test set, transponder

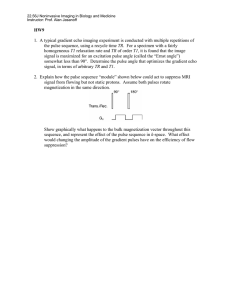

advertisement