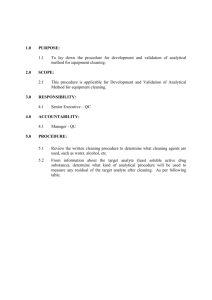

Guidance for the Validation of Analytical Methodology and

advertisement