfacer Europe 2004 WB POWDER SB 40% 2% 58% 100% Americas Powder East & Central Europe 2004 10% 0% 90% 100% Japan Asia Europe Eastern&Central E. w/b solvent Americas 2004 Japan 2004 8% 51% 41% 100% 10% Asia 2004 (Outside JP) 5% 90% 100% 95% 100% Primer Surfacer Europe 2010 WB POWDER SB 70% 4% 26% 100% Americas Powder East & Central Europe 2010 14% 0% 86% 100% Japan Asia solvent Americas 2010 Japan 2010 11% 70% 19% 100% 30% Asia 2010 (Outside JP) 10% 70% 100% 90% 100% Primer Surfacer - Basics Application of the Primer Surfacer with ESTA (electrostatic application) by means of high speed bells Dry film thickness (DFT) can vary from 20 – 35µm Standard baking conditions: 20min/165°C (at some OEMs lower temperatures down to 145°C ) Each OEM / OEM line has more or less different requirements 38 Basics Main Requirements for the Primer Surfacer Excellent Appearance (gloss, leveling, absolutely NO surface defects) Broad application window = high robustness of the Primer Surfacer (temperature, humidity, application speed , baking conditions……) to achieve high first run o.k. rates Excellent adhesion to different CED- and PVC qualities Excellent intercoat adhesion to a broad variety of Basecoats Excellent humidity resistance Excellent mechanical properties – tough elastic even at -20°C Shear & storage stability ……. ...... 39 Primer Surfacer – The Coating Composition s/b Primer Surfacer Polyester (mod. Alkyd) Epoxy resin Melamine Crosslinker Benzoguanamine Crosslinker Pigments Extenders Additives Solvents (> 40%) w/b Primer Surfacer mod. Alkyd Polyester (PU- mod.) Melamine Crosslinker blocked Polyisocyanate Pigments Extenders Additives Solvents (< 5%) 40 Primer Surfacer – The Coating Composition EPOXY Modifier Resin Adhesion Corrosion resistance Pigment wetting Basic Resin Levelling Hardness Economic efficiency Polyester Modifier Resin Stone chip resistance IMPROVE PU Modifier Resin 41 Trends / Challenges for the Primer Surfacer Layer: Further improved appearance (gloss, leveling) further broadening of application window („robustness“) Lower cost / higher productivity Low bake (< 120°C?) Elimination of Primer Surfacer layer in „Compact Paint processes“ 42 Basecoat A short introduction Basecoat History Basics Coating composition Trends Basecoat - History Only solventbased (s/b) chemistry till mid 1990s All German OEM‘s meanwhile use w/b Basecoat Today w/b Basecoat is „state of the art“ but still a high amount of s/b technology in use (Fiat, Renault, PSA, OEM‘s in US and Asia,……) Due to steadily increasing legislative pressure in China w/b Basecoat technology is growing much quicker than expected. 45 w/b Basecoat in Global Car Production 90 80 70 Mio Cars 60 50 40 30 20 10 0 1997 1999 2001 2003 2005 World (w/b) 2007 2009 World (all) 2011 2013 2015 % w/b BC Conversion from s/b to w/b OEM Basecoat Basecoat - Basics Application of the Basecoat with ESTA (electrostatic application) by means of high speed bells or for metalic Basecoats ins 2 runs (ESTA / pneumatic gun) Dry film thickness (DFT) can vary from 10 – 30µm (color dependant!) Standard baking conditions: 10min/80°C, followed by 20min/145°C (together with Clearcoat) Due to the huge variety of colors and effects the most sophisticated paint layer of the car. An advanced formulation know how as well as carefull resin selection is key! 48 Basecoat - Basics Main Requirements for the Basecoat Excellent appearance (effect, leveling, absolutely NO surface defects) Excellent adhesion to different Primer Surfacer qualities Excellent intercoat adhesion to a broad variety of Clearcoats Excellent humidity resistance Excellent mechanical properties – tough elastic even at -20°C Shear & storage stability Robust in application ……. ...... 49 Basecoat – The Coating Composition s/b Basecoat Polyester (PUD mod.) CAB Melamine Crosslinker Pigments Talcum Additives Solvents (> 70%) w/b Basecoat PUD, Polyester, Acrylic Thickener Melamine Crosslinker Pigments Talcum Additives Solvents (~ 10%) 50 Basecoats – The Modular Approach Polyurethane dispersion (PUD) Is providing adhesion, flexibility, appearance (flip flop effect in metallic BC) and stone chip properties. Very important component in the formulation! Acrylic dispersion Is providing hardness, physical drying, helps to fix the aluminum pigment and is decreasing overall formulation cost Melamine resin Is improving leveling, wetting of Clearcoat, and intercoat adhesion (BC/CC), increase open time of BC Polyester Can help to improve levelling, adhesion, flexibility and stone chip properties. Is also used in pigment pastes. Thickener Is providing the rheological properties for the BC. Very important in metallic BC to achieve a perfect flip flop effect Structure of PU-Dispersions In the synthesis of PU dispersions Polyisocyanates (hard segments) and Polyols (soft segments) are co- reacted in a polyaddition reaction. Soft - Segments Hard - Segments OH-Polyester OH-Alkyd OH-Polyether OH- Acrylate OH- Polycarbonate Polyisocyanate (TDI, IPDI, TMXDI...) Diol Dimethylolpropionic acid (Amine) 52 Typical Hard - Segments Aliphatic / Cycloaliphatic (CH2)6 N O O C N (CH2)6 N C O O C N Hexamethylene diisocyanate (HDI) (CH2)6 N O N (CH2)6 (CH2)6 Urethdion N Isocyanurate N (CH2)6 N C O (CH2)6 H O H O C N (CH2)6 O C N CH3 CH3 O C N N N N O H3C N C O O O O C N N C O O N C O (CH2)6 N C O Biuret N C O N C O Isophorone diisocyanate (IPDI) Dicyclohexylmethandiisocyanate (Desmodur W) 53 Typical Hard - Segments Aromatic CH3 CH3 N C O O C N N C O N C O Toluylene diisocyanate (TDI) N C O O C N N C O N C O Diphenylmethane diisocyanate (MDI) 54 Schematic Production Process for PUDs Soft-Segments Hard-Segments Co-reacting Soft- and Hard-Segments Neutralization (amines or strong bases) Dispersing in water Chain elongation Chain stopping 55 Different Production Procedures for PUDs „ACETONE“ PROCESS 1. Polyaddition (i.e. co- reaction of soft segments with Polyisocyanates and a hydrophilic acid component) as well as the chain extension step (with Di- oder Polyamines) is run in Acetone (homogeneous phase) (instead of Acetone solvents like e.g. MEK, MIBK, THF are also suitable) 2. After the neutralization- and dispersion step the Acetone is distilled off Advantages: • Very universal • Viscosity during synthesis easy to control Disadvantages: • complex and expensive • residual solvent in the resin • Process not sustainable • Unfavorable yield Different Production Procedures for PUDs „MELT“ PROCESS 1. Polyaddition (i.e. co- reaction of soft segments with Polyisocyanates and a hydrophilic acid component) is run WITHOUT any solvent (in a melt) 2. A potential chain extension step is run AFTER the neutralization and dispersion step (i.e. in water) Advantages: • NO residual solvent • Food yield • No „solvent waste“ Disadvantages: • Tricky process (very high viscosities) • Process not suitable for all the different PUD- chemistries Different Production Procedures for PUDs „SOLVENT“ PROCESS 1. Polyaddition (i.e. co- reaction of soft segments with Polyisocyanates and a hydrophilic acid component) is run WITH solvent (NMP/NEP are the most common ones) 2. A potential chain extension step is run AFTER the neutralization and dispersion step (i.e. in water) Advantages: • very universal • viscosity during synthesis easy to control Disadvantages: • Resin may contain quite high amounts of solvent • Toxicology and price of NMP / NEP Different Production Procedures for PUDs „MONOMER“ PROCESS 1. Polyaddition (i.e. co- reaction of soft segments with Polyisocyanates and a hydrophilic acid component) is run in acrylic monomers (acrylic /methacrylic acid and esters thereof) that act as „solvent“ 2. A potential chain extension step is run AFTER the neutralization and dispersion step (i.e. in water) 3. Radical polymerization of the acrylic monomers yields a solvent free, acrylic modified PUD (graft polymer) Advantages: • NO residual solvent • Good yield • No „solvent waste“ Disadvantages: • Smart but tricky process • Only for acrylic modified PUDs (graft polymers) Film Morphology Hard - Segment „ net-points“ Soft - Segment flexibility Soft- and Hard- Segments within the polymer are leading to a „structure of domains“. This special stucture is creating the well known tough-elastic behaviour of PUD based coatings (even at low temperatures!) 60 PU Dispersions – Structure Properties O R NH C Urea O NH R R NH C O R‘ Urethane Urea- as well as Urethane groups have a strong dipole moment. This is causing strong interactions with the surface of substrates excellent adhesion to “difficult substrates” like e.g. plastics Moreover this dipole moment is causing strong intermolecular forces (cohesion) outstanding mechanical properties and elasticity 61 PUD Basics – The „Take Aways“ 1. PUD‘s are produced by a polyaddition- reaction of soft segments (OH- group containing pre- polymers) with Polyisocyanates (hard segments) and a hydrophilic acid component 2. The different production procedures for PUD- resins are tricky and complex 3. The majority of the hard segments (Polyisocyanates) as well as many soft segments (OH- Polycarbonates, OH- Polyethers,….) are high price raw materials leading to PUD‘s with elevated price level 4. The achieved properties like • • • • Adhesion to critical substrates Outstanding mechanical properties Excellent elasticity and abrasion resistance Tough elastic behaviour even at low temperatures make PUD‘s a first choice for Automotive OEM Basecoat applications! Polyurethane Dispersions Structure – Property Relationships PUDs – Soft Segments Soft Segment Advantage Disadvantage OH- Polyester Very good appearance V. good mech. properties Hydrolytic stability OH- Alkyd Good body Good substrate penetration Yellowing, outdoor durability Hydrolytic stability OH- Polyether Low viscosity Hydrolytic stability Poor light- and thermo stability OH- Polyacrylate Quick drying Outdoor durability Stability against oxidants OH- Polycarbonate Hydrolytic stability Outdoor durability High Price PUDs – The Molecular Weight PUD‘s with low / medium molecular weight („chain stopped“ grades) designed for crosslinking with Polyisocyanates or Amino resins Advantages: • Good leveling (due to slow physical drying) • Good degassing • Good pigment wetting • Excellent chemical- and solvent resistance properties • Excellent mechanical- and adhesion properties • Can be formulated with little to no solvents Disadvantages: • Need crosslinker (Polyisocyanate or Amino resin) • More complicated handling (valid only for 2K formulations) • Potlife (valid only for 2K formulations) • Price (expensive Polyisocyanate) PUDs – The Molecular Weight PUDs with high / very high molecular weight („chain extended“ grades) Designed for 1-pack applications (further crosslinking is possible) Advantages: • Quick physical drying • Excellent orientation of metalic pigments (bright metalic effect!) • Outstanding elasticity, adhesion and mechanical properties • No need for crosslinker • Easy handling (1 pack!) • No potlife Disadvantages: • Weak pigment wetting • Weak chemical- and solvent resistance properties • Poor leveling (due to quick physical drying) • Should be formulated with solvents PUDs – Preferred Fields of Application SUBSTRATE Plastic Metal LAYER MAIN BENEFIT Primer Adhesion, mech. properties Basecoat Monocoat Adhesion, metalic effect, mech. properties Primer Surfacer Adhesion, stone chip properties Basecoat Adhesion, metalic effect, mech. properties Current Trends in the Base Coat Area Completely eliminate NMP/NEP from recipes (change in legislation) „Lower cost“ Further improved robustness i.e. stable color position regardless of humidity / temperature conditions, spraying conditions, type of Clearcoat, substrate,……. New color effects Bell / bell application Clearcoat A short introduction Clearcoat Technology- and market overview Basics Coating composition Trends OEM Clearcoats – Technology Overview Till 2010 the Clearcoat layer was the one with the broadest diversification. Following technologies were in use: Technology In use at s/b 1K- Clearcoat Fiat, Peugeot, Renault,… s/b 1K- Clearcoat Toyota and other Japanese OEM‘s s/b 2K- Clearcoat VW, Audi, Mercedes, BMW,……. w/b 1K- Clearcoat Opel (Eisenach plant only), Mercedes (Melamine crosslinked) (Carboxy – Epoxy technology) (Polyisocyanate crosslinked) (Melamine crosslinked) Powder Clearcoat (Rastatt plant only) BMW (ONLY!!) Technology Segmentation Clearcoat: Development from 2004 to 2010 100% 100% 90% 90% 80% 80% 70% 70% 60% 60% 50% 50% 40% 40% 30% 30% 20% 20% 10% 10% 0% Europe Eastern&Central E. w/b CLEAR COAT Europe 2004 WB 1K Melamine 2K 1K_Acidcar boxy Powder 1.6% 100% 1K s/b Americas 2K s/b Japan Carboxy-Epoxy Asia 0% Europe Powder Eastern&Central E. w/b Middle/East/ Central EU2004 Americas 2004 Japan 2004 Asia 2004 (Outside JP) CLEAR COAT Europe 2010 1.7% 70.0% 80% 60% 21% 58% WB 1K Melamine 26.7% 20% 15% 25% 30% 49% 16% 26% 2K 1K_Acidcar boxy Powder 100% 100% 100% 100% 1K s/b 2K s/b Americas Japan Carboxy-Epoxy Asia Powder Middle/East/ Central Europe 2010 Americas 2010 Japan 2010 Asia 2010 (Outside JP) 4% 54% 80% 57% 21% 62% 38% 20% 15% 27% 30% 49% 14% 24% 100% 0.3% 100% 4.6% 100% 100% 0.5% 100% OEM Clearcoats – Technology Overview Since 2010 a steady consolidation of Clearcoat technologies is ongoing: w/b 1K Clearcoat stopped at Opel Eisenach and Mercedes Rastatt -> switch to s/b Clearcoat! BMW stopped powder Clearcoat -> switch to s/b 2K Clearcoat s/b 2K Clearcoat is increasing, but worldwide s/b 1K Clercoat still has a share of approx. 80% Clearcoats – Basics Application of the Clearcoat with ESTA (electrostatic application) by means of high speed bells Dry film thickness (DFT) in the range from 50 – 60µm Standard baking conditions: 20min/145°C The paint layer where majority of final properties is provided by the resin technology. Carefull resin selection is key! 74 Clearcoats – Basics Main Requirements for the Clearcoat PREMIUM Appearance (gloss, leveling, absolutely NO surface defects) Excellent adhesion to different Basecoat qualities Excellent outdoor durability, no yellowing Excellent humidity resistance Excellent mechanical properties – tough elastic even at -20°C Excellent chemical resistance (solvents, chemicals, acids, …….) Excellent scratch resistance (carwash!!) Robust in application Easy to repair by sanding or polishing ...... 75 s/b 1K Clearcoats Basic components Properties Acrylic resin Outdoor durability, chemical resistance and hardness Polyester resin Body, leveling, adhesion, scratch resistance, outdoor durability Sca mod. resins Antisagging and good flow/aspect Melamine Crosslinker Blocked Isocyanate Flexibility, chemical resistance Catalyst Reactivity (if necessary) s/b 2K Clearcoats Basic components Properties Acrylic resin Outdoor durability, chemical resistance and hardness Polyester resin Body, leveling, adhesion, scratch resistance, outdoor durability Sca mod. resins Antisagging and good flow/aspect Polyisocyanate Crosslinker Melamine resin Additional crosslinking OEM Clearcoats – Technology Comparison Technology s/b 1K (Melamine) s/b 2K (Polyisocyanate) PROS Price Robustness Scratch resistance Easy handling (no 2K equipment!) No Formaldehyde issue Acid- / chemical resistance Film build Appearance Gloss Suitable for compact process CONS Formaldehyde release Acid- / chemical resistance Film build Appearance , gloss not for compact process 2K equipment needed Price Scratch resistance Current Trends for the Clearcoat Appearance, appearance, appearance „Lower cost“ Further improved robustness (less rework!) Improved scratch resistance Higher solids content (due to more stringent legislation) Contact Details: Dr. Ulrike KUTTLER Global Application Technology Manager, Automotive Ulrike.Kuttler@allnex.com Phone: +43 50399 1302 Disclaimer: Allnex Group companies (“Allnex”) decline any liability with respect to the use made by anyone of the information contained herein. The information contained herein represents Allnex's best knowledge thereon without constituting any express or implied guarantee or warranty of any kind (including, but not limited to, regarding the accuracy, the completeness or relevance of the data set out herein). Nothing contained herein shall be construed as conferring any license or right under any patent or other intellectual property rights of Allnex or of any third party. The information relating to the products is given for information purposes only. No guarantee or warranty is provided that the product and/or information is adapted for any specific use, performance or result and that product and/or information do not infringe any Allnex and/or third party intellectual property rights. The user should perform its own tests to determine the suitability for a particular purpose. The final choice of use of a product and/or information as well as the investigation of any possible violation of intellectual property rights of Allnex and/or third parties remains the sole responsibility of the user. Notice: Trademarks indicated with the ®, ™ or * are registered, unregistered or pending trademarks of Allnex Belgium SA or its directly or indirectly affiliated Allnex Group companies. © 2013 Allnex Belgium SA. All Rights Reserved 81