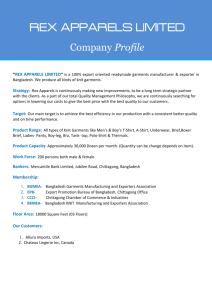

1st ISO Garments Factory In Bangladesh

advertisement

First ISO Certified Garments Factory in Bangladesh Greenland Garments Ltd (Unit –One) Greenland Garments Ltd (Unit – Two) Year of Establishment: 1995 Manpower: 1000 Floor Space: 48,000 SF Production Capacity: 450,000 Pcs/Month Year of Establishment: 2008 Manpower: 700 Floor Space: 30,500 SF Production Capacity: 350,000 Pcs/Month First ISO Certified Garments Factory in Bangladesh GREENLAND GARMENTS LTD CAPABILITY STATEMENT We are green at Greenland. Greenland Garments is a manufacturer of high quality knit garments being the first garments industry in Bangladesh to be ISO-9002 certified. Our project is quality driven, which we are confident has led to our success and stability. The Quality Management System has now been upgraded to the current ISO9001: 2008 certification. Greenland’s modern Dyeing and Finishing Plant is also the first ISO-14001: 2004 certified Plant in Bangladesh. The company has adopted a comprehensive and integrated quality and environment management system with the objective of making continuous improvement in every aspects of its operation, so that every employee works together to foster a quality driven culture in the organization. The most recent achievement has been manifested through the attainment of WRAP Gold Certificate of compliance certified for the period of 26 April 2013 to 26 April 2014. All Greenland facilities are owned by the company ensuring safety with assured structural integrity. All structures are certified by experts in their field. At Greenland we have taken the following steps to face the challenges of a competitive world. Improve sustainable supply chain management system. Enhance efficiency at every level of production and management. Strive to attain highest quality levels as an ongoing process. Preserving ethically sensitive trading practices and prudent care of the environment. Ensure safety from fire and structural weaknesses. First ISO Certified Garments Factory in Bangladesh Certifications WRAP Gold Certificate of compliance certified ISO-9001:2008 Quality Management System Certified ISO 14001:2004 Environment Management Systems certified COTTON USA licensee First ISO Certified Garments Factory in Bangladesh Our Clients Since inception, Greenland has had the privilege to work for some of the finest names the apparel business has to offer. Our experience stands beyond the realms of Department Stores and Retail Brands. We are well accustomed to the versatile world of Promotional garment manufacture, where longer lead times are a luxury and requirements change at lighting-speed. A list of our clients is given below: Direct Buyers Country Canadelle Inc. (Hanes Brand) Canada Hanes Brands Others Australia Formark (Evans, Dorothy Perkins, BHS) United Kingdom Bonmarche United Kingdom Impact (Inter Sport) France Greenland Garments Ltd has vast experience manufacturing garments for world reputed clothing brands, couples of are showed below. First ISO Certified Garments Factory in Bangladesh GARMENTS- (Cutting, Sewing & Finishing) In terms of style, our Garments Unit is capable of handling almost all requirements. In producing Men’s pique Polo, all types of men’s /ladies, children T-shirt, ladies camisole, boys/girls legging/rugby shirt using the best Japanese sewing machines. The factory is housed in a six-story building, right outside Dhaka city limits, the ground floor of which is occupied by our knitting unit. Production in the new unit 2 facility started in the middle of October 2008 Machinery listing is at APPENDIX-ONE Garments Fabrics (Knitting Division) Greenland was one of the first factories in Bangladesh to use Mayer Knitting Machines, since then we have never looked back. The Mayer technology enables us to produce a range of high quality fabrics servicing, both our export needs and the requirements of several other garment plants. All our machines, including the flat collar machines are fitted with Lycra drives. Fabric Versatility Types of knit fabrics: Single Jersey-Pique-Ribs (1x1, 2x 2 etc.)-Interlock-French Terry-Lacoste-Waffle Knit-Fleece Fabrics GSM Range 130~300GSM Machinery listing is at APPENDIX-TWO First ISO Certified Garments Factory in Bangladesh Dyeing division (Dyeing Plant) Greenland’s Dyeing Unit was commissioned in October of 2002. The plant is equipped with state of the art dyeing and finishing machines, all of which are of European origin. Additionally, the plant has at its disposal a cutting edge laboratory that serves to ensure quality and efficiency. The plant has 8 tons fabrics dyeing capacity per day. Machinery listing is at APPENDIX-THREE Auxiliary Machines & Equipment To keep garments production un-interrupt the company management has been developed world-class supportive facilities in its production plants. To confirm electricity available round the clock it established high capacity industry size power generators in the plants. Textile waste such as dyeing chemical and other toxic textile waste are serious harmful elements for nature, the company management developed a effluent treatment plant to purify the toxic waste, after proper purification it drain out the solid waste and clean water into the Nature, the high expensive effluent treatment plant they operate in their plant to confirm their corporate social responsibility (CSR). Beside all these above GGL developed its own lab test facilities in their plants for examine their garments fabrics as well as products. Machinery listing is at APPENDIX-FOUR Testing Laboratory Adequate testing capability is imperative to repeatedly achieve the desired quality parameters. The in house testing laboratory is equipped with the following brand and origin. Machinery listing is at APPENDIX-FIVE Testing Lab First ISO Certified Garments Factory in Bangladesh Effluent Treatment Plant Our ETP has garnered many plaudits from a variety of sources, in or outside the industry. With its unique design, having tanks installed on top of each other, it ensures that all environmentally sensitive parameters are well within the natural levels prior to discharge into water bodies. The effluent from the Dying plant is being treated by means of a 720 cubic metric per hour combined Fluidized Anaerobic Bed (FAB) reactor and mechanical process. This is the first time that this process has been adopted in Bangladesh. Greenland is the only Dyeing unit to be ISO 14001:2004 certified in Bangladesh. ETP Plant New Affiliation The latest addition to the already growing list of services provided by Greenland is automated printing. Tired of cumbersome, slow moving manual screen-printing houses, we have affiliated ourselves with a state-of-the-art automated printing house situated in Tejgaon. Euro Printers Ltd. (a sister concern of Greenland Garments Ltd.) attempts to hurdle traditional boundaries that limited the old screen printers by being one of the first introduce the world of automated printing to Bangladesh. They are equipped with 5 automatic and 2 manual cutting edge carousel printing machines, which are able to handle the most complicated prints up to 14 colors. Euro Printers Ltd. Safety and Structural integrity All production facilities are owned by the company. Greenland employs the services the most reputed structural engineering and fire safety consultants to independently certify, train and monitor all such aspects. Greenland is most conscious of the importance of maintaining a safe working place First ISO Certified Garments Factory in Bangladesh s Our Banks BASIC Bank Ltd Main Branch, 73, Motijheel C/A, Dhaka-1000 Bangladesh. Phone : 8802-956 3068-69, Telex : 632185 BASIC BJ. Fax : 880-2-9569417 SWIFT: BKSIBDDH002 International Finance & Investment Bank Ltd (IFIC) Kawran Bazar Branch P.O. Box 3668 Dhaka 1212, Bangladesh. Phone: 8115423(M), 8115435. Telex: 642998 Contact Us Corporate Office Overseas Office – North America Greenland Garments Ltd. Suite – 2207, 5418 Yonge St Toronto. Ontario M2N 6X4, Canada Phone: (1) 647 350 3857 E mail: junaid.rahman@thinkexemplar.com Hasney Tower (6th Floor), 3/A, Kawran Bazar, Dhaka-1215, Bangladesh Tel: (8802)913 0058-9, 912 1928,913 2683 Fax : (8802) 913 0176, 913 0177. E mail : info@greenlandgarments.com Website: www.greenlandgarments.com Factory – (Unit One) Factory – Unit Two Greenland Garments Ltd. Greenland Garments Ltd. Hasna Tower, Kashimpur Road Konabari,Gazipur. Bangladesh. Phone : (8802) 9298302, 9298303, Fax : (8802) 9298303 E mail : info@greenlandgarments.com Mollik Tower (6 Floor), 13-14, Zoo Road, Mirpur-1, Dhaka-1216, Bangladesh. Phone: 9012951, 9012957, Fax : (8802) 9012973. E mail : info@greenlandgarments.com th First ISO Certified Garments Factory in Bangladesh Appendix-One: Capacity and List of sewing machines Type Unit –One Brand Qty. Unit – Two Brand Unit-2 Plain Machine Juki=69, Brother= 41 110 Brother 112 Flat lock Pegasus 48 Pegasus 42 Overlook (3Thread) Pegasus 7 - 0 Overlook (2Thread) Pegasus 3 - 0 Overlook (4Thread) Pegasus=67, Zuki=1 68 Pegasus 70 Overlook (5Thread) Kansai 5 Pegasus 0 Overlook (6Thread Upgrade) Pegasus 0 Pegasus 14 Tape cutting Shinzu 5 - 5 Back Tape Kansai Special 1 - 0 Button Stitch Brother=4, Juki=4 8 Brother 5 Button Hole Brother=2, Juki=2 4 Brother 3 P.M.D (Kansai) Kansai Special 2 Kansai 2 Cutting Machine East Man=8, K.M=2 10 East Man 6 Picoting Machine Kansai Special 3 Kansai 2 Feed of the Arm Juki=1,Brother= 4 5 Brother 7 Smoking Machine (33 & 12 Needle) Kansai Special 2 - 0 Smoking Machine (PMD) Kansai Special 1 - 0 Snap Button Machine Local 3 - 0 Heat Seal Machine USA-01, China-04 5 - 0 Fusing Machine Hashima 1 Hashima 1 Production Area 48,000 SFT 30,500 SFT (6 Floor area) Production Capacity per month (T-Shirt equivalent) 450,000 Pcs. 350,000Pcs. First ISO Certified Garments Factory in Bangladesh Appendix – Two: Knitting production capacity & machineries detail SL Machine Type Brand Origin 1 Circular Knitting Mayer Dia Gauge Per day Capacity Germany 20,24,28 (S/J) 550 • 2 = 1100 Kgs. Mayer Germany 18 (Rib machine) 500 • 1 = 500 Kgs. Mayer Germany 16 (Rib machine) 500 • 1 = 500 Kgs. Mayer Germany 24,28 (S/J) 330 • 3 = 990 Kgs. Unitex Singapore 24 (Interlock) 450 • 1 = 450 Kgs. Unitex Singapore 24 (S/J) 250 • 1 = 250 Kgs. Unitex Singapore 24/20 (S/J) 275 • 1 = 275 Kgs. Unitex Singapore 24 (S/J) 300 • 1 =320 Kgs. Unitex Singapore 24/20 (S/J) 290 • 1 = 290 Kgs. Unitex Singapore 24/20 (S/J) 325 • 1 = 325 Kgs Total 2 Flat Collar Knitting Matsuyo Japan 100cm Qty 13 1 13 14 2600 Set. First ISO Certified Garments Factory in Bangladesh Appendix – Three: Machineries detail in Dyeing plant & testing laboratory SL Machine Type Brand Origin Qty Capacity 1 Dyeing Machines Thiess Germany 1 50 kgs (High Temp.) Thiess Germany 1 250 kgs Thiess Germany 2 500 kgs Thiess Germany 1 750 kgs Dilmenler Turkey 1 900 kgs Dilmenler Turkey 1 25 kgs Lab dip machine Shirley UK 1 Lab dip Machine Fongs China 1 Dryer Strahm Swiss 1 5 tons Dryer Santex Swiss 1 5 tons Detwister Santex Swiss 1 8 tons Detwister Beneks Turkey 1 8 tons Compactor/ Calendar Santex Swiss 1 5 tons Compactor/ Calendar FAB-CON USA 1 5 tons Brushing Machine Mario Crosta Italy 1 2 Finishing Machines First ISO Certified Garments Factory in Bangladesh Appendix – Four: Auxiliary Machineries Detail Machine Type Brand Origin Qty (Unit-1) Capacity (Unit-1) Qty (Unit-2) Gas Generator Perkins British 1 750 KVA 0 Gas Generator Caterpillar USA 1 750 KW 0 Standby FG Wilson UK 1 500 KVA FG Wilson UK 1 635 KVA 01 (550 KVA) Boiler Cleaver brooks USA 1 6.3 MT 02 (250 Kgs- Oshima) Compressor Kaesor German 1 Fabric Examining AATPR Thailand 3 Fabric Inspection Examining Uzu 0 1 Tread Suction Machine Nisho 0 2 Needle Detector Oshima Taiwan 1 0 Spot Cleaning Machine Malkan Turkey 1 1 Metal Detector Cintex China 1 1 W.T.P Thermax India 1 Diesel Generator Standby Diesel Generator 0 3 50 m /h First ISO Certified Garments Factory in Bangladesh Appendix – Five: Testing Laboratories detail Test Machine Make Origin Colour Matching Spectrophotometer Gretag/Macbeth USA Colour Matching Spectrophotometer Data Color USA Pilling Test Pilling Tester James H. Heal Ltd. UK GSM measuring Cutter/Scale Shirley UK Colour Comparison Cabinet Shirley UK Yarn Count Wrap Reel/Scale Shirley UK Yarn Fault Yarn Tester Shirley UK Ph/Temperature Meter Shirley UK Colour Fastness Rotawash Shirley UK Rubbing Fastness Crockmeter Shirley UK Shrinkage Wascator Shirley UK Electronic Twist Twist Testers Mesdan Italy Tester