PK Catalogue 2015

advertisement

Fully Integrated,Yet Flexible

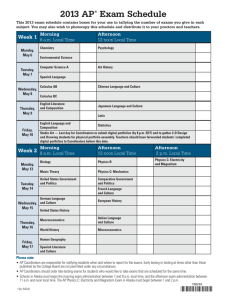

15

16

19

17

14

6

8

18

7

22

20

23

24

13

9

11

12

10

5

4

21

3

25

2

1

01. Entrance, Lounge

05. Machinery Shop

08. Meterial R&D Center

13. Lounge

02. Main Office

09. Laboratory 10. Pattern Shop

14. New Foundry Shop

18. Health Clinic

23. Production Warehouse

03. Machinery Shop , Test Shop , Auditorium

06. Foundry Shop, Molding Shop, Heat Treatment Furnace, Test Shop

19. Painting Shop

11. Facility Maintenance Office

15. Pattern Warehouse

20. Test Shop 24. Office , Cafeteria, Production Warehouse

16. Painting Shop

21. R&BD Center

04. Cryogenic Test Shop

07. Foundry Office

12. After Sales Service Shop

17. Casting Warehouse

22. Packaging Shop

25. Receiving Inspection Shop

All of our passion and energies have been committed

mitted to the developated services for

ment and supply of high quality valves and related

more than 60 years, and during that time we have taken a leading

role in the advancement of designs, technology, and service.

ow,

In the rapidly changing world of today and tomorrow,

PK Valve will step up to the challenges and lead ourr industry.

We are responsible for the quality and impact of our

nity

products and services on the industrial community

e

and on our environment. As we continue to serve

industries such as traditional power generation,

nuclear power, oil & gas, shipbuilding, semiconductor, aerospace, marine industries, and others,

ng

we will remain committed and disciplined in meeting

our responsibilities while leading our industry.

Dong-Soo Yoon

MANAGEMENT POLICY

On the basis of "Base on Reliability” as a fundamental management philosophy, all employees at PK Valve Co., Ltd. respect human

life and worker’s health care before all production activities, provide satisfactory products and services that meet the requirements

of customers by means of management activities in harmony with environment and continuing technological development and

quality innovations, and further make every effort to fulfill our social responsibilities and obligations with the realization of human

happiness as our top priority, including the policies specified below.

o3FDPHOJ[FUIF4BGFUZ)FBMUI&OWJSPONFOU2VBMJUZ4)&2

NBOBHFNFOUBTLFZGBDUPSTJOBDDPNQMJTIJOHPVSDPOUJOVPVT

stability and growth.we also comply with all legal and regulatory requirements, other applicable requirements as agreed and

internal regulations that relate to safety, health, environment, and quality aspects.

o*NQSPWFBOEVQHSBEFNBOBHFNFOUTZTUFNDPOUJOVPVTMZUISPVHIQSPDFTTJNQSPWFNFOUBOEUFDIOPMPHJDBMEFWFMPQNFOUTP

that all the factors impeding safety, health, environment, and quality activities can be minimized.

o&TUBCMJTIBOEJNQMFNFOUUIFNBOBHFNFOUPCKFDUJWFTBOEUBSHFUTUPBDDPNQMJTIPVS4)&2NBOBHFNFOUQPMJDZBOESFWJFX

and improve the continuing suitability of the management policy and system.

o (JWF DBSFGVM DPOTJEFSBUJPO UP TBGFUZ IFBMUI FOWJSPONFOU BOE RVBMJUZ PWFS UIF XIPMF QSPDFTT SBOHJOH GSPN QSPEVDU

development, design, production, servicing, and disposal.

o.BLFFWFSZFGGPSUUPQSFWFOUBDDJEFOUTCZUBLJOHQSFDBVUJPOTUPFMJNJOBUFIBSNGVMBOEEBOHFSPVTGBDUPSTJOWPMWJOHTBGFUZ

health, and environment activities, and where an accident occur, take a proper measure to minimize the damage.

o%PPVSCFTUUPFBSODVTUPNFSlTUSVTUBOEMPWFCZHSBTQJOHBDDVSBUFMZUIFRVBMJUZSFRVJSFNFOUTPGDVTUPNFSBOEGVSOJTIJOH

the best quality products that always satisfy customer’s expectations and requests.

o $POUJOVPVTMZ HJWF USBJOJOH UP BMM 1, 7BMWF FNQMPZFFT BOE PUIFS SFQSFTFOUBUJWFT XIP QFSGPSN TBGFUZ IFBMUI FOWJSPONFOU

and quality related activities to inspire awareness and induce active participation.

PK_6

PK_6

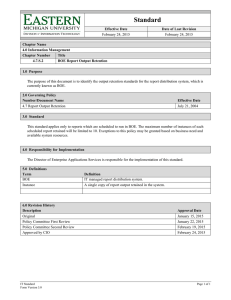

QUALITY APPROVAL

4

3

1

6

8

5

2

7

9

10

11

12

13

16

16

16

16

14

15

"4.&/"4.&

].BZ

"4.&/15"4.&

].BZ

3. *40#72*#VSFBV7FSJUBT2VBMJUZ*OUFSOBUJPOBM

.BOBHFNFOU4ZTUFN]4FQ

4. *40#72*#VSFBV7FSJUBT2VBMJUZ*OUFSOBUJPOBM

.BOBHFNFOU4ZTUFN]/PW

0)4"4#72*#VSFBV7FSJUBT2VBMJUZ*OUFSOBUJPOBM

.BOBHFNFOU4ZTUFN]/PW

,&1*$,PSFB&MFDUSJD1PXFS*OEVTUSZ$PEF

./]"VH

$&$PNNVOJUZPG&VSPQF

1&%&$]+VM

-3-MPZElT3FHJTUFSPGTIJQQJOH

4UFFM$BTUJOH]0DU

"1*"NFSJDBO1FUSPMFVN*OTUJUVUF

%].BS

/,/JQQPO,BJKJ,ZP,BJ

4UFFM$BTUJOH]/PW

"1*"NFSJDBO1FUSPMFVN*OTUJUVUF

]/PW

,3,PSFBO3FHJTUFSPG4IJQQJOH

4UFFM$BTUJOH]0DU

#7#VSFBV7FSJUBT

4UFFM$BTUJOH]"QS

/&1/FX&YDFMMFOU1SPEVDU

]+BO

%/7%FU/PSTLF7FSJUBT

4UFFM$BTUJOH]'FC

4*-4BGFUZ*OUFHSJUZ-FWFM

]%FD

PK_7

PK_7

COMPANY HISTORY

1946 (VWDEOLVKHG%XVDQ3RNXP,QG&RPSDQ\LQ%XVDQ.RUHD

1988 /LVWHGDVDPDQXIDFWXUHUIRULQVWDOODWLRQRIQXFOHDUSRZHUSODQWDW

.(3&2.RUHD(OHFWULF3RZHU&RUSRUDWLRQ1RQ6DIHO\&ODVV

1968 5HRUJDQL]HG%XVDQ3RNXP,QG&R/WG

$16,%9$/9(/LFHQFH1R

2EWDLQHGFHUWL¿FDWHRIPDQXIDFWXUHUIRU1XFOHDU9DOYHE\0LQLVWU\

1971 2EWDLQHG³.6´.RUHDQ,QGXVWULDO6WDQGDUGPDUNIRU%URQ]H

RI6FLHQFHDQG7HFKQRORJ\5HSXEOLFRI.RUHD

/LVWHGDVPDQXIDFWXUHURI&U\RJHQLF9DOYHLQ

&DVW,URQ9$/9(,WHPV%%%%%

1974 5HPRYHGDOOIDFLOLWLHVDQGIDFWRU\WR&KDQJZRQ,QGXVWULDO

&RPSOH[&XUUHQW/RFDWLRQ

1975 2EWDLQHG³.6´PDUNIRU&DVW6WHHO0DULQH9$/9(,WHPV

%%%%99999

.*&.RUHD*DV&RUSRUDWLRQ/LVW1R

1989 /LVWHGDVDPDQXIDFWXUHUIRULQVWDOODWLRQRIQXFOHDUSRZHUSODQWDW

.(3&26DIHW\&ODVV$60(Ⳕ9DOYH

/LVWHGDVDPDQXIDFWXUHUIRULQVWDOODWLRQRIWKHUPDOK\GURHOHFWULF

SRZHUSODQWDW.(3&2

1978 $SSURYHG6WHHO9DOYH0DQXIDFWXUHUE\$3,$PHULFDQ3HWUROHXP

,QVWLWXWH$3,'3LSH/LQH9$/9(*DWH&KHFN%DOO3OXJ

$SSURYHG&DUERQ6WHHO6WDLQOHVV6WHHO&DVWLQJV

1992 /LVWHGDVDPDQXIDFWXUHUIRULQVWDOODWLRQRIQXFOHDUSRZHUSODQWDW

.(3&2$16,%0RWRU2SHUDWHG9DOYH

0DQXIDFWXUHUE\.5.RUHDQ5HJLVWHURI6KLSSLQJ

1993 /LVWHGDVDPDQXIDFWXUHUIRULQVWDOODWLRQRIQXFOHDUSRZHUSODQWDW

1979 ([SDQGHGODERUDWRU\E\LQVWDOOLQJ63(&7520(7(5DQG

RWKHUHTXLSPHQW

2EWDLQHG³.6´PDUNIRU&DVW%URQ]H9DOYH

,WHPV%%

1980 5HQDPHGWR3DQ.RUHD0HWDO,QG&R/WG

$SSURYHG6WHHO&DVWLQJ0DQXIDFWXUHUE\

/5/OR\G¶V5HJLVWHURI6KLSSLQJ

1981 'HVLJQDWHGDVVSHFLDOL]HGLQVWDOODWLRQRI3RZHUSODQWE\

0LQLVWU\RI&RPPHUFHDQG,QGXVWU\5HSXEOLFRI.RUHD

$SSURYHG6WHHO&DVWLQJ0DQXIDFWXUHUE\

1.1LSSRQ.DLML.\RNDL/LFHQFH1R

1983 $SSURYHG6WHHO&DVWLQJ0DQXIDFWXUHUE\'19

'HW1RUVNH9HULWDV

1985 'HYHORSHG&U\RJHQLF9$/9(

1986 /LVWHGDVVSHFLDOL]HGLQVWDOODWLRQRISRZHUSODQWDW

.+,&.RUHD+HDY\,QGXVWULHV&RQVWUXFWLRQ&R/WG/LVW1R

$I¿OLDWHGDVPHPEHURI.$,).RUHD$WRPLF,QGXVWULDO)RUXP

2EWDLQHG&HUWL¿FDWHRI0DQXIDFWXUHUIRU(PHUJHQF\6KXWRII

%DOO9DOYHE\*RYHUQPHQW

$SSURYHG6WHHO&DVWLQJV0DQXIDFWXUHUE\%9%XUHDX9HULWDV

.(3&2$16,Ⳕ0RWRU2SHUDWHG9DOYH

2EWDLQHG,62FHUWL¿FDWHE\

%94,%XUHDX9HULWDV4XDOLW\,QWHUQDWLRQDO

1994 $SSURYHG$3,$3,$60($16,%0DQXIDFWXUHU

E\0RELO5HVHDUFK'HYHORSPHQW&RUS

1996 'HYHORSHG%HOORZV6HDO*DWH*OREHYDOYH

'HYHORSHG0HWDO6HDW%DOOYDOYH

'HYHORSHG:DIHU7LOWLQJ&KHFNYDOYH

6WDUWHG/RZ)XJLWLYH(PLVVLRQWHVW

1997 2EWDLQHG4XDOLW\$VVXUDQFH4XDOL¿FDWLRQFHUWL¿FDWHE\.(3,&

1998 2EWDLQHG789FHUWL¿FDWHE\7895KHLQODQG

2EWDLQHG(0([FHOOHQW0DFKLQH0HFKDQLVPDQG0DWHULDO

PDUNIRU+LJK3UHVVXUH0HWDO6HDW7LOWLQJ&KHFNYDOYH

1999 'HYHORSHG/RZ(PLVVLRQ3DFNLQJIRUYDOYH

'HYHORSHG6XSHU'XSOH[6WDLQOHVV6WHHOIRUFDVWLQJ

2000 'HYHORSHG7ULSOH2IIVHW%XWWHUÀ\9DOYH

2001 6HOHFWHGDV,112%,=

2EWDLQHG&(&RPPXQLW\RI(XURSH3('(&FHUWL¿FDWH

2EWDLQHG(0PDUNIRUKLJKSUHVVXUH7ULSOH2IIVHW%XWWHUÀ\9DOYH

1987

$SSURYHG)LUH6DIH%DOO9$/9(E\$07(&+$3,

'HYHORSHG3UHVVXUH6HDO7\SH9$/9(IRUKLJKSUHVVXUHDQG

KLJKWHPSHUDWXUH

2EWDLQHG7\SH$SSURYDORI)LUH6DIH%DOO9DOYHE\'19

PK_8

PK_8

2002 /LVWHGDSSURYHGYDOYHPDQXIDFWXUHUE\([[RQ0RELO

/LVWHGDSSURYHGYDOYHPDQXIDFWXUHUE\6KHOO&KHPLFDO

2EWDLQHG(0PDUNIRU7ULSOH2IIVHW0HWDO6HDW%XWWHUÀ\9DOYH

GGGGGGGGGGGGGGGGGGGGGGGGGGGGG

CONTENTS

1.BOLTED BONNET VALVE

2003

/LVWHGDSSURYHGYDOYHPDQXIDFWXUHUE\6DXGL$UDPFR

-RLQHG16661XFOHDU6WHDP6XSSO\6\VWHPIRU0RWRU2SHUDWHG

9DOYHDVRQHRIWKH9HQGRUV

2005

2EWDLQHG,622+6$6E\%94,

2006

2EWDLQHG1(30DUNIRU&U\RJHQLF0HWDO6HDWHG%XWWHUÀ\9DOYH

&KDQJHGFRPSDQ\QDPHDQGORJRWR3.9DOYH&R/WG

2007

+RQRUHGZLWK80LOOLRQV$FKLHYHPHQW$ZDUGDWWKHWK

$QQXDO7UDGH'D\

$ZDUGHGE\*RYHUQPHQWIRU1HZ7HFKQRORJ\3UDFWLFDOLW\

3URPRWLRQ

2EWDLQHGWKH3DWHQWRI/LYHORDGLQJ6HDW6XSSRUWLQJIRU

&U\RJHQLF%XWWHUÀ\9$/9(

&DUULHGRXWWKH40(WHVWIRU1666

1XFOHDU6WHDP6XSSO\6\VWHP%\:\OH/DERUDWRULHV

2008

$SSRLQWHGDVH[FHOOHQWFRPSDQ\IRUSURGXFWLYLW\LPSURYHPHQW

E\*RYHUQPHQW

2009

2EWDLQHG$60(1137FHUWL¿FDWHV

2010

$ZDUGJDWHYDOYH

STEEL VALVE

- GATE VALVE

- GLOBE VALVE

- Y-GLOBE VALVE

- SWING CHECK VALVE

- TILTING DISC CHECK VALVE

- DUAL PLATE CHECK VALVE

STAINLESS

STEEL VALVE

- GATE VALVE

- GLOBE VALVE

- SWING CHECK VALVE

2.PRESSURE SEAL VALVE

- GATE VALVE

- GLOBE VALVE

- Y-GLOBE VALVE

- SWING CHECK VALVE

- TILTING DISC CHECK VALVE

3.PARALLEL SLIDE GATE VALVE

- BOLTED BONNET TYPE

- PRESSURE SEAL BONNET TYPE

4.CRYOGENIC VALVE

&RQVWUXFWHGDQHZ3URGXFWLRQ2I¿FH

2011

CAST

(VWDEOLVKHG0DWHULDO5'&HQWHU

%XLOWDQHZ5%'&HQWHU

'HYHORSHGKLJK3UHVVXUHIRUJHGVWHHO9DOYH

2012

$ZDUGHGWKH7RZHURIPLOOLRQ([SRUW

2013

([SDQGHGDSSURYDOUDQJHVWRKLJKSUHVVXUHDQG

FU\RJHQLFYDOYHIRU&KHYURQ

2014

$ZDUGJDWHYDOYH

- GATE VALVE

- GLOBE VALVE

- SWING CHECK VALVE

- BUTTERFLY VALVE

5.BELLOWS SEAL VALVE

- GATE VALVE

- GLOBE VALVE

6.BUTTERFLY VALVE

2EWDLQHG6,/6DIHW\,QWHJULW\/HYHO

2EWDLQHG*RVW5FHUWL¿FDWHV

- TRIPLE OFFSET TYPE

- DOUBLE ECCENTRIC TYPE

- CONCENTRIC TYPE

7.BALL VALVE

- FLOATING BALL

- TRUNNION BALL

8.FORGED STEEL VALVE

- GATE VALVE

- GLOBE VALVE

- LIFT CHECK VALVE

- SWING CHECK VALVE

9.HIGH PRESSURE FORGED

STEEL VALVE

- GATE VALVE

- Y-GLOBE VALVE

10.ACCESSORIES

PK_9

PK_9

PK FIGURE NUMBER SYSTEM

Example

0 GATE

G 1 5 0

1

RT J

1 0

N C F 3M P S B

1 GLOBE

2 SWING CHECK

3 TILTING CHECK

4 PISTON CHECK

HANDWHEEL

G GEAR OPERATOR

WCB

2 API TR.2

5 API TR.5

L C B LCB

L C C LCC

9 ANGLE GLOBE

A GLOBE CHECK

8 API TR.8

0 API TR.10

W C 6 WC6

C 5 C5

D LIFT CHECK

E DUAL PLATE CHECK

P PNEUMATIC ACTUATOR

3 0 CL 300

1 API TR.1

7 SLURRY

8 Y-GLOBE

B Y-GLOBE CHECK

C ANGLE GLOBE CHECK

M MOTOR OPERATOR

A AIR OPERATOR

1 5 CL 150

5 BALL

6 BUTTERFLY

R F RAISED FACE

B W BUTT WELD END

C 1 2 C12

C F 8 CF8

1 API TR.11

1 2 API TR.12

S L API 603 S/S

S H API 600 S/S

1

CF8M

C F 3 M CF3M

NON NACE

N NACE

BOLTED BONNET

P S

B PRESSURE SEAL

R E

D REDUCE PORT

6 0 CL 600

R T

8 0 CL 800

W A F WAFER

C G S CRYOGENIC SEVICE

9 0 CL 900

L U G LUG

B E

L BELLOWS TYPE

F

L FLOATING TYPE

1 5 0 CL 1500

F

J

1

RING TYPE JOINT

F FLAT FACE

2 5 0 CL 2500

T R TRUNNION TYPE

4 5 0 CL 4500

T O B TRIPLE OFFSET TYPE

D O B DOUBLE ECCENTRIC

PK_10

PK_10

1. BOLTED BONNET VALVE

CAST STEEL VALVE

- GATE VALVE

- GLOBE VALVE

- Y-GLOBE VALVE

- SWING CHECK VALVE

- TILTING DISC CHECK VALVE

- DUAL PLATE CHECK VALVE

STAINLESS STEEL VALVE

- GATE VALVE

- GLOBE VALVE

- SWING CHECK VALVE

PK_11

CAST STEEL VALVE

SERVICE FEATURES

o4FWFSBMUSJNDPNCJOBUJPOTBWBJMBCMFGPSWBSJPVTTFSWJDFT

o4USBJHIUUISPVHIQPSUEFTJHOPGGFSJOHBHPPEGMPXXJUINJOJNVNGSJDUJPOBMMPTTBOEUVSCVMFODF

o$BTUTUFFM7BMWFTVJUBCMFGPSXPSLTEFNBOEJOHTUSFOHUITIPDLSFTJTUBODFFMPOHBUJPOBOEIFBUSFTJTUBODF

o#PUUPNTFBUJOHPGTFBUSJOHTHSPVOEBDDVSBUFMZGPSNBYJNVNTUSFOHUIBOEUJHIUOFTTHMPCF

o#ZQBTTNPVOUJOHUPFRVBMJ[FQSFTTVSFT

o/PSNBMZPLFCVTIJOHGVSOJTIFEXJUIEVDUJMJUZSFTJTUBOUUPIJHINFMUJOHQPJOUPGBCPWF'

o-FWFMBOEXFJHIUBWBJMBCMFUPBDDFMFSBUFEFDFMFSBUFEJTDDMPTJOHTXJOHDIFDL

o%FTJHOFEGPSNBYJNVNGMPXXJUINJOJNVNQSFTTVSFESPQJGQPTTJCMF

o1SFDJTJPOHSPVOETFBUJOHTVSGBDFTBOESFWPMWJOHEJTDQSPWJEJOHBMPOHMJGF

*OUIFSFGJOFSJFTQPXFSQMBOUTVUJMJUJFTBOEQFUSPDIFNJDBMDIFNJDBMQSPDFTTJOEVTUSJFT1,DBTUTUFFMWBMWF

have been regarded as of great importance about their excellent performance and reliability.

By discriminatory blending of carefully selected materials combined with sound design and precision

NBDIJOJOHBTTFNCMZVOEFSTUSJDURVBMJUZDPOUSPMT1,TUFFMWBMWFIBWFHBJOFEHFOFSBMBOEXJEFBDDFQUBODF

5IFQSPEVDUTBSFNBOVGBDUVSFEJOBDDPSEBODFXJUI"45."/4*PSPUIFSJOUFSOBUJPOBMTUBOEBSET

CAST STEEL VALVE PRODUCTION RANGE

UNIT : NPS

Class

150

300

600

900

1500

2500

GATE

2-96

2-80

2-48

2-48

2-24

2-30

GLOBE

2-24

2-24

2-24

2-24

2-24

2-24

SWING CHECK

2-56

2-48

2-48

2-36

2-24

2-30

TILTING CHECK

2-48

2-48

2-48

2-36

2-24

2-30

Y-GLOBE

2-24

2-24

2-24

2-24

2-24

2-24

ANGLE GLOBE

2-24

2-24

2-24

2-24

2-24

2-24

Type

PRODUCTION MATERIALS

o$BSCPO4UFFM"45."8$#PS&RVJWBMFOU

o"MMPZ4UFFM"45."8$8$$$$"PS&RVJWBMFOU

o4UBJOMFTT4UFFM"45."$'$'.$'$'.$/.PS&RVJWBMFOU

o%VQMFY4UBJOMFTT4UFFM"45."""""PS&RVJWBMFOU

o4QFDJBM"MMPZ4UFFM*ODPOFM*ODPMPZ)BTUFMMPZ$.POFM"-#30/;&

o"4.&4"EFTJHOBUJPONBUFSJBMFH"4.&4"8$

PK_12

PK_12

GATE VALVE

FUNCTION

(BUFWBMWFJTDIBSBDUFSJ[FECZBTMJEJOHXFEHFXIJDIJTNPWFE

CZ BDUVBUPS QFSQFOEJDVMBS UP UIF GMPX EJSFDUJPO 5IFSF BSF B

WBSJFUZPGWBMWFTJ[FTBOEUZQFT5IFWBMWFJTVTFEQSJNBSJMZBTB

TUPQ WBMWF UP PQFO PS DMPTF GVMMZ /PSNBMMZ JU XPSLT GPS TMVSSJFT

WJTDPVT GMVJE FUDCVU OPU GPS UISPUUMJOH 5IF HBUF WBMWF VTVBMMZ

has a minimum pressure drop in full open and a tight seal in full

close, and therefore there is little possibility that contaminants

may enter the valve.

BODY AND BONNET

5IF CPEZ BOE CPOOFU JT EFTJHOFE UP BDIJFWF NPTU VOJGPSN

distribution of stress on all sides and minimum turbulence and

SFTJTUBODF UP GMPX 5IF CPOOFU PO WBMWF JT FRVJQQFE XJUI CBDL

TFBUSJOHVQUPGPS$MBTTBOEVQUPGPS$MBTT

PSIJHIFS5IFZPLFJTJOUFHSBUFEXJUICPOOFU

BODY-BONNET JOINT

#PEZCPOOFUKPJOUPGHBUFWBMWFJTNBDIJOFEBTGPMMPXT

$MBTT................................... Plain faced

$MBTTBOEIJHIFSDMBTT.........BMFBOEGFNBMF

8FDBOTVQQMZBOZLJOETPGHBTLFUBTSFRVJSFECZDVTUPNFS

WEDGE

5IF WBMWF JT OPSNBMMZ TVQQMJFE XJUI B POFQJFDF GMFYJCMF XFEHF PG XIJDI UIF DSPTT TFDUJPO JT B UBQFSFE )

shape.

"MMXFEHFTBSFGVMMZHVJEFE5IFGMFYJCMFXFEHFJTDBTUPSNBDIJOFEXJUIDJSDVNGFSFOUJBMHSPPWFTUPBMMPXUIF

TFBUJOHGBDFTUPNPWFJOEFQFOEFOUMZBOEBEKVTUUIFNPWFNFOUPGCPEZTFBU

*U JT VTFE XIFSF UIF MJOF MPBE PS UIFSNBM FYQBOTJPO PG TZTUFN NBZ EJTUPSU UIF TFBUJOH GBDF PG WBMWF BOE

especially uesful to prevent sticking that may happen in case the valve is closed at a hot temperature and

opened at a cold temperature.

*EFBMMZUIFXFEHFJTTVJUBCMFGPSTUFBNBOEPUIFSIJHIUFNQFSBUVSFTFSWJDF

PK_13

SEAT RING

5IFTFBUSJOHBTBXFMEFEJOUZQFJTEFTJHOFEUPQSFWFOUBOZUVSCVMFODFBOEEBNBHFCZDPSSPTJPO*UJTGPSHFEPSSPMMFE

type into one piece for all dimensions, heat treated to obtain the desired surface hadness, and cleaned thoroughly

before assembling.

STEM

5IFTUFNDPOOFDUJPOUPUIFXFEHFTIBMMIBWFBOJOUFHSBUFEUFFIFBEXJUIPVUXFMEJOH

BOEJTSFDUJGJFEJOUIFQBDLJOH

BSFBUPFOTVSFBMPOHMJGFBOEQFSGFDUUJHIUOFTT5ISPVHIFYQFSJNFOUTXFIBWFDBMDVMBUFEBOEDIFDLFEUIFDPOOFDUJPOT

between stem and wedge not to disengage the stem from wedge while gate valve is working.

5IFTUSFOHUIPGTUFNBOEXFEHFDPOOFDUJPOTJTTUSPOHFSUIBOUIBUPGTUFNBMPOFBUUIFSPPUPGUISFBE

PACKING

5IFQBDLJOHTJ[FJTEFTJHOFEUPTFDVSFNBYJNVNUJHIUOFTTBMPOHUIFTUFNBOEUIFTUBOEBSEQBDLJOHJTBOPOBTCFTUPT

UZQF8FDBOTVQQMZBOZLJOETPGQBDLJOHBTSFRVJSFECZDVTUPNFS

YOKE SLEEVE

5IFZPLFTMFFWFJTEFTJHOFEUPBCMFUPCFEJTBTTFNCMFEXJUIPVUEJTDPVOUJOHCPOOFUBOETUFNBOEQSPWJEFEXJUICBMM

CFBSJOHPGPSPWFSGPS$MBTT_WBMWFPSPWFSGPS$MBTTBOEPSPWFSGPS$MBTT_

GLAND

5IF HMBOE JT NBEF PG UXP QJFDFT 1BDLJOH HMBOE JT JO DPOUBDU XJUI UIF QBDLJOH XIJDI JT DPOOFDUFE UP HMBOE GMBOHF

UISPVHIBTQIFSJDBMKPJOU1BSUJDVMBSEFTJHOQFSNJUTBDPSSFDUQSFTTVSFPOUIFQBDLJOHXJUIPVUBOZEBNBHFUPTUFNEVF

to friction or corrosion.

STUFFING BOX

5IFTUVGGJOHCPYHJWFTNBYJNVNQBDLJOHTUFNTFBM

-BOUFSOSJOHBOEHSFBTFJOKFDUPSTIBMMCFGVSOJTIFEPOMZJGTQFDJGJFEPOUIFQVSDIBTFPSEFS

HAND WHEELS

)BOEXIFFMTBSFEFTJHOFEGPSFBTZPQFSBUJPO8JUIHFBSJOHNPUPSBDUVBUPSPSDZMJOEFSBDUVBUPSJUJTBMTPBWBJMBCMFGPS

more difficult services.

BOLTS AND NUTS

#PMUTBOEOVUTBSFNBEFGSPNGPVSEJGGFSFOUUZQFTPGTUFFMNBUFSJBMTJODPOGPSNJUZXJUIUIF"45.TQFDJGJDBUJPO

"(SBEF#*UIBTBNJOJNVNUFOTJMFTUSFOHUIPGQPVOETQFSTRVBSFJODILH⽉

5IF OVUT OPSNBMMZ VTFE XJUI NBDIJOF CPMUT BSF B IPU QSFTTFE TUFFM DPOGPSNJOH UP "45. TQFDJGJDBUJPO " XIJDI JT

usually applied to hinge bolts and nuts.

"(SBEF##*UVTVBMMZSFUBJOTUIFTUSFOHUIXFMMBUBOFMFWBUFEUFNQFSBUVSFBOEPGGFSTIJHIFSSFTJTUBODFUP

DSFFQUIBOBOZPUIFSIJHIHSBEFTUFFMVTFEBTCPMUJOHNBUFSJBMT5IJTTUFFMJTSFHVMBSMZVTFEJOCPOOFUCPMUT

"(SBEF)5IFOVUTPGUIJTHSBEFTIBMMCFSFIFBUFEBCPWFUIFDSJUJDBMSBOHFPGTUFFMRVFODIFEJOBTVJUBCMF

NFEJVNBOEUIFOUFNQFSFEBUBUFNQFSBUVSFOPUMFTTUIBO'$

5IJTTUFFMJTSFHVMBSMZVTFEJOCPOOFUOVUT

$BSCPOTUFFM*UJTVTFEJOIBOEXIFFMOVUTTFUTDSFXTPSOJQQMFT

PK_14

PK_14

END CONNECTIONS

*O PVS TUBOEBSE QSPEVDUJPO PG WBMWF UIF GMBOHF FOET3'''

BOE UIF GBDF UP GBDF EJNFOTJOPT DPOGPSN UP "/4* # BOE

"4.&#SFTQFDUJWFMZBOEUIFZIBWFBSBJTFEGBDFTFSSBUFEGJOJTIUZQFPSPUIFSGJOJTIUZQFBTSFRVFTUFE

'PS CVUUXFMEFE FOET #8

PG XIJDI UIF FOE UP FOE EJNFOTJPO DPOGPSNT UP "4.& # DVTUPNFS NVTU TQFDJGZ UIF

schedule type required, pipe class, or bore diameter.

3JOHUZQFKPJOUGMBOHFEFOET35+

DPOGPSNUP"4.&#BOEUIFFOEUPFOEEJNFOTJPOGPMMPXT"4.&#5IFPUIFS

special end connections may be supplied as required by customer.

GEAR OPERATED VALVE

Valve can be supplied with gear operators.

MOTOR OPERATED VALVE

Valve can be supplied with actuators, either electric or pneumatic, accordings to customer’s requirements.

ACCESSORIES

8FDBOTVQQMZBWBMWFGJUUFEXJUIBDDFTTPSJFTTVDIBTCZQBTTMPDLJOHEFWJDFDIBJOXIFFMFYUFOTJPOTUFNFUD'PSNPSF

details, refer to the Accessories column.

PACKING AND GASKET MATERIALS

1BDLJOH NBUFSJBM TVQQMJFE JO TUBOEBSE WBMWF JT OPOBTCFTUPT HSBQIJUF XJUI CSBJEFE HSBQIJUF SJOHT BOE EJFGPSNFE SJOHT

DPOGJHVSFEUPQSPWJEFSFMJBCMFBOEMPOHMBTUJOHQFSGPSNBODF#SBJEFESJOHTBSFDPBUFEXJUI[JODEVTUUPJOIJCJUDPSSPTJPO

%JFGPSNFESJOHTBSFDBSCPONJOJNVN

BOEIBWFNBYJNVN11.DIMPSJEF11.TVMGVSDPOUFOU

'PSTUBOEBSEWBMWFHBTLFUNBUFSJBMTBSFBTGPMMPXT

$MBTTHSBQIJUFTIFFUUZQFXJUITUBJOMFTTTUFFMUBOHFEJOTFSUNNNJOJNVNPWFSBMMUIJDLOFTT

$MBTTTQJSBMXPVOETUBJOMFTTTUFFMBOEHSBQIJUF

$MBTTTBNFBTDMBTTPS

$MBTTBOE3JOHUZQFKPJOU

SEAL AREA DESIGN

Cast steel valve are designed and manufactured to satisfy strict requirements in order to prevent external leakage and to

meet fugitive emission requirements of most customers.

4UVGGJOHCPYGJOJTIFTPGUP3.4TUFNGJOJTIFTPGUP3.4DPOUSPMPGTUSBJHOUOFTTBOEDPODFOUSJDJUZPGTUFNT

and controlled diametrical clearances between stem and gland, stem and backseat, and gland and stuffing box, all combine

to quarantee consistent performance of stem seals.

(BTLFU TVSGBDFT CFUXFFO CPEJFT BOE CPOOFUT BSF TUSJDUMZ DPOUSPMMFE UP GJOJTIFT PG UP ""3) 8IFO DPNCJOFE XJUI

engineered bolting design, quality materials and strict assembly procedures, these finishes quarantee consistent sealing in

gasket areas.

PK_15

øD

H (OPEN)

H1

øD1

GOV (GEAR OPERATED)

END CONNECTION

3''-"/(&%&/%450"4.&#

#8&/%450"4.&#

35+'-"/(&%&/%450"4.&#

L(RF), L1(BW)

4*;&"/%-"3(&3'-"/(&%&/%4

"$$03%*/(50"4.&#4&3"034&3#

STANDARD MATERIAL SPECIFICATIONS

PK_16

PK_16

NO

PART NAME

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

BODY

BONNET

WEDGE

STEM

HAND WHEEL

BODY SEAT RING

BACK SEAT RING

GASKET

PACKING

GLAND FLANGE

HINGE BOLT

HINGE NUT

HINGE PIN

PACKING GLAND

BONNET BOLT

BONNET NUT

YOKE CAP

YOKE SLEEVE

HANDLE NUT

SET SCREW

NIPPLE

GEAR BOX

STEM COVER

MATERIAL

A217 - WC6

A217 - WC6

A217 - CA15 + STL

A479 - 410

A197

A182 - F11 + STL

A479 - 410

SPIRAL WOUND / GRAPHITE+304+304

GRAPHITE+GRAPHITE WITH INCONEL WIRE

A105

A105

A307 - B

A307 - B

A194 - 2H

A194 - 2H

A576 - 1020

A576 - 1020

A479 - 410

A576 - 1020 + Cr

A193 - B16

A193 - B7

A194 - 4

A194 - 2H

A576 -1020

A576 - 1020

A439 - D2C

A439 - D2C

A47 - 32510 + Zn

A47- 32510 + Zn

STEEL

STEEL

STEEL + Cr

STEEL + Cr

DUCTILE IRON

DUCTILE IRON

A53

A53

A216 - WCB

A216 - WCB

A217 - CA15 + STL

A479 - 410

A197

A576 -1020 + STL

A479 - 410

A351 - CF8

A351 - CF8

A351 - CF8 + STL

A479 - 304

A197

A240 - 304 + STL

A479 - 304

A351 - CF8

A193 - B8

A194 - 8

A479 - 304

A479 - 304

A193 - B8

A194 - 8

A576 -1020 + Zn

A439 - D2C

A47 - 32510 + Zn

STEEL + Cr

STEEL + Cr

DUCTILE IRON

A53

DIMENSION AND WEIGHT

CLASS 150

SIZE

L

L1

D

D1

H

H1

WEIGHT(Kg)

CLASS 300

SIZE

L

L1

D

D1

H

H1

WEIGHT(Kg)

CLASS 600

SIZE

L

L1

D

D1

H

H1

WEIGHT(Kg)

CLASS 900

SIZE

L

L1

D

D1

H

H1

WEIGHT(Kg)

CLASS 1500

SIZE

L

L1

D

D1

H

H1

WEIGHT(Kg)

UNIT : mm

2

3

4

6

8

10

12

14

16

18

20

24

26

28

177.8

215.9

200

339

16

203.2

282.4

224

441

29

228.6

304.8

250

535

43

266.7

403.4

315

250

735

950

72

292.1

419.1

355

250

927

1071

116

330.2

457.2

400

355

1125

1260

173

355.6

501.7

450

355

1317

1462

263

381.0

571.5

500

355

1550

1658

388

406.4

609.6

560

500

1823

1830

535

431.8

660.4

630

500

1900

2058

648

457.2

711.2

710

630

2120

2268

822

508.0

812.8

800

630

2502

2660

1276

558.8

710

2950

1552

609.6

900

710

2873

3052

1777

2

3

4

6

8

10

12

14

16

18

20

24

26

28

215.9

215.9

200

340

22

282.4

282.4

224

442

41

304.8

304.8

250

536

59

403.4

403.4

355

250

745

895

119

419.1

419.1

400

355

951

1087

193

457.2

457.2

450

355

1142

1269

291

501.7

501.7

500

355

1325

1470

410

762.0

762.0

560

500

1631

1669

687

838.2

838.2

630

500

1692

1849

876

914.4

914.4

710

630

1909

2065

1201

2

3

4

6

8

10

12

14

16

18

292.1

292.1

200

394

35

355.6

355.6

250

475

64

431.8

431.8

355

591

110

558.8

558.8

450

355

801

995

222

660.4

660.4

500

500

1005

1233

405

787.4

787.4

630

500

1192

1360

626

838.2

838.2

630

1605

878

889.0

889.0

630

1792

1165

30

609.6

900

710

3066

3268

2119

UNIT : mm

30

990.6 1143.0 1244.6 1346.2 1397

990.6 1143.0

800

900

630

710

800

800

900

2119 2492

2272 2667 3057 3265 3475

1500 2258 3026 3450 4147

20

24

26

28

UNIT : mm

30

990.6 1092.2 1193.8 1397.0 1447.8 1549.4 1651

990.6 1092.2 1193.8 1397.0

710

710

800

900

900

900

900

2079 2160 2366 2740 3002 3235 3480

1490 1836 2410 3639 4437 5589 6933

2

3

4

6

8

10

12

14

16

18

20

368.3

368.3

250

474

73

381.0

381.0

355

250

623

678

103

457.2

457.2

355

250

718

900

159

609.6

609.6

500

500

958

1112

318

736.6

736.6

630

500

1290

1322

568

838.2

838.2

710

630

1451

1542

908

965.2

965.2

710

1786

1234

1028.7

1028.7

710

1792

1628

1130.3

1130.3

710

1955

2288

1219.2

1219.2

900

2308

3025

1320.8

1320.8

900

2466

3850

2

3

4

6

8

10

12

368.3

368.3

250

474

81

469.9

469.9

355

603

141

546.1

546.1

400

355

730

880

227

704.9

704.9

560

500

944

1106

515

831.9

831.9

800

630

1205

1350

992

990.6

990.6

900

710

1414

1570

1603

1130.3

1130.3

800

1826

2572

UNIT : mm

24

1549.4

1549.4

900

2889

5200

UNIT : mm

16

1384.4

1092

800

2129

2341

5255

PK_17

GLOBE VALVE

FUNCTION

5IFHMPCFWBMWFJTVTFEXIFSFUISPUUMJOHBMPOFPSCPUIUISPUUMJOHBOETIVUPGGJTOFFEFE*UNBZBMTPCFVTFEGPS

POPGG TFSWJDF CVU CFDBVTF PG IJHI QSFTTVSF ESPQ TVDI BQQMJDBUJPO JT MJNJUFE UP UIF DBTFT UIBU UIF WBMWF JT

normally closed and the pressure drop is of no importance in valve open condition.

1,DBTUTUFFMHMPCFWBMWFJTSFHVMBSMZNBEFJOPVUTJEFTDSFXBOEZPLFEFTJHOXJUIGVMMXBZUZQFEJTD

BODY AND BONNET

5IFCPEZIBTBTQIFSJDBMGPSNXJUIMBSHFSBEJVTXIJDIQFSNJUT

the stress, turbulence and resistance to flow to be kept

NJOJNVN 5IF CPOOFUT PO WBMWF BSF FRVJQQFE XJUI CBDL TFBU

rings.

BODY-BONNET JOINT

#PEZCPOOFUKPJOUPGHMPCFWBMWFJTNBDIJOFEBTGPMMPXT

All ...............................BMFBOEGFNBMF

8FDBOTVQQMZBOZLJOETPGHBTLFUBTSFRVJSFECZDVTUPNFS

DISC

5IFWBMWFJTOPSNBMMZTVQQMJFEXJUIQMVHUZQFEJTD

SEAT RING

5IFWBMWFJTOPSNBMMZTVQQMJFEXJUICPUUPNTFBUFEUZQFPOPS

larger valve, and the disc has bottom guide type seat rings.

STEM

"MMTUFNIBWFUIFUVSOJOHBOESJTJOHDVU"$.&UISFBET

PK_18

PK_18

18

YOKE BUSH

5IF ZPLF OVUT PO HMPCF WBMWF BSF UISFBEFE BOE

mounted to the bonnet, where it is secured with tack

welding.

PACKING

5IF QBDLJOH TJ[F JT EFTJHOFE UP TFDVSF NBYJNVN

tightness along the stem, and the standard packing

JT B OPOBTCFTUPT UZQF 8F DBO TVQQMZ BOZ LJOET PG

packing as required by customer.

GLAND

5IFHMBOEJTNBEFPGUXPQJFDFT1BDLJOHHMBOEJTJO

contact with the packing which is connected to gland

GMBOHF UISPVHI B TQIFSJDBM KPJOU 1BSUJDVMBS EFTJHO

permits a correct pressure on the packing without any

damage to stem due to friction or corrosion.

STUFFING BOX

5IF TUVGGJOH CPY HJWFT NBYJNVN QBDLJOH TUFN TFBM

-BOUFSOSJOHBOEHSFBTFJOKFDUPSTIBMMCFGVSOJTIFEPOMZ

if specified on the purchase order.

HAND WHEELS

)BOE XIFFMT BSF EFTJHOFE GPS FBTZ PQFSBUJPO 5IFZ

BSFQSPWJEFEXJUIIBNNFSCMPXUZQFPGBOEPWFSGPS

$MBTTWBMWFBOEPWFSGPS$MBTTBOEBOE

PWFSGPS$MBTTBOEBOEPWFSGPS$MBTT

8JUIHFBSJOHNPUPSBDUVBUPSPSDZMJOEFSBDUVBUPSUIFZ

are also available for more difficult services.

PK_19

19

øD

H1

H (OPEN)

øD1

GOV (GEAR OPERATED)

END CONNECTION

L(RF), L1(BW)

3''-"/(&%&/%450"4.&#

#8&/%450"4.&#

35+'-"/(&%&/%450"4.&#

4*;&"/%-"3(&3'-"/(&%&/%4

"$$03%*/(50"4.&#4&3"034&3#

STANDARD MATERIAL SPECIFICATIONS

PK_20

PK_20

NO.

PART NAME

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

21

22

23

24

BODY

BONNET

DISC

STEM

HAND WHEEL

BODY SEAT RING

BACK SEAT RING

GASKET

PACKING

GLAND FLANGE

HINGE BOLT

HINGE NUT

HINGE PIN

PACKING GLAND

BONNET BOLT

BONNET NUT

YOKE BUSH

LOCK NUT

HANDLE NUT

SHAKE ADAPTER

HANDLE COVER

GEAR BOX

STEM COVER

MATERIAL

A216 - WCB

A216 - WCB

A217 - CA15+STL

A479 - 410

DUCTILE IRON

A216 - WCB+STL

A479 - 410

A283 - D

A307 - B

A194 - 2H

A576 - 1020

A576 - 1020+Cr

A193 - B7

A194 - 2H

A439 - D2C

A479 - 410

A563 - A

DUCTILE IRON

A283 - D

DUCTILE IRON

A53

A217 - WC6

A217 - WC6

A217 - CA15+STL

A479 - 410

DUCTILE IRON

A217 - WC6+STL

A479 - 410

SPIRAL WOUND / GRAPHITE+304+304

GRAPHITE+GRAPHITE WITH INCONEL WIRE

A283 - D

A307 - B

A194 - 2H

A576 - 1020

A479 - 410

A193 - B16

A194 - 4

A439 - D2C

A479 - 410

A563 - A

DUCTILE IRON

A283 - D

DUCTILE IRON

A53

A351 - CF8M

A351 - CF8M

A351 - CF8+STL

A479 - 304

DUCTILE IRON

A351 - CF8+STL

A479 - 304

A351 - CF8

A193 - B8

A194 - 8

A479 - 304

A479 - 304

A193 - B8

A194 - 8

A439 - D2C

A479 - 304

A194 - 8

DUCTILE IRON

A283 - D

DUCTILE IRON

A53

DIMENSION AND WEIGHT

CLASS 150

SIZE

L

L1

D

D1

H

H1

WEIGHT(Kg)

UNIT : mm

2

3

4

6

8

10

12

14

16

18

20

203.2

203.2

200

284

14

241.3

241.3

250

344

27

292.1

292.1

315

388

43

406.4

406.4

355

505

91

495.3

495.3

355

450

623

577

178

622.3

622.3

400

450

805

626

256

698.5

698.5

400

500

839

800

409

787.4

787.4

560

922

616

914.4

914.4

630

980

825

978.0

978.0

630

1140

960

978.0

800

1825

1387

24

2

3

4

6

8

10

12

16

18

20

24

266.7

266.7

200

286

20

317.5

317.5

250

346

37

355.6

355.6

315

392

58

444.5

444.5

355

618

140

558.8

558.8

400

500

793

805

260

622.3

622.3

450

560

1145

880

422

711.2

711.2

500

630

1260

971

567

863.6

863.6

710

1120

975

914.4

710

1220

1700

1016.0

800

1674

2090

1346.2

800

2086

3481

2

3

4

6

8

10

12

14

16

18

20

24

292.1

292.1

224

392

35

355.6

355.6

315

478

63

431.8

431.8

315

531

120

558.8

558.8

450

500

675

689

233

660.4

660.4

560

754

415

787.4

787.4

630

959

652

838.2

838.2

800

1690

1316

889.0

800

1871

1565

990.6

800

2015

2120

1092.2

800

2449

3110

1193.8

800

2504

3490

1397.0

800

2595

4320

1295.4

800

2029

1988

CLASS 300

SIZE

L

L1

D

D1

H

H1

WEIGHT(Kg)

UNIT : mm

28

1498.6

800

2338

4590

CLASS 600

SIZE

L

L1

D

D1

H

H1

WEIGHT(Kg)

CLASS 900

SIZE

L

L1

D

D1

H

H1

WEIGHT(Kg)

L

L1

D

D1

H

H1

WEIGHT(Kg)

30

1651.0

800

3237

10800

UNIT : mm

2

3

4

6

8

12

14

368.3

368.3

315

498

77

381.0

381.0

315

513

103

457.2

457.2

355

400

605

600

177

609.6

609.6

450

560

730

710

388

736.6

736.6

710

630

894

970

655

965.2

965.2

710

1101

1288

1029

900

1913

1500

CLASS 1500

SIZE

UNIT : mm

UNIT : mm

2

3

4

6

8

14

368.3

368.3

315

497

77

469.9

469.9

355

584

147

546.1

546.1

400

400

714

700

262

704.9

704.9

500

630

1065

1105

669

831.9

831.9

800

710

1191

1100

1187

990.6

990.6

800

1206

1827

PK_21

Y-GLOBE VALVE

øD1

H1

H

(O

P

EN

)

øD

GOV (GEAR OPERATED)

NOTE

Pø

%&4*(/"4.&##4

'"$&50'"$&%*.&/4*0/"4.&#

THK'

&/%'-"/(&%*.&/4*0/"4.&#

4*;&-"3(&3"4.&#

13&4463&5&45"1*

L(RF), L1(BW)

STANDARD MATERIAL SPECIFICATIONS

PK_22

PK_20

NO.

PART NAME

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

21

22

23

24

BODY

BONNET

DISC

STEM

HAND WHEEL

BODY SEAT

BACK SEAT RING

GASKET

PACKING

GLAND FLANGE

HINGE BOLT

HINGE NUT

HINGE PIN

PACKING GLAND

BONNET BOLT

BONNET NUT

YOKE BUSH

LOCK NUT

HANDLE NUT

SHAKE ADAPTER

HANDLE COVER

GEAR BOX

STEM COVER

MATERIAL

A216 - WCB

A216 - WCB

A217 - CA15+STL

A479 - 410

DUCTILE IRON

A216 - WCB+STL

A479 - 410

A283 - D

A307 - B

A194 - 2H

A576 - 1020

A576 - 1020+Cr

A193 - B7

A194 - 2H

A439 - D2C

A479 - 410

A563 - A

DUCTILE IRON

A283 - D

DUCTILE IRON

A53

A217 - WC6

A217 - WC6

A217 - CA15+STL

A479 - 410

DUCTILE IRON

A217 - WC6+STL

A479 - 410

SPIRAL WOUND / GRAPHITE+304+304

GRAPHITE+GRAPHITE WITH INCONEL WIRE

A283 - D

A307 - B

A194 - 2H

A576 - 1020

A479 - 410

A193 - B16

A194 - 4

A439 - D2C

A479 - 410

A563 - A

DUCTILE IRON

A283 - D

DUCTILE IRON

A53

A351 - CF8

A351 - CF8

A351 - CF8+STL

A479 - 304

DUCTILE IRON

A351 - CF8+STL

A479 - 304

A351 - CF8

A193 - B8

A194 - 8

A479 - 304

A479 - 304

A193 - B8

A194 - 8

A439 - D2C

A479 - 304

A194 - 8

DUCTILE IRON

A283 - D

DUCTILE IRON

A53

DIMENSION AND WEIGHT

CLASS 150

SIZE

L

L1

D

D1

H

H1

d

THK ’

UNIT : mm

2

4

6

8

12

14

228.6

228.6

200

353

50.8

8.6

368.3

368.3

315

491

101.6

11.2

470.0

470.0

355

644

152.4

11.9

596.9

596.9

355

450

803

757

203.2

12.7

775.0

500

980

304.8

16.1

787.4

787.4

560

1185

336.6

17.0

CLASS 300

SIZE

L

L1

D

D1

H

H1

d

THK ’

2

2 1/2

3

4

6

8

10

12

266.7

266.7

200

355

50.8

9.7

292.1

292.1

224

385

63.5

11.2

317.5

317.5

250

465

76.2

11.9

355.6

355.6

315

467

101.6

12.7

444.5

444.5

355

774

152.4

16.0

558.8

558.8

400

500

1006

1018

203.2

17.5

622.3

622.3

450

560

1367

1102

254.0

19.2

711.2

711.2

630

1264

304.8

20.7

UNIT : mm

14

838.2

838.2

630

1326

336.6

23.0

CLASS 600

SIZE

L

L1

D

D1

H

H1

d

THK ’

UNIT : mm

3

4

8

16

20

355.6

355.6

315

578

76.2

13.2

431.8

431.8

315

669

101.6

16.0

660.4

660.4

560

1075

200.0

25.6

990.6

900

1637

374.7

38.5

1193.8

900

2158

463.6

45.0

PK_23

PK_21

SWING CHECK VALVE

FUNCTION

5IF TXJOH DIFDL WBMWF JT EFTJHOFE TP UIBU JU JT PQFOFE

automatically at the forward flow and closed at the reverse

GMPXJOIPSJ[POUBMPSWFSUJDBMVQXBSEGMPXPOMZUISPVHIWBMWF

QJQJOH SVOT *U IBT BO BEWBOUBHF PG MPX QSFTTVSF ESPQ BOE

therefore is best suitable for velocity application.

BODY

5IF CPEZ IBT B TQIFSJDBM GPSN XJUI MBSHF SBEJVT XIJDI

permits the stress, turbulence and resistance to flow to be

kept minimum.

BODY-COVER JOINT

#PEZDPWFS KPJOU PG TXJOH DIFDL WBMWF JT NBDIJOFE BT

GPMMPXT

$MBTT...................................BMFBOEGFNBMF

$MBTTBOE....................BMFBOEGFNBMF

$MBTTIJHIFSDMBTT............. 3JOHUZQFKPJOU

8FDBOTVQQMZBOZLJOETPGHBTLFUBTSFRVJSFECZDVTUPNFS

SEAT RING

5IFTFBUSJOHBTBXFMEFEJOUZQFJTEFTJHOFEUPQSFWFOUBOZ

UVSCVMFODF BOE EBNBHF CZ DPSSPTJPO *U JT GPSHFE PS SPMMFE

into one piece for all dimensions, heat treated to obtain the

desired surface hardness, and cleaned thoroughly before

assembling.

END CONNECTIONS

*O PVS TUBOEBSE QSPEVDUJPO PG WBMWF UIF GMBOHF FOET 3'

BOE UIF GBDF UP GBDF EJNFOTJOPT DPOGPSN UP "/4*

#BOE"4.&#SFTQFDUJWFMZBOEUIFZIBWFBSBJTFEGBDFTFSSBUFEGJOJTIUZQFPSPUIFSGJOJTIUZQFBT

requested.

'PS CVUUXFMEFE FOET #8

PG XIJDI UIF FOE UP FOE EJNFOTJPO DPOGPSNT UP "4.& # DVTUPNFS NVTU

specify the schedule type required, pipe class, or bore diameter.

3JOHKPJOUGMBOHFEFOET35+

DPOGPSNUP"4.&#BOEUIFFOEUPFOEEJNFOTJPOGPMMPXT"4.&#5IF

other special end connections may be supplied as required by customer.

HINGE ARRANGEMENT

o#PEZQFOFUSBUJPOJTTFBMFEXJUICMJOEGMBOHFBOETQJSBMXPVOEHBTLFU

o"SNQJOJTMPDBUFEOFBSUIFEJTDDFOUFSPGHSBWJUZNJOJN[JOHTFBMJOHTVSGBDFSBEJVTSPUBUJPOBOEUIVTWFMPDJUZ

ARM ARRANGEMENT

o )ZESPGPJM QSPGJMF NBJOUBJOT UIF EJTD TUBCJMJUZ XIJMF CFJOH MJGUFE CZ B IZESPEZOBNJD GPSDF BU B GMPX JODMVEJOH

pulsating.

o )FBWZCBMBODFE XFJHIU JOTVSFT UIBU EJTD HPFT UP TFBU JNNFEJBUFMZ VQPO DFTTBUJPO PG GMPX BOE NJOJNJ[FT

water hammer.

PK_24

PK_22

H

END CONNECTION

3''-"/(&%&/%450"4.&#

#8&/%450"4.&#

35+'-"/(&%&/%450"4.&#

4*;&"/%-"3(&3'-"/(&%&/%4

L(RF), L1(BW)

"$$03%*/(50"4.&#4&3"034&3#

STANDARD MATERIAL SPECIFICATIONS

NO.

PART NAME

1

2

3

4

5

6

7

8

9

10

11

12

13

14

BODY

BONNET

DISC

ARM

ROD PIN

BODY SEAT RING

PLUG BOLT

GASKET

PLUG GASKET

BONNET BOLT

BONNET NUT

DISC NUT

PIN

WASHER

MATERIAL

A216 - WCB

A216 - WCB

A217 - CA15+STL

A216 - WCB

A479 - 410

A576 - 1020+STL(S20C)

A307 - B

SOFT STEEL

A193 -B7

A194 - 2H

A194 - 8

304 S.S

304 S.S

A217 - WC6

A217 - WC6

A217 - CA15+STL

A216 - WC6

A479 - 410

A182 - F11+STL

A479 - 304

SPIRAL WOUND / GRAPHITE+304+304

304 S.S

A193 -B16

A194 - 4

A194 - 8

304 S.S

304 S.S

A351 - CF8

A351 - CF8

A351 - CF8+STL

A351 - CF8

A479 - 304

A240 - 304+STL

A479 - 304

304 S.S

A193 - B8

A194 - 8

A194 - 8

304 S.S

304 S.S

PK_25

PK_23

H

INTERNAL TYPE SW-CH VALVE

END CONNECTION

3''-"/(&%&/%450"4.&#

#8&/%450"4.&#

35+'-"/(&%&/%450"4.&#

4*;&"/%-"3(&3'-"/(&%&/%4

L(RF), L(BW)

"$$03%*/(50"4.&#4&3"034&3#

STANDARD MATERIAL SPECIFICATIONS

PK_26

PK_24

NO.

PART NAME

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

BODY

COVER

DISC

ARM

ROD PIN

BODY SEAT RING

INTERNAL BOLT

INTERNAL NUT

WASHER

GASKET

BONNET BOLT

BONNET NUT

DISC NUT

PIN

PLAIN WASHER

MATERIAL

A216 - WCB

A216 - WCB

A217 - CA15+STL

A216 - WCB

A479 - 410

A576 - 1020+STL

A193 - B8

A194 - 8

316 S.S

A193 - B7

A194 - 2H

A194 - 8

304 S.S

304 S.S

A217 - WC6

A217 - WC6

A217 - CA15+STL

A217 - WC6

A479 - 410

A182 - F11+STL

A193 - B8

A194 - 8

316 S.S

SPIRAL WOUND / GRAPHITE+304+304

A193 - B16

A194 - 4

A194 - 8

304 S.S

304 S.S

A351 - CF8

A351 - CF8

A351 - CF8+STL

A351 - CF8

A479 - 304

A240 - 304+STL

A193 - B8

A194 - 8

316 S.S

A193 - B8

A194 - 8

A194 - 8

304 S.S

304 S.S

DIMENSION AND WEIGHT

CLASS 150

SIZE

L

L1

H

WEIGHT(kg)

2

3

4

6

8

10

12

14

16

18

20

203.2

203.2

160

16

241.3

241.3

190

26

292.1

292.1

225

45

355.6

355.6

260

78

495.3

495.3

320

136

622.3

622.3

350

214

698.5

698.5

380

319

787.4

787.4

405

412

863.6

863.6

460

514

977.9

977.9

505

749

2

3

4

6

8

10

12

14

16

18

266.7

266.7

160

21

317.5

317.5

199

42

355.6

355.6

227

54

444.5

444.5

278

124

533.4

533.4

322

222

622.3

622.3

383

291

711.2

711.2

435

444

838.2

838.2

510

632

863.6

863.6

521

786

24

26

UNIT : mm

28

30

977.9 1295.4 1295.4 1447.8 1524

977.9 1295.4

570

680

865

918

962

933

1346 1727 1964 2247

CLASS 300

SIZE

L

L1

H

WEIGHT(kg)

20

24

26

UNIT : mm

28

30

977.9 1016.0 1346.2 1346.2 1498.6 1593.9

977.9 1016.0 1346.2

572

622

712

979

983

1115

1058 1210 1916 2000 2600 3664

CLASS 600

SIZE

L

L1

H

WEIGHT(kg)

2

3

4

6

8

10

12

14

16

292.1

292.1

197

31

355.6

355.6

210

56

431.8

431.8

256

103

558.8

558.8

329

204

660.4

660.4

364

342

787.4

787.4

464

624

838.2

838.2

486

776

889.0

889.0

572

938

990.6

990.6

660

1250

18

20

24

1092.2 1193.8 1397.0

1092.2 1193.8 1397.0

711

787

864

1518 2390 3686

L

L1

H

WEIGHT(kg)

2

3

4

6

8

10

12

368.3

368.3

267

68

381.0

381.0

290

106

457.2

457.2

306

139

609.6

609.6

338

294

736.6

736.6

460

525

838.2

838.2

500

731

965.2

965.2

578

1025

14

1028.7

1028.7

647

1444

16

18

20

1130.3

1130.3

710

1850

1219.2

1219.2

785

2610

1320.8

1320.8

850

3407

CLASS 1500

SIZE

L

L1

H

WEIGHT(kg)

2

3

4

6

8

10

12

368.3

368.3

267

73

469.9

469.9

296

125

546.1

546.1

355

212

704.9

704.9

465

470

831.9

831.9

540

825

990.6

990.6

657

960

1130.3

1130.3

728

1510

30

1448

1028

4000

CLASS 900

SIZE

UNIT : mm

26

1651

1135

5502

UNIT : mm

24

1549.4

1549.4

1006

5842

UNIT : mm

16

1384.3

1384.3

1116

4630

PK_27

PK_25

TILTING DISC CHECK VALVE

FUNCTION

5PEBZ IJHIFS WFMPDJUZ BOE QSFTTVSF PG QJQJOH PGUFO SFRVJSFT B TPQIJTUJDBUFE DIFDL WBMWF SBUIFS UIBO

conventional swing type valve. PK tilting disc check valve is designed to handle such higher velocities, prevent

damages due to turbulence and avoid “water hammer”phenomenon in piping systems, and it is closed quickly

BOERVJFUMZ5IFWBMWFJTDMPTFERVJDLMZCFDBVTFJUTQJWPUIJOHFQJOT

JTTIVUCZBWFSZTNBMMBSD.PSFPWFSMJOF

fluid flows both over and under the disc, so that valve closing is cushioned by the line fluid itself. By virtue of

RVJDLBOERVJFUDMPTJOHBCJMJUZVQUPOPX1,UJMUJOHEJTDDIFDLWBMWFIBTFBSOFEHPPESFQVUBUJPOBTBmOPO

slam”check valve.

BODY

#PEZDPWFSKPJOUPGTXJOHDIFDLWBMWFBSFNBDIJOFEBTGPMMPXT

$MBTT..................................................BMFBOEGFNBMF

$MBTTBOE...................................BMFBOEGFNBMF

$MBTTBOE................................. 3JOHUZQFKPJOU

8FDBOTVQQMZBOZLJOEPGHBTLFUQFSDVTUPNFSSFRVJSFNFOUT

SEAT RING

4FBU SJOHT BSF XFMEFE JOUP WBMWF CPEJFT JO PSEFS UP QSFWFOU UVSCVMFODF BOE BWPJE EBNBHF EVF UP DPSSPTJPO

seats, forged or rolled in one piece for all dimensions, heat treated to obtain the required surface hardness,

and perfectly cleaned before assembly.

END CONNECTIONS

0VSTUBOEBSEQSPEVDUJPODPWFSTWBMWFXJUI

'-"/(&%&/%43'

UIBUDPOGPSNUP"4.&#BOEGBDFUPGBDFEJNFOTJPOTUIBUDPOGPSNUP"4.&#

XJUIBSBJTFEGBDFTFSSBUFEGJOJTIPSPOSFRVFTUXJUIBOZPUIFSGJOJTI

#6558&-%*/(&/%4#8

XJUIFOEUPFOEEJNFOTJPOTUIBUDPOGPSNUP"4.&#

$VTUPNFSNVTUTQFDJGZUIFTDIFEVMFSFRVJSFEPSDMBTTPGQJQFPSEJBNFUFSBOECPSF

3*/( +0*/5 '-"/(&% &/%435+

UIBU DPOGPSN UP "4.& # BOE XJUI FOE UP FOE EJNFOTJPOT UP "4.&

#0UIFSTQFDJBMFOEDPOOFDUJPOTBSFTVQQMJFEUPDVTUPNFSSFRVJSFNFOUT

PK_28

PK_24

H

L(RF), L1(BW)

END CONNECTION

3''-"/(&%&/%450"4.&#

#8&/%450"4.&#

35+'-"/(&%&/%450"4.&#

4*;&n"/%-"3(&3'-"/(&%&/%4

"$$03%*/(50"4.&#4&3"034&3#

STANDARD MATERIAL SPECIFICATIONS

NO.

PART NAME

1

2

3

4

5

6

7

8

9

10

11

12

13

14

BODY

BONNET

DISC

BODY SEAT RING

GASKET

HINGE PIN

BUSHING

BONNET BOLT

BONNET NUT

COVER

COVER BOLT

COVER NUT

COVER GASKET

EYE BOLT

MATERIAL

A216 - WCB

A216 - WCB

A216 - WCB+STL

A576 - 1020+STL(S20C)

A479 - 410

A479 - 304

A193 - B7

A194 - 2H

A576 - 1020

A193 - B7

A194 - 2H

A307 - B

A217 - WC6

A217 - WC6

A217 - WC6+STL

A182 - F11+STL

SPIRAL WOUND / GRAPHITE+304+304

A479 - 410

A479 - 304

A193 - B16

A194 - 4

A240 - 304

A193 - B7

A194 - 2H

SPIRAL WOUND / GRAPHITE+304

A307 - B

A351 - CF8

A351 - CF8

A351 - CF8+STL

A240 - 304+STL

A479 - 304

A479 - 304

A193 - B8

A194 - 8

A240 - 304

A193 - B8

194 - 8

A307 - B+Cr

PK_29

PK_25

DIMENSION AND WEIGHT

CLASS 150

UNIT : mm

SIZE

2

3

4

6

8

10

12

14

16

18

20

L

L1

H

WEIGHT(kg)

203.2

203.2

152

19

241.3

241.3

190

31

292.1

292.1

195

54

355.6

355.6

242

94

495.3

495.3

298

163

622.3

622.3

320

257

698.5

698.5

384

383

787.4

787.4

381

494

863.6

863.6

465

617

977.9

977.9

517

899

977.9

977.9

579

1120

SIZE

2

3

4

6

8

10

12

14

16

18

20

L

L1

H

WEIGHT(kg)

266.7

266.7

163

25

317.5

317.5

202

50

355.6

355.6

205

77

444.5

444.5

331

149

533.4

533.4

298

266

622.3

622.3

345

349

711.2

711.2

425

533

838.2

838.2

490

758

863.6

863.6

494

943

977.9

977.9

554

1270

24

26

CLASS 300

1524

970

2696

UNIT : mm

24

26

28

1016.0 1346.2 1346.2 1498.6

1016.0 1346.2

578

690

909

977

1452 2299 2400 3120

CLASS 600

UNIT : mm

SIZE

2

3

4

6

8

10

14

16

18

20

26

28

30

L

L1

H

WEIGHT(kg)

292.1

292.1

170

37

355.6

355.6

190

67

431.8

431.8

225

124

558.8

558.8

305

245

660.4

660.4

379

410

787.4

787.4

466

749

889.0

889.0

520

1126

990.6

990.6

534

1500

1092.2

1092.2

697

1822

1193.8

1193.8

695

2868

1447.8

1216

5560

1600.2

1176

5810

1651

1306

7150

CLASS 900

UNIT : mm

SIZE

3

4

6

8

10

16

L

L1

H

WEIGHT(kg)

381.0

381.0

288

127

457.2

457.2

292

167

609.6

609.6

378

353

736.6

736.6

448

530

838.2

838.2

510

877

1130.3

1130.3

948

2220

CLASS 1500

PK_30

PK_26

30

1295.4 1295.4

1295.4

597

820

1615 2072

UNIT : mm

SIZE

2

3

4

6

8

10

12

14

16

L

L1

H

WEIGHT(kg)

368.3

368.3

260

88

469.9

469.9

288

150

546.1

546.1

350

254

704.9

704.9

434

564

831.9

831.9

512

990

990.6

990.6

633

1152

1130.3

1130.3

722

1812

1257.3

1257.3

873

3582

1384.3

1384.3

948

5556

DUAL PLATE CHECK VALVE

TYPICAL CONSTRUCTIONS

%VBMQMBUFDIFDLWBMWFBSFTVQQMJFESFUBJOFSMFTTBTTUBOEBSE0VSQBUFOUFEEFTJHOEPFTOPUIBWFBOZUISFBEFE

QMVHTJOUIFQSFTTVSFCPVOEBSZBOEUPUBMMZFMJNJOBUFTUIFQPUFOUJBMMFBLQBUIUPBUNPTQIFSF5IJTEFTJHONFFU

fugitive emission control.

VALVE FEATURES & ADVANTAGES

%VBMQMBUF$IFDL7BMWFJTFDPOPNJDBMPOJOTUBMMBUJPOBOENBJOUFOBODFCFDBVTFJOTUBMMBUJPOJTSFRVJSFEMFTTBOEMJHIUXFJHIU

%VBMQMBUF$IFDL7BMWFJTQPTTJCMFUPQSFWFOUXBUFSIBNNFSJOHEVFUPDMPTJOHWBMWFEJTLCZPQFSBUJOHUIFTQSJOHJO

WBMWFCFGPSFCBDLGMPX"MTP%VF$IFDLWBMWFQSFWFOUTMBSHFQJQJOHUIFGPSCJHHBQXBUFSMFWFMT

%VBMQMBUF$IFDL7BMWFDBOBQQMZWBSJPVTMZJOQJQJOHMJOFCFDBVTFPGMFTTUIBOFYJTUJOH$IFDL7BMWFPOSFTUSJDUJPOT

of instaling direction.

-JGFTQBOTJTMPOHFSUIBOFYJTUJOH$IFDL7BMWF"OEQSFTFSWBUJPOBOESFQBJSBSFTJNQMF

*UTQPTTJCMFUPSFEVDFNBJOUFOBODFGFFEVFUPMPOHFSEVSBCJMJUZUIBOFYJTUJOHDIFDLWBMWFFBTZNBJOUFOBODF

RANGE

APPLICATION

NORMINAL SIZE

1 1/2”(40A) - 84”(2100A)

FLUID

Water, Air, Steam, Gas, Sea Water

RATING

JIS 10K, 20K, 30K, ANSI 150#, 300#, 600#, 900#, 1500#, PN 10, 16, 20, 40, AWWA C 207

END CONNECTION

Wafer, Lugged, Flanged

TEMP. RANGE

-50 ~ 600Ⳅ

MATERIAL

BODY

A126-CLB, A536 Gr. Carbon Steel (A216-WCB etc.) Stainless Steel (CF8, CF8M, CF3 etc.)

B148-C97800, Special Steel (Alloy etc.)

DISC

Carbon Steel (A216-WCB etc.) Stainless Steel (CF8, CF8M, CF3 etc.)

B148-C95800, Special Steel (Alloy etc.)

SEAT

Rubber (EPDM, Buna-N etc.) Metal (Stainless Steel, Stellite #6 etc.)

SPRING

Stanless Steel (304, 316 etc) Inconel (625, X750 etc)

MATERIAL TEMPERATURE LIMITS

UPPER TEMPERATURE LIMITS

MATERIAL

UPPER LIMIT F(Ⳅ)

LOWER TEMPERATURE LIMITS

MATERIAL

LOWER LIMIT F(Ⳅ)

316SS

250(121)

WCB

-20(-28.9)

INCONEL X 750

1000(537)

LCC

-50(-45.6)

MONEL

400(204)

CF8M

-450(-268)

HASTELLOY

800(426)

BUNA-N(NBR)

-70(-56.7)

ALLOY20

250(121)

EPDM

-14(-11.4)

BUNA-N(NBR)

250(121)

VITON

-40(-40)

EPDM

300(149)

PTFE

-200(-129)

PTFE

450(232)

METAL TO METAL

AS BODY

METAL OVELAY

AS BODY

METAL TO METAL

AS BODY

PK_31

PK_27

STANDARD DESIGN

WAFER TYPE

FLANGED TYPE

SOLID LUG TYPE

Retainerless design supplied as

standard

'MBOHFEJNTUP"/4*#

.4441

'BDFUPGBDFEJNTUP"1*

'MBOHFEJNTUP"/4*#

.4441

'BDFUPGBDFEJNTUP"1*

5ISFBEFEMVHUZQFBMTPBWBJMBCMF

o ANSI B16.5

o API 6A

o JIS 2210 & KS B1511

'MBOHFEJNTUP"/4*#

.4441

'BDFUPGBDFEJNTUP"1*

'MBOHFEJNTUP"1*"

'BDFUPGBDFEJNTUP"1*"

'MBOHFEJNTUP"/4*#

o API 605

o API 6D

'MBOHFEJNTUP"1*

'BDFUPGBDFEJNTUP"1*

'MBOHFEJNTUP"/4*#

'BDFUPGBDFEJNTUP"1*%

PRESSURE CLASSES o"4.&50-#1/50

o EXTENDED BODY

o+*4,4,50,

NOMINAL SIZE RANGE

"4.&*CUP

"4.&*CUP

"4.&*CUP

"4.&*CUP

"4.&*CUP

-BSHFSEJBNFUFS7"-7&GPSUIFSFTQFDUJWF

pressure classes can be designed and

manufactured on request.

RETAINERLESS DESIGN

%VBM QMBUF DIFDL 7"-7& BSF TVQQMJFE SFUBJOFSMFTT BT TUBOEBSE 0VS QBUFOUFE EFTJHO EPFT OPU IBWF BOZ

UISFBEFE QMVHT JO UIF QSFTTVSF CPVOEBSZ BOE UPUBMMZ FMJNJOBUFT UIF QPUFOUJBM MFBLQBUI UP BUNPTQIFSF 5IJT

design meet fugitive emission control.

SEAT

5IFTFBUJTEFTJHOFEFRVBMQSFTTVSFBUUIFQMBUFXJUIUIFTUBUFPGTUBUJPOBSZIPVS5IFTIBQFPGSVCCFSTFBU

DPVMEOPUCFDIBOHFEFWFOJONBOZPQFSBUJPOCFDBVTFPGIBWJOHJUTNPTUIBSEOFTTTBUJTGBDUJPO5IFNFUBMUP

NFUBMTFBUFEWBMWFJTUFTUFEUP"1*

DISC (PLATE)

5IFUXPTFNJDJSDMFQMBUFSFTQPOTJWFOFTTPGPQFOJOHBOEDMPTJOHJTRVJDLBOEJUJTTUSPOHBHBJOTUDPSSPTJPOBMTP

has a strong durability.

SPRING

5IFTQSJOHTIBWFCFFOEFTJHOFEUPFOEVSFTUSFTTFTBOEBMTPFOTVSFPQFSBUJOHXJUIPVUGBJMVSFGPSNVDIDZDMFT

RUBBER LINED

'VMMZ3VCCFS-JOFE7BMWFUPBWPJEDPSSPTJPO*OTJEFBSFBWBJMBCMF

PK_32

PK_28

DUAL PLATE CHECK VALVE TYPES

8BGFS3FUBJOFSMFTT

4PMJE-VH3FUBJOFSMFTT

'MBOHFE3FUBJOFSMFTT

)VC&OEFE

STANDARD MATERIAL SPECIFICATIONS

NO.

PART NAME

1

2

3

4

5

6

7

8

9

10

BODY

DISC

SEAT

HINGE PIN

STOP PIN

SPRING

GUIDE

WASHER

SET SCREW

EYE BOLT

MATERIAL

A216 - WCB

A351 CF8M

SS 316

A276 316

A276 316

INCONEL X-750

A276 316

A276 316

A193 B7

SS400 or SS304

A351 CF8M

A351 CF3M

13 CR

A276 410

A276 410

SS 316

A276 410

A276 304

A193 B8

SET SCREW

A351 CF3M

A217 CA15

STELLITE $6

A276 304

A276 304

A276 304

A193 B8m

SS304

PK_33

PK_29

ⴠ

øD

ød

ⴜ

ⴘ

ⴝ

ⴟ

ⴞ

ⴙ

ⴛ

ⴠ

DIMENSION AND WEIGHT

CLASS 150

UNIT : mm

SIZE

2

3

4

6

8

10

12

14

16

18

20

24

ØD

Ød

L

102

60

60

133

87

73

171

113

73

219

166

98

276

207

127

337

260

146

406

300

181

448

339

184

511

387

191

546

438

203

603

487

219

714

580

222

SIZE

2

3

4

6

8

10

12

14

16

18

20

24

ØD

Ød

L

108

60

60

146

87

73

178

113

73

248

166

98

305

207

127

359

260

146

419

300

181

483

339

222

537

387

232

594

438

264

651

487

292

772

580

318

SIZE

2

3

4

6

8

10

12

14

16

18

20

24

ØD

Ød

L

108

60

60

146

87

73

191

113

79

264

166

137

317

207

165

397

260

213

454

300

229

489

339

273

562

387

305

610

438

362

679

487

368

787

580

438

SIZE

2

3

4

6

8

10

12

14

16

18

20

24

ØD

Ød

L

140

60

70

165

87

83

203

113

102

286

166

159

356

207

206

432

260

241

495

300

292

518

339

356

571

387

384

635

438

451

695

487

451

835

580

495

SIZE

2

3

4

6

8

10

12

14

16

18

20

24

ØD

Ød

L

140

60

70

171

87

83

206

113

102

279

166

159

349

207

206

432

260

248

518

300

305

575

339

356

638

387

384

702

438

468

752

487

533

899

580

559

CLASS 300

UNIT : mm

CLASS 600

UNIT : mm

CLASS 900

UNIT : mm

CLASS 1500

PK_34

PK_30

UNIT : mm

STAINLESS STEEL VALVE

4UBJOMFTT TUFFM WBMWF BSF VUJMJ[FE JO UIF DIFNJDBM QFUSPDIFNJDBM GPPE QBQFS BOE QIBSNBDFVUJDBM

processing industries all over the world.

4UBJOMFTT TUFFM WBMWF BSF EFTJHOFE BOE NBOVGBDUVSFE JO DPOGPSNJUZ XJUI "1* "/4* #4 BOE PUIFS

standards recognized with quality meeting the stringent requirements for such industrial applications.

4UBJOMFTT TUFFM WBMWF BSF TQFDJBMJ[FE QSPEVDUT UISPVHI UIF QSPDFTTFT PG EFTJHO NBUFSJBM TFMFDUJPO

manufacturing, quality control, and experiences to final product.

PRODUCTION RANGE

UNIT : NPS

CLASS

150

300

GATE

1/2-24

1/2-24

GLOBE

1/2-12

1/2-12

SWING CHECK

1/2-24

1/2-24

TYPE

INVESTMENT CASTING

*OWFTUNFOUDBTUJOHTIBMMCFNBOVGBDUVSFEVQUPGPSDMBTTBOE

VALVE SHELL MATERIALS

4IFMMNBUFSJBMTTIBMMCFJOBDDPSEBODFXJUI"45."(SBEF$'.$'BOEUIFPUIFSTBSFPQUJPOBM

ASTM DESIGNATION

MAXIMUM WORKING TEMPERATUREⳅⳄ

A351 Gr. CF8

1500ⳅ ( 816Ⳅ )*

A351 Gr. CF8M

1500ⳅ ( 816Ⳅ )*

A351 Gr. CF3

800ⳅ ( 427Ⳅ )

A351 Gr. CF3M

850ⳅ ( 454Ⳅ )

A351 Gr. CF8C

1500ⳅ ( 816Ⳅ )*

A351 Gr. CN7M

300ⳅ ( 149Ⳅ )

A890 Gr 4A ( UNS J92205 )

600ⳅ ( 316Ⳅ )

A890 Gr 6A ( UNS J93380 )

600ⳅ ( 316Ⳅ )

ⲼAt temperatures over 1000ⳅ, use the material only when the carbon contents is 0.04% or higher.

PK_35

PK_31

OPTIONAL BONNET FLANGE GASKET MATERIAL

%FQFOEJOH PO TFSWJDF DPOEJUJPOT WBSJPVT NBUFSJBMT BSF BWBJMBCMF PQUJPOBMMZ GPS GMBOHF HBTLFU BOE TUFN

packing.

"(BTLFUNBUFSJBMT

B. Packing materials

(MBTTGJCFSTIFFU

4QJSBMXPVOENBUFSJBM(SBQIJUFPS15'&

15'&

.FUBMSJOH

(SBQIJUF

15'&

(SBQIJUF

(MBTTGJCFSTIFFU

DESIGN FEATURES OF PK STAINLESS STEEL GATE VALVE WEDGES

1,BEPQUTBO)TIBQFEGMFYJCMFXFEHFPGXIJDIUIFTJ[FJTBOEMBSHFSGPS$MBTTBOEBOEIJHIFS

GPS $MBTT 5IF )TIBQFE GMFYJCMF XFEHFT BSF GFBUVSFE XJUI NFDIBOJDBM GMFYJCJMJUZ UP CF BCMF UP

BEKVTUUPUIFTIBQFPGCPEZTFBUGPSTFDVSFNVUVBMDPOUBDUT

*U IBT B QBSUJDVMBS JNQPSUBODF XIFO MBSHF HBUF WBMWF JT BQQMJFE UP FYUSFNFMZ IJHI QSFTTVSF BOE

temperature that temporary deformation may occur in valve all the time.

*GUIF)TIBQFXFEHFJTQSPWJEFEPQFSBUJOHUPSRVFXPVMEHFUTNBMMFSTFBUXFBSMFTTBOEWBMWFDMPTJOH

tighter.

UNIT : NPS

ONE PIECE SOLID WEDGE

FLEXIBLE ONE PIECE WEDGE

CLASS

150

2 1/2 & SMALLER

3 & LARGER

300

1 & SMALLER

1 1/2 & LARGER

600

PK_36

PK_54

-

2 & LARGER

DESIGN FEATURES OF GLOBE VALVE DISC

(MPCFWBMWFBEPQUTQMVHUZQFEJTD5IFCPUUPNHVJEFUZQFQMVHEJTDTIBMMCFBQQMJFE

following the range shown below.

#0550.(6*%&

5:1&

1-6(%*4$

1-6(%*4$

UNIT : NPS

CLASS

SIZE

150

10 AND LARGER

300

8 AND LARGER

DESIGN FEATURES OF GATE VALVE YOKE SLEEVE

*UJTNBOVGBDUVSFECZUXPEJGGFSFOUXBZTEFQFOEJOHPOUIFWBMWFTJ[F

TYPE A

TYPE B

UNIT : NPS

TYPE A

TYPE B

5 AND SMALLER

6 AND LARGER

:PLFDBQTUZQF#JTNBEFPG$4;OQMBUJOH

PK_37

PK_55

DESIGN FEATURES OF GATE VALVE YOKE

0OBOETNBMMFSWBMWFUIFZPLFJTJOUFHSBUFEXJUICPOOFU

0OBOEMBSHFSWBMWFUIFZPLFJTTFQBSBUFEGSPNCPOOFU

*/5&(3"-:0,&

4&1"3"5&:0,&

DESIGN FEATURES OF VALVE BONNET BOLTS

*UJTNBOVGBDUVSFECZUXPEJGGFSFOUXBZTEFQFOEJOHPOWBMWFDMBTTBOETJ[F

UNIT : NPS

CLASS

Type A

Type B

SIZE

150

5 AND SMALLER

300

2 1/2 AND SMALLER

150

6 AND LARGER

300

3 AND LARGER

5:1&"

)&9)&"%&%#0-5

BOLT

HEX. HEAD

FULL THREAD.

BOLT & NUT

5:1&#

456%#0-5

DESIGN FEATURES OF VALVE HAND WHEELS

)BOEXIFFMTBSFNBEFJOBDDPSEBODFXJUI"45."GPSFYUFSOBMEJNFOTJPONNBOE"45."

8$#GPSPWFSNN"IBNNFSCMPXUZQFIBOEXIFFMPG"45."8$#JTQSPWJEFEGPS$MBTTTJ[F

7"-7&BOE$MBTTBOEPWFSWBMWFTJ[F

PK_38

PK_56

GATE VALVE

STANDARD MATERIAL SPECIFICATIONS

øD

NO. PART NAME

BODY

BONNET

WEDGE

STEM

HAND WHEEL

BODY SEAT

BACK SEAT

GASKET

PACKING

GLAND FLANGE

HINGE BOLT

HINGE NUT

HINGE PIN

PACKING GLAND

BONNET BOLT

BONNET NUT

YOKE CAP

YOKE SLEEVE

HANDLE NUT

SET SCREW

NIPPLE

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

H (OPEN)

MATERIAL

A351 - CF8M

A351 - CF8

A351 - CF8M

A351 - CF8

A351 - CF8M

A351 - CF8

A479 - 316

A479 - 304

A197

A197

A351 - CF8M

A351 - CF8

A351 - CF8M

A351 - CF8

SPIRAL WOUND / GRAPHITE+316+316

GRAPHITE+GRAPHITE WITH INCONEL WIRE

A351 - CF8

A351 - CF8

A193 - B8

A193 - B8

A194 - 8

A194 - 8

A479 - 304

A479 - 304

A479 - 316

A479 - 304

A193 - B8

A193 - B8

A194 - 8

A194 - 8

A576 - 1020+Zn

A576 - 1020+Zn

A439 - D2C

A439 - D2C

304 S.S

304 S.S

STEEL+ Cr

STEEL+ Cr

STEEL+ Cr

STEEL+ Cr

END CONNECTION

L(RF), L1(BW)

3''-"/(&%&/%450"4.&#

#8&/%450"4.&#

35+'-"/(&%&/%450"4.&#

$0/46-564'03-"3(&34*;&

DIMENSION AND WEIGHT

CLASS 150

UNIT : mm

SIZE

1/2

3/4

1

1 1/2

2

2 1/2

3

4

6

8

10

12

L

L1

D

H

WEIGHT(kg)

108.0

108.0

120

208

6

117.3

117.3

120

208

6

127.0

127.0

120

226

6

165.1

165.1

140

285

9

177.8

215.9

160

333

12

190.5

241.3

160

384

18

203.2

282.4

200

424

23

228.6

304.8

250

531

35

266.7

403.4

315

730

62

292.1

419.1

355

938

102

330.2

457.2

355

1114

147

355.6

501.7

400

1317

213

SIZE

1/2

3/4

1

1 1/2

2

2 1/2

3

4

6

8

10

12

L

L1

D

H

WEIGHT(kg)

139.7

139.7

120

208

8

152.4

152.4

120

211

8

165.1

165.1

120

279

8

190.5

190.5

200

306

16

215.9

215.9

200

346

18

241.3

241.3

200

388

29

282.4

282.4

224

447

39

304.8

304.8

250

542

54

403.4

403.4

355

758

112

419.1

419.1

400

949

202

457.2

457.2

450

1152

253

501.7

501.7

500

1417

390

CLASS 300

UNIT : mm

PK_39

PK_57

GLOBE VALVE

STANDARD MATERIAL SPECIFICATIONS

NO. PART NAME

øD

H (OPEN)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

L(RF), L1(BW)

BODY

BONNET

DISC

STEM

HAND WHEEL

BODY SEAT

BACK SEAT

GASKET

PACKING

GLAND FLANGE

HINGE BOLT

HINGE NUT

HINGE PIN

PACKING GLAND

BONNET BOLT

BONNET NUT

YOKE BUSH

LOCK NUT

HANDLE NUT

WASHER

MATERIAL

A351 - CF8M

A351 - CF8

A351 - CF8M

A351 - CF8

A351 - CF8M

A351 - CF8

A479 - 316

A479 - 304

A197

A197

A351 - CF8M

A351 - CF8

A351 - CF8M

A351 - CF8

SPIRAL WOUND / GRAPHITE+316+316

GRAPHITE+GRAPHITE WITH INCONEL WIRE

A351 - CF8

A351 - CF8

A193 - B8

A193 - B8

A194 - 8

A194 - 8

A479 - 304

A479 - 304

A479 - 316

A479 - 304

A193 - B8

A193 - B8

A194 - 8

A194 - 8

A439 - D2C

A439 - D2C

A479 - 316

A479 - 304

A194 - 8

A194 - 8

304 S.S

304 S.S

END CONNECTION

3''-"/(&%&/%450"4.&#

#8&/%450"4.&#

35+'-"/(&%&/%450"4.&#

$0/46-564'03-"3(&34*;&

DIMENSION AND WEIGHT

CLASS 150

UNIT : mm

SIZE

1/2

3/4

1

1 1/2

2

2 1/2

3

4

6

8

10

12

L

L1

D

H

WEIGHT(kg)

108.0

108.0

100

174

4

117.3

117.3

100

174

4

127.0

127.0

140

224

4

165.1

165.1

160

259

10

203.2

203.2

160

266

13

215.9

215.9

200

281

21

241.3

241.3

224

342

27

292.1

292.1

280

377

42

406.4

406.4

355

429

76

495.3

495.3

355

558

149

622.3

622.3

400

740

241

698.5

698.5

400

803

395

SIZE

1/2

3/4

1

1 1/2

2

2 1/2

3

4

6

8

10

12

L

L1

D

H

WEIGHT(kg)

152.4

152.4

100

185

9

177.8

177.8

100

194

9

203.2

203.2

140

224

9

228.6

228.6

160

267

15

266.7

266.7

160

329

17

292.1

292.1

200

354

33

317.5

317.5

224

383

34

355.6

355.6

280

443

46

444.5

444.5

355

567

125

558.8

558.8

400

625

218

622.3

622.3

450

881

367

711.2

711.2

500

989

521

CLASS 300

PK_40

PK_58

UNIT : mm

SWING CHECK VALVE

STANDARD MATERIAL SPECIFICATIONS

NO. PART NAME

BODY

BONNET

DISC

ARM

ROD PIN

BODY SEAT RING

PLUG BOLT

GASKET

PLUG GASKET

BONNET BOLT

BONNET NUT

DISC NUT

PIN

WASHER

1

2

3

4

5

6

7

8

9

10

11

12

13

14

H

MATERIAL

A351 - CF8M

A351 - CF8

A351 - CF8M

A351 - CF8

A351 - CF8M

A351 - CF8

A351 - CF8M

A351 - CF8

A479 - 304

A479 - 304

A351 - CF8M

A351 - CF8

A479 - 304

A479 - 304

SPIRAL WOUND / GRAPHITE+316+316

304 S.S

304 S.S

A193 - B8

A193 - B8

A194 - 8

A194 - 8

A194 - 8M

A194 - 8

304 S.S

304 S.S

A240 - 304

A240 - 304

END CONNECTION

3''-"/(&%&/%450"4.&#

#8&/%450"4.&#

35+'-"/(&%&/%450"4.&#

$0/46-564'03-"3(&34*;&

L(RF), L1(BW)

DIMENSION AND WEIGHT

CLASS 150

UNIT : mm

SIZE

1/2

3/4

1

1 1/2

2

2 1/2

3

4

6

8

10

12

L

L1

H

WEIGHT(kg)

108.0

108.0

85

5

117.3

117.3

89

5

127.0

127.0

102

5

165.1

165.1

120

11

203.2

203.2

138

13

215.9

215.9

155

18

241.3

241.3

160

22

292.1

292.1

201

36

355.6

355.6

248

62

495.3

495.3

293

119

622.3

622.3

330

155

698.5

698.5

354

235

SIZE

1/2

3/4

1

1 1/2

2

2 1/2

3

4

6

8

10

12

L

L1

H

WEIGHT(kg)

152.4

152.4

93

10

177.8

177.8

96

10

215.9

215.9

112

10

241.3

241.3

126

14

266.7

266.7

152

19

292.1

292.1

164

25

317.5

317.5

176

33

355.6

355.6

186

53

444.5

444.5

262

109

533.4

533.4

312

199

622.3

622.3

355

231

711.2

711.2

393

308

CLASS 300

UNIT : mm

PK_41

PK_59

MEMO

PK_42

PK_32

2. PRESSURE SEAL VALVE

- GATE VALVE

- GLOBE VALVE

- Y-GLOBE VALVE