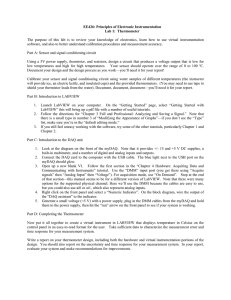

LabVIEW Data Acquisition Basics Manual

advertisement