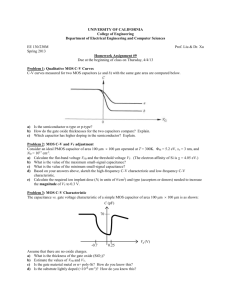

CAPACITANCE-VOLTAGE SPECTROSCOPY IN METAL

advertisement