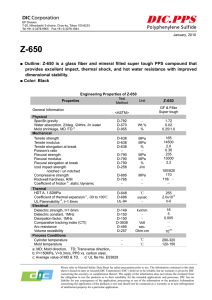

Fortron PPS Product Brochure (B240)

advertisement