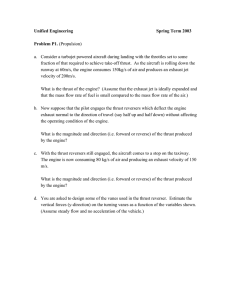

B767 Engines - SmartCockpit

advertisement