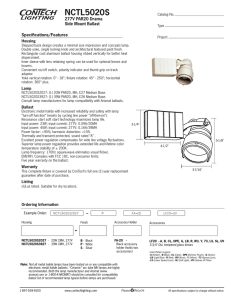

Ballasts For High Intensity Discharge Lamps

advertisement