The Advantages of High Efficiency Sample

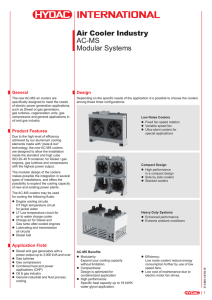

advertisement

"The Advantages of High Efficiency Sample Coolers" What Size Sample Cooler Do I Really Need? In visiting power plants throughout the world, we have run across many different types of sample coolers. Some are a homemade variety (coil tubing in a coffee can), others shell and tube type heat exchangers, while others are more sophisticated coil and shell coolers similar to those made by Sentry. Commercially available coolers generally range from one to five square feet of teat transfer surface. Selecting one size cooler for all samples is uneconomical, and can be hazardous to personnel and/or equipment. Specific temperature, pressure and flow conditions should be considered for each sample point. Unfortunately, many coolers that we see are too small or inefficient to reduce the sample temperature adequately. This has multiple effects: 1. If the grab sample becomes too hot to handle, the operator will throttle the flow to unacceptably low levels. You are no longer getting a contemporary sample. This is a universal problem with coaxial (tube in a tube) coolers. 2. Analyzer accuracy suffers as the sample temperature gets further away from 25°C. 3. Plastic parts such as cation columns can be damaged. 4. If secondary cooling is being used, more load is dumped onto the refrigeration system when the primary coolers do not keep up. This latter effect commonly comes up when we are asked to add secondary cooling to an older system. We have to convince the customer to first replace the primary coolers in order to reduce the load which would otherwise have to be picked up by the chiller. (Continued on next page) Every Employee an Owner, Every Customer a Commitment Sentry Equipment Corp • PO Box 127• Oconomowoc, WI 53066 Phone: 262.567.7256 • Fa x: 262.567.4523 • E-mail: sales@sentry-equip.com (Continued from previous page) How big of a sample cooler do I really need? Based on a 1200 cc/min blowdown sample at 2500 psig and 643°F, the performance is shown below of three different size sample coolers. Two things should be noted: 1. There is a substantial difference between performance of the smallest cooler (1.2 ft²) and the mid- size (2.4 ft²). The 6000 btuh difference in load would require an extra half ton of refrigeration if secondary cooling was used. In addition, 130 °F temperature is borderline for an operator to comfortably handle. A small increase in fouling of the cooler will result in an objectionable ample temperature, and odds are that the flow will be reduced to compensate. 2. Although there is a large increase in performance between selections 1 and 2, there is no significant jump when going to the largest (3.5 ft²) cooler. This holds true for most water samples. The largest cooler normally is only required for steam samples with relatively high flow rates, or where pressure drop is a limiting consideration. Design of the cooler is also critical. If we take the cooler in selection 3 and increase baffle spacing between tube passes by less than ½" (selection 3A), the heat rejection goes down by 3445 btuh per hour and the sample temperature increases to 112°F (see table below). To achieve equal performance in sample cooler 3A, cooling water flow rate would have to increase by a factor of 5, i.e. 25 gpm vs. 5 gpm. This shows the dramatic effect of proper design on sample cooler performance and water usage. This fact should not be overlooked in smaller sample coolers as well. Our selections 1 and 2 are based on efficient Sentry designs, less efficient designs would increase these temperatures and require more cooling water. In summary, select coolers carefully with due consideration to specific requirements for each line. This will ensure adequate flow rates, optimize system performance, lower secondary cooling demand, and provide safe grab samples. Every Employee an Owner, Every Customer a Commitment Sentry Equipment Corp • PO Box 127• Oconomowoc, WI 53066 Phone: 262.567.7256 • Fa x: 262.567.4523 • E-mail: sales@sentry-equip.com