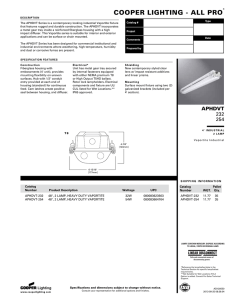

Ordering Information

advertisement