Energy Sector Methane Recovery and Use

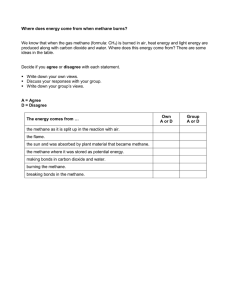

advertisement