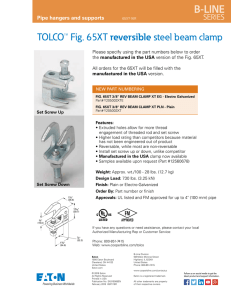

SCREW SUPPORT Centering type SCREW SUPPORT Screw type

advertisement

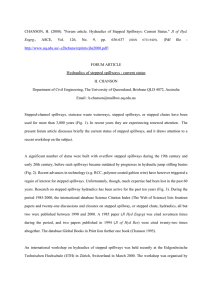

SCREW SUPPORT SCREW SUPPORT Centering type Screw type B ● Convenient for centering operation for unevenly processed object such as rough surfaces. G ● Optimal for using with the body of uni-clamps (TPS・TPU・FGB and FPB-B). ● Spherical bag-shaped surface of swivel nut enables a slant in front, back, left and right directions up to 6 degree. B d Swivel nut H H φD φD (Unit:mm) (Unit:mm) Item No. H Stroke B φD G FJ60 FJ80 FJ100 75∼ 93 100∼125 120∼165 24 49 TM32×3 100 30 63 TM40×4 160 Allowable load kN Weight (kg) 0.70 1.60 1.90 Item No. H φD d B FR 10 FR 12 FR 16 FR 20 48 60 78 94 35 40 50 60 M10 M12 M16 M20 5 6 8 10 Allowable load kN Weight (kg) 11 16 28 37 80 117 240 445 Minimum (Height) Optimal for vertical- and horizontaltype jigs ● The Block has a magnet built in the bottom, so it is free from accretion of swarf. CLAMPING ELEMENTS STEPPED BLOCK (Step type) STEPPED BLOCK with Magnet (Step type) Maximum (Height) ● A pair A pair A The number of magnets to be built in depends on block weight min D max E Combination of stepped clamp and stepped block B C ● (Fig-2) (Fig-3) (Fig-1) Item No. M 1S M 2S M 3S M 4S M 5S M 6S M 7S M 8S M 9S Combination of plane clamp and stepped block Optimal for using in combination with a stepped clamp and for adjusting the heigt with a two piece set. (Unit:mm) (Unit:mm) A B C D∼E Allowable load kN Weight (kg) (A pair) Item No. A B C D∼E Allowable load kN Weight (kg) (A pair) 29 45 98 59 98 139 59 98 139 17 27 57 35 57 81 35 57 81 25 25 25 38 38 38 50 50 50 19∼ 46 28∼ 68 58∼150 36∼ 90 58∼150 82∼210 36∼ 90 58∼150 82∼210 132 210 462 417 694 990 555 926 1,325 0.10 0.27 1.00 0.60 1.57 3.08 0.83 2.00 4.00 1S 2S 3S 4S 5S 6S 7S 8S 9S 29 45 98 59 98 139 59 98 139 17 27 57 35 57 81 35 57 81 25 25 25 38 38 38 50 50 50 19∼ 46 28∼ 68 58∼150 36∼ 90 58∼150 82∼210 36∼ 90 58∼150 82∼210 132 210 462 417 694 990 555 926 1,325 0.11 0.27 1.00 0.62 1.59 3.09 0.82 2.10 4.02 *Withstand loads are indicated for Fig. 2, and are reduced by about 50% for Fig. 3. STEPPED BLOCK *Withstand loads are indicated for Fig. 2, and are reduced by about 50% for Fig. 3. (Tiered type) ● It is a convenient step to get 6-phased height by altering the vertical and horizontal direction. ● The round face connected to clamping fittings enables good clamping fitness even on slightly slanted bodies. h3 h2 h1 h6 h5 ● ● h4 Combination of step block and uni-clamp W 79 Item No. W FW 40 FW 50 FW 80 40 50 80 6-phased changeable hight dimensions h1 10 13 20 h2 22 28 44 h3 34 43 68 h4 16 20 32 h5 28 35 56 h6 40 50 80 Weight (kg) 0.27 0.47 1.58