thesis evaluating the long-term durability of fiber reinforced polymers

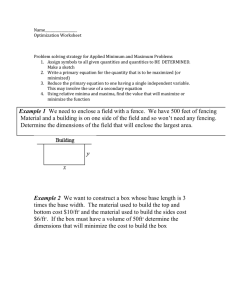

advertisement