Analysis of the Voltage Stresses on Transformer Windings under

INTERNATIONAL JOURNAL OF ELECTRICAL SYSTEMS AND CONTROL (IJESC)

Vol. 3, No. 1, Jan-June 2011, pp. 27– 32

Analysis of the Voltage Stresses on Transformer Windings under Different Type of Surges

Poulomi Mitra

1

, Abhinandan De

2

, and Abhijit Chakrabarti

3

Abstract: Standard high voltage lightning and switching impulse tests are performed on Extra High Voltage

(EHV) transformers during manufacture to ascertain the breakdown strength of insulation used. But during their service, transformers encounter numerous voltage transients of complex and varying wave shapes which do not necessarily resemble these standard surge type voltages. This paper reports the results of investigation on the internal response of transformer windings under standard lightning impulse voltage and system originated oscillatory transient over-voltages and the results were compared. The present study should promote understanding and assessment of voltage stresses in transformer windings under various probable terminal disturbances and this knowledge may be useful in incorporating necessary changes in transformer dielectric test standards.

Keywords: Transformer, Excitation, Lightning Impulse, Oscillatory Transient.

1. INTRODUCTION

Transformers in EHV power networks often encounter voltage transients of complex and varying wave shapes which can result in voltage stresses well above normal operating values in transformers or its sections. This phenomenon have been investigated and reported in [1].

Transients, generated in electrical grid due to lightning strokes, power system faults etc, have significant impact on grid connected transformers. These voltage transients are of unknown shapes and are mostly oscillatory in nature. Dielectric test standards [2] are based on pulse shapes which were felt to be reasonable simulations of transient voltages which could be experienced in service.

As a consequence, the transformer designer has been concerned about the response of windings to these standard pulse shapes [3, 4]. However, the actual nature of terminal disturbances experienced by a transformer in the field are unknown and may be very different from these standard pulse shapes and response of the transformer to these non-standard disturbances need to be assessed.

This paper focuses on the response of transformer to standard as well as non standard excitation voltages of the following types:

(a) Standard lightning impulse voltage

(b) Non-standard oscillatory transient voltages

A comparative assessment of the voltage stresses developed on windings under these excitation voltages has been made. A high frequency Electromagnetic

Transient Programme (EMTP) model of a 400/220 kV transformer has been developed for the study.

Investigations were made to know the nature of internal voltage amplification and to assess the voltage stresses on major and minor windings insulations under each of the disturbances mentioned above. As said earlier, responses of the same transformer under 1.2/50 µ s lightning impulse voltage have been studied to examine whether the surge type test wave represents the worst possible voltage stresses experienced by transformers or whether oscillatory transient over voltages can produce even more severe stress conditions for winding insulations.

The observations reported from the present study should provide invaluable information for transformer designers, manufacturers and power system professionals.

1 St. Thomas College of Engineering and Technology,

West Bengal, India 4 Diamond Harbour Road, Kolkata –

700023, E-mail: Poulomi_hazra@rediffmail.com.

2 Bengal Engineering and Science University, Shibpur,

Howrah, West Bengal, E-mail: Abhinandan.de@gmail.

com.

3 Bengal Engineering and Science University, Shibpur,

Howrah, West Bengal, E-mail: A_chakraborti55@ yahoo.com.

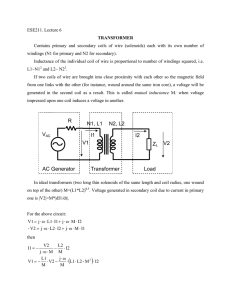

2. MODELLING OF THE TRANSFORMER

WINDINGS

For investigation of the transient phenomena inside a transformer, a lumped parameter high frequency circuit model of the concerned 400/220 kV transformer has been developed by the authors based on transformer geometry

28 International Journal of Electrical Systems and Control (IJESC) and configuration [5, 6]. Complete details of the proposed modelling technique are provided in Appendix A.

Relevant data pertaining to the transformer are provided in Appendix B. Since the objective is to obtain the voltage stresses on major and minor winding insulations, coil by coil representation of the windings has been considered to be sufficient for the present purpose. Following parameters have been considered in the development of the EMTP model:

(i) Self and mutual inductance of the coils for all the windings - the value of core permeability is constant and its value is estimated on the basis of operating conditions. This assumption is valid since the transformer is not operated near saturation.

(ii) Coil- to-coil capacitances for all the windings- the values have been calculated from the principles of electrostatic energy conservation.

(iii) Coil-to - ground capacitances for all the windings capacitances- the values have been calculated assuming that the coils and core leg and the metal tank form cylindrical electrode systems.

However, small capacitances formed between a coil and other distant coils, spurious stray capacitances existing in the transformer were not considered as it is impossible to ascertain their values accurately and also they have

Fig. 1: Developed Equivalent Circuit Model of the 315 MVA 400/220 kV Transformer.

marginal effect on the model’s response.

A schematic diagram of the lumped parameter model developed for the 315 MVA, 400/220kV transformer is presented in Fig. 1 for detailed understanding of the model.

The frequency responses of the winding admittance

(neutral current/applied impulse voltage) of the original transformer match very closely with the results obtained from the model, showing similar resonant peaks and crossovers. The agreement in both amplitude and frequency is very good, which is indicative of good modelling accuracy.

Fig. 2: Transfer Function (Winding Admittance)

Frequency Response of the Transformer.

3. RESPONSE OF THE 400 KV MAIN AND TAP

WINDINGS UNDER DIFFERENT TYPE OF

SURGES

In order to design the insulation structure of a transformer, the transient voltage stresses [7, 8, 9] to which all sub-components of the structure will be exposed must be known. The effect of different types of terminal disturbances on the transformer windings are discussed below:

(a) Response Under Standard Lightning Impulse

Lightning Impulse tests are traditionally conducted on transformers with standard wave-shape of 1.2/50µs. It is to be noted that lightning disturbances do not always have the standard wave-shapes like a laboratory simulated full waves, chopped waves or steep front waves. However, by defining the amplitude and shape of these waves, it is

Analysis of the Voltage Stresses on Transformer Windings under Different Type of Surges possible to establish a minimum impulse dielectric strength that a transformer should meet. If a lightning disturbance travels some distance along the line before it reaches a transformer, its wave-shape often approaches that of the full wave referred above. Response of the transformer’s

400 kV winding under 1.2/50 µ s standard lightning impulse is shown in Fig. 3.

Fig. 4: Response of Transformer Terminal Due to

Oscillatory Transient Excitation.

29

Fig. 4a: Response of Main Winding under Oscillatory

Transient Excitation.

Fig. 3: Response of Windings under Lightning

Impulse

The peak voltage across the group of 15 disk coils of the 400 kV main and tap windings are observed to be

40% and 10% of the applied terminal voltage respectively.

(b) Effect of Oscillatory Transient Excitation Voltage

As majority of the system generated transients resemble damped sinusoids [10, 11] of the form Ve (– α t ) sin 2 π ft where α determines the degree of damping), hence such a form of wave has been the natural choice for simulation of oscillatory excitation voltage [12, 13].

Fig. 4 represents the voltage response of the group of 15 disk coils of main and tap windings when transformer terminal is excited by their natural frequencies.

The maximum voltage across the main disk coil is 62% while that of tap is 19.2%. The result depicts the resonance phenomenon which occurred at the disk coils due to matching of their natural frequencies at the terminal oscillation frequency.

Fig. 4b: Response of Tap Windings under Oscillatory

Transient Excitation.

Fig. 5 represents the response of the same group of main winding disk coils when the excitation frequency is de-tuned from resonance by about 30%, keeping the amplitude unchanged. The results reveal that 30% detuning from resonant frequency results in as large as

49% reduction in voltage amplification, illustrating the sensitivity of the winding to resonant frequency.

Fig. 5: Response of Main Winding under Oscillatory

Terminal Excitation When Detuned.

30 International Journal of Electrical Systems and Control (IJESC)

The peak voltage stresses on the main and tap winding coil groups are summarized in Table 1.

Table 1

Peak Voltage Stresses on the Main and Tap Winding Coil Groups

Type of excitation voltage

1.2/50 µ s standard lightning impulse

Peak voltage across Main

Winding coil groups

40%

Peak voltage across Tap winding coil groups

10%

Oscillatory switching transient voltage

62%

19.2%

The results clearly indicate that the classical transformer test standards like lightning impulse test do not stress the insulation to the level encountered under oscillatory terminal excitation which often arises during transformer energization and de-energization under light loads, faults (initiation and clearing), capacitor and reactor switching (both connection and disconnection) etc.

4. COMPARISON OF THE STRESSES ON INTER

DISK INSULATION UNDER DIFFERENT

EXCITATION VOLTAGES

The response of the 400 kV winding to 1.2/50 µ s standard lightning impulse at BIL voltage of 1400 kV

(peak)

has been studied for comparing the voltage stresses on the windings. Fig. 6 shows a comparison of the developed voltages across the disk coils of the 400 kV main and tap windings under 1.2 p.u.(392 kV peak impulse.

) oscillatory terminal excitation and under the 1400 kV peak

standard lightning

Fig. 6a: Comparison of the Voltage Stresses on Tap

Winding Coils under Oscillatory Terminal Excitation and under Standard Lightning Impulse.

The bar charts show that in all cases the developed voltage stresses on the disk coils of main and tap windings under the oscillatory terminal excitation exceed the stresses under standard lightning surge. As evident from

Fig.6a, for the tap changer coils, which are physically located far away from the transformer live terminal, the impact of a line end incident surge on the tap changer coils is much less. On the contrary these coils experienced severe voltage stresses under oscillatory terminal excitations, possibly due to internal resonance and voltage amplifications there off. The voltage stresses developed in some of the tap changer disk coils under oscillatory terminal excitation were observed to be as high as 14 times the stress under standard lightning impulse voltage excitation.

5. CONCLUSION

The data presented suggest the following conclusions:

Surge waveforms as specified in ANSIC57:12.90 do not reflect the worst possible working stresses on transformers. Studies indicate that winding’s response to certain oscillatory voltages can be worse than lightning impulse. For power transformers, where the investment is substantial, it is therefore important for the industry to recognize the potential hazards associated with these oscillatory transient voltages and to assess how the windings will respond to such voltages. Suitable oscillatory transient over voltages tests can also be adopted in transformer test standards in conjunction with necessary design modifications to overcome this problem.

Fig. 6: Comparison of the Voltage Stresses on Main

Wnding Coils under Oscillatory Terminal Excitation and under Standard Lightning Impulse.

APPENDIX A

1. Self Inductance of Disk Coils

The formula used here applies to coils of disc shape, for which the radial dimension is considerably greater than the axial dimension. The equivalent self inductance is given by

L = Ls – 0.004 × π × N × a ( G 1 + H

1

) ...(1)

Ls = 0.001

N 2 aP µ H ( a is in cm) ...(2) and

Analysis of the Voltage Stresses on Transformer Windings under Different Type of Surges

P = 4 π

In

8 a

– 0.5

c

+

1

24 2 c a

2

×

In

8 a c

+ 3.583

...(3)

All nomenclatures are given along with Fig.7

31

Fig.7. Schematic of a Disk Coil.

2. Mutual-Inductance Between the Elements

The mutual inductance between two coaxial circular filaments of negligible cross-sectional area and radii a and A, respectively, separated by distance d between their planes is found to be dependent upon the two parameters: a / A and d / A . The mutual inductance is computed by Lyle method of equivalent filaments . The dimensions of equivalent filaments are illustrated by

Fig. 8. It shows two circular coils of rectangular crosssections of mean radii a and A, axial dimension b

1 b

2

, radial dimensions c

1

and c

2

and

, having number of turns

N 1 and N 2 and spacing of median planes D . The Lyle method replaces the two coils by four equivalent filaments. Each filament is assumed to have half the number of turns of its coil. If the axial cross-sectional dimension b

1 is greater than radius c

1

22´ will have an equivalent radius r

, filaments 11´ and slightly larger than

1 the mean radius a , and the two filaments are located at an axial distance β on either side of the median plane.

If on the other hand the second coil has its radial dimension c

2

greater than axial b

2

the coil is to be replaced by two co-planer circular filaments 33´ and 44´ located at the median plane but having equivalent radii ( r

2 and ( r

2

– δ ) respectively.

+ δ )

The mutual inductance between the two coils is then given by

M = N

1

N

2

M

13

+ M

14

+ M

23

+ M

24

4

...(4)

Fig. 8: Reduction of Coils to Equivalent Filaments.

3. Series Capacitance of Interleaved Disk Coils

The series capacitance of a disk coil is composed of two parts, being the resultant of inter-disc capacitance and inter-turn capacitance.

A. Determination of Average Inter Disk Capacitance

The calculation of resultant inter-disc capacitance is based on the principle that sum of the energies accumulated in all the part capacitances within a section is equal to the entire energy of the section. Let, C dr

= resultant inter disk capacitance between two interleaved members and

C

Dr

= resultant inter disk capacitance between two adjacent interleaved groups. Since there are 24 turns in a main winding disc coil, each interleaved disc pair consist of 48 turns. Assuming a linear distribution voltage among the turns and applying the energy principle:

1

2

2 =

1

2

C d

V 2

48 2

×

(1 2 + + +

(43 2 + ...47 )

+ and similarly

+

...(5)

1

2

C V 2 =

1

2

C

D

V 2

48 2

×

(1 2 + + +

(49 2 + ...71 )

+ +

...(6)

C d

and C

D

are calculated at mid-turn of the disc coils, applying the formula for capacitance between parallelplate electrodes, assuming that pressboard covers 35% of the total horizontal surface area of a disc coil and oil covers the remaining 65%.

B. Determination of Inter-Turn Capacitances

Applying the same energy principle and assuming C tr the resultant inter turn capacitance, is

1

2

2 =

1

2

C t

V

21

+

1

2

C t

23

48

.

V

21

...(7)

C t is calculated at mid turn of a disk coil, applying the formula for parallel-plate capacitors with electrodes separated by paper dielectric.

32 International Journal of Electrical Systems and Control (IJESC)

4. EQUIVALENT HIGH FREQUENCY

RESISTANCE OF DISK COILS

Here we assume a case of subdivided (laminated) conductors placed in iron slot. Again it is assumed that the conductor is divided in N layers, each of height h

1 width b and length L . Total height of all the layers is

, h = N h

1

. The average loss ratio for N layers is given by:

K e ( ave )

=

R

AC

R

DC

= 1 + ( α h

1

) 4

N 2

9

...8

where R

DC

is the DC resistance and R

AC

is the equivalent AC resistance at high frequency considering the skin effect. The factor α is given as:

α =

πµ

0

ρω bf

...(9) where f is frequency and ρ is the resistivity of the conductor. The generalized expression can be extended for a transformer winding if each winding of axial height L

C

can be considered to be located in a slot of width is the height of the transformer window and equation 14 can be modified as:

H w

which

α

APPENDIX B

=

πµ

ρ

0

H

ω fL c ...(10)

Technical specifications of the transformer are as under:

Design Data

Tap Winding

1. Type of winding continuous disk continuous disk

2. Number of disk

36

3. Turns per disk

18

4. Separation between disks interleaved disk pair interleaved

Main Winding

I n t e r l e a v e d

I n t e r l e a v e d

48

24

(i) 8mm between

(i) 6 mm between disk pairs two successive two successive

(ii) 12mm between

(ii) 8mm between groups groups i n t e r l e a v e d i n t e r l e a v e d

REFERENCES

[1] R.J Musil, G. Preininger, E. Sehopper, S. Wenger;

“Voltage Stresses Produced by Aperiodic and

Oscillating System Over-Voltages in Transformer

Windings”, IEEE Transactions on PAS , PAS-100 , no.1, January 1981.

[2] “Power Transformer-Insulation Levels and Dielectric

Tests”, IEC Publication , 76-3, 1980.

[3] ANSI C57.12.00-1968, “General Requirements for

Distribution, Power and Regulating Transformers, and

Shunt Reactors”.

[4] ANSI C57.12.90-1968, “Test Code for Distribution,

Power and Regulating Transformers and Shunt

Reactors”.

[5] A. De, and N. Chatterjee, “Part Winding Resonance:

Demerit of Interleaved High-Voltage Transformer

Winding”, IEE Proceedings-Electric Power

Applications , 147 , No.3, PP.167-174, May 2000.

[6] A. De, and N. Chatterjee, “Recognition of Impulse

Fault Patterns in Transformers using Kohonen’s Self-

Organizing Feature Map”, IEEE Trans. on Power

Delivery , 17 , No.2, PP. 489–494, 2002.

[7] A. Morched, L. Marti and J. Ottenvangers, “A High-

Frequency Transformer Model for the EMTP”, IEEE

Trans. on Power Delivery , 8 , no.3, PP.1615-1625, July

1993.

[8] A. O. Soyal, “A Method for Wide Frequency Range

Modeling of Power Transformer and Rotating

Machines”, IEEE Trans. On Power Delivery , 8 , No.4,

PP.1802-1810, Oct. 1993

[9] F. W. Grover, “Inductance Calculation: Working

Formulas and Tables”, Dover Publications , Inc., 1962.

[10] A.De, D.Debnath and A. Chakrabarti, “ A Study on the Impact of Low-Amplitude Oscillatory Switching

Transients on Grid Connected EHV Transformer

Windings in a Longitudinal Power Supply System”,

IEEE Transactions on Power Delivery(USA) , 24 , No.2,

April 2009, PP.679-686

[11] M.Popov, Van der sluis,G.C.Paap and H.de Herdt,

“Computation of Very Fast Transient Overvoltages in Transformer Windings”, International conference on Power System Transients (IPST’05)in Montreal ,

Canada on June, 19-23,2005.