“Mechanical Characterization of Na

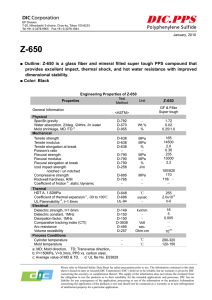

advertisement

International Journal of Emerging Technology and Advanced Engineering Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 2, Issue 12, December 2012) “Mechanical Characterization of Na-MMT Glass Fiber Reinforced Polyester Resin Composite” Manoj Mohbe1, Prof. Praveen Singh2, Dr. S.K. Jain2 1 2 Manoj Mohbe M.Tech final year BUIT Bhopal, manojmohbe@gmail.com Prof. Praveen Singh Professor Department of mechanical Engineering BUIT Bhopal 2 Dr. S.K. Jain Senior Technical Officer CIPET Bhopal Abstract - In this study of the effect of (Na-MMT) nanoclay on GRP composite is to be investigated in order to improve the mechanical properties of GRP composite. This investigatio0n carried out by preparing thin sheets of GRP composite with varying the content of Na-MMT by weight of polyester resin. There is no variation of quantity of glass fiber; it remains same for all the sheets. 1%, 2% and 3% weight of polyester resin is replaced by the weight of Na-MMT. The sheets are prepared by hand layup method. The investigation of all the standard specimens of different composition show that the mechanical strength such as tensile strength, impact strength and flexural strength is improves with the increment of quantity of Na-MMT. Keywords- Na-MMT, Nanocomposite reinforced, Polyester, Sr. no. Sheet name Polyester resin Glass fiber 1 2 3 4 GRP GRPN1 GRPN2 GRPN3 60 59 58 57 40 40 40 40 Hybrid I. INTRODUCTION Nanoclays are modified silicates used as a hybride material due to their use in wide range of application such as polymer nanocomposites. These are o two type natural and synthetic, the most common synthetic material used in polymer nanocomposite is montmorillonite which is the major component of bentonite. In this study we added small amount of Na-MMT (sodium montmorillonite) by weight of polyester resin in GRP (glass fiber reinforced polyester resin with an object to increase the mechanical strength such as flexural strength, impact strength and tensile strength.To attend the goal we prepared four different sheets of GRP (glass fiber reinforced polyester resin) by hand layup method of different compositions. One sheet is general GRP and remaining three are modified of varying percentage of Na-MMT. This percentage of weight of Na-MMT is replaced by the weight of polyester resin. The composition and names of all the sheets are as. (a) GRP (b) GRP1 (c)GRPN2 (d) GRPN3 Fig. 1 702 NaMMT (% of resin) 00 01 02 03 International Journal of Emerging Technology and Advanced Engineering Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 2, Issue 12, December 2012) II. EXPERIMENTAL III. RESULT AND DISCUSSION Tensile test After performing all the experiments the following readings are obtained. Testing method - ASTM- D638 1. Flexural test Type of specimen - 1 Test speed For finding the exact value of flexural test two readings are taken for each composition so that the errors may be minimize. - 50 mm/min Test condition o o Temperature - 23 ± 20C Humidity - 55 ± 5% Flexural Test Testing method - ASTM- D790 (a) Specimen size - 127mm X 12.7mm X 3 mm Test speed - 1.13 mm/min GRP Test condition o o Temperature - 23 ± 20C Humidity - 55 ± 5% (b) GRPN1 (c) GRPN2 (d) GRPN3 Notched izod impact test Testing method - ASTM- D256 Specimen size - 127mm X 12.7mm X 3 mm Test condition o o Temperature - 23 ± 20C Humidity - 55 ± 5% Fig. 2 703 International Journal of Emerging Technology and Advanced Engineering Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 2, Issue 12, December 2012) Fig. 2 shows the graphs plotted between flexural load and flexural extension for different compositions. Fig. 2 (a) , (b) , (c) and (d) represent the load verses flexural extension for GRP, GRP1, GRP2 and GRP3 respectively. Maximum flexural stress = 201.85136 Mpa Minimum flexural stress = 185.87231 Mpa GRP Sr. no. 1 2 Average flexural stress Width (mm) Thickness (mm) Span length (mm) Load (N) Flexural stress (Mpa) 13.55 2.15 36.00 223.52 192.70793 13.40 2.15 34.50 221.98 185.45416 GRPN3 Sr. no . Widt h (mm) 1 14.50 2 14.90 Maximum flexural stress = 192.70793 Mpa Minimum flexural stress = 185.45416 Mpa Average flexural stress 1 2 Width (mm) = 189.08 Mpa Load (N) 2.45 38.00 323.4 2.15 38.00 239.9 Average flexural stress Thickness (mm) Span length (mm) Load (N) Flexural stress (Mpa) 13.20 2.35 38.00 240.78 188.27339 13.30 2.35 38.00 251.82 195.42198 1. Average flexural stress S. No. = 191.84 Mpa Span length (mm) Load (N) 2 13.20 2.60 42.00 285.90 Impact test 1 2 3 4 Flexural stress (Mpa) Width mm 2.10 2.10 2.10 2.10 Depth mm 10.16 10.16 10.16 10.16 Breaking Energy Kj Impact Strength 2.6715 3.1730 2.3065 3.2248 125.21 148.72 108.10 151.15 2 Kj/m 201.85136 Minimum impact strength = 108.10 Kj/m2 13.20 2.60 42.00 257.86 198.51 = 205.152 Mpa Maximum impact strength = 148.72 Kj/m2 1 211.79 GRP GRPN2 Thickness (mm) Flexura l stress (Mpa) Izod impact testing machine (ASTMD 256) Impact strength = Breaking Energy/ Area (Kj/m2) Minimum flexural stress = 188.27339 Mpa Width (mm) Span length (mm) Minimum flexural stress = 198.51109 Mpa Maximum flexural stress = 195.42198 Mpa Sr. no. Thickn ess (mm) Maximum flexural stress = 211.79382 Mpa GRPN1 Sr. no. = 193.86 Mpa 185.87231 Average impact strength = 133.18 Kj/m2 704 International Journal of Emerging Technology and Advanced Engineering Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 2, Issue 12, December 2012) GRPN1 S. No. 1 2 3 4 Width mm 2.10 2.10 2.10 2.10 GRPN3 Depth mm 10.16 10.16 10.16 10.16 Breaking Energy Kj Impact Strength 3.22 2.96 2.78 2.55 151.14 139.19 130.20 119.54 S. No. 2 Width mm Depth mm Kj/m Breaking Energy Kj Impact Strength 2 Kj/m 1 2.10 10.16 3.53 161.23 2 2.10 10.16 2.94 140.80 3 2.10 10.16 3.59 163.25 4 2.10 10.16 3.25 148.73 Maximum impact strength = 161.23 Kj/m2 Maximum impact strength = 151.14 Kj/m2 Minimum impact strength = 140.80 Kj/m2 Minimum impact strength = 119.54 Kj/m2 Average impact strength = 153.50 Kj/m2 Average impact strength = 135.01 Kj/m2 1. Tensile Test GRPN2 S. No. 1 2 3 4 Width mm 2.10 2.10 2.10 2.10 Depth mm 10.16 10.16 10.16 10.16 Breaking Energy Kj Impact Strength 3.39 2.65 3.33 3.36 159.10 124.64 156.1 157.93 2 Kj/m (a)GRP Maximum impact strength = 159.10 Kj/m2 Minimum impact strength = 124.64 Kj/m2 Average impact strength = 149.44 Kj/m2 (b)GRPN1 705 International Journal of Emerging Technology and Advanced Engineering Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 2, Issue 12, December 2012) GRP Sr. no 1 2 3 Width (mm) Thickness (mm) Load (N) 12.50000 2.20000 2625.14 Tensile stress (Mpa) 95.45 12.80000 2.50000 3393.94 106.1 13.40000 2.50000 3203.11 95.6 Maximum tensile stress = 106.1 Mpa Minimum tensile stress = 95.45 Mpa (c) GRPN2 Average tensile stress = 99.05 Mpa GRPN1 Sr. no 1 2 3 Width (mm) Thickness (mm) Load (N) 13.70000 2.35000 3075.14 Tensile stress (Mpa) 95.5 14.20000 2.40000 3333.33 97.8 14.20000 2.40000 3685.23 108.13 Maximum tensile stress = 108.13 Mpa (d) GRPN3 Minimum tensile stress = 95.5 Mpa Fig. 3 Average tensile stress = 100.48 Mpa GRPN2 Fig. 3 shows the graphs plotted between tensile load and extension for different compositions. Fig. 3 (a) , (b) , (c) and (d) represent the load verses extension for GRP, GRP1, GRP2 and GRP3 respectively. Sr. no 1 2 3 Width (mm) Thickness (mm) Load (N) 13.75000 2.25000 3285.48 Tensile stress (Mpa) 106.2 13.80000 2.30000 3687.03 116.2 13.20000 2.10000 2895.41 104.45 Maximum tensile stress = 116.2 Mpa Minimum tensile stress = 104.45 Mpa Average tensile stress = 108.95 Mpa 706 International Journal of Emerging Technology and Advanced Engineering Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 2, Issue 12, December 2012) REFERENCE GRPN3 [1] Sr. no 1 Width (mm) Thickness (mm) Load (N) 14.96 2 3747.62 Tensile stress (Mpa) 125.3 “Fatigue Study Of E-Glass Fiber Reinforced Polyester CompositeUnder Fully Reversed Loading And Spectrum Loading”. [2] 2 13.70 2.2 3768.07 125.0 15.00 2 4195.36 139.8 Dr. Muhannad Z. Khelifa, Hayder Moasa Al-Shukri :6/4/2008 V. Naga Prasad Naidu, G.Ramachandra Reddy, M.Ashok Kumar, M.Mohan Reddy, P. Noorunnisha Khanam, S.Venkata Naidu “Compressive & impact properties of sisal/glass fiber 3 reinforced hybrid composites”. [3] Maximum tensile stress = 139.8 Mpa H.P.G. Santafé Júnior; F.P.D. Lopes; L.L. Costa; S.N. Monteiro “Mechanical properties of tensile tested coir fiber reinforced polyester composites”. Minimum tensile stress = 125 Mpa [4] Average tensile stress = 130.03 Mpa N. Srinivasababu K. Murali Mohan Rao J. Suresh kumar “Tensile properties characterization of okra woven fiber reinforced polyester composites” IV. RESULT ANALYSIS Tensile test S r. n o. 1 2 3 4 Shee t nam e GRP GRP N1 GRP N2 GRP N3 Ma x Loa d (N) 339 3.94 368 5.23 368 7.03 419 5.36 Tensi le Stres s (Mpa ) 99.05 100.4 8 108.9 5 130.0 3 Flexural test Flex Max ural Loa stres d s (N) (Mp a) 223. 189. 62 08 251. 191. 82 84 285. 193. 90 86 323. 206. 40 15 [5] Yeong Suk Choi, Min Ho Choi, Ki Hyun Wang, Sang Ouk Kim,Yoon Kyung Kim, and In Jae Chung “Synthesis of Exfoliated PMMA/Na-MMT Nanocomposites via Soap-Free Emulsion Polymerization” Impact strength (kj/m2) [6] K. E. Strawhecker and E. Manias June 20, 2000 “Structure and Properties of Nanocomposites” 133.8 135.02 149.44 153.50 This is the table for analysis of results includes the average values of tensile stress, flexural stress and impact strength for GRP, GRP1, GRP2 and GRP3 which show that in the increase of quantity of Na-MMT the mechanical properties are get improves and we can say that in order to improve the mechanical strength of GRP polymer composite we can add little amount of Na-MMT. 707 Poly(vinyl alcohol)/Na+Montmorillonite