Transformer Winding Hot Spot Temperature Determination

advertisement

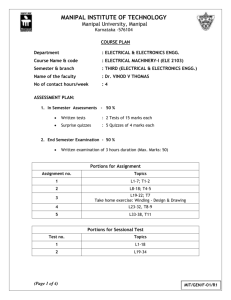

Transformer Winding Hot Spot Temperature Determination Jean-Noël Bérubé Jacques Aubin W. McDermid Neoptix, Inc. Manitoba Hydro Weidmann-ACTI’s Fifth Annual Technical Conference November 2006 Albuquerque, NM Why Monitoring Temperatures ? In power transformers, winding temperatures have a direct impact on insulation aging Proper monitoring of operating temperatures are essential to assess the value of insulation aging and resulting remaining life Allows for better asset management and revenue generation strategies Limitations of Transformer Temperature Rise Tests “Heat Run” tests reveal average winding temperature under rated load What is of interest for insulation aging is the winding hottest spot temperature Temperature is highest at top of winding Oil is hotter Stray losses in winding are higher Winding insulation often calls for more paper to provide better insulation against voltage surges Correct knowledge of operating temperatures is needed to evaluate insulation aging and remaining life Aging Acceleration Factor Winding insulation sensitivity to temperature 1000 Normal Kraft Paper (IEC) 100 10 Normal Kraft paper (IEEE) 1 0.1 60 80 . Thermally Upgraded Paper 100 120 140 0.01 Hot-Spot temperature 160 180 Winding Hottest Spot Temperature Model Winding Hottest Spot Temperature Model Top oil temperature Winding hot-spot temperature Winding Hottest Spot Temperature Model Top-Oil Temp. Hot-Spot Temp. Wi nd ing Oi l Hot-Spot Rise Average Winding Temp. Temperature (oC) Winding Hottest Spot Temperature Model For any load level, the hottest winding temperature is assumed to be: Winding hot-spot temp. = Top-Oil Temp. + Hot-spot rise at rated load * (%Load)2m For several decades, this method was a standard feature: • IEEE C57.91 - 1995 “IEEE Guide for Loading Mineral Oil Immersed Transformers” • IEC 60354 - 1991 “Loading Guide for Oil-Immersed Power Transformers” Winding Hottest Spot Temperature Model This simplified method is now regarded as inadequate • To estimate the aging of transformers • Given increasing occurrences of overloads IEEE and IEC are proposing new methods to take account of (neglected in the previous equation): • True oil temperature in the cooling duct • Change in winding resistance with temperature • Change in oil viscosity with temperature • The effect of tap changers • Oil inertia in case of sudden overload of large magnitude Winding Hottest Spot Temperature Model This evolution in calculation method indicates: • Methods used until now are not very accurate • New methods will require additional parameters that are not always readily available • New models still rely on information provided by the transformer manufacturer and not always validated • Direct measurement of winding temperature with fiber optic sensor is recognized as the best method Direct Temperature Monitoring Direct winding temperature measurement provides valuable information for design, heat-run testing, maximizing loading and maintenance Safely maximizes transformer loading Avoids catastrophic failure and emergency shutdowns by monitoring long-term, gradual transformer deterioration Allows better timing for winding cooling requirements, to avoid overheating around hot-spot immediate areas Gathers valuable information for scheduling maintenance and replacement of units Introduction to Fiber Optic Fiber optic (glass) is a method of carrying information, as a copper wire. But unlike the copper wire, fibers carry light (photons) instead of electricity (electrons) Some advantages of fiber optic are compared to RTD sensors and IR based sensors: Immunity to electromagnetic fields All dielectric material probe construction Can be installed in harsh environments Robust, flexible and chemically resistant probes True intrinsic safety in explosive environments Minimal thermal shunting Relative ease of installation Operating Principle Based on a well understood and reproducible phenomenon: the variation in the absorption spectrum of the semiconductor GaAs with respect to temperature A direct contact temperature sensor System Design White Light Source o Pr be Optical Coupler Spectrometer The system is very simple yet elegant and consists of a light source, an optical coupler, the probe and a spectrometer. Multi-channel models use the same design but the number of component (other than the probe) is greater. Oil-Immersed Transformer Probe Probe Design Details Designed to allow complete oil impregnation, rapid response time, high dielectric strength and chemical resistance GaAs based probe characteristics: Designed for a minimum life time of 25 years No drift No recalibration Ruggedized design allows for minimal probe breakage and lost during installation Probe Design An optical fiber delivers white light to the semiconductor crystal Some of the light is more or less absorbed--this absorption is dependent on the temperature at the tip of the probe The light is reflected back by a dielectric mirror and returns through the same fiber for analysis semiconductor crystal fiber core fiber cladding dielectric mirror Fiber Optic Sensor can be in Contact with Conductor Fiber Optic Sensor can Inserted in Disk Spacer Can be inserted between the last few disks near the top of the winding Location in Disk Spacer is Adequate Temperature (°C) 2.2 FO Sensor in contact with conductor (top of bundle) 2.0 FO Sensor in contact with conductor (bottom of bundle) 1.8 1.6 1.4 1.2 1.0 0.8 0.6 Load 0.4 0.2 80 60 40 20 0 0 12 24 36 Time (h) 48 60 72 Load (p.u.) FO Sensor in spacer 100 Optic Fiber Handling & Testing During transformer assembly, optical fibers are safely spooled and attached to the winding. Bright colors, such as orange or blue, also help minimize breakage during installation. A portable test unit can be very useful for testing probes as they are installed. Feed-Through Connection Development in optical fiber technology allows for low loss connection and leak free operation (epoxy-less design) Temperature sensor, inside transformer Tip Extension cable, to monitoring system Feedthrough for tank wall Interfacing & Communication Systems are now available with open communication protocols Some popular protocols include: No more proprietary communication schemes! OPC (T/Guard+) Modbus (T/Guard) Others: CANopen, Profibus, Devicenet Analog outputs (4-20mA) Hardware interfacing is also flexible RS232 RS422 – RS485 TCPIP (Ethernet) emulation Analog outputs An Example: Monitoring System (T/Guard) Supports up to 16 channels in a single unit Ruggedized design for heavy industry applications RS-232 and analog output standard Assistant Windows™ compatible software -Options: -Modbus protocol -RS485 -Supports a network of 32 T/Guard’s -TCPIP interface An Example: Monitoring and Controlling System (T/Guard+) Supports up to 8 channels in a single unit 16 Type-C relays, can be set as type A, B or C relays) Ruggedized design for heavy industry applications; built with a PLC, galvanic-isolated relays. RS-232 and analog output standard OPC Server built-in Options: Communication: CANopen Profibus, Modbus, Devicenet and Ethernet server. Data logging OPC-Based Communication International Industry Standard Organization Fully supported by Microsoft (uses DCOM) The Vision of OPC is the Adapted Standard for interOperability 280+ member companies 1500+ total companies build OPC products = 7500+ products For moving information vertically from the factory floor through the enterprise of multi-vendor systems For moving information between devices on different networks from different vendors Not just data but information… Reliable - Secure Integration is built-in www.opcfoundation.org OPC and the T/Guard+ An example: direct logging to Excel Can monitor/set 500+ variables Field Experience – – – – Converter transformer ODAF cooling 107 MVA Dorsey sub, Manitoba Hydro Field Experience Temperature (°C) 100 80 1.6 1.4 1.2 1.0 0.8 0.6 0.4 0.2 60 40 Load 20 Ambient 0 0 12 24 36 Time (h) 48 60 72 Load (p.u.) Prediction from manufacturer using IEEE model 2.2 Measured value with FO sensor 2.0 Corrected Prediction 1.8 Economic Benefits of Accurate Temperature Measurement •Transformers have inherently some overloading capability •The loading capability is highly dependent on winding temperature •Dependable measurements of winding temperatures allow to take full advantage of overloading capability •Market opportunities can generate important benefits if extra load can be handled under safe and predictable conditions Economic Benefits, Transformer Overloading, An Example 1.Transformer rated power (MVA) 100 2.Overloading margin made available by monitoring (%) 10 3.Probability of overloading opportunity (hr/year) 450 4.Financial benefit from energy transmitted ($/MWh) 80 Yearly benefit from extra loading (1 x 2 x 3 x 4 ) = $360,000 Economic Benefits, Transformer Overloading, An Example 5. Replacement cost of transformer ($) 2 000 000 6. Transformer normal life duration (hours) 150 000 7. Additional aging factor at 110% load (125°C) 3.4 Cost for additional loss of life ((5 / 6) x 7 x 3 ) = $20,400 Net yearly benefit from overloading : $360,000 - $20,400 = $339,600 Conclusions (1) •For operators and utilities, overloading of transformers is often a better alternative to more and/or larger transformers •Aging of power transformers is mainly driven by winding temperature •More frequent loading to full capacity has shown need for better control of winding temperature •Recent developments in IEEE and IEC loading guides have shown that simple calculation methods used in the past are not fully dependable Conclusions (2) •Fiber optic sensors have reached a level of dependability that makes them a natural choice for this important function •Interfacing to utility’s computers is now easier than ever, thanks to open communication schemes, such as Modbus, OPC, and other non-proprietary communication schemes. Thanks!

![FORM NO. 157 [See rule 331] COMPANIES ACT. 1956 Members](http://s3.studylib.net/store/data/008659599_1-2c9a22f370f2c285423bce1fc3cf3305-300x300.png)