System i and System p: Physical Site Planning and Preparation

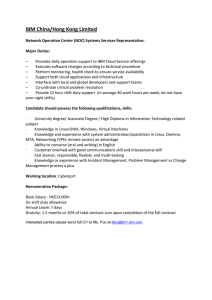

advertisement