The cycloconverter is a power-electronic equipment designed to

advertisement

J. Indian Inst. Sci,, Sept.-Oct. 1997,77, 397-419.

O Indian Institute of Science

AJITK. CHATTOPADWYAY*

FIEEE, FNAE, Department of Electrical Engineering, Bengal Engineering College (Deemed University), Howrah7 1 1 103. India.

Abstract

Significant developments have taken place in control, analysis, modelling and practical implementation aspects of

cycloconverters and their applications to the ndjuslable-speed ac drives. This paper attempts to make a comprehensive

and chronological review on the progress of research and industrial development, all over the world, to provide a

background information on the present status of cycloconverters and cycloconverter-fed drives. In the process, it

highlights the substantid research work done at the Indian Institute of Technology (IIT), Kharagpur towards developing practical control schemes and simulation models for cycloconvcrter-fed induction and synchronous motor drives.

Keywords: Cycloconverters, Drives, Power Electronics, Induction motor drives, Synchronous motor drives.

Major Discipline: Electrical Engineering (Acijustable-speed drives).

The cycloconverter is a power-electronic equipment designed to convert constant voltage constant frequency ac power to adjustable voltage adjustable frequency ac power without any intermediate dc link. The basic ;rinciple of this converter, conceived and patented by ~azeltine'

in 1926 is to construct an alternating voltage wave of lower frequency from successive voltage

waves of a higher frequency rnultiphase ac supply by a switching arrangement. Grid-controlled

mercury arc rectiliers were used in these converters in 1930's to obtain 1-phase 16"~Hz supplies for rtc traction motors in Gernmy from a 3-phase 50 Hz system2while at the same time a

cyclocmverter using thyratrons"or supplying a 400 hp synchronous motor was in operation for

some years as a power station auxiliary drive in USA, However, the practical and cornrnercial

utilisation of these schemes waited until the thyristors became available in the 1960's. With the

availability of large rating SCRs and later the development of micropmcessor-bascd control, the

cycloconverter today is a practical proposition in large power applications with synchro~iousor

induction motors like gearless mill drive in cement industry4-", centrifugal pump and compressors'" electric traction'"'', rolling mill^^"'^, variable-speed constant frequency (VSCF) sysmine winder^^'-^^, ship propellers25etc.

tems'" sstatic Scherbius

A cycloconverter is a naturally cornmutated converter with inherent capability of bidirectional power flow and there is no real limitations on its size which is otherwise restricted in the

case of a thyristor inverter due to the size of commutating elements. Here the switching losses

are considerably low, the regenerative operation at full power over complete speed range is

inl~erentand it delivers a nearly sinusoidal waveform resulting in rnininwn torque pulsations

and harmonic heating effects. It is capable of operation even with blowing out of individual

*Formerly with the Department of Electrical Engineering, Indian Institute of Technology, Kharagpur 73 1 302, India.

'40" w o o t o 5 uC

where &is the firing delay

maan output

voltage

-inversion

---, mean

output

currant

--

--,,

r e t t i f i cation

---.----

4

invar sion

-

rtrtificntion --..-

FIG.1. Output voltage wnveform for one phase of a thrcc phase cyclaconvertcr operating at 1.5 Hz ilrw 5 0 ti/

0.6 p. f. lagging load"'.

411ppIj.

thyristor fuse (unlike inverter) and the requirements regarding turn-off time, currcat ~.iscLinw

and dv/dt sensitivity of thyristors ace low, The main limitations of the naturally co~nnlutatcd

cycloconverters are (1) limited frequency range (less than half of the irnput t'sclcprency~for- subharmonic-free and efficient operation and (2) poor input displacetncnt m d powcr t':ictrbr, pas..

riculaly at low output voltages. However, with improved control lecl~ni~ucs'" thcsc p n b

lems are being overcome.

'".

Significant developments, that have taken place in control, modelling and m~ilysis.anti

application aspects of cycloconverter drives are focussed in the next few sections hcsc.

2. Cy doconverter control

2.1. Basic Principle of Operation

The process af cyclaconversion is illustrated in Fig. "'1 far a 3-pulse cycloconverter ;it 15 Hz,

0.6 pf lagging load from 50 Hz supply. As the firing delay angle a is cycled from zem at ';I' tt,

180 at 'j', half a cycle of output frequency is produced. For this load, it can be see11 tlrtit al-

CYCLOCONVERTER-FED DRIVES

3-PHASE 50UZ

SUPPLY

A

a C

399

P-GROUP

( A ) P o s i t i v e group o u t p u t v o l t a g e

VARIABLE VOLlAGE

VARIABLE FREQUENCY OUTPUT TO

3-PHASE LOAD

( 0 ) Nagetivsa group o u t p u t

(C

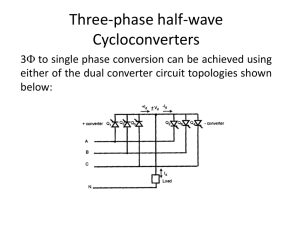

FIG. 7. Three-phase half-wave cyclocvnvertcr powur

circuit.

voltage

lnstontonaous difference voltage bdweun poaltiv

and n ~ g a B v vg r o u p

FN;. 3. Voltiigc waveforms for

cur-rent cycloconvertcr.

i)

six-pulsc circulating

though the mean output voltage reverses at X, the current (assumed sin~midal)remains positive

until Y. During XY the positive group of rectifier thyristors A,B,C are 'inverting'. A similar

period exists at the end of the ncgutive half-cycle o f the output voltage when D, E and F thyristors will be 'inverting'. Thus, the opcratiox~of the groups follows in the order of 'rectification'

and 'inversion'in a cyclic manner, the relativc durations being dependent on load p.f. The output frequency is that of the firing delay oscillation about the quiescent point of 90" (condition

when the mean output voltage is zero). Actually, the firing angle of each arm uf the co~lvertcris

defined by the time at which a control or refcrmce voltngc of' output frequency and a modulating voltage of input freqiicncy rise ic2entical. Variation of cx within the limits of 180" wtornaticnlly provides for 'n;tturnl' line cornmutation of thc thyristors. The ?-group or N-group thyristors (Fig. 2 sliotvs the basic 3-pulse or 3-phase halt' wave cyclaconverter with 18 thyristors with

3 thyristors in each group while use of 31111-w;ivc 3 phase bridge will need 36 thyristors with 6

thyristors in each group) receive firing pulses which are timed such that each group delivers the

same mean terminal voltage. This is :ichievrd by maintaining the firing angle constraints of the

two groups as at)= (1 80' - ~x,~).

However, the instantaneous voltages of lElc two groups are not

identical and large circulating current may result as shawn in Fig. 3 for a six pulse cycloconverter unless limited by intergroup reactors (circulating current cycloconverter) or completely

suppressed by removing the gate pulses from non-conducting group by intergroup blanking

logic (circulating cu~rent-freecycloconverter). These devcloprnents are concurrent with the

similar developments in dual converters For supplying reversing dc motor drives.

2.2. Control Schemes: Analog

Various possible analog control schemes for deriving triggering signals for controlling the basic

cycloconverter (Fig. 2) as developed in late 60Q'sand early 70's are described in l i t e r a t ~ r e ' ~ It

~'.

FIG.4. Deriving firing signals fur onc group'S.

which equation shows that the amplitude, frequency and pf~ascof thc r~utptttwltugrb catl be

controlled by controlling the corresponding parameters of tl~crcf'orcncc vcrltugcs, tttm ~ t ~ ; i k i t ~ g

the transfer-characteristic of the cyclocoxlverter linetir. Ttx dcrivriticu~trf' two r~>r~tlrfciiietltt~~y

voltage waveforms for the P-group and N-group converter 'Ixtrzks' in this kvriy i s illtxsrriklctl in

Fig. 6, The final cycloconverter output waveshape is cornposed of altcmitc tlalC-cyclescgallt:rits

of the complementary P-type and N-type output voltage waveforms which ctsi~~ridc.

wirh t k

positive or negative current half cycles.

2.2.1. Typical Control Implernentaticm

Fig. 7 shows a simplified block diagram of thc circulating current-frct. control circuit (IS Ihc.

cycloconverter implementated with IC's using cosine control" in the early seventics id the

3 Phaw

5SQHr sine waves

I

FIG.5. Derivation of cosine modulating voltage^“^.

t .F, sine wav

I

CYCLOCONVERTER-ED DRIVES

FIG.6 . Derivation of P-group and N-group output voltages.

FIG.7. Block diagram for a circulating current-free cycloconverter control circuit."

E+tlwcr. 2llc*cttnzrticsI . a h ~ i t o r . yin IIrl' K l ~ i i ~ ~ t gOut

p ~ ~~* i.tllc

' varictus blocks sl~owil,the group

seluctic~rlm r l h1;tnhing circuit i h ncrf ncc~ictlfor thc c'i~'culitting cu~rcrltrrictdc operation of the

C

3.

-

COMPARATOR

- 1NvEsTEs

MONO-STABLE

-.L ? M ? E

t

(6)

ANKING CIRCUIT

01 r[l F&

FIG.9. Block diagram of the main logic and triggering circuit (for phase n of the output only)".

CYCLOCONVERTER-FED DRIVES

-

AN0 GATE

P CROUP

(FIG

8)

AND C N E

N-GROUP

(FIG .Q)

FIG.10a. Group selection and blanking logic circuit for phase a, b. Cunent sensing circuit".

quency reference source using a simple hardware circuit is shown in Fig. 8, when a variablefrequency UJT relaxation oscillator of frequency 6fd triggers a 3-stage ring counter to produce

3-phase square-wave output of frequency fLlwhich is used to modulate a I-phase fixed frevariable amplitude sitlusoidal voltage in a 3-phase full-wave transistor chopper. The

quency

3-phase output contains Cf, -$J, V;.+J.;J, (3Lf-t-f;.)etc. frequency components from where

the 'wanted' frequency comporlent (f;.-,f;,) is filtered o ~ iby

t using low pass filters. For example,

z and frequency of the relaxation oscillator varying between 2820 to 3180 Hz,

a 3-phase 0-30 Hz reference output can be obtained with the facility for phase-sequence reversal. The block diagram of Fig. 9 shows the main logic and triggering circuits for one of the

phases - where cornpariators are used to coxnpare the refercrice voltages with modulating

voltages and the inverters shown act as buffer stages. Outputs from the latches feed the thyristor gates through AND gates and blocking oscillators, the second input to the AND gates

being from the group-selection and blanking circuit. The "first zero' crossing of the current

at the end of each half cycle is detected by a current-sensing cirwhich may be disco~ztin~~ous

cuit and processed through the grmp-selection rtnd blanking circuit (Fig. 10, for one of the

n

currents

phases) whcre comprators also monitor the refcreilce voltage source apart S ~ w load

to ensure proper group switching. The tIclay circuits dclay thc gate signals to the N-group thyristors until the already conducting P-gmup thyristors are completely off to avoid circulating

currents.

a.)

Fig. 1 1 shows typical oscillogmrns of the oulput currents of the irnplcrnexlted cyclocotlverter

feeding induction motors at two different frequencies.

FIG.11. Typical oscillograms of cycloconvener-fed induction motor curront at (a)). 163 Hz (b) 5 Hz.

CYCLOCONVERTER-FED DRIVES

405

sufficient for very low frequencies. Alternative sctremes like continuous monitoring of voltage

across each thyristor'7 or co~lductionstate of each SCR series thyristor-diode circuits"may

simplify the requirements of an accurate bank selection signal for eliminating the need of large

interphase reactors.

With the rapid development of microprocessors, software control of cycloconverters has been

attemlxed4"-"" m reduce cost atid complexity and increase the accuracy and reliability of the

controllers. Exly ;ittemptJ" was to directly imple~ilentthe conventional cosine timing wave approach i n connection with sinusoidal reference voltrige - in which casc it was recognised that

the digital compnriso~~

of two trigonoinetric functions as proposed by the numerical techniqiie

was too slow to be practical. An efficient :ilgoritlmnl was presented in" using regular sampling

method with desirable output perfosmance. Expcrirnental arrangement was built around M6800

evaluation kit with MC 61540 t i n w modulc and an MC6S30 pia unit. There was no need to generate three ;~ctualtiming waves, nor u continuous reference signal and six channel cotnpu~-ator

circuits as in the analog CiW.

Later dt.velopments iilcludes the digital cycloconvcrtcr conirol (DCC) based on the subcliw11crc ;L sioosoidal output voltage is ;ippmximated by ;i stepped wavevided interval

fhrm to get a suit;iblc ainpiitude !'or tho m a n outpiit voltugc at c~1c11subdivided interval - tlic

mean value of which was utilised to dcter~nincthe firing anglcs. New methods arc suggested

i*,50.~o,~~~l

whcre all the input cosine witIics arc. trunst'cst-t.dwith n sct of pnmllcl lil~esby nicans of

co-ordinate transfor~natior?or il p h ; plarw

~

called a 'time pr'occss c1lar.t'. 'Tlic stsaiglit line approxini;ttions avoid the use of trigontmi~\tricor invui.sc tsip,orzomctric I'nnctions. S O ~ irnC

s

p - ~ ~ v e n ~ e n t simplementing

iil~

cosinc wave crossing pulse liming ~ ~ ~ e t h oi nd microcomputerh;wd cycloconva.ter 11:ive hecn suggestedi* seceotly.

For a six pulse non-circulating current cycloci~nvest~r-Ccci

synchrt~nousmotor drive with a vcctor control schc~nuand flus c~hscrvcr,a conhitiation nt' nnr\log and digitid control (called hybrid

'1.1

control sche~ne)Ilas beon reccntly devclopcd uk 11'1' KI~aragpur

. Hcre the timction such iis

comparison, group sclccrion, blanking hetwt.cn the groups and the triggering signal generation,

filtering and phase conversion ilre loft to thc andog cotitluller and the digital controller t:ikes

care of more serious tasks like voltiige decoujiing for cuuent regulation, flux estiniation using

observer, spoecl, flux and Sitlld current xgulutors using PI-controllers, position and speed caleutation leading to an improvement of sampling time and dcsign accuracy. The scheme us sllowtl

in block diagram fcxm in Fig.13 has bren ir~iple~~letitud

with a 386-DX PC based system with

387 support'".

3. Cycloconverter-contro11td induction motor drives

In earlier applications"', cycloconvester fed multiple induction motor drives were used to drive

hot-strip mill run out table motors, In one installrition, 300 motors of 2.4 hp, 2 12 I-pm each were

used and the speed rringe (1 3-0-13 Hz) with 6 pole was suitable for the application with a 60 Hz

system. Individual induction motor drive for high performance servo applications with in-

CorPrated 'slip-limit' devicdO,'flux controller'"" and controlled slip-frcqoeoey driw ftir diwA

66

electric h m m t i v e Were developed in 1960's. Slip power corumllcr drives with diprillg induction

..

motors either in the form of a cycloconvertcr type thyristor com*~~~likt&"

in thc t m r to

lnJect a slip-frequency emf as in the case of a stator-fed commutator motor Wig. 1-1 i)r with

c~cloconverter2'-"were also developed. Another interesting q~plic:ttion of C ~ C ~ C W

verter was in realising the dc series motor chartlcteristics with stator and rotor windings cunnetted in series6' where the torque angle was controlletl by ;i shaft coupled iritnsducc~which

the firing ofthe thyristors (Fig. 15) to provide a stabilised opcrirtioo.

-

CYCLQCONVERTER-FEh) DRIVES

FK;. 13. Cyclocon\~ertcr-rypcthyristor commtitator motor'",

contrd schetm as developed by Toshiba with Sumitorno Industries o f Japan consists of three

36-bit xnicroprocessors and six singlc chip microcomputers for executi~rgvarious colltrol functions and firing of 72 thyristors. A high performance cross-current type cyclocollverter eonfiguration, controlled by two 16-bit microprocessors was suggested in"' where the output voltage

waveform is built up by simultaneously using positive and negative converters and allowing the

nlem voltage of the two converters to appear rzcrass the load. The advantages claimed are increase of output frequency limit and high input pf.

4. Cycloconverter-controlled synchronous motor drives

The first ever experi~nentalsemiconductor cycloconverter variablc drive began with a synchronous motor driveg'. The cycloconvcrter-fed synchronous motor proved itself successful in

AJIT K. CHAT'I'OPADHYAY

'ION

POLYPHASE

DOUBLY-FED MACHIN

FIG.15. Cycloconverter control of a doubly-fed induction motor"l'.

practice in the cement industry for large gearless Tube or Ball mills ( S bIW) since carly i'.j70',

as developed by Siemens and Brown Boveri. One of the early inst:rll;~tiof~s

( I 9hV1 1*111ph1 ~ ;I

~ 4

motor rating of 8700 hp, having a rotor drum 5 m in diameter 2nd 16.5 rn long w h i k tlrc. stator

IjP!:C:

6-Pulse Cycloconverter & Control

Vft: Vector Rotator

f

CYCLOCONVERTER-FED DRIVES

4 10

construction was similar to that of a hydroelectric generator with 44 poles requiring 5.5 Hz for

~iiaximumspeed of 15 rpm. The motor is flanged into the mill cylinder without any additional

bearings or 'wrapped' directly round it - known as 'ring motor'"'. With 'self control mode' or

;IS 'ci~mmutatorless;K nlotoi'", hunting and stability problems are eliminated and the torque is

not limited to pull out value.

Wirh I'ield, control, the operation can be at unity power factor. With 'field orientution' or

vector control '32'."2.04 (Fig. I(,), the transient magnetizing current demand to maintain the c ~ t e d

t1~1xcan temporarily be supplied t'ro~nthe stator side to improve the response time instead of the

field ousrent control which is sluggish because of large time conslant. A stator flux orientcd

vector control scheme fi)r a 6-pulse non-circulating current cycl~~convertes-Si3dsynchronous

nnotor with u flux observcr as developed recently at I.I.T. Kharagpur for a rolling mill drive is

reported in Reference 'I4. Fia. I h slmws the implementation scheme which aims at a stator llux

oriented vector control that maintains ;I spatial orthogonality between the flux vector iy, and the

;irmature current vector i,, as hewn In the space phasor diagram of Fig. 17. The reference speed

:ind the reference flux conimtlnds are given to the vectur controller that generates the reference

analog voltages for the cycloconvertcr and the field converter. The stator flux is estirnated by a

closed loop robust reduced order flux observer. Referring to Fig. 16, C, is the speed controller

that generates the torcpe cornmand which is divicied by the stator flux to generate the torque

component of current i$,. The ~nagnclisingcurrcnt dong the flux :lais (i,;,) is obtained lion1 a

tlux cnntro1le1-C,. Thc trmsicnt stator flux component of currcnt is,,, is obtained from tlx rclutionship, ia,,,, = ii, - l,(,cosS which c1co:iys down to zero in the steady state. The steady slot?

djsplucement mgle is deeiclccl by the displacement angle controller. The set value of the field

current is obtained fin111the rehtion i,,, = iir / C O S Ci

~ . is the field cunnlt controller that generates the control voltage tbr triggering the fielcl converter. The vector rotator (VR) t~~msf'onns

the vcctors fro111 the t\vc~ixcsflux-tory~rcseference finme to abc stationary reference Srnrne.

Thc observer and the co~~troller

design aspects togetlicr with il PC-based impleriwxtaticm are

cfctnilcd in ~cferencc'"'.

The application ot' cycIoconvcrtei'-kci ,syt~ch~.onous

motor drive with vector control hnvc

been estc~ldcdto n)lli~ig~ i l l s ' (?/-I

" MW), minu-winders :~ndhiiuliye" and traction" wliicli

were dominatccl h t tic drives clue to rccluirements of spccd ucc~u'acyand dynamic speed c o n ~ o l .

Methods 01' cornpwsating armaturl: reaction and crrntrol delay of' c~irrentcontrol circuit wcrc

suggested in ~efcrencc".

.TWOclifkrrnt modes of operution wcrc uscct to control the cycloconvertcr ovcr tlic entire

spcal nr frequency range for a cycloa~ovcrtcr-fcdsynchronous motor drivelx: sinusoidiil iind

trapezcridnl. The trapezoidal mock is cmployed to itnprove the mains powcr factor in the upper

speed range where the cyclocorlverte~.also has lo supply higher v o l t q p . Closed loop conlrol

methods with static and dynamic llux models were i~lsudescribed in ~efcrencc"'.

Syilci~ronousmachines l w c been preferred as they can he built for higher capacity at low

speed ;md their speed can be maintained canst;mt for a particular frcquency regardless of load

or line voltage variation wid the line power factor c m be improved thrrwgh excitation contrd

with possible dual method of commutation".

FIG. 17. Space phasor diagrm of' u vector controlled

synchronous motor'",

tyw

An extremely flexible drive arrilngernent cnf a cycioctm~wtcr~

cc~ltlt~i~~t~t!ttx'E~*'c~

mrttw

simulation analysis of cycloconverters cirives

Digital and hybrid computer sirnulation of induction motor drive feti I'rm grc~ttp- r t igphrcil

mode cycloconverter which provides a trapezoidal wnvelbnn l w c heea sttldicd ciirlicl-'" ". .I

comprehensive two-axes digital model of a 3-pulse phase contrrdled cyclc~cc~nv~r~~r-ir~~~t~cti~ur~

motor system suitable for dynamic and stcudy state anitlysis d'thc systems wits prcsvnlctiS'" '

FIG. 19. Cycloconvener equivalent circuit

(P/~Nw&;

LE= L;E, = KEdosinw,t.

'', R E =

FIG. 20. Representation of induction motor with

switchings in the statorx3.

CYCLOCONVERTER-FEDDRIVES

'

FIG.21a. Digitally computed steady-state currcilt wavehml for 5 Hz. h. Dyna~nicperformance of induction motor

with 3-pulse cycloconverter. Digital siiztulation results, j;,= 16

k, = 0.806, V, = 0.5 pu, Tr = 0.5 pu (Noncirculating current ~mde)".

for both continuaus and discontinuous current operation under circulating ns we11 as noncirculating current operation. The induction motor model used follows the approach suitable for

any reference frame". A generalized mathematical model has been derived in ~eference" for

this purpose using switching variables to represent thyristors' conducting states (Fig, 20) and

combining five sets of equations in five relevant modes of operation involving only a 4 x 4 matrix without need of any matrix inversion. The cycloconverter model for digital computation of

output waveforms is discussed in ~eference*'.One of the methods which is very fast and convenient is the 'cross-over points' method - which gives the cross-over points (intersections of

modulating and reference waves) and the conducting phase numbers for both P- and "J Oroups

Fw. 22a. Sinusoidnl mode OF operation (a) Simulated (b) E~pelirnental"~

6-pulse cycloconvcrlcr-ft'tI

motor drive, 300 rpm, U.P.F.

FIG.22b. Trapezoidal mode of operation (a) Simulated (b) Experimental".

,>~)~.jlst,l~~,tl~

CYCLOCONVERTEIZ-FED DRIVES

'

.

,)1.?."

. , .,. .2. .I{.%'

, . . . , .. . . ,

-

R?li

!!we .

; r . . . , . . . . , . . . . , . . . .T.*.

.,

FIG.3 2 ~ Response

.

of the drive to step speed chmges (:I) Simulated (b) ~ s ~ e r i m e n t a e300

l ~ " to -300 rpm.

out vector control in'". Fig22 shows typical simulated nild experimental results (for sinusoidal

:md tmpezoidaI mode of operation). The fhctors to bc considered for selecting either a synchronous motor or an induction motor for cycloconverter use have becn discussed in a recent pa-

pei".

A comprehensive but bricf survey of cycloconvc=slersand their applications to the control of ac

driveb has been presented here to provide background infimmtion regarding the present research and development trends in the area. Systems e~nployingcycloccmverter are gaining

ground steadily with iilciusion of microcomputers and literature on them have proliferated.

Only some salient features ancl significant cievclopn~erltshave been highlighted here and fixproper design and eva1u:ition for a particular :ippIication, one has to study in depth many tradeoff considerations and relevant texts given in the references.

References

An irliproved method of and apparatus for converting clecrric

powcr, British Pmnt Nu. 218. 695, 1926.

2. R~ssni,H.,

hltwury Arc Consertcrs, Sir Issac Pitman & Sons, 19%.

4. Rrcn, E. A. E.,

Conccpls of pirless Ball-Mill drives, lEEE Trorts., 1969, Vo!.

IGA-5, pp 13-17.

5. BLAUENSTEIN,

E.,

The first gearless drive for n Tube Mill, Brown Boveri Review,

1970,57, pp 96-105.

L ~ ~ t i l i iJ.,

t,

Static Frequency changer supply system for slynchronous mrtor

driving tube mills, Brown Boveri Review, 1c270, 57, pp 1 12 -1 10.

7. Sttmmkr, H.,

Drive system and elcctric control squipnrent of the gciirless hihe

mill, Brown Boveri Review, 1070,57, pp 120-128.

8. WURCLER,

H. V,,

The World's First Gearless Mill Drive, IEER f i m v . 1C;rl-A. 1970,

pp 524-527.

9. Richlein, D.,

Gearless Drive for a Cement Mill, Sicnlens Review, 1971, 38, pp

398-40 1.

10. ALLEN,J. A., WYETW,W. A.,

NERZOG,

G. W. AND YOUNG,J. A. I:,

Electrical aspects of the 8950 hp Gearless Ball Mill Drive at

St. Lawrence Cement Company, IEEE, 1A-11, 1975, pp 681-687.

6.

11. Salzmann, T.,

Cycloconverter and automatic control of Ring Motors drjving lube

mill, Siemens Review, XLV, 1978, pp 3-8.

12. MUSIL,R,,

State of development of Gearless drives of' Ball Mill, Siemens

Review. Vol.XLIII,3, 1976, pp. 542-546.

13. Weiss, H. W.,

Adjustable-speed ac drive systems for punlp and conipresstrl iipplications, IEEE Trans. IA, Vol. IA-10, 1, 1975, pp 162-107

L.J., MATOUKA,M. F.,

14. JACOVIDES,

Shimer, D. W.,

A cycloconverter synchronous drive for traction applications, IEEE

Trans. IA Vol. IA-12,4, JulyIAug 1981 pp 407-41 8

SAIJO,

T., et ul.,

Charactenstics of linear synchronous niotar clrivc cyclocontatc~

for Maglev Vehlcle ML-500 a1 Miya~ak~

Test Track', 16Eh' lirrni.

IA-17, 1981, pp. 533-543.

TIMPE,

W.,

Cycloconverter drives for rolling m~lls,lEEE Trmr ljl- 1S, 1982,

41, pp 401-404

SUGI,K.,et al.,

A microcomputer-based high cap'lcity cyclrtconvcrter d111u

matn rolling mill, Proc, IPEC, Tokyo, 1983, pp 744-75.5

NAKANO,

T.,ONSAWA,

H. AND Endoh, K.,

A high performance cycloconvertcr-led synchroncw n1.1c11raeilnbC

system', IEEE Trc~ns.IA-20, 1984,5, pp. lX"?- 1284.

CHIRGWIN,

K.M. AND STRATON,

L. J.,

Vanable-speed constant frequency gcnerdnr \ystibm IOI ,utCr,tft,

AIEE Trans. Vol. 78, pt It, 1959, pp. 3 0 4 3 10).

CHATTOPADI-IYAY,

A. K.,

An adjustable-speed induction motor drivc wlth *I cyi k tcom cbrrur type thyristor commutator in the rotor, IEEE Trtrn~Id-$- 14, 1 '17 K. 2.

pp. 116-122.

SMITH,

G. A.,

Static Scherb~usSystem of inducttorl motor colltrol, i'rrtr IEiIi.

Vol. 124, 1973,pp. 557-560.

DIRR,R., et ul.,

New Electronic control equipment fur Doubly -fed ~alinct~oa

nw

tors of high rating, Siemens Rev. 3, 1972, pp. 121- l2h

Gr~ss,F.S.,

Power Engineering for tomorrow's industry-plmi. Elccrl cnr 1c.t , ~ n d

Power, 1982, pp. 41-45.

101

24. MADISETR,

V, K. AND RAMLU,

M. A.,

,Trends in the Electronic Control of Minc EIoists, 1EEIi 7h11i.v. I.4.

22, l986,6, pp. 1105-1 112.

25. HILL,W, A., et al.,

A vector-controlled cycloconverter drive for ;In icu-hrettkcr, lIXI3

Trans. IA-23, 1987, 6, pp. 1036-1041.

CUCLOCONVERTER-FEDDRIVES

415

26. BIRR,B.M. AND FORD,J. S.

Improvement in phase-controlled circulating current cycloconverter

using communication principles, Proc. IEE, Vol. 121, 1974,

pp. 1146-1 149.

27. SMITH,

G. P. AND RAMSREN,

V. S.,

A study of new technologies for the control of cycloconverters with

reference to ac mechine control, Proc. Inst. of En,pheer.s (Austraiia), EE-14, 1978,2, pp. 92-96.

Control method and upper limit frequency in circulating - current

type cycloconverter, IEEE - IAS Ann. Meeting Colt$ Rec., 1982,

pp. 3 13-323.

P.W. AND JACOVIDES, L. J.

29. SHIMEII,

An improved triggering method for a high power cycloconverterinduction motor drive, IEEE-IA-15,1979, 5, pp. 472-481.

30. BOWLER,

P.,

The application of cycloconverter to the control of induction rnotors, ZEE Conf Pnb., 1965, 17, pp. 137-145.

3 1. PELLY,

B. R.,

Thyristor phase-controlled converters and Cyclocon~~errers,

Wiley

Interscience, 1971.

32. Mcmurray, W.,

The Theory rind design of cycloco~zvertel;r,The MIT Press, Cambridge, 1972,

33. GYUGI,

L. AND PELLY,

B. R.,

Srcitic Power Prepcncy Cllangel;~,John Wiley & Sons Inc. New

York, 1976.

34. BLAND,

R. J.,

Fslctors affecting the operation of a phase-controlled cyclocon

verter, Proc. lEE, Vol. 1 14, 1967, 12, pp. 1908-1916.

35. LAWSON,

L. J.,

The Practical Cycloconverter, IEEE Truns. Vol. IGA-4, 1968, pp.

141-144.

I. AND MIYARI,

S.,

36. TAKAHASI,

Triggering schemes and waveforni analysis of cycloconverter,

Elec. Engg. in Jqwn, Vol. 90,1970, 2, pp. 95-104.

37. HAMHI-IN,

T. M. AND BARTON,

T. H.,

Cycloconverter control circuits, ZEEE Trans. M-8, 1972, pp. 443453.

38. CW.ATI-OPADHYAY,

A. K. AND Kilo, T. J.

Simplified control electronics for a prcictical cycloconverter, Int. J.

electronic.^, Vol. 43, 1977, 2, pp. 137-1 50.

39. SC'HONUNC~,

A. AN11 S'TEMMI.I:R, H.,

Static frequency changer with subharnomic control in conjunction

with re versiblc speed ac drives, Brown Boveri Review , Vo1.51,

1964, pp. 555-599.

40. REVANKAK,

G.N. AND NAI.I.ATHAMNI,

K., Three phase half wave cycloconverter, JITE(I), Vo1.18, 1972 2,

pp. 79-84.

3 1 . WALI)EN,

J. P. ANI:, TURNBULL,

F. G.,

Adjustable voltage and frequency polyphase sine wave signal gcncrator, IEEE IAS Con$ Rcc.. 1974, pp. 10 15-1 0 19. .

32. PARASURAM,

M. K,AN[) RAMASWAMI,

B., A three phase sine wave reference generator for thyristosizcd motor

controllers, IEEE Trcm. ZECI-23, 1976, 3, pp. 270-276.

43. RAHAMAN,

A. AND Haque, S. B,

A simple three-phase variable frequency oscillator, Irlr. J. Electronics, 1982, Vol. 53, 1, pp 83-89.

44, CLARKE,

D.J. AND SEN,P. C.,

A versatile three phase oscillator, IEEE Trms. IECI-24, 1977, 1,

pp. 57-60.

416

AJIT K. CHATTOPADHYAY

45. MATOUKA,

M. F.

Read only Memory (ROM) trigger generator for phase controlled

cycloconverter, IEEE Trarrs. IECI-25, 1978,2, pp. 155-164.

56. B ~ o w u G.

, M. iwo Szebades, B

A flexible hybrid firing controller for cycloconverter drives, IEEE

Trans. IE-33, 1986,3, pp. 297-303.

47. TADAKUMA,

S. ~LUDTAIMURA,

Y.,

Current response simulation in six phase and twelve-phase cycleconverters, IEEE Trans. IA-15, 1979,4, pp. 41 1-420.

48. ISSAWI,

A. M. et al.,

A novel twelve pulse cycloconverter for the speed control of induction motors, IEE ConJon Power Elecr. and Varaible Speed

drives, London, 1984, pp. 257-260.

A microprocessor control of a three puke cycloconverter, IEEE

Trans. IECI-24, 1977,4, pp. 226-230.

49. CHEN,H. H.,

50. SINGH,

D.AND HOFT, G. R.,

Microprocessor-controlled single phase cycloconverter, IEEE

Trans. IECI-25, 1978,3, pp. 233-246.

E. D.,

5 1. Tso, S. K. AYD SPWNER,

Efficient Microprocessor based cyclonconverter control, Proc.

IEE., Vol. 127, 1980, B3, pp. 190-196.

57. TSO,S.K. AND LAUNG,

C. C.,

Microprocessor control of triac cycloconverter, Proc. IEE, Vol.

130,1983, B3, pp. 193-200.

53. BETZ,R. E. AND Evans, R. J.,

Microprocessor control of a cycloconverter, IEEE Trans., Vol.

IECI-32,1985, 2, pp. 120-130.

54. ICHIDA,

H.. et al.,

Microprocessor-based digital control (DCC) cycloconvener application to' induction motor speed control, IEEE Trans. IECI-32,

1985,4, pp. 414-421.

55. SHARDE,

N. K., er al.,

Microprocessor control of cycloconverter Techniques for implementation and testing, IEEE Trans. IE-33, 1986, pp. 281-291.

56. MIBAZARA,

S.. et al.,

'

A new method for developing the control scheme of a CVVF cycloconverter, IEEE Trans. IE-33, 1982, pp. 304-309.

57. TSO, S. K.x.DTang, K. H.,

Digital control stratagies for sinewave - output cycloconverters,

IEEE Trans. IE-37, 1990, pp. 70-76.

58. A ~ s o vG.,

,

A novel algorithm for microcomputer based digitally controlled

cycloconverter, IEEE Trans. IE-38, 199 1 , pp. 404-405.

59. MIYAZA\VA,

S., eta[.,

Effective approximations suitable for the control algorithm of

microprocessor-based control of a single-phase output cycloconverter, IEEE Trans. IE-30, 1989, pp. 560-567.

60. MIYUAWA,

S., et a/.,

A novel strategy for microcomputer based control of a single-phase

output cycloconverter, IEEE Trans. IE-36, 1989, pp. 560-567.

61. VEDA,R., er al.,

Stabilization of bank selection in no-circulating cycloconverter

by means of reliable current zero and current polarity detection,

IEEE Trans. IA-20, 1984, pp. 827-833.

62. Hosada, H., er al.,

A high performance cross current type cycloconverter-fed induction motor drive system, IEEE Trails. IA-24, 1988, pp. 479-486.

63. HAMILTON,

R. A. AID LEZAN,G. R.,

Thyristor adjustable frequency power supplies for hot strip mill

run-out table, IEEE trans. IGA-3, 1967, pp. 168-175.

Precise controt of a three phase s q u i d cage induction motor

using a practical cycloconverter, IEEE Trms. JG.4-2, 9966, pp.

774-280.

65. t l c c ~R.

, aso MEYER,M.,

A static frequency changer-fed squire1 cage motor drive for vwiable-speed and relfersing,Siemens Review, 1963. pp. 1 0 1 1 0 5 .

66. PINTER,

6.E.,

The cycloconverter adjustabie-speed drives, Machine Design.

1966, pp. 150-157.

67. NASSE,K.,

Control of cycloconverters for feeding of asynchronous machines,

Proc. WAC Comrol o f P o n e r Elecirorrics and Elect. Drives, 1977,

pp. 537-546.

68. MAYER,

C. B.,

High response control of stator watts and vars for large wound

rotor induction motor adjustable speed dpives, IEEE-lAS 1979 . A m

Meet. Rec., 1979. pp. 817-823.

69. LONG,W. F. AND Schmitz, N.D.,

Cycloconvesder control of the doubly-fed induction motor, IEEE

Trans. IGA-6, 1990, pp. 349-356.

70. HUNTER,

6.P. .4NDRamsden, V. S.,

New improved modulat~onmethod for a cyc1oconvester driving an

~nductlonmotor, Proc. IEE, Vol. 135, pt B, 1988, pp. 324-333.

7 1. KURUSOWA,

R., er nl.,

A mxrocomputer based high power cycloconverter-fed induct~on

motor dnve, IEEE-IAS Ann. Merr Rec., 1982, pp. 162-467

72. TSVCNIYA,

T.,

Basic characteristics of cycloconverter type commutator Jess motors, IEEE Trutts. IGA-6, 1970, pp. 359-356.

T. AND KOBATA,

M.,

73. MAENO,

AC cornmutatorless and brushless motors, IEEE Trans. P.4S-91,

1972, pp. 1176-1181.

71. FINLAYSON,

P. T.AND WASHDLKN,

D. C..

Cycloconverter-controlled synchronous machines for load compensation on ac power systems, IEEE Truns. 1.4-10, 1974, pp. 806813.

75. 0tiu-1OUMA, T.,et al.,

Cycloconverter-fed synchronous motor drive for steel rolling mill,

IEEE -IASAi.m. Meet., 1978, pp. 820-827.

76. TERENS,

L., el nl.,

The cycloconverter-fed synchronous motor, Brown Boveri Review

U5, 1982, pp. 122-132.

77. BLASCHE,F.,

The principle of field orientation as applied to the new transveclor

closed loop control system for rotating machine, Siemens Review,

Vol. 39,s. 1972, pp. 217-2".

78. B;\YER,K. H., el al.,

F~eldonentated close-loop control of a synchronous machine wrrh

the new Transvector control system, Sicmens Review, Vol. 39,

1972, pp. 210-113.

79. Ahla~o,C. S.,

An ac equivalent circuit for a cycloconverter. IEEE TI-cms. IG.4-2.

5, 1966, pp. 358-362.

80. KWAN, S. D., et al.,

Digital simulation of n high performance ac drive ;system. lEEE

Trans. 1.4-10, 3, 1 9 7 3 . p ~ 391-396.

.

8 I . Krause, P. C., er a!.,

Application of andog and hybrid computers in Electrical Power

system, Proc. IEEE, Vol. 62, 1971, pp. 994-1009.

418

AJIT K. CHATTOPADHYAY

82. CHA~OPADHYAY,

A. K.AND Rao, T.J.,

Digital simulation of a phase - controlled cyclooonvcrtcr inrluction

motor drive system, IEEE-IAS Ann. Mtvtirt,q Rtlc"., 1078, pp. 85.3860.

83. CHATTOPADHYAY,

A. K.ANDRAO,T. J.,

A generalised method of computer sinmulation of induction niotors with stator current discontinuities and its application ttr ii

cycloconvcrter-fed drive, IEEE Trrins. Vol. IA-lli, 1980, pp. 2.74241.

84. KRAUSE,

P.C. AND THOMAS,

C. H.,

Simulation of symmetrical induction machinery, ZEEE 7hin.s. PAS84,1965, pp. 1038-1053.

A. K. AND RAO,T.J.,

85. CHATTOPADHYAY,

Methods of digital computation of phase-controlled cycloconvertcr

performance, IEEE-IAS Ann. Mcer Rec., 1978, pp. 432439.

86. CHATTOPADHYAY,

A. K.AND RAO,T. J.,

State variable steady state analysis of a phase-controiled cyclocunverter induction motor drive, IEEE Trans. IA-15, 1979, pp, 3 133 19.

87. CHATTOPADHYAY,

A. K.,

Analog computer simulation of an adjustable speed induction rnotor drive with cycloconvener type thyristor coInrnutntor in the

rotor, IEEE Traru. IECI-22, 1975, pp. 433440.

88. CHATTOPADHYAY,

A. K.,

Digital computer simulation of an adjustnble speed induction noto or

drive with cycloconverter type thyristor cornmulator in rhe rcbtcr,

IEEE Trans. IECI-23, 1976, pp. 89-97.

89. SZKLARSKI,

L. M. AND DZIADECKI,

A.,

The analysis of dynamics of induction niotor drives o f minewinders with frequency control, Proc. IFXC- S w p . on C'rrrrrtid of

Power Elec. and Drives, 1977, pp. 699-701).

90. MAHMOUD,

S. AND LEDOEUFF,

R.,

A simulation study of an optimal nun~criculcontrol 01' a tl~tccphase cycloconverter, Electric Ilkic~hiric~s(111d l'rr,t3r1r. .Yl'srt'ta,\.

1984, pp..325-334.

9 1. GRIFFITN,

D.C. AND ULMER,R. M.,

A semi-conductor variable speed ac n~otorJrtvc. f:'lt*c.~ 1 : n g ~,

1961, pp. 350-353.

92. BOSE,B. K.,

Power Elecronics & AC Drirw, Prenticc Hall, Ncw Jerwq. 1OSh

93. FUJIWARA,

M., e t al.,

Development of large capacity reactive power ~ o t ~ y ~ i ' sci~ictJ ~\ \ d

converter, Proc. IPEC, Tokyo, 1983, pp. 1110- 1-t.W.

94. DAS,S. P.AND CHATTOPADHYAY,

A. K.,

95. DAS,S. P. AND CHATTOPADHYAY,

A. K.,

96. DAS,S. P. AND CHATTOPADHYAY,

A. K.,

97. DAS,S. P. AND CHA-ITOPADHYAY,

A. K.,

Design and simulation of il rohusr rcduccd osdcr nhwricr lor ,t

synchronous nlotor drivc, GN$Yroc. NS'C'W. I>uy;tlh;tgh (A~r,i),

1995, pp. 619-622.

CYCLOCONVERTER-FED DRIVES

419

Simulation of cycloconverter-fed three- and six-phase synchronous

motors during discontinuous stator current, Pruc. Int. Cunf oil

Evolution arid Modem aspects o f Syn. Mc~chhes,Zurich, 1991,

pp. 367-372.

99. LEWIS,E. A,,

100. DM, S. P.,

Cycloconverter drive systems, IEE Cot$ Proc. PEVLl'96, 1996,

pp. 382-389.

Design, sirnulation nrzcl PC-based ir?z~~le~nerzr~~tioiz

of a high per.formarzce cyc10converte1~-fedsynchrurzou.~motor drive system.

PhD Thesis, submitted to Elec. Engg. Dept., IIT Kharagpur, September. 1996.