Inductor Basics Inductors dissipate power in the core and in the

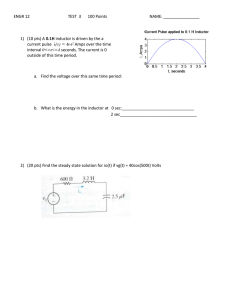

advertisement

By Travis Eichhorn, Applications Engineer, Maxim Integrated Products, Sunnyvale, Calif. Inductors dissipate power in the core and in the windings. Although exact calculations of these losses can be complex and difficult, they can be readily estimated using data sheet parameters available from magnetic component suppliers. H(t), magnetic flux ⌽(t), magnetic-field density B(t), permeability , and reluctance ℜ. To avoid the complicated physics of electromagnetic fields, we offer only a brief treatment of these parameters. The magnetic field strength generated by an inductor is measured in amperes multiplied by turns per meter. The magnetic field is created when current flows in the turns of wire that wrap around the magnetic core. For switchmode power inductors, we can approximate the magnetic field by assuming it is completely contained within the core. Magnetic-field density, measured in teslas, is equal to the magnetic-field strength, H(t), multiplied by the magnetic-core permeability, : switch-mode power supply incurs loss in many areas of its circuitry, including the MOSFETs, input and output capacitors, quiescent controller current and inductor. The power dissipated in the inductor arises from two separate sources: the losses associated with the inductor core and those associated with the inductor windings. Though determining these losses with precision can require complex measurements, an easier alternative exists. Inductor losses may be estimated using readily available data from core and inductor suppliers along with the relevant power supply application parameters. A Inductor Basics An inductor consists of wire wound around a core of ferrite material that includes an air gap. A subset within the broad inductor category, power inductors operate as energy-storage devices. They store energy in a magnetic field during the power supply’s switching-cycle on time and deliver that energy to the load during the off time. To understand power loss in inductors, you must first understand the basic parameters associated with inductors. These include magnetomotive force F(t), magnetic-field strength Power Electronics Technology April 2005 Magnetic flux, which is measured in webers, equals the magnetic-field density, B(t), multiplied by the cross-sectional area of the core, AC: Permeability, measured in henrys/m, expresses the capability of a specific material to allow the flow of magnetic flux more easily. Thus, higher permeability enables a mate14 www.powerelectronics.com INDUCTOR POWER LOSS rial to pass more magnetic flux. Permeability is a product: in which 0 is the permeability of free space (0 = 4 ⫻ 10-7 H/m) and R is the material’s relative permeability (a dimensionless Fig. 1. This magnetic circuit (a) is represented by the equivalent circuit model (b). quantity). For example, R for iron is approximately 5000 ment (ℜAIR) in series with a low-reluctance ferrite material and R for air—the other extreme—is 1. The core of a (ℜFe), thereby locating the bulk of the magnetomotive force, power inductor contains an air gap and ferrite material, so ni(t), at a desired location—that of the air gap. The inducits effective is somewhere between that of ferrite and air. tor value is calculated as: Magnetomotive force, F(t), is approximated in our case as the magnetic-field strength, H(t), multiplied by the effective length of the core, lE: F (t )=H (t )⋅ l E Because ferrite materials have high permeability, they offer an easy path for magnetic flux (low reluctance). That characteristic helps contain the flux within the inductor’s core, which in turn enables the construction of inductors with high values and small size. This advantage is evident in the inductance equation above, in which a core material with high value allows for a smaller cross-sectional area. where the units for F(t) are amperes multiplied by turns. Effective length is the length of the path followed by the magnetic flux around the core. In a magnetic circuit, F(t) can be regarded as the generator of magnetic flux (Fig. 1). Finally, reluctance, which is measured in amperes multiplied by turns/weber, is the resistance of a material to magnetic fields. Reluctance is also the ratio of magnetomotive force, F(t), to magnetic flux, ⌽(t), and therefore depends on the physical construction of the core. Substitution of the above equations for F(t) and ⌽(t) yields the following equation for reluctance: Inductor Operation The power inductor in a buck or boost converter operates as follows. Turning on the primary switch applies a source voltage VIN across the inductor, causing the current to increase as: di (t ) VIN = dt L Inductors operate according to the laws of Ampere and Faraday. Ampere’s Law relates current in the windings— or turns of wire—to the magnetic field in the core of the inductor. As an approximation, one assumes the magnetic field in the inductor’s core is uniform throughout the core length (lE). That assumption lets us write Ampere’s Law as: This changing current, di(t)/dt, induces a changing magnetic field in the core material according to Ampere’s Law: dH (t ) n di (t ) = ⋅ dt l E dt H (t )⋅ l E =n ⋅ i (t ) In turn, magnetic flux through the inductor’s core increases as: where “n” is the number of wire turns around the inductor core and i(t) is the inductor current. Faraday’s Law relates the voltage applied across the inductor to the magnetic flux contained within the core: and that increase can be rewritten in terms of magnetic-field density: dB (t ) n di (t ) = ⋅ dt A ⋅ ℜ dt where ⌽(t) is the magnetic flux and “n” is the number of wire turns around the core. The functional diagram of Fig. 1 shows a power inductor and its equivalent magnetic circuit. As shown, the air gap places a high-reluctance elePower Electronics Technology April 2005 The primary switch opens during the off time and removes VIN, causing the magnetic field to decrease. In re16 www.powerelectronics.com INDUCTOR POWER LOSS A graph of B(t) as a function of H(t) for a sinusoidal input voltage produces the hysteresis loop shown in bold lines on Fig. 2. B(t) is measured as H(t) is increased. The response of B(t) versus H(t) is nonlinear and exhibits hysteresis, hence the name hysteresis loop. Hysteresis is one of the core-material characteristics that causes power loss in the inductor core. Minor hysteresis loop Power Loss in the Inductor Core Energy loss due to the changing magnetic energy in the core during a switching cycle equals the difference between magnetic energy put into the core during the on time and the magnetic energy extracted from the core during the off time. Total energy (ET) into the inductor over one switching period is: Using Ampere’s Law: Fig. 2. A plot of magnetic field density B(t) versus magnetic field strength H(t) reveals the major and minor hysteresis loops associated with an inductor core. sponse, a decreasing d⌽/dt in the inductor’s core induces (according to Faraday’s Law) a voltage -n d⌽/dt across the inductor. lE ⎞ ⎛ ⎜⎝ i (t )=H (t )⋅ ⎟⎠ n and Faraday’s Law: dB (t )⎞ ⎛ ⎜⎝ v (t )=n ⋅ A ⋅ dt ⎟⎠ the equation for ET can be rewritten as: E T =A ⋅ l E ∫ H ⋅ dB Thus, the total energy put into the core over one switching period is the area of the shaded region within the B-H loop of Fig. 2 multiplied by the volume of the core. The magnetic field decreases as inductor current ramps down, tracing a different path (following the direction of the arrows in Fig. 2) for magnetic flux density. Most of the energy goes to the load, but the difference between stored energy and delivered energy equals the energy lost. Energy lost in the core is the area traced out by the B-H loop multiplied by the core’s volume, and the power lost is this energy (ET) multiplied by the switching frequency. Hysteresis loss varies as a function of ⌬Bn, where (for most ferrites) “n” lies in the range 2.5 to 3. This expression applies on the conditions that the core is not driven into saturation, and the switching frequency lies in the intended operating range. The shaded area in Fig. 2, which occupies the first quadrant of the B-H loop, represents the operating region for positive flux-density excursions, because typical buck and boost converters operate with positive inductor currents. The second type of core loss is due to eddy currents, which are induced in the core material by a time-varying flux d⌽/dt. According to Lenz’s Law, a changing flux in- From 1 Watt up to 300 Watts Transformers Inductors Filters EMI/RFI CMCs For UL/CSA recognized magnetic components...for SMPS applications...designed for use with leading semiconductors...for application notes and reference circuits...call Premier, the "Innovators in Magnetics Technology". 20381 Barents Sea Circle Lake Forest, CA 92630 Tel. (949) 452-0511 www.premiermag.com/switcher CIRCLE 213 on Reader Service Card or freeproductinfo.net/pet Power Electronics Technology April 2005 18 www.powerelectronics.com INDUCTOR POWER LOSS of change of flux in the core. Since the rate of change of flux is directly proportional to the applied voltage, the power loss due to eddy currents increases as the square of the applied inductor voltage and directly with its pulse width. Thus: PE ∝ where VL is the voltage applied to the inductor, tAPPLIED is the on or off time, and TP is the switching period. Because the core material has high resistance, losses due to eddy currents in the core are usually much less than those due to hysteresis. The data given for core losses usually includes the effects of both hysteresis and core eddy currents. Core-loss measurements are difficult because they require complicated setups for measuring flux density and because they involve the estimation of hysteresis-loop areas. Many inductor manufacturers do not supply this data, but curves are available from ferrite manufacturers to help you approximate the core loss in an inductor. Such curves indicate power loss in W/kg or W/cm3 as a function of peak-to-peak flux density, B(t), and frequency (f). The magnetics division of Spang and Co. in Pittsburgh supplies ferrite material for inductor manufacturers. From the website www.mag-inc.com, you can obtain material data sheets that include curves for core loss versus flux density at various frequencies. If you know the particular ferrite material and the volume of the inductor’s core, these curves enable you to make a good estimate of core loss. Such curves for a given ferrite material (Fig. 3) are taken with a sinusoidal applied voltage using bipolar flux swings. When estimating the core loss for dc-dc converters that operate with unipolar flux swings and rectangular applied voltages, which consist of higher-frequency harmonics, you can approximate the loss using the fundamental frequency and one-half the peak-to-peak flux density: Fig. 3. AC core loss for a particular ferrite material is plotted as a function of flux density at different frequencies. (Data courtesy of Spang and Co.) duces a current that itself induces a flux in opposition to the initial flux. This eddy current flows in the conductive core material and produces an I2R, or V2/R, power loss. That effect also can be seen via Faraday’s Law. If you imagine the core as a lumped resistive element with resistance RC, then the voltage vI(t) induced across RC according to Faraday’s Law is: The core volume can usually be estimated with a rough measurement. A few inductor manufacturers do offer core-loss graphs or equations that enable more accurate estimations of core power loss. For example, Pulse Engineering in San Diego provides inductor core-loss equations in some of its inductor data sheets (see www.pulseeng.com). See SMT power inductors P1172/P1173 for examples. These data sheets include an equation using constants (K-factors) that enable the calculation of core loss as a function of frequency and peak-to-peak ripple in the inductor current. On the other hand, Coiltronics, headquartered in Boynton Beach, Fla., presents core loss for many of its inductors in graph form (see FLAT-PAC 3 series power inductors for example at www.coiltronics.com). Fig. 4 shows where AC is the cross-sectional area of the core. The power loss in the core due to eddy currents is 2 PE = v I (t ) RC This power loss is proportional to the square of the rate Power Electronics Technology April 2005 VL2 t APPLIED ⋅ RC TP 20 www.powerelectronics.com INDUCTOR POWER LOSS the curve for core power loss versus flux density and frequency from a Coiltronics Flat-Pac 3 data sheet. Power Loss in Inductor Windings The preceding discussion presented losses in the inductor core, but losses also occur in the inductor windings. Power loss in the windings at dc is due to the windings’ dc resistance and the RMS current through the inductor (IRMS2 RDC). Resistance (R) is defined as: z Fig. 4. AC core loss for a particular inductor is plotted versus flux density at different frequencies. (Data courtesy of Coiltronics.) where is the resistivity of the winding material. This material is usually copper, for which =1.724 10 -8(1+ .0042 (T⬚C-20⬚C))Ωm). Physically smaller inductors typically use smaller wire, and thus exhibit a higher dc resistance due to the smaller cross-sectional area of the wire. Larger-value inductors have more turns of wire, and therefore also have higher resistance due to the longer length. Winding losses at dc are due to the dc resistance (RDC) of the windings and are given in the inductor data sheet. With increasing frequency, the winding resistance increases due to a phenomenon called skin effect, caused by a chang- ing i(t) within the conductor. The changing current induces a changing flux (d⌽/dt) perpendicular to the current that induced it. According to Lenz’s Law, the changing flux induces eddy currents that induce a flux themselves, in opposition to the initial changing flux. These eddy currents are of a polarity opposite that of the initial current. The induced flux is strongest at the conductor’s center and weakest at the surface, causing the current density at the center to decline from its dc value with increasing frequency. As a result, current gets pushed to the surface of the conductor, pro- z z Kooler Inductors Inductors made from Magnetics’® Kool Mµ® E cores run cooler than those made with gapped ferrite cores. Eddy currents, caused by the fringing flux across the discrete air gaps of a gapped ferrite, can lead to excessive heat due to heavy copper losses. The distributed air gaps inherent in Kool Mµ can provide a much cooler inductor. Kool Mµ E cores are available in many industry standard sizes. Magnetics now offers cores in 14 sizes (from 12 mm to 80 mm) and four permeabilities (26µ, 40µ, 60µ, and 90µ). New sizes are being added. Standard bobbins are also available. If you are using gapped ferrite E cores for inductor applications, see what Kool Mµ E cores can do for you. You may even be able to reduce core size in addition to having a cooler unit. Production quantities are now in stock. For more information, contact Magnetics. P.O. Box 11422 • Pittsburgh, PA 15238-0422 Phone 412.696.1333 • Fax 412.696.0333 1-800-245-3984 New Sizes Available! email: magnetics@spang.com www.mag-inc.com CIRCLE 215 on Reader Service Card or freeproductinfo.net/pet www.powerelectronics.com 21 Power Electronics Technology April 2005 INDUCTOR POWER LOSS ducing a lower current density at the center and a higher current density at the surface. Resistance increases because the resistivity of copper remains constant and the conductor’s effective current carrying area decreases. The windings’ ac resistance is found by determining the depth, known as penetration depth, to which current exists in the conductor at a particular frequency. Current density at that point falls to 1/e times the current density at the surface, or at dc. This depth (DPEN) can be calculated as: face area of a conducting ring with thickness equal to the skin depth. Because resistivity remains constant, the ratio of RAC to RDC is simply the ratio of the two areas: Furthermore, RAC/RDC multiplied by RDC is the effective resistance at a given frequency for a straight wire in free space. Eddy currents in the inductor windings are also induced by other nearby conductors, a phenomenon known as the proximity effect. For inductors with many overlapping wire turns and adjacent wires, the increased eddy currents cause a resistance considerably higher than that from the skin effect alone. The proximity effect becomes complicated, however, due to the various configurations and distances with which conductors can be placed relative to each other. Because such calculations are beyond the scope of this article, the reader should refer to the references provided. A simple circuit illustrates losses in the inductor (Fig. 4). RC represents the core losses, and RAC and RDC represent the ac- and dc-dependent winding losses. RC is determined by core loss calculations or estimates, while RDC is the dc winding resistance and RAC is the ac resistance due to skin effect, proximity effect or both. An example of this loss model can be developed using the MAX5073 switching power supply. We operate the MAX5073 as a buck converter with VIN = 12 V, VOUT = 5 V, fSW =1 MHz, and IOUT = 2 A. A 4.7-H inductor (FP3-4R7 from Coiltronics) produces an inductor current ripple (⌬I(t)) of 621 mA. A graph of core loss versus flux density and frequency is shown in Fig. 4. Peak-to-peak flux density (⌬B) is what matters. It traces out a small hysteresis loop within the larger hysteresis loop (see the inner loop in Fig. 2). You can find ⌬B using the equation given in the inductor data sheet: where is the resistivity of the conductor (usually copper) and is the conductor’s permeability ( = 0 R, where R = 1 for copper). This calculation is accurate when the conductor is a flat surface or when the radius of the conductor is much larger than the penetration depth. Note that ac resistance (RAC) acts as a power loss only to the ac current, which for buck and boost converters is the inductor-current ripple. DC current in the inductor only creates power loss in RDC. You find RAC by calculating the effective conducting area of the copper wire at a given frequency. For conductors that have radii larger then the skin depth at the given operating frequency, the effective conducting area is the surz where K is a constant given in the data sheet (K = 105 in our case), and L is the inductance in microhenries. In this example: As an alternative, you can estimate ⌬B(t) using the inductor volt-second product divided by the number of turns and the core area within the turns: Going to the FP3 data sheet, core loss at 613 gauss and fSW= 1 MHz is approximately 470 mW. RC in Fig. 5 is the equivalent parallel resistance that accounts for power loss in the inductor core. That resistance is calculated from the RMS voltage across the inductor and the core power loss: VRMS =VIN ⋅ D=12 V ⋅ 0.417=7.75 VRMS CIRCLE 216 on Reader Service Card or freeproductinfo.net/pet Power Electronics Technology April 2005 22 www.powerelectronics.com INDUCTOR POWER LOSS Fig. 5. An equivalent loss model for a power inductor includes terms representing the ac- and dc-dependent winding losses (RAC and RDC) and the core losses (RC). RC is then 60.1 V2/0.470 W=128 Ω, where VIN ⫻ D is the RMS value of a rectangular wave with duty cycle D and amplitude VIN. RDC from the data sheet is 40 mΩ, assuming a zero temperature rise for the inductor, which would otherwise increase the value of RDC. The penetration depth for a 1-MHz switching frequency, using only the fundamental of the triangular current ripple at TA = +20°C, is 0.065 mm. A rough measurement of the conductor’s radius gives 0.165 mm, which results in an RAC value of: This resistance only dissipates power due to the RMS ac current. The RMS value of inductor current ripple is: Thus, the total estimated losses are: &UJI3EMICONDUCTOR)NC (IGHLANDER7AY #ARROLLTON4853! PETech 0HONE &AX References 1. Erickson, Robert W., and Dragan Maksimovic. Fundamentals of Power Electronics, 2001. Chapters 13 and 14, pp. 491562. 2. Kassakian, John G., Martin F. Schlecht, and George C. Verghese. Principles of Power Electronics, 1991. Chapter 20, pp. 565-601. 3. Dixon, Lloyd H. Magnetics Design for Switching Power Supplies. Sections 1-5. 6ISITOURWEBSITEAT WWWFUJISEMICOM FORMOREDETAILS CIRCLE 218 on Reader Service Card or freeproductinfo.net/pet Power Electronics Technology April 2005 24 www.powerelectronics.com