INTERNATIONAL STANDARD IEC 62040-1-1

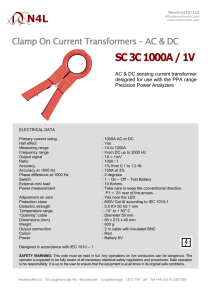

advertisement