Construction Manual for Architects, Engineers

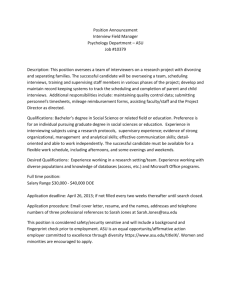

advertisement