Control of electrical power assist systems

advertisement

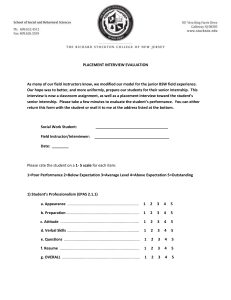

JSAE Review 22 (2001) 435–444 Control of electrical power assist systems: H N design, torque estimation and structural stability Rakan C. Chabaana, Le Yi Wangb,* a Advanced Steering Controls and Electronic Design, Ford Motor Company, 20000 Rotunda Dr., Mail Drop 5021, Dearborn, MI 48121-2053, USA b ECE Department, Wayne State University, Detroit MI 48202, USA Received 26 March 2001 Abstract In this paper, the H N method is employed to design controllers for improved performance and robustness of electrical power assist steering systems (EPAS). EPAS systems are nonlinear MIMO systems with multiple objectives, including fast response to the driver torque command, good driver feel, and attenuation of load disturbance and sensor noises. Since the EPAS system has nonlinear frictions, component deviations and load disturbances, its linearized model is subject to significant modeling errors and external disturbances. Consequently, EPAS controllers must provide substantial robustness. In this paper, a control design method is introduced which employs the boost curve to form a feedforward control and an MISO H N optimal feedback to ensure refined performance, robustness, and disturbance attenuation. Since the driver’s torque command cannot be directly measured, due to packaging and cost issues, a torque estimator is introduced to generate the driver’s torque command by using other measured signals which are normally available in the vehicle. Introduction of the torque estimator leads to an additional feedback loop, affecting system robust stability and performance in a fundamental manner. Robust stability under this circumstance is established. The controllers are evaluated via simulation on both linearized systems and original nonlinear systems, and verified on vehicle testing data. r 2001 Society of Automotive Engineers of Japan, Inc. and Elsevier Science B.V. All rights reserved. 1. Introduction In this paper, the H N method is employed to design controllers for improved performance and robustness of electrical power assist steering systems (EPAS). In the recent years, the automotive industry has pursued rigorously to improve automotive fuel economy and provide variable assist capabilities. EPAS systems are introduced as one potential solution to meet these challenges. EPAS systems have several major advantages over conventional hydraulic systems: ð1Þ increased fuel economy up to 4%; ð2Þ weight savings; ð3Þ complexity reduction, due to elimination of fluid filling operation and reduction of mechanical components; ð4Þ package simplification due to elimination of hoses or fluid cooler; ð5Þ flexibility in providing adaptive and responsive on-demand steering assist; ð6Þ software programmable steering characteristics; ð7Þ increased *Corresponding author. E-mail addresses: rchabaan@ford.com (R.C. Chabaan), lywang@ece.eng.wayne.edu (L.Y. Wang). reliability through self-diagnostic protection features. To development engineers, the most important feature of an EPAS system is that desired steering feel can be changed without major physical modifications to valve shape, torsion bar stiffness and boost pressure. An EPAS system is a control system that electrically amplifies the driver steering torque inputs to the vehicle for improved steering comfort and performance. An EPAS system consists of a steering wheel, a column, a rack, an electric motor, a gearbox assembly, as well as some torque, position and speed sensors. The essential operation of an EPAS system can be depicted in the system diagram shown in Fig. 1. Currently, all EPAS systems employ a pinion torque sensor, between the steering column and pinion, to determine the amount of the torque assist to the driver which is calculated via a tunable nonlinear boost curve. Then, this signal is used as control command to the electric motor to achieve the appropriate level of assist. EPAS systems are nonlinear MIMO systems with multiple objectives, including fast response to the driver’s torque command, good driver feel, and attenuation 0389-4304/01/$20.00 r 2001 Society of Automotive Engineers of Japan, Inc. and Elsevier Science B.V. All rights reserved. PII: S 0 3 8 9 - 4 3 0 4 ( 0 1 ) 0 0 1 2 6 - 6 JSAE20014496 436 R.C. Chabaan, L.Y. Wang / JSAE Review 22 (2001) 435–444 on robust stability is investigated in Section 6. Computer simulation results are presented in Section 7 to demonstrate the effectiveness of the torque estimator and robustness of the closed-loop EPAS system. Verification is further conducted by employing actual vehicle testing data in Section 8. Finally, some conclusions are drawn in Section 9. The key results of this paper were presented at the AVEC 2000 Conference [9,10]. 1.1. Literature Fig. 1. EPAS models. of load disturbance and sensor noises. Since the EPAS system has nonlinear frictions, component deviations and load disturbances, its linearized model is subject to significant modeling errors and external disturbances. Consequently, EPAS controllers must provide substantial robustness. In this paper, a control design method is introduced which employs the boost curve to form a feedforward control and an MISO H N optimal feedback to ensure refined performance, robustness, and disturbance attenuation. To facilitate the application of the H N method, the nonlinear EPAS model is first linearized around its nominal values. The multiple objectives, including steering feel, disturbance attenuation and assist torque performance, are formally introduced into a frequencydomain performance index. On the basis of the performance index, the linearized model of the plant is augmented into a state space model of higher dimensions. This system is then controlled by a feedforward compensator via the boost curve for fast response and an H N optimal feedback for enhanced robustness. Due to the lack of direct measurement of the driver’s torque, an estimator is developed to estimate the driver’s command torque from the measured pinion torque. For a production EPAS system, the overall performance of the designed control system is evaluated by simulation and verified on vehicle testing data. The paper is organized as follows. Section 2 presents a generic EPAS model. Its components and their roles are explained. The control problem is formulated in Section 3. After a discussion on the basic performance requirements of an EPAS system, a control system structure is introduced which includes a feedforward compensator and a feedback controller. The H N optimal controller is designed in Section 4. It is shown that the original plant model must be further expanded to satisfy the basic requirements of the H N design. Additional channels and state variables are hence introduced. The original feedforward and feedback control uses the driver torque Td as an input signal. Since this signal is not measured, an estimator is designed in Section 5. The implication of the estimation Analysis of stability of EPAS systems has been reported on several EPAS products. In [1], analytical expressions of transfer functions are derived to model assist dynamics, steering system compliance, and driver feel of the road for a dual-pinion system.1 The analytical estimation of stability boundary in terms of assist stiffness-inertia envelopes was presented, which gives an approximation for the maximum torque KaoKm G that can be generated by the assist system. In [2,3,11], vibration control techniques are used for dynamic analysis of a single-pinion system.2 Two lead-lag compensators were employed for control design. The controller synthesis using constrained optimization procedure is further explored. One of the advantages of this method is that they can reduce the torque ripple and optimize steering feel for given assist steering gains. On the other hand, the design processes rely on several additional sensors such as steering wheel position, steering wheel velocity, motor position, motor velocity, and torque sensor at pinion. Along a similar direction, analysis of stiffness and feel was reported in [4]. Mathematical equations, which relate rack force to the driver torque and steering angles, were developed to help EPAS gear engineers design an appropriate boost curve. These mathematical equations can assist in determining the regions of boost curves for which the steering feel varies as a function of vehicle speed. The paper [5] studied the problem of power steering ‘road feel’. The relationship between the pump pressure vs. steering torque was derived. It was argued that a gear can be designed on the basis of a set of boost curves which can be adapted as a function of vehicle speed. These boost curves can accommodate the desirable reduction of effort at parking and increased effort at straight driving as the vehicle speed increases. Numerous feedback control techniques have been applied to EPAS systems, ranging from traditional leadlag compensation to more advanced control techniques. For example, the paper [6] investigated control design by employing an H N -type criterion to provide an 1 In the dual-pinion arrangement, the driver input acts through one pinion and the power assist acts through another. 2 In the single-pinion arrangement, the driver input and power assist act through one pinion only. R.C. Chabaan, L.Y. Wang / JSAE Review 22 (2001) 435–444 appropriate steering feel based on road information. It was revealed that the key element for the EPAS system was frequency rectification between the rack force and the reaction torque. In [7], several key points in implementing EPAS system in vehicle were described. A three-degree-of-freedom model of the EPAS was developed. It was shown that by eliminating certain higher frequency components a reduced order model could be obtained. An analysis on the closed-loop system was performed to understand compromises in system design. In [8], it was explained that increasing assist gain reduces steering torque for drivers. However, it may cause undesirable steering vibration at specified frequencies around 30 Hz: Motor angular velocity was needed for this control algorithm. An estimator design was investigated to obtain this signal without installing such a sensor. Two methods were investigated: Observer 437 and back e.m.f. The authors pointed out that back e.m.f. was superior to the observer method and no additional cost was needed. 2. EPAS systems Following Newton’s laws of motions, we can establish a nonlinear dynamic model of the EPAS system as follows (see Fig. 2): Kc Jc y. c þ Bc y’ c þ Kc yc ¼ xr þ Td þ fc ðyc ; y’ c Þ; rp Kc 1 Km G G M x. r þ Br x’ r ¼ yc xr þ ym x r rp rp rp rp Ft þ fr ðxr ; x’ r Þ; Jm y. m þ Bm y’ m ¼ Tm Ta þ fm ðym ; y’ m Þ; Fig. 2. A nonlinear EPAS model. ð1Þ 438 R.C. Chabaan, L.Y. Wang / JSAE Review 22 (2001) 435–444 where Td and Ta are the driver torque ðN mÞ and assist torque ðN mÞ: yc ; xr ; ym are steering wheel rotary position (rad), rack position (m), and assist motor rotary position (rad), respectively. Plant parameters include Jc (steering column rotational moment of inertia ðkg m2 ÞÞ; Kc (steering column stiffness (N/rad)), Bc (steering column viscous damping (N s=rad)), M (mass of the rack (kg)), Br (viscous damping on the rack (N s=rad)), rp (steering column pinion radius (m)), G (motor gear ratio), Km (motor shaft and gearbox rotational stiffness (N/rad)), Jm (motor rotational moment of inertia ðkg m2 ÞÞ; Bm (motor shaft and gearbox viscous damping ðN s=radÞÞ; Kt (tire or rack centering spring rate (N/m)). fc ; fr ; and fm are nonlinear friction terms in the model. Here, G Ta ¼ Km ym xr rp is the assist torque. The motor electromagnetic torque input Tm ðN mÞ is related to motor current input by an inner loop Tm ¼ Gin ðsÞu where u is the motor input and Gin is the inner-loop transfer function. In the frequency band of interest, Gin 61 (per normalization of mechanical units). As a result, one may simply view Tm as the control input. Also, the resistance term Ft ¼ Kt xr þ Fr : We note that the resistance force on the rack is mainly Kt xr : The remaining disturbances from road condition changes are denoted by Fr : Generically, an EPAS system has two main external inputs: The driver torque Td which is not measured and the assist motor input current u which is a control signal. Due to variations in road and tire conditions, sensor inaccuracy and measurement noise, the EPAS system is subject to external disturbances Fr (resistance force on the rack) and d (sensor noises). The dimension of d is identical to the number of sensors utilized in the system. The key outputs which are to be controlled include assist torque Ta and the pinion torque Tc : Ta is not measured directly. On the other hand, in all current EPAS systems a torque sensor is used to measure Tc : Other measured signals vary with hardware configurations. The methodology we introduce in this paper is generic and applicable to all types of sensor configurations. Based on a production EPAS system, we shall assume that the column angle yc and assist motor angular velocity y’ m are measured. Upon an approximation of the nonlinear components fc ; fr ; fm by their linear nominal expressions, a linearized state space can be obtained in the state space form x’ ¼ Ax þ B1 Td þ B2 Fr þ B3 u; y ¼ Cx þ D1 Td þ D2 Fr þ D3 u ð2Þ or transfer function form 2 3 2 3 Ta G11 G12 G13 2 3 Td 6 7 6 6 Tc 7 6 G21 G22 G23 7 76 7 6 7¼6 74 u 5: 6 yc 7 4 G G33 5 31 G32 4 5 Fr G41 G42 G43 y’ m ð3Þ 3. Control problems 3.1. Design objectives An EPAS system responds to a driver’s torque command Td and delivers an appropriate level of assist torque Ta via a tunable boost curve by controlling the motor input u: The system is subject to external disturbances Fr and sensor noises dT on Tc ; dc on yc and dm on y’ m : It follows that a typical EPAS system can be generically described as in Fig. 3. The goals of EPAS design can summarized as follows. Assist torque generation: The desired level of assist is defined by a boost curve which relates the driver torque to the desired assist torque. The boost curve can be expressed as Ta* ¼ BðTd ; vÞ; where v is the vehicle speed (mph). A typical boost curve is shown in Fig. 4. Due to dynamic delays of the EPAS system in responding to changes in Td ; the actual Ta generated by the EPAS may be significantly different from the desired Ta* ; depending on control designs. The first objective of a well-designed EPAS system is to deliver Ta that is reasonably close to Ta* in a frequency band ½0; w0 ; where w0 is about 40 Hz to deliver a desirable steering feel. Driver’s feel: When road condition changes, the resistance force Fr on the rack will vary. To provide a Fig. 3. Inputs and outputs of EPAS systems. 439 R.C. Chabaan, L.Y. Wang / JSAE Review 22 (2001) 435–444 closed-loop pole positions tend to move towards unstable regions when Ka becomes large. A common remedy for this situation is to design a very conservative EPAS control. Consequently, system performance is compromised. 3.2. Control structures We will start with the control structure when Td is available. Afterwards, Td will be replaced by its estimate T#d to derive an implementable control system. Under nominal operating conditions with Fr ¼ 0; dT ¼ dc ¼ dm ¼ 0; the EPAS system can be linearized and represented by Ta ¼ P11 Td þ P12 u; ð4Þ y ¼ P21 Td þ P22 u; ð5Þ where y ¼ ½Tc ; yc ; y’ m T is the measurement vector, and P11 ¼ G11 ; P12 ¼ G12 ; P21 ¼ ½G21 ; G31 ; G41 T ; P22 ¼ ½G22 ; G32 ; G42 T : Suppose that the nominal value of the input torque is Td0 : From the boost curve, we can derive desired assist torque Ta0 ¼ BðTd0 Þ (for a given vehicle speed). From Eqs. (4) and (5), the steady-state relationship Ta0 ¼ P11 ð0ÞTd0 þ P12 ð0Þu0 Fig. 4. Boost curve for a given vehicle speed. desirable level of driver’s feel of driving conditions, the driver must perceive a suitable amount of changes in the twist torque Tc : In other words, one can define a desired mapping from Fr to Tc as Tc ¼ Gf Fr : For instance, one may require Gf ¼ Kf ¼ 0:15 in a specified low frequency range. Robustness: The EPAS system contains nonlinear components such as frictions and damping. Also, unit-to-unit deviations and component wearing will introduce parameter deviations from the nominal models. Furthermore, road condition changes and sensor noises introduce uncertainties during its operation. An EPAS system must be designed to provide satisfactory performance in the presence of such uncertainties. A main challenge in EPAS control system design is that the controller must perform well under all possible operating conditions of the boost curve. Using Tc in place of Td results in a feedback loop whose loop gain depends on the slope Ka of the boost curve. In a traditional hydraulic EPAS system, Ka can range from 0 to 50: In a simple feedback system where Tc is sent through the boost curve to generate control input, the ð6Þ can be used to determine the steady-state control value u0 : While u0 can be directly computed from Eq. (6) for the given Td0 and Ta0 ; u0 is in fact approximately BðTd0 Þ: Indeed, u0 ¼ Ta0 P11 ð0ÞTd0 BðTd0 Þ P11 ð0ÞTd0 ¼ : P12 ð0Þ P12 ð0Þ Without modeling errors, P12 ð0Þ ¼ 1 and usually BðTd0 Þ is much larger than P11 ð0ÞTd0 : Hence, we may view u0 ¼ BðTd0 Þ as the nominal feedforward control. Then, y0 can be calculated from y0 ¼ P21 ð0ÞTd0 þ P22 ð0Þu0 : Correspondingly, the equilibrium value x0 of the state variable from Eq. (2) can be determined. Now, by defining * x ¼ x0 þ x; Td ¼ Td0 þ T*d ; Ta ¼ Ta0 þ T*a ; u ¼ u0 þ u; * y ¼ y0 þ y; * we can derive a perturbation system x’* ¼ Ax* þ B1 T*d þ B2 Fr þ B3 u; * y* ¼ C1 x* þ D1 T*d þ D2 Fr þ D3 u: * 440 R.C. Chabaan, L.Y. Wang / JSAE Review 22 (2001) 435–444 Fig. 6. H N control structure. Fig. 5. Control structure. The goal of feedback control is to employ a feedback u* ¼ CðsÞy* such that the effects of disturbances T*d ; Fr ; dT ; dc ; dm on T*a is minimized. CðsÞ will eventually be designed by using H N control. It follows that the control structure consists of a feedforward and a feedback controllers, as illustrated in Fig. 5. 4. H N design 4.1. Design procedure The purpose of the feedback C is to provide robust stability of the closed-loop system and minimize the effect of Fr ; dT ; dc ; dm on T*a : To facilitate the design of C by using the H N design tools, we must modify the system state space models. The original plant is x’ ¼ Ax þ B1 Td þ B2 Fr þ B3 u; y ¼ Cx þ D1 Td þ D2 Fr þ D3 u: The control objectives can be qualitatively stated as: ð1Þ Reduction of jjWa T*a jj2 for desired torque production, where T*a ¼ Ta Ta* and jj jj2 is the H 2 norm. ð2Þ Reduction of jjWf ðTc Kf Fr Þjj2 ; for appropriate road feel. ð3Þ Reduction of control jjKu ujj2 for fuel economy. Here, Wa and Wf are weighting functions that define frequency ranges in which the reductions are to be effective. Typical examples of the weighting functions are Wa ðsÞ ¼ ca b1 s þ 1 ; a1 s þ 1 Wf ðsÞ ¼ cf b2 s þ 1 : a2 s þ 1 Since the weighting functions are dynamic systems, they must be incorporated into the state space model. A state space model for Wa can be derived as follows: Let ea ¼ Wa T*a : Then 1 b1 b1 w’ a ¼ wa þ ca 1 1 Td ; C1 x þ Ca Ka a1 a1 a1 1 b1 Ca b1 Ka Td ea ¼ wa þ ca C1 x a1 a1 a1 is a state space model for the weighting function. Similarly, a state space model for Wf can be derived as 1 b2 b2 w’ f ¼ wf þ cf 1 1 Kf Fr ; C2 x þ cf a2 a2 a2 1 b2 b2 ef ¼ wf þ cf C2 x cf Kf Fr : a2 a2 a2 By expanding the state variable to 2 3 wa 6 7 x1 ¼ 4 wf 5; x the inputs to u1 ¼ ½d; uT with d ¼ ½dT ; dc ; dm ; Td ; Fr ; outputs to y1 ¼ ½w; yT with controlled output w ¼ ½eu ; ea ; ef and measured output y ¼ ½Tc ; yc ; y’ m ; as shown in Fig. 6, we can obtain an augmented state space model * 1 þ B* 1 u þ B* 2 d; x’ 1 ¼ Ax " # d * * y1 ¼ Cx1 þ D ; u where 2 a11 6 A* ¼ 6 4 0 0 a12 0 3 0 6 7 B* 1 ¼ 4 0 5; B3 0 ca ð1 ba11 ÞC1 3 7 cf ð1 ba22 ÞC2 7 5; A 2 B* 2 ¼ ½BT ; Bc ; Bm ; Bd ; BF : R.C. Chabaan, L.Y. Wang / JSAE Review 22 (2001) 435–444 441 Here 2 0 0 2 6 6 6 6 6 6 6 Bm ¼ 6 6 6 6 6 6 6 4 1 a2 0 0 01 6 6 60 0 6 6 60 0 D* ¼ 6 6 6e 0 6 60 e 4 0 0 7 7 7 7 7 0 7 7 7; 0 7 7 GKm 7 7 rp 7 7 0 5 Km 0 0 3 7 ca ba11 C1 7 7 cf ba22 C2 7 7 7; C3 7 7 7 C4 5 0 0 0 3 2 0 0 0 3 3 2 0 0 7 6 7 6 b2 7 BF ¼ 4 0 5 þ 6 4 cf ða2 1ÞKf 5; B2 06 1 3 0 6 7 Bd ¼ 4 0 5; B1 61 6 a1 6 60 6 C* ¼ 6 60 6 6 40 6 0 7 7 6 7 6 6 0 7 7 6 6 K 7 6 c7 7 Bc ¼ 6 6 0 7; 7 6 6 Kc 7 6 rp 7 7 6 7 6 4 0 5 0 0 2 0 2 2 6 0 7 7 6 7 6 6 0 7 7 6 7 6 6 1 7 7; 6 BT ¼ 6 7 6 0 7 6 1 7 6 rp 7 7 6 7 6 4 0 5 0 2 3 3 C5 0 0 0 0 Ca ba11 Ka 0 0 0 cf ba22 Kf 0 0 0 0 0 0 e 0 0 Ku 3 7 0 7 7 7 0 7 7; 7 0 7 7 0 7 5 0 where e is a small positive number which makes the lower left 3 5 submatrix of D* full rank. Also the nonzero Ku makes the top right 3 1 submatrix of D* full rank. As a result, the H N design problem is nonsingular.3 It follows that the design problem can be formulated as an H N minimization problem: Find the feedback matrix u ¼ CðsÞy which minimizes w in the presence of disturbance d: The controller can be designed by using the m-Tools Toolbox [12]. 5. Estimation of Td The desired level of assist torque is defined by a boost curve which relates the driver torque to the desired assist torque. However, since the driver torque is not 3 The reader is referred to the user’s manual of the m-Tools Toolbox for more detailed explanations of conditions on state space H N solutions. Fig. 7. Td and Tc in open-loop responses. measured, the boost curve cannot be directly implemented to generate the desired assist torque. Currently, a pinion torque sensor is installed to measure Tc : In most EPAS systems, Tc signal is used as an approximation of Td for boost curve input (feedforward control) and feedback control implementations. However, although at steady state, Tc and Td are essentially identical, they differ dramatically during dynamic transitions. The difference is mostly pronounced when the assist torque is present. Without compensation of this dynamic difference, the dynamic behavior and performance of the EPAS will be severely compromised. Figs. 7 and 8 demonstrate their differences in open and closed-loop configurations. From the preliminary analysis and test data, the column, steering shaft torsion stiffness, and moment of inertia are shown to be difficult to determine exactly due to the nonlinearity of the system. Also, the center of gravity of the steering wheel varies when the driver rotates the wheel while driving. Hence, the driver torque and pinion torque are different during dynamic transitions if Jc and Kc are not modeled correctly. In this paper we introduce an estimator for Td by using the signal Tc and plant models. Since Tc ¼ G21 Td þ G22 u; 442 R.C. Chabaan, L.Y. Wang / JSAE Review 22 (2001) 435–444 feedback loop has variable loop gain, depending on Ka ; which changes with the vehicle speed and input torque. To guarantee stability of the entire system, it is necessary to establish robust stability conditions under which the closed-loop system is stable for all possible values of Ka : These conditions are given in the following theorem. Note that by the H N design, both 1=ð1 þ CP22 Þ and C=ð1 þ CP22 Þ are stable. From the plant model and estimator design, we have the following relationships: y ¼ P12 Td þ P22 u; u ¼ Ka F 0 T#d Cy; T#d ¼ Qy þ Q2 u; where the boost-curve gain 0pKa pkmax and F 0 is a stable filter for frequency-domain loop shaping. Theorem 1. Suppose that the uncertainty on the system is given by 0pKa pkmax and jjWDjjN pe: If 1 0 W F 1 1 þ CP ok e; 22 N max then the closed-loop system is robustly stable. Proof. Since the output Ta is related to the inputs by Ta ¼ P11 Td þ P12 u and P11 and P12 are stable systems, Ta will be bounded whenever u is bounded. As a result, for stability analysis, we only need to establish the boundedness of u: Fig. 8. Td and Tc in closed-loop responses. u ¼ Ka F 0 ðQy þ Q2 uÞ Cy the exact relationship between Td and Tc is Td ¼ G1 21 ðTc G22 uÞ: ¼ ðKa F 0 Q CÞy þ Ka F 0 Q2 u It is noted, however, that G1 21 is improper and unstable. Since the frequency band in which Td must be accurately estimated is relatively narrow, it is possible that a proper and stable estimator can be found which approximate G1 21 over the frequency band of interest. For a production EPAS system, such an estimator was found as T#d ¼ Q1 Tc þ Q2 u ¼ Qy þ Q2 u; where Q1 and Q2 are proper and stable, and Q ¼ ½Q1 ; 0; 0: From the design of the estimator, it is easy to verify that D ¼ QP22 Q2 is small over the low frequency band of interest. More accurately, there exists a bi-stable weighting function W (both W and W 1 are stable) such that jjWDjjN pe: ð7Þ 6. Stability analysis When Tc is measured and used to predict Td and used as an input to the boost curve to generate control signals, an additional feedback loop is formed. This ¼ ðKa F 0 Q CÞðP12 Td þ P22 uÞ þ Ka F 0 Q2 u ¼ ðKa F 0 Q CÞP12 Td þ ððKa F 0 Q CÞP22 þ Ka F 0 Q2 Þu ¼ ðKa F 0 Q CÞP12 Td þ ðKa F 0 D CP22 Þu: It follows that ð1 þ CP22 Ka F 0 DÞu ¼ ðKa F 0 Q CÞP12 Td and W 1 F 0 ðKa F 0 Q CÞP12 1 Ka DW Td : u¼ 1 þ CP22 1 þ CP22 By the H N design, the right-hand side ðKa F 0 Q CÞ P12 =ð1 þ CP22 Þ is stable with ðKa F 0 Q CÞP12 pZoN: 1 þ CP22 N Furthermore, by hypothesis 1 0 W F W 1 F 0 o1: m ¼ Ka DW pk jjDWjj max N 1 þ CP22 N 1 þ CP22 N It follows from the Banach Space Contraction Principle that 1 Ka DW½ðW 1 F 0 Þ=ð1 þ CP22 Þ is invertible in R.C. Chabaan, L.Y. Wang / JSAE Review 22 (2001) 435–444 443 H N and 1 W 1 F 0 1 : 1 Ka DW p 1m 1 þ CP22 N Therefore, the closed-loop system is stable and 1 W 1 F 0 ðKa F 0 Q CÞP12 Z : p 1 Ka DW 1m 1 þ CP22 1 þ CP22 N & 7. Computer simulation Simulations were performed on the linearized system as well as the original nonlinear EPAS system (see Fig. 1) to ensure that the linear controller can be implemented. Fig. 9 depicts the responses of the linearized EPAS system to the driver’s torque command for a step with a sine wave to simulate a worst-case condition to the EPAS system. As the figure shows, the H N controller provides very good response of desired torque (Tadesired) vs. produced torque by an EPAS to achieve the desired steering feel. Fig. 10 is the responses of the original nonlinear system. The figure shows that the RMS error has increased from 5:49% of linear system to 11:9% of nonlinear. However, the increase in RMS error will not hinder the steering feel since the difference is 0:14 N m which cannot be detected by the driver due to some unfiltered vibration in steering column and road disturbances. Fig. 11 shows the relationship between the driver torque and the assist torque, produced by the closedloop system. The shape approximates closely the desired boost curve. Fig. 9. Controlled responses on linearized systems. Fig. 10. Controlled responses on original systems. Fig. 11. Relationship between the driver torque and the assist torque. 8. Vehicle data verification To test H N control algorithms and the driver torque estimator, a small vehicle was instrumented with a single-pinion EPAS system as shown in Fig. 1. Several measurement channels were installed to measure vehicle speed (mph), driver torque (nm), steering angle (deg), rack displacement (m), motor position (deg), motor velocity (deg/s), and boost curves. These signals were measured by using a Dspace box at 500 Hz with vehicle speeds ranging from 10 to 30 mph for 60 s: The measured driver torque, steering angle, and rack displacement are shown in Fig. 12. The measured data are then inputed to the control system and torque estimator to generate torque estimation. Fig. 13 compares the measured driver torque to the estimated torque. It is apparent that the torque estimator provides sufficiently accurate estimates for the driver torque. The performance of the H N controller is verified by employing the measured driver’s torque as the command input. Fig. 14 compares the desired assist torque from 444 R.C. Chabaan, L.Y. Wang / JSAE Review 22 (2001) 435–444 Fig. 12. Measured signals. Fig. 14. Vehicle data verification: desired assist torque vs. generated assist torque. production of satisfactory robust controllers, leading to reduction of development time. The controllers introduced in this paper are currently undergoing technology transfer to production EPAS systems and patent applications. References Fig. 13. Vehicle data verification: measured driver torque vs. estimated torque. the boost curves and the actual assist torque generated by the closed-loop system, as well as their differences. 9. Concluding remarks The EPAS system is of unique importance in automotive system development. It is an important technology advancement from the classical hydraulic systems. Understanding its control requirements and developing generic design methodologies will facilitate rapid development of control strategies following hardware alternations. Unlike traditional PID or lead-lag compensations which require substantial tuning and manual calibration on individual systems, the method introduced in this paper can potentially lead to fast [1] Zaremba, A., Davis, R.I., Dynamic analysis and stability of a power assist steering system, Proc. ACC, Seattle, Washington, June, pp. 4253–4257 (1995). [2] Zaremba, A.T., Liubakka, M.K., Stuntz, R.M., Vibration control based on dynamic compensation in an electric power steering system, Preprint of the Int. Conf. On Control of Oscillations and Chaos, St. Petersburg, Vol. 3, pp. 453–456 (1997). [3] Zaremba, A.T., Liubakka, M.K., Stuntz, R.M., Control and steering feel issues in the design of an electric power steering system, Proc. ACC (1998). [4] Baxter, J., Analysis of stiffness and feel for a power-assisted rack and pinion steering gear, SAE Paper 880706 (1998). [5] Adams, F.J., Power steering road feel, SAE Paper 830998 (1983). [6] Sugitani, N., Fujuwara, Y., Uchida, K., Fujita, M., Electric power steering with H-N control designed to obtain road information, Proc. ACC, Alpuquerque, New Mexico, June ð1997Þ: [7] Badaway, A., Zuraski, J., Bolourchi, F., Chandy, A., Modeling and analysis of an electric power steering system, SAE 1999-010399, Detroit, Michigan, 03/1-4 ð1999Þ: [8] Kurishige, M., Kifuku, T., Inoue, N., Zeniya, S., Otagaki, S., A control strategy to reduce steering torque for stationary vehicles equipped with EPS, SAE 1999-07-0403, Detroit, Michigan, 03/1-4 (1999). [9] Chabaan, R., Wang, L.Y., H N control of electrical power assist systems, Proc. AVEC 2000, Ann Arbor, August ð2000Þ: [10] Chabaan, R., Wang, L.Y., Torque estimation in electrical power assist systems, Proc. AVEC 2000, Ann Arbor, August ð2000Þ: [11] Liubakka, M., Zaremba, A., Electric power assist steering vehicle level control system, Ford Motor Co. Internal Report 1998: [12] Doyle, J.C., Glover, K., Khargonekar, P.P., Francis, B.A., State space solutions to standard H2 and Hinf control problems, IEEE Trans. Automat. Control, Vol. 34, No. 8, August ð1989Þ: