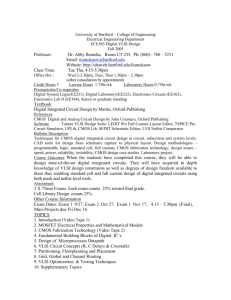

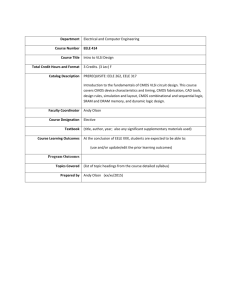

Layout, Fabrication, and Elementary Logic Design

advertisement

Introduction to CMOS VLSI Design Layout, Fabrication, and Elementary Logic Design Adapted from Weste & Harris CMOS VLSI Design Overview Implementing switches with CMOS transistors How to compute logic functions with switches Fabricating transistors on a silicon wafer and connecting them together Fabrication and Layout CMOS VLSI Design Slide 2 Silicon Lattice Transistors are built on a silicon substrate Silicon is a Group IV material Forms crystal lattice with bonds to four neighbors Fabrication and Layout CMOS VLSI Design Slide 3 Dopants Silicon is a semiconductor Pure silicon has no free carriers and conducts poorly Adding dopants increases the conductivity Group V: extra electron (n-type) Group III: missing electron, called hole (p-type) Fabrication and Layout CMOS VLSI Design Slide 4 p-n Junctions A junction between p-type and n-type semiconductor forms a diode. Current flows only in one direction Fabrication and Layout CMOS VLSI Design Slide 5 nMOS Transistor Four terminals: gate, source, drain, body Gate – oxide – body stack looks like a capacitor – Gate and body are conductors – SiO2 (oxide) is a very good insulator Fabrication and Layout CMOS VLSI Design Slide 6 nMOS Operation Body is commonly tied to ground (0 V) When the gate is at a low voltage: – Source-body and drain-body diodes are OFF – No current flows, transistor is OFF Fabrication and Layout CMOS VLSI Design Slide 7 nMOS Operation When the gate is at a high voltage: – Positive charge on gate of MOS capacitor – Negative charge attracted to body – Inverts a channel under gate to n-type – Now current can flow through n-type silicon from source through channel to drain, transistor is ON Fabrication and Layout CMOS VLSI Design Slide 8 pMOS Transistor Similar, but doping and voltages reversed – Body tied to high voltage (VDD) – Gate low: transistor ON – Gate high: transistor OFF – Bubble indicates inverted behavior Fabrication and Layout CMOS VLSI Design Slide 9 Power Supply Voltage GND = 0 V In 1980’s, VDD = 5V VDD has decreased in modern processes – High VDD would damage modern tiny transistors – Lower VDD saves power VDD = 3.3, 2.5, 1.8, 1.5, 1.2, 1.0, … Fabrication and Layout CMOS VLSI Design Slide 10 Transistor Abstraction 3D structure formed by fabrication 2D planar “layout” view Schematic symbol Switch CMOS VLSI Design Slide 11 Transistors as Switches We can view MOS transistors as electrically controlled switches Voltage at gate controls path from source to drain Fabrication and Layout CMOS VLSI Design Slide 12 Switching Logic conducts iff a•b (0 only) a a b s conducts iff a+b (0 only) d d s b a s a b d d s b conducts iff a'•b' or (a+b)' (1 only) CMOS VLSI Design conducts iff a'+b' or (a•b)' (1 only) Slide 13 Implementation of Logic Gates OR gate a 1 f(a,b) b a b a+b 0 0 0 0 1 1 1 0 1 1 1 1 Two problems – 1) when a=b=0, f(a,b) is undefined (floating) – 2) n- type switches do not conduct 1 well Two solutions – when f=0, connect output to 0v using n-type switches – when f=1, connect output to 1v using p-type switches CMOS VLSI Design Slide 14 Complementary CMOS Gates Pull-up network consisting of p-type devices Pull-down network consisting of n-type devices 1v (logic 1) P inputs output N Example: an inverter a a' 0 1 1 0 pull-up pull-down 0v (logic 0) ↑: a' a a' ↓: a CMOS VLSI Design Slide 15 CMOS Inverter A Y 0 1 Fabrication and Layout CMOS VLSI Design Slide 16 CMOS Inverter A Y 0 1 0 Fabrication and Layout CMOS VLSI Design Slide 17 CMOS Inverter A Y 0 1 1 0 Fabrication and Layout CMOS VLSI Design Slide 18 CMOS NAND Gate A B 0 0 0 1 1 0 1 1 Y Fabrication and Layout CMOS VLSI Design Slide 19 CMOS NAND Gate A B Y 0 0 1 0 1 1 0 1 1 Fabrication and Layout CMOS VLSI Design Slide 20 CMOS NAND Gate A B Y 0 0 1 0 1 1 1 0 1 1 Fabrication and Layout CMOS VLSI Design Slide 21 CMOS NAND Gate A B Y 0 0 1 0 1 1 1 0 1 1 1 Fabrication and Layout CMOS VLSI Design Slide 22 CMOS NAND Gate A B Y 0 0 1 0 1 1 1 0 1 1 1 0 Fabrication and Layout CMOS VLSI Design Slide 23 CMOS NOR Gate A B Y 0 0 1 0 1 0 1 0 0 1 1 0 Fabrication and Layout CMOS VLSI Design Slide 24 3-input NAND Gate Y pulls low if ALL inputs are 1 Y pulls high if ANY input is 0 Fabrication and Layout CMOS VLSI Design Slide 25 3-input NAND Gate Y pulls low if ALL inputs are 1 Y pulls high if ANY input is 0 Fabrication and Layout CMOS VLSI Design Slide 26 Switch Logic vs. Gate Logic Example: two-input multiplexer a b 2:1 f f=a, when s=0 f=b, when s=1 f=s'a+sb s CMOS VLSI Design Slide 27 Switch Logic vs. Gate Logic Two-input mux with gate logic (14 transistors) Two-input mux with switch logic (6 transistors) complementary pass transistor CMOS VLSI Design Slide 28 Implementing LUTs Multiplexor logic – simple switch network (a tree) – inputs: programming bits Bit0 Bit1 Bit2 Bit3 Bit4 – controls: inputs to CLB A' – output: function value However, series transistors A are slow – O(n2) Bit5 Bit6 Bit7 B' B C' C F CMOS VLSI Design Slide 29 Programmable Interconnect Switches connect wires at intersections Can also be used to segment wire Repeaters needed every so often – simple non-inverting buffers (2 inverters) – otherwise, too many switches in series slow down signal CMOS VLSI Design Slide 30 Master-Slave Register CMOS VLSI Design Slide 31 Dynamic Register CMOS VLSI Design Slide 32 Latch-Based Design Switches and/or gates compute new values to store on next clock cycle straightforward implementation CL φ2 φ1 this circuit can use the entire clock cycle – no wasted time - a form of retiming CL CL φ2 CMOS VLSI Design φ1 Slide 33 Static Memory Cell 8-transistor cell N-transistor only: 6T cell bit bit' rd or wr (rd or wr)' CMOS VLSI Design Slide 34 Dynamic Memory Cell 1-transistor cell precharge to intermediate voltage level storage capacitor is one end of transistor charge sharing with bus capacitance (Ccell << Cbus) extra demands on sense amplifier to detect small changes in bus charge destructive read (must immediately write back) CMOS VLSI Design Slide 35 Dynamic storage Capacitor implemented by gate capacitance of transistor No capacitor is perfect – charge leaks away through imperfect switches Must be replenished or refreshed – 'memory' lasts about 1ms Solution: periodically read the value and write it back CMOS VLSI Design Slide 36 Read-only Memory Cells To store constants or other invariant data Popular for control implementation bit1 bit2 bit3 read1 read2 programmable logic array structure (exploits distributed NOR gate structure) CMOS VLSI Design Slide 37 Multi-ported Register Cells Augment 6T cell for more I/O bus2' bus1 row-bus1 row-bus2 bus2 bus1' CMOS VLSI Design Slide 38 CMOS Fabrication CMOS transistors are fabricated on silicon wafer Lithography process similar to printing press On each step, different materials are deposited or etched Easiest to understand by viewing both top and cross-section of wafer in a simplified manufacturing process Fabrication and Layout CMOS VLSI Design Slide 39 The wafer Czochralski process – Melt silicon at 1425 °C – Add impurities (dopants) – Spin and pull crystal Slice into wafers – 0.25mm to 1.0mm thick Polish one side CMOS VLSI Design CMOS VLSI Design Crystal and wafer Wand (a finished 250lb crystal) A polished wafer CMOS VLSI Design The mask Illuminate reticle on wafer – Typically 4× reduction Typical image is 25×25mm – Limited by focus Step-and repeat across wafer – Limited by mechanical alignment CMOS VLSI Design 4X reticle Wafer Lithography Patterning is done by exposing photoresist with light Requires many steps per “layer” Example: Implant layer CMOS VLSI Design Reference: FULLMAN KINETICS Grow Oxide Layer CMOS VLSI Design Reference: FULLMAN KINETICS Add Photoresist CMOS VLSI Design Reference: FULLMAN KINETICS Mask CMOS VLSI Design Reference: FULLMAN KINETICS Expose using UV Light CMOS VLSI Design Reference: FULLMAN KINETICS Develop and Remove Resist CMOS VLSI Design Reference: FULLMAN KINETICS Etch Silicon Dioxide CMOS VLSI Design Reference: FULLMAN KINETICS Remove Resist CMOS VLSI Design Reference: FULLMAN KINETICS Implant Dopant CMOS VLSI Design Reference: FULLMAN KINETICS Inverter Cross-section Typically use p-type substrate for nMOS transistor – Requires n-well for body of pMOS transistors – Several alternatives: SOI, twin-tub, etc. Fabrication and Layout CMOS VLSI Design Slide 53 Inverter Layout Transistors and wires are defined by masks Cross-section taken along dashed line Fabrication and Layout CMOS VLSI Design Slide 54 Advanced Metallization - Copper CMOS VLSI Design Copper versus Aluminum ~ 40% lower resistivity ~ 10× less electromigration A View of Interconnect Layers CMOS VLSI Design Slide 56 Package-to-Board Interconnect © Digital Integrated Circuits CMOS VLSI Design 2nd Flip-Chip Bonding © Digital Integrated Circuits CMOS VLSI Design 2nd Package Types CMOS VLSI Design © Digital Integrated Circuits2nd Multi-Chip Modules © Digital Integrated Circuits CMOS VLSI Design 2nd