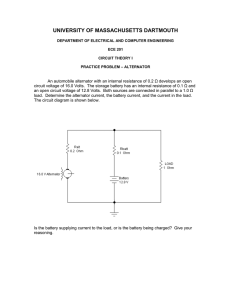

AIRCRAFT ALTERNATOR OWNER`S MANUAL ALTERNATOR

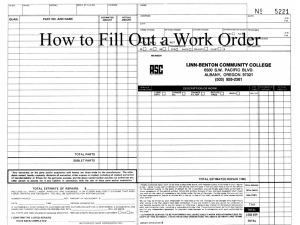

advertisement