FOR AUTOMOTIVE APPLICATIONS

advertisement

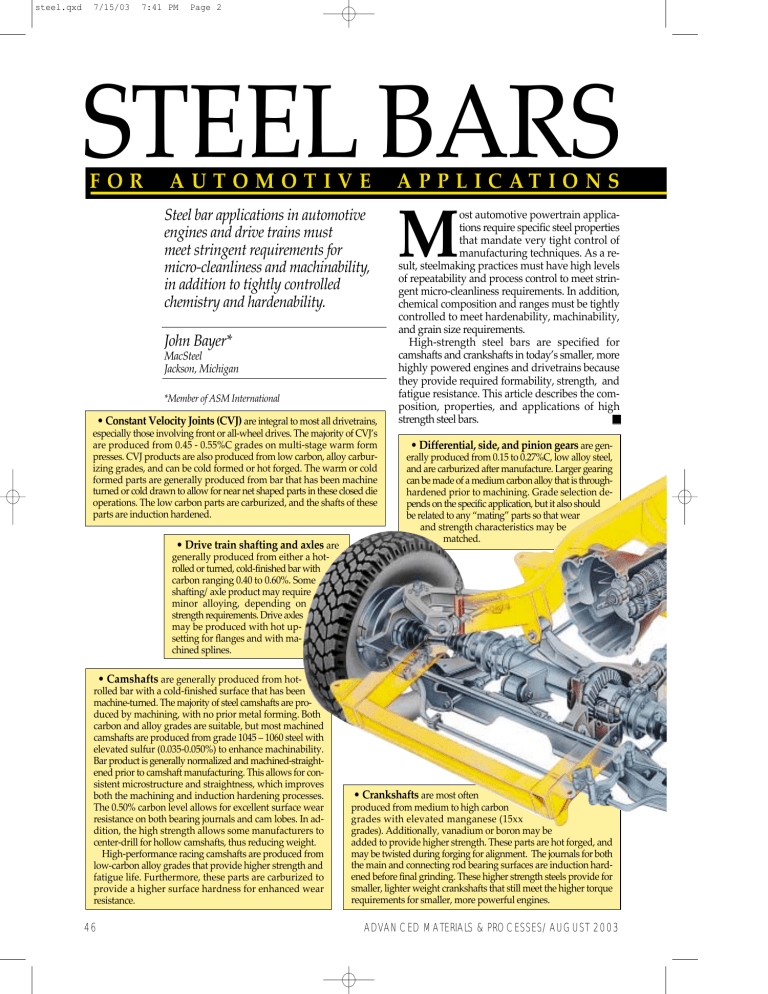

steel.qxd 7/15/03 7:41 PM Page 2 STEEL BARS FOR AUTOMOTIVE Steel bar applications in automotive engines and drive trains must meet stringent requirements for micro-cleanliness and machinability, in addition to tightly controlled chemistry and hardenability. John Bayer* MacSteel Jackson, Michigan *Member of ASM International • Constant Velocity Joints (CVJ) are integral to most all drivetrains, especially those involving front or all-wheel drives. The majority of CVJ’s are produced from 0.45 - 0.55%C grades on multi-stage warm form presses. CVJ products are also produced from low carbon, alloy carburizing grades, and can be cold formed or hot forged. The warm or cold formed parts are generally produced from bar that has been machine turned or cold drawn to allow for near net shaped parts in these closed die operations. The low carbon parts are carburized, and the shafts of these parts are induction hardened. • Drive train shafting and axles are generally produced from either a hotrolled or turned, cold-finished bar with carbon ranging 0.40 to 0.60%. Some shafting/axle product may require minor alloying, depending on strength requirements. Drive axles may be produced with hot upsetting for flanges and with machined splines. • Camshafts are generally produced from hotrolled bar with a cold-finished surface that has been machine-turned. The majority of steel camshafts are produced by machining, with no prior metal forming. Both carbon and alloy grades are suitable, but most machined camshafts are produced from grade 1045 – 1060 steel with elevated sulfur (0.035-0.050%) to enhance machinability. Bar product is generally normalized and machined-straightened prior to camshaft manufacturing. This allows for consistent microstructure and straightness, which improves both the machining and induction hardening processes. The 0.50% carbon level allows for excellent surface wear resistance on both bearing journals and cam lobes. In addition, the high strength allows some manufacturers to center-drill for hollow camshafts, thus reducing weight. High-performance racing camshafts are produced from low-carbon alloy grades that provide higher strength and fatigue life. Furthermore, these parts are carburized to provide a higher surface hardness for enhanced wear resistance. 46 A P P L I C AT I O N S M ost automotive powertrain applications require specific steel properties that mandate very tight control of manufacturing techniques. As a result, steelmaking practices must have high levels of repeatability and process control to meet stringent micro-cleanliness requirements. In addition, chemical composition and ranges must be tightly controlled to meet hardenability, machinability, and grain size requirements. High-strength steel bars are specified for camshafts and crankshafts in today’s smaller, more highly powered engines and drivetrains because they provide required formability, strength, and fatigue resistance. This article describes the composition, properties, and applications of high ■ strength steel bars. • Differential, side, and pinion gears are generally produced from 0.15 to 0.27%C, low alloy steel, and are carburized after manufacture. Larger gearing can be made of a medium carbon alloy that is throughhardened prior to machining. Grade selection depends on the specific application, but it also should be related to any “mating” parts so that wear and strength characteristics may be matched. • Crankshafts are most often produced from medium to high carbon grades with elevated manganese (15xx grades). Additionally, vanadium or boron may be added to provide higher strength. These parts are hot forged, and may be twisted during forging for alignment. The journals for both the main and connecting rod bearing surfaces are induction hardened before final grinding. These higher strength steels provide for smaller, lighter weight crankshafts that still meet the higher torque requirements for smaller, more powerful engines. ADVANCED MATERIALS & PROCESSES/AUGUST 2003 steel.qxd 7/15/03 7:42 PM Page 3 Effects of common alloying elements in automotive steels Element Effects Carbon The principal strengthening element in steel. It can have a great effect on numerous metallurgical properties. Increased carbon levels can provide increased hardness and strength. Lower carbon (less than 0.25%) improves weldability, ductility, and toughness at the expense of strength. Alloying elements have a major impact Increases strength and toughness. Manganese has one of the strongest on properties of steel and the subsequent elemental effects on steel’s hardenability (the ability of steel to harden at costs of part manufacture. As every engia depth from the surface through quenching). Higher levels have a neer knows, the goal is to develop a steel negative effect on weldability. chemistry that will meet all the required Considered an impurity, except when intentionally added to improve objectives with the most cost-effective machinability. It combines with manganese to produce manganese manufacturing process. sulfide (MnS) inclusions, which assist as “chip breakers” in machining The sulfur level of steels provided for steels. Higher sulfur levels have a detrimental effect on impact resistance. many powertrain applications is generally elevated to a level to provide maxA deoxidizer, it is added to steel to tie up free oxygen. The term “killed imum machinability without negatively steel” is used when it is deoxidized, thus providing improved internal impacting product performance. The soundness and surface quality. Higher levels slightly increase hardenability (the ability of steel to develop hardenability; however, silicon can have a negative impact on a specific hardness level at a depth from machinability. the quenched surface) is generally tightly Table continues on next page controlled through chemistry. This allows the engineer to define specific strength and toughness criteria based on the needs and geometry of the part. Manganese Sulfur Silicon • The majority of transmission main and counter shafts, in addition to input and output shafts, are produced from medium carbon grades (0.40 to 0.55%C) and are cold or warm formed. These shafts have spline gearing that is cold roll formed or machined, then induction hardened. Transmission and transfer case gearing consists predominantly of alloy carburizing steel that is warm or hot forged, surface hardened, and machined. • Smaller shafting for Constant Velocity Joints (CVJ) is generally cold drawn bar product with rolled splines. The spline gearing area of drive shafts is predominantly induction hardened. Shafting, like gearing, requires machinability, and shafts must be able to develop specific strength, fatigue, and wear properties after surface hardening or heat treatment. • Yokes are predominantly hot forged from 0.35 to 0.45%C grades, much of which may be resulfurized (11xx series) to improve machinability. Yoke ears are machined, and the spline gearing may be machined or formed on either the ID or OD of the shaft. After machining, these parts are induction hardened. Yokes may be friction welded to longer shafting (solid or hollow) if required, or mated with hollow aluminum drive shafting for weight reduction. Yoke spiders are generally produced from low carbon, carburizing alloy grades. They are then warm formed for net or near net shape control before hardening and final grinding. • Hubs and spindles (wheel bearings) are produced from higher carbon (>0.50%), bearing quality steel. These parts are hot forged, induction hardened, and machined. New generation wheel bearings have bearing races that are not external, but instead are designed into the part. This requires a machined and ground, hardened raceway, hence the steel cleanliness is critical. ADVANCED MATERIALS & PROCESSES/AUGUST 2003 47 steel.qxd 7/15/03 7:42 PM Page 4 Effects of common alloying elements in automotive steels, continued Element Effects Nickel When combined with other alloying elements, it produces steels with excellent strength and low-temperature toughness in the quenched and tempered condition. Chromium Provides wear resistance, hardenability, and low temperature toughness. At high levels, it provides corrosion and oxidation resistance, and assists in maintaining strength levels at elevated temperatures. Molybdenum Has a strong effect on hardenability (similar to manganese). Molybdenum also increases strength at elevated temperatures. Aluminum Acts as a deoxidizer and helps control grain size. It can have a negative impact on machinability. Columbium (Niobium) Helps produce fine grain steel, and improves the strength of micro-alloyed steels. Vanadium Also helps produce fine grain steel. Additionally, it can be used to increase strength, impact toughness, and hardenability. Vanadium can have a negative impact on machinability. Titanium Primarily a deoxidizer and nitrogen scavenger in the making of boron steels. Also acts as a grain refiner. Titanium can have a detrimental effect on machinability. Boron Increases hardenability in steel with less than 0.80% carbon, replacing other alloying elements. Common bar steel grades: properties and applications Carbon grades Grade Key properties Typical applications 1016-1025 Carburizing steel with considerably better machining characteristics than more formable lower-carbon steels. Recommended for die forging and hot upsetting. Commonly selected for low-strength-fastener applications. Widely used for inexpensive massproduced carburized parts; popular carburizing steel. Can be strengthened by cold working or surface hardened by carburizing or cyaniding. Relatively soft. Good weldability and formability. 1030 On the low end of the medium carbon types. Selected instead of low-carbon steels where higher mechanical properties are needed. Its hardness and strength can be increased by heat treatment or cold working. 1038 1137 1141 Offers advantages in notch toughness . Response to hardening is well suited for applications requiring some machining in the quenched and tempered condition. Strength can be increased either by hardening or by cold drawing. Response to die forging and hot upsetting is excellent. Better mechanical properties than 1038, due to higher carbon. Response to hardening is well suited to applications that require machining in the quenched condition. Strength is increased by hardening or cold drawing. Good for normal machining operations. Readily forged, formed, and upset at elevated temperatures. Extensive deformation at room temperatures is not recommended. Combines strength with moderate resistance to abrasion and wear in the heat-treated condition. Response to hardening is excellent. Superior response to hardening by heating to the appropriate temperature and quenching in either water or oil. When quenched and tempered, moderately tough and resistant to cracking and fatigue-type failure. Superior forging characteristics. 1045 1050-1060 1070 48 Very suitable for carburized parts that require considerable cold forming. Camshafts, bearing retainers, and chain rollers are typical parts that are carburized. Low-strength bolts, nuts, rivets, tie rod ends, and a variety of general hardware are among the products that are not carburized. Cold-extruded piston pins. Widely used for low-strength bolts and cold-formed parts. Used in the case-hardened condition for internal-combustion engine parts where cold strength is not critical. Very suitable for small parts of moderate strength. Used for parts that are cold headed; before cold heading, it is usually spheroidize annealed to improve workability. Popular for gear and sprocket production. Camshafts, tie rods, wheels, hubs, and other similar applications. Widely used in medium-strength, heat-treated forgings intended for a variety of components. Crankshafts, hubs, connecting rods, steering arms, axles, camshafts, couplings, yokes, and gears are typical applications; selection depends primarily on strength requirements, details or fabrication and processing, and cost. Used for a variety of medium-to-high-strength heat-treated forgings in automotive applications. Frequently cold-drawn to specified mechanical properties for use without heat treatment in some applications. Widely used for medium-strength, forged parts and accessories, particularly those requiring good torsional strength and some abrasion resistance. Typical automotive applications include camshafts, CVJs, and input/output shafts. Used for springs, and a variety of parts requiring good fatigue resistance, moderate toughness, and resistance to mechanical shock. In spring applications, grade 1070 is preferred for lighter sections and lighter loads, whereas grade 1080, because of higher hardenability and strength, can be employed where heavier sections are required. Used for integrated wheel bearings – hubs & spindles. Good for induction hardening in applications requiring a relatively thin, hard case for wear resistance augmented by a strong core for load-bearing and shock resistance. Widely used in the manufacture of case-hardened shafts and gears. ADVANCED MATERIALS & PROCESSES/AUGUST 2003 steel.qxd 7/15/03 7:43 PM Page 5 Common bar steel grades: properties and applications, continued Grade Key properties Typical applications Carbon manganese grades 1522 Especially suited to heat treating by either normalizing or Increasingly popular as an automotive gear steel, for quenching in water and tempering to reasonably highapplications such as pinions and side gears. Can be strength levels. Can be carburized for high surface hardness. carburized by the various methods. 1541 Responds in much the same manner as an alloy grade in that through-hardening can be obtained in limited sections and uniform strength levels can be engineered into the finished component. Can be induction hardened. Suitable for complex automotive transmission component shafting where splines and gears are an integral part of the shaft. Used for automotive connecting rods. 1552 Higher carbon level provides higher surface hardness. Automotive axle components where the material can be induction hardened to high surface hardness and uniform high-strength level can be maintained through the balance of the cross section. Through-hardening alloy grades 4140 Slightly difficult to process, is rarely cold formed but rather forged or machined. Used in Q&T or N&T condition. Can be heat treated to a high-strength level over a wide range of sizes. Has good toughness. Heavy gears, piston rods, heavy-duty crankshafts. Can be used for demanding applications requiring high strength and toughness 4340 Readily hot forged. Should be full annealed for machining, spheroidize annealed for cold forming. Used in Q&T or N&T condition. Used for large industrial gears . Used for shafting, piston rods. 5140 Should be fully annealed to facilitate machining. Should be spheroidize annealed for cold forging or extruding. Used predominantly in the Q&T or N&T condition. Gears, light shafting. 8640 Readily hot forged. Should be fully annealed for machining, Industrial gears, automotive ball studs. spheroidize annealed for cold forming. Used in Q&T or N&T condition. Carburizing alloy grades 4027 Can be hot forged. Can be machined in the as-rolled condition. Can be cold forged to a limited degree. Higher core hardness than the usual gear steel compositions. Used for carburized gears in automotive applications. 4118 Can be hot or cold formed. Can be machined without prior annealing. Carburized by conventional methods Used principally for automotive carburized gears subjected to moderate loading. 4320 Similar to 4620 in forging and other processing. Has higher hardenability than 4620. Good for carburized gears for heavy loading. Widely used for carburized bearings. 4620 Can be forged similarly to the other carburizing grades. Generally requires thermal treatment to facilitate cold forming or machining. Excellent for gears for moderate and heavy-duty applications. AISI Grade Designation System The American Iron & AISI System of designations for commonly used grades Steel Institute (AISI), the Grade Grade American Society for designation Steel Types designation Steel Types Testing and Materials (ASTM), and the Society 10xx Carbon Steel Grades 51xx Chromium 0.80, 0.95 or 1.05 % of Automotive Engineers 11xx Resulfurized Carbon Steel Grades 51xxx Carbon 1.00 % - Chromium 0.50, 1.00 (SAE) provide standards or 1.45 % for general specifications 12xx Rephosphorized and Resulfurized when ordering steel. Carbon Steel Grades 86xx Nickel 0.55 % - Chromium 0.50 % However, it should be Molybdenum 0.20 % 13xx Manganese 1.60 to 1.90 % noted that very little bar 87xx Nickel 0.55 % - Chromium 0.50 % 15xx Manganese 1.00 to 1.35 % steel for automotive apMolybdenum 0.25 % plications is supplied to 23xx Nickel 3.50 % 93xx Nickel 3.25 % - Chromium 1.20 % general requirements. 33xx Nickel 3.50 % - Chromium 1.55 % Molybdenum 0.12 % 40xx Molybdenum 0.25 % 94xx Manganese 1.00 % - Nickel 0.45 % Chromium 0.10 % - Molybdenum 0.12 % 41xx Chromium 0.95 % - Molybdenum 0.20 % For more information: 97xx Nickel 0.55 % - Molybdenum 0.20 % 43xx Nickel 1.80 % - Chromium 0.50 or John Bayer, MacSteel, Chromium 0.17 % 0.80 % - Molybdenum 0.25 % One Jackson Square Jackson, MI 49201 46xx Nickel 1.80 % - Molybdenum 0.25 % 98xx Nickel 1.00 % - Chromium 0.80 % tel: 517/782-0415 Molybdenum 0.25 % 48xx Nickel 3.50 % - Molybdenum 0.25 % e-mail: jbayer@macsteel.com Web site: www.macsteel.com. 50xx Chromium 0.30 or 0.60 % ADVANCED MATERIALS & PROCESSES/AUGUST 2003 49