Series HD00007

advertisement

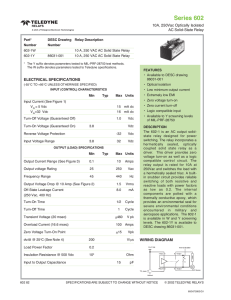

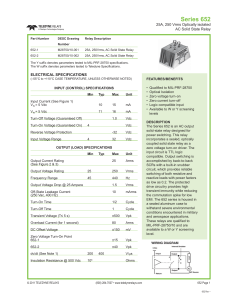

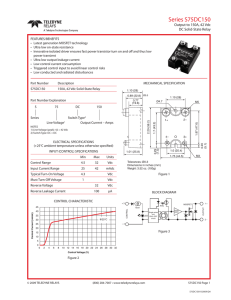

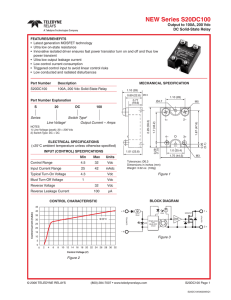

Series HD00007 1.20A, 60Vdc True Output Status Feedback, Short-Circuit Protected DC Solid-State Relay Part* Number Relay Description HD00007 SSR with Short Circuit Protection and Switching Status *Parameters tested to MIL-PRF-28750 specifications. ELECTRICAL SPECIFICATIONS FEATURES (-55°C TO +105°C AMBIENT TEMPERATURE UNLESS OTHERWISE NOTED) • • • • • • Bias Supply Current @ VBIAS = 5 Vdc1517 mAdc Short-circuit/current overload protection Status output TTL and CMOS compatible control Low ON resistance power FET output Fast switching speed Meets 28 Vdc system requirements of MIL-STD-704 • Optical isolation • Low profile hermetic package • Built and tested to the requirements of MIL-PRF-28750 Off State Bias Supply Current (Note 9) DESCRIPTION INPUT (CONTROL) SPECIFICATION (CMOS or open collector TTL) Min Typ Max Units (See Fig. 1 & Note 1) Control Current VCONTROL = 5 Vdc Control Voltage Range Bias Supply Voltage Turn Off Voltage (Guaranteed Off) 250 µAdc 0 5 Vdc 4.5 5.5 Vdc 3 3.2 mAdc Vdc Turn On Voltage (Guaranteed On) 0.3 Vdc Bias Supply Voltage below which relay output is guranteed to be Off 2.0 Vdc OUTPUT (LOAD) SPECIFICATIONS (See Note 2) Min Typ Max Units Continuous Load Current @ +25°C (See Fig. 3)1.20 Adc Leakage Current @ VLOAD = 60 Vdc 2.0 Output Voltage Drop 0.36 Vdc mA Continuous Operating Load Voltage 60 Vdc Transient Blocking Voltage (See Note 7) 80 Vdc ON Resistance Rds (on) at ILOAD = 100 mAdc TJ = 25°C (See Note 4) Turn-On Time (See Fig. 5) 0.25 Ohm 5 ms Turn-Off Time (See Fig. 5)1 ms Electrical System Spike ±600 Vdc Output Capacitance at 25 Vdc, 100 KHz 850 pF Exponential Rate of Voltage Rise100 V/µs Input to Output Capacitance10 pF Dielectric Strength @ 1mA leakage1000 Vac Insulation Resistance @ 500 Vdc109 Ohm Output Junction Temperature125 @ ILOAD = IMAX RATED °C Maximum Junction Temperature (TJ Max)125 °C © 2007 TELEDYNE RELAYS This all solid-state relay utilizes the latest technology to provide a low ON resistance and an optically isolated output. The control (input) and load (output) are optically isolated to protect input logic circuits from voltage and current transients which can occur on the output supply. The optical isolation also provides a full floating output, thus allowing the load to be connected to either output terminal. The control circuit is buffered to enable the relay to be driven directly from standard CMOS or open collector TTL logic circuits. Features include short-circuit and current over load protection, which provides complete protection for both the relay and the system wiring. This feature not only provides protection should a short or overload occur while the relay is on, but will also provide protection should the relay be switched into a short. In either case, the relay will sense the short-circuit condition and then block it indefinitely until the short is removed and the unit is reset by cycling the input control. The second feature is a status output line in switch status configuration. Switch status returns the true status of the output switch and is optically isolated from the load. It provides status indication independent of the control circuit of the relay. The status line provides a logic (0) low when the input circuit is off and load circuit continuity is present. The status line provides a logic 1 (high) when the output is on. (800) 284-7007 • www.teledynerelays.com HD 2DSHD00007 Rev 01 Series HD00007 STATUS OUTPUT SPECIFICATIONS Min Typ Max Units Status Supply Voltage (See Fig. 1)118Vdc Status Supply Blocking Voltage, ILK ≤ 10 µA18 Vdc Status (sink) Current (VSO < 0.4 Vdc) 700 µAdc Status Turn-On Time (See Fig. 6) 3.5 ms Status Turn-Off Time (See Fig. 6) 8.0 ms Status Rise Time (Note 10) 300 µs Status Fall Time (Note 10) 30 µs SHORT CIRCUIT PROTECTION SPECIFICATIONS (See Notes 3, 6, 8) Relay power controller will not be damaged by a short on the load or by being turned on into a shorted load WIRING CONFIGURATIONS FIGURE 1 BLOCK DIAGRAM Relay power controller will not be damaged by continuous overload condition Overload Current See Figure 7 Short Circuit Reset Time10 ms minimum (remove short/overload and cycle input) ENVIRONMENTAL SPECIFICATIONS THERMAL: Operating TA (performance as specified) -55°C to +105°C Storage TA -55°C to +125°C Thermal Resistance Output Junction to Ambient 90°C/W Thermal Resistance Output Junction to Case 25°C/W MECHANICAL: mechanical specifications Vibration100g, 10 to 3000Hz Shock 50g, 11 ms Acceleration (Y1 Axis only) 5000 g Leak Rate1x10-8 atm-cc/s MECHANICAL SPECIFICATIONS Weight Case 5.5gm max 6 pin dip Hermetically sealed Pin Material Kovar gold plated Can Material Grade A nickel Header Material Kovar gold plated • Weight: 5.5 gm max • Case: Hermetically sealed DIP • Material and Plating: Pins and Header:Kovar gold plated per MIL G-45204 Type III, Grade A, Class 1 DIMENSIONS ARE SHOWN IN INCHES (MILLIMETERS) HD Specifications are subject to change without notice © 2007 TELEDYNE RELAYS 2DSHD00007 Rev 01 INSPECTION & TESTING Inspection shall following procedures according to MIL-PRF-28750 Issue D Section 4.6 Group A Tests Group A inspection shall be carried out on each batch for delivery Group A1 Requirement Test Method Sampling Plan Internal Visual 3.7.2 4. 7.2.2 4.6.1.2.1 Temperature Cycling 3.7.3 4.7.2.3 4.6.1.2.1 Constant Acceleration 3.7.4 4.7.2.4 4.6.1.2.1 Load Conditioning 3.7.5 4.7.2.5 4.6.1.2.1 Burn-in Test 3.7.7 4.7.2.7 4.6.1.2.1 Requirement Test Method Sampling Plan Insulation Resistance 3.10 4.7.5 4.6.1.2.1 Dielectric Withstanding Voltage 3.11 4.7.6 4.6.1.2.1 Electrical Characteristics* 3.12 4.7.7 4.6.1.2.1 Requirement Test Method Sampling Plan 3.9 4.7.4 4.6.1.2.1 3.1, 3.4, 3.6, 3.23, 3.24 4.7.1 4.6.1.2.1 Group A2 #1 Group A3 #2 #3 Seal Visual & Mechanical *Electrical Tests at -55°C, +25°C and +105°C; see Electrical Specifications for limits. System Spike, overload and power dissipation are not included. Transient Voltage and exponential rate of voltage rise (dv/dt) shall be performed at 25°C only. #1 Test Sequence is optional #2 Physical dimensions and weight shall be measured on two samples per batch. See the Mechanical Specifications for dimensions and mechanical outlines. #3 Minor Deficiencies, such as marking, may be reworked Group B Tests Group B inspection shall be made on sample parts which have been subjected to and have passed Group A tests listed above Group A1 Requirement Test Method Vibration 3.15 4.7.10 4 samples Terminal Strength 3.16 4.7.11 4 samples 0 failures allowed Insulation Resistance 3.10 4.7.5 4 samples 0 failures allowed Electrical Characteristics 3.12 4.7.7 4 samples 0 failures allowed Seal 3.9 4.7.4 4 samples 0 failures allowed 3.1, 3.4, 3.6, 3.23, 3.24 4.7.1 4 samples 0 failures allowed Visual & Mechanical © 2007 TELEDYNE RELAYS (800) 284-7007 • www.teledynerelays.com Sampling Plan 0 failures allowed HD 2DSHD00007 Rev 01 Series HD00007 BIAS (INPUT) CURRENT VS BIAS (OUTPUT) VOLTAGE FIGURE 2 (See Note 1) HD LOAD CURRENT DERATING CURVE FIGURE 3 NORMALIZED ON RESISTANCE VS JUNCTION TEMPERATURE FIGURE 4 (See Note 4) OUTPUT TURN-ON AND TURN-OFF TIMING FIGURE 5 STATUS TURN-ON AND TURN-OFF TIMING FIGURE 6 TYPICAL TRIP CURRENT VS TIME FIGURE 7 (See Note 5) Specifications are subject to change without notice © 2007 TELEDYNE RELAYS 2DSHD00007 Rev 01 NOTES: 1. Control input is compatible with CMOS or open collector TTL (with pull up resistor). Input transition should be ≤ 1 msec duration and input drive should be “bounceless contact” type. 2. The status is an open-collector npn BJT reference to input ground. See Figure 1 for wiring. Conditions for status timing shall be 5 volt status supply at 700 uA status supply current. 3. The rated input voltage for functional tests shall be 5 Vdc. This includes tests for on-resistance, output voltage drop, timing and short-circuit protection. 4. For typical on-status resistance at junction temperatures greater than +25°C, use the following equation: RON = 213 + 0.69 TJ WhereR = on resistance at TJ in milliohms TJ = junction temperature in °C 5. The relay loads may be connected to the high (+) or low (-) side of the relay output terminals Reversing polarity of output may cause permanent damage. 6. Inductive loads must be diode suppressed. System series inductance in “load-shorted” mode of operation to be ≤ 50 microhenries. Maximum input repetition rate into shorted load not to exceed 10 Hz. Overload testing to the requirement of MIL-PRF-28750 is constrained to the limits imposed by the short-circuit protection requirements of this specification. 7. Transient voltage requirements are limited to 80 Vdc max per MIL-STD-704A. 8. To return unit to normal operating condition, remove short circuit or overload condition. Then remove and reapply input control voltage for the minimum specified short circuit reset time. 9. Off state input bias current. Guaranteed but not tested. 10. The Limits for Status Rise Time and Status Fall Time are based on components specification, and are not 100% tested. 11. To prevent overheat, the repetitive switching rate shall be kept 10 Hz maximum. The control pulse width must be equal or greater than 6 mS (sum of the maximum turn-on and maximum turn-off time) for the relay output to follow the control command. The relay may or may not respond to a control command if the pulse is less than 6 mS. In any case, regardless of the control pulse width, the relay will not enter into a false short circuit trip mode, as long as the load current and the line voltage are within the specified range. 12. Test carried out on behalf of the Eurofighter Program in Germany have indicated that HD00006 meets the requirements under the specified levels for Neutron, Gamma Dose & Gamma Dose Rate radiation. Teledyne has not tested the HD00006 relay, or the HD00007 replacement relay, against the radiation levels required by Eurofighter, nor is Teledyne privy to the details of the testing such as shielding effect, level of assembly tested, or any other detail of the test carried out on behalf of the Eurofighter Program. © 2007 TELEDYNE RELAYS (800) 284-7007 • www.teledynerelays.com HD 2DSHD00007 Rev 01