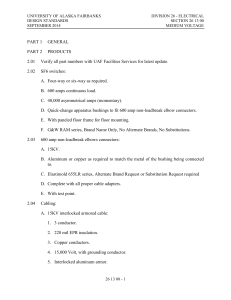

Wire and Cable Catalog-Section 13

advertisement