Components From Cooper Power Systems

advertisement

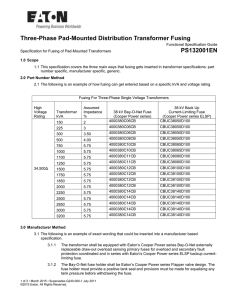

Components From Cooper Power Systems Cooper Power Systems Components and Protective Equipment is an international leader in supplying electrical components to transformer and switchgear manufacturers. Our customers have learned through experience that Cooper can be trusted to deliver components they can rely on — every time. Reliability, performance, safety, ease of use — all in components that are recognized as the best in the industry. Cooper Power Systems has over 25 years of experience in the research, product development and quality manufacturing of transformer components. We also have a long history of supplying products to distribution equipment manufacturers. Our components and protective equipment have been developed in conjunction with both users and equipment manufacturers, for the best in performance and quality. Many Cooper innovations have now become industry standards. We’re continually working on innovations for connectors, components and protective systems, to best fit the changing needs of our customers. The latest manufacturing equipment and sophisticated process monitoring and quality control techniques ensure that every product that passes through Cooper’s component manufacturing facilities will be a product that you can rely on for excellent performance. We adhere to international standards of quality control. Our Pewaukee manufacturing plant is an ISO 9001 registered facility. Our goal is to consistently exceed industry quality standards. Our Product Specialists, your link to Cooper Power Systems, are committed to providing you accurate and timely technical assistance. Our Customer Service Representatives use real time information to communicate availability and expedite orders for quick turnaround. We stock a large inventory of standard components to provide consistently short lead times and scheduling flexibility for our customers. For long term reliability and durability, connect with bushings by Cooper Power Systems. We manufacture an extensive line of primary and secondary bushings for liquid-filled distribution transformers and switchgear. A complete range of distribution primary (high voltage) bushings is available in 200 A (loadbreak) and 600 A (deadbreak) designs. High voltage loadbreak bushing contacts have all copper current paths for superior product life and more reliable operation. Secondary Bushings Secondary (low voltage) bushings, from 600 A to 4515 A, are available in copper or aluminum. A wide variety of internal/external connection options is available. (A) (kV) Secondary Bushings: Tri-clamp 600-1400 1.2 Aluminum spade/spade 1210, 3010 1.2 Copper spade/spade 2410, 4515 1.2 Primary Bushings: Bushing wells 200 15, 25 & 28 Integral loadbreak bushing 3Ø rated 200 15, 25 & 35 Deadbreak apparatus bushing 600 15, 25 & 35 Deadbreak PUSH-OP ® apparatus bushing 600 15, 25 & 35 Primary and secondary porcelain bushings are available in standard configurations or custom made to unique configurations. Primary Bushings Zytel ® HTN Secondary Bushings Cooper Power Systems manufactures a full range of 200 A loadbreak and 600 A deadbreak connectors, complying with ANSI Standards. A recent introduction to the product line is Cooper’s new European style deadbreak connectors, meeting ANSI and IEC Standards. Manufacturing these quality molded rubber products is achieved by maintaining complete control of the process — from the raw materials used to final inspection. We formulate EPDM rubber compounds from our own proprietary formulas. All EPDM rubber is then mixed in-house, using the most advanced mixing system with integral process control. Screw ram injection molding technology provides optimum control of critical molding parameters in manufacturing these products. Cooper engineers hold many patents for innovations in loadbreak and deadbreak technology. Porcelain Bushings Primary, secondary and specialty electrical grade porcelain bushings are available from Cooper. In manufacturing, all facets of the critical processes used to make electrical grade porcelain, including material mixing, turning (shaping) and firing are automated and computer controlled. Process control provides superior mechanical strength and unmatched dimensional part quality. U-OP ™ Visible Break Switchgear Components for Oil or SF 6 Applications Cooper Power Systems manufactures a variety of externally operated singleand three-phase oil switches to meet a wide range of utility applications. Tap changer, series multiple (dual voltage) and loadbreak switches can be customized to meet special application needs. Cooper switches offer design flexibility to transformer manufacturers, and safe, reliable operation to utility line personnel. Tap Changer Switches Tap changer switches regulate voltage in the transformer as lines are extended and loads grow. Loadbreak on/off switches, designed with a tough, reliable spring loaded activating mechanism, ensure quick loadmake and loadbreak operations in less than one cycle, and have an excellent field service record. The versatile 300 A, 38 kV rated, two-position loadbreak switch can be used for most distribution transformer applications. Series Multiple Switches Series multiple switches connect transformer windings in series or in parallel, resulting in a voltage change with a simple turn of the switch once the transformer has been de-energized. This allows one transformer to be used for two or three different voltage systems, resulting in less transformer inventory for a utility. Three-phase, under-oil loadbreak sectionalizing switches add versatility in loop configurations. They allow energization from either of two sources, as well as feed-through capability. (A) (kV) Externally operated 1, 2, and 3 phase tap changer switch 100, 150, 300 35 Externally operated series multiple (dual voltage) switches 50, 150, 300 25 & 35 Sectionalizing loadbreak switches 200, 300, 600 15, 25 & 35 300 38 2-position on/off loadbreak switches Loadbreak Switches Surge arresters designed and manufactured by Cooper incorporate the latest metal oxide varistor (MOV) technology. Cooper offers two different surge arrester designs: gapless MOV (VariSTAR ®) and gapped MOV (VariGAP ®). The VariGAP’s gapped configuration offers substantial improvements in temporary overvoltage performance, protective levels, and durability over conventional gapless arresters. VariSTAR arresters are available for station, intermediate and distribution classes. VariGAP arresters are available in distribution class only. For alternate transformer protection, the VariSTAR Type AZU under-oil arrester is available. The under-oil environment keeps the arrester cooler and protects it from surface contamination, wildlife and vandalism. Cooper’s STORM TRAPPER ® H. E., the industry’s first family of distribution class, low voltage arresters can be used on the secondary side of the transformer for more complete overvoltage protection. Both external and under-oil designs are available. Porcelain and silicone rubber housed arresters are used on overhead distribution systems. A porcelain housing provides high dielectric strength and high external creepage distance. Silicone rubber arresters are totally non-fragmenting, providing increased safety for personnel and equipment. Silicone rubber offers superior track resistance, surface hydrophobicity, resistance to solar ultaviolet radiation, and chemical inertness when compared to other polymer materials on the market today. For deadfront pad-mounted transformer installationsCooperoffers RTE ® M.O.V.E. Elbow and Parking Stand arresters in gapless and gapped MOV designs in a premolded rubber elbow. VariSTAR ®, VariGAP ® and STORM TRAPPER ® Arresters Low Voltage Distribution Class 175-650V Distribution Class 3-36 kV Intermediate Class 3-120 kV Station Class 3-312 kV Elbow and Parking Stand 9-27 kV Used in combination with feed-thru bushing well inserts, elbow arresters give primary side surge protection for both loop-feed and radial-feed transformers. Parking stand arresters provide an economical means of overvoltage protection for energized but parked open point cable runs. The VariGAP arresteroffers previously unavailable performance characteristics for underground systems. M.O.V.E.® Arresters Under-oil Arrester and Arrester Disconnector Cooper Power Systems offers three complete product lines of fusing equipment—RTE®, McGraw-Edison ® and Combined Technologies ®. We have the broadest range of overcurrent protective devices to meet your application needs. In the late 1960s, RTE introduced the Bay-O-Net assembly and links to the industry for pad-mounted transformer protection. The Bay-O-Net fuse has grown into the industry standard protection package for single- and three-phase transformers. The assembly combines the ease of hotstick operation with the safety of deadfront construction and is used with an isolation link to prevent line personnel from closing into a fault when replacing a blown Bay-O-Net link. Alternately, a back-up, current-limiting fuse can be used in place of the isolation link to increase interrupting ratings to 50 kA. The patented Flapper™ valve closes when the stabber is removed, minimizing the risk of hot transformer oil spilling from the tank, an added safety measure for line personnel. The Flapper valve minimizes environmental concerns and reduces oil contamination on molded rubber elbow connections. RTE ® Flapper ™ Bay-O-Net ® Assembly with ELSP Current-Limiting Backup Fuse RTE ® Flapper ™ Bay-O-Net ® Assembly ® A resettable primary breaker for distribution transformers, the MagneX Interrupter also switches the transformer on and off. A primary breaker results in dramatically lower losses than secondary breakers saving energy and money. It also eliminates core losses on transformers not in service. (A) RTE ® Bay-O-Net ®, MagneX ® Interrupter and Current-Limiting Fuses Cooper Power Systems is an innovator in full-range, current-limiting fuse technology. Designed for areas where available fault current levels are higher than an expulsion fuse can withstand, current-limiting fuses can be used in all your applications to extend equipment life, enhance power quality, reduce fire hazards and increase safety to line personnel and the public. Full range current-limiting fuses have the ability to successfully interrupt any normal 60 cycle current that will melt their element. I2t testing verifying the integrity of the silver ribbon is performed on each current-limiting fuse before it leaves the factory, assuring you of excellent performance in the field. Our extensive testing and research and development capabilities have resulted inthe development of many innovative new products, providing overcurrent protective equipment solutions to utility customers around the world. The MagneX Interrupter offers a solution to the utility wanting to totally eliminate oil exposure in the field when operation occurs due to transformer overloads. Eliminating the need for replacement fuse links adds economic value to the user. A MagneX interrupter in series with a back-up, current-limiting fuse offers additional protection. (kV) Full-range current-limiting fuses 4-400 A 4.3-35 kV Back-up under-oil current-limiting fuses 30-400 A 8.3-23 kV Bay-O-Net fuse links and holder 6-125 A 8.3-23 kV Edison ® links 1-200 A 15-38 kV Current-limiting power fuses 2-200 A 5.5-23 kV Capacitor expulsion and current-limiting fuses 10-125 A 8.3-23 kV MagneX® Interrupter 25 A 8.3-23 kV Current-Limiting Fuses ® R-Temp fluid is a fire-resistant hydrocarbon fluid (FRHF). This dielectric coolant is formulated primarily for use in distribution transformers, where its unique electrical, thermal and safety properties offer many advantages. R-Temp fluid is non-toxic and biodegradable. It is compatible with standard insulating materials, and processing equipment and procedures. R-Temp fluid is also referred to as a High Fire Point Fluid, a High Molecular Weight Hydrocarbon, or a Less-flammable Dielectric Liquid. With its excellent performance characteristics and proven reliability, R-Temp fluid is also used in a variety of other equipment, including sectionalizing switches, electromagnets, voltage regulators, rectifiers and high voltage substations. The Thomas A. Edison Technical Center, one of the most highly respected electrical research and development centers in the world, uses the latest technologies for product development and quality control testing. Complete chemical and material analysis, high power (short-circuit), and voltage testing can be conducted. Consulting services are also available such as system studies, field measurements and diagnostic software. Technical workshops and papers provide information to the industry, sharing practical recommendations for solving complex system problems. ® Envirotemp 200 fluid is a fire-resistant dielectric coolant developed for applications requiring high performance under extreme temperature conditions. Its unique formulation provides a very low freezing/melting point, well under -50°C. Envirotemp 200 is a biodegradable synthetic ester whose performance has been augmented by proprietary additives. The result is a low viscosity fluid with excellent dielectric, thermal and mechanical properties. These properties make it particularly well suited for forced liquid cooling applications, like traction transformers. Following is a list of the components and protective equipment manufactured byCooperPower Systems. This breadth of product, and commitment to quality and innovation, are what make Cooper the best source for OEM equipment manufacturers and the electrical industry. VariSTAR ® STORM TRAPPER ® High Energy Arrester VariGAP ® AZS Arrester VariGAP® AZSPArrester VariGAP ® AZLPArrester VariGAP ® AZLArrester VariSTAR ® AZLArrester VariSTAR ® AZLP Arrester VariSTAR® AZU Arrester VariSTAR ® AZS Arrester VariGAP ® M.O.V.E Arrester VariGAP ® Parking Stand Arrester MOV Gapless Elbow Arrester VariSTAR ® AZF Arrester VariSTAR ® ATZ Arrester RTE ® Tap Changer Switch RTE ® Series Multiple (Dual Voltage) Switch RTE ® Sectionalizing (Loadbreak) Switch RTE ® Two Position Loadbreak Switch ELF™ Current-limiting Dropout Fuse SM-Limiter™ Current-limiting Dropout Fuse X-Limiter™ Current-limiting Q Fuse NX ® Companion ® Back-up Current-limiting Fuse K-Limiter™ Back-up Current-limiting Fuse In-Line X-Limiter™ Current-limiting Fuse NXD Fault Guard Tool NXC ® Current-limiting Capacitor Fuse Capacitor Expulsion Fuse Tube Edison ® Links RTE® Flapper Bay-O-Net Link RTE® Bay-O-Net Links ELSP Current-limiting Backup Fuse MagneX ® Interrupter ELS and EL Bay-O-Net Oil-immersed Weak Link Fuse X-Limiter™ Current-limiting Fuse NX ® Indoor Current-limiting Fuse ELX Full-range Current-limiting Fuse NX ® II Full-range, Current-limiting Air-insulated Fuse BT X-Limiter™ Current-limiting Fuse ELST Full-range Current-limiting Tandem Fuse Assembly ELSG Full-Range Current-limiting Fuse SX-Limiter™ Current-limiting Fuse ELG Current-limiting Power Fuse EOD X-Limiter™ Power Fuse Molded (Zytel ® HTN) Tri-clamp Bushings Internal/External Spade Bushings Integral Loadbreak Bushings Integral Deadbreak Bushings Integral PUSH-OP ® Deadbreak Bushings Zytel ® HTN Bushing Well RTE ® Loadbreak Elbows RTE ® Loadbreak Bushing Insert RTE ® Rotatable Feedthru Insert PUSH-OP ® Connector System U-OP™ Connector System R-Temp ® Fluid Envirotemp ® Fluid NX ®, NXC ®, MagneX ®, Edison ®, VariSTAR ®, STORM TRAPPER ®, VariGAP ®, PUSH-OP ®, R-Temp ®, Envirotemp®, McGraw-Edison ® and RTE ® are all trademarks of Cooper Industries, Inc. Zytel ® is a registered trademark of Dupont. Cooper Power Systems ISO9001-1994 Cert. #000449 Pewaukee, Wisconsin Quality from Cooper Industries Cooper Power Systems Components and Protective Equipment Bulletin 95054 Printed in USA MI12M1095 © 1995 Cooper Power Systems, Inc. All Rights Reserved. 1045 Hickory Street Pewaukee, WI 53072 (414) 691-0070