Quantification of Electron Transfer Rates to a Solid Phase Electron

advertisement

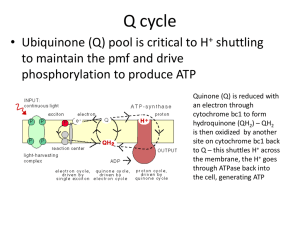

Environ. Sci. Technol. 2010, 44, 2721–2727 Quantification of Electron Transfer Rates to a Solid Phase Electron Acceptor through the Stages of Biofilm Formation from Single Cells to Multicellular Communities J E F F R E Y S . M C L E A N , * ,† G R E G W A N G E R , † YURI A. GORBY,† MARTIN WAINSTEIN,† JEFF MCQUAID,† SHUN’ ICHI ISHII,† ORIANNA BRETSCHGER,† HALUK BEYENAL,‡ AND K E N N E T H H . N E A L S O N †,§ The J. Craig Venter Institute, San Diego, CA, The Gene and Linda Voiland, School of Chemical Engineering and Bioengineering and Center for Environmental, Sediment and Aquatic Research, Washington State University, Pullman, WA, and University of Southern California, Los Angeles, CA Received October 11, 2009. Revised manuscript received February 8, 2010. Accepted February 13, 2010. Microbial fuel cell (MFC) technology has enabled new insights into the mechanisms of electron transfer from dissimilatory metal reducing bacteria to a solid phase electron acceptor. Using solid electrodes as electron acceptors enables quantitative real-time measurements of electron transfer rates to these surfaces. We describe here an optically accessible, dual anode, continuous flow MFC that enables realtime microscopic imaging of anode populations as they develop from single attached cells to a mature biofilms. We used this system to characterize how differences in external resistance affect cellular electron transfer rates on a per cell basis and overall biofilm development in Shewanella oneidensis strain MR-1. When a low external resistance (100 Ω) was used, estimates of current per cell reached a maximum of 204 fA/cell (1.3 × 106 e- cell-1 sec-1), while when a higher (1 MΩ) resistance was used, only 75 fA/cell (0.4 × 106 e- cell-1 sec-1) was produced. The 1 MΩ anode biomass consistently developed into a mature thick biofilm with tower morphology (>50 µm thick), whereas only a thin biofilm (<5 µm thick) was observed on the 100 Ω anode. These data suggest a link between the ability of a surface to accept electrons and biofilm structure development. Introduction Dissimilatory metal reducing bacteria (DMRB) can utilize solid phase electron acceptors such as iron and manganese oxides as electron acceptors to respire anaerobically via a process termed extracellular electron transport (EET). This ability has important implications for metal cycling in the environment, the ecophysiology of these organisms, their potential use for bioremediation (1–3) and also microbial fuel cell applications (4, 5). Three different and perhaps * Corresponding author e-mail: jmclean@jcvi.org. † The J. Craig Venter Institute. ‡ Washington State University. § University of Southern California. 10.1021/es903043p 2010 American Chemical Society Published on Web 03/03/2010 overlapping strategies for coordinating extracellular electron transfer to solid phase electron acceptors are apparently used: direct cell-mineral contact with multiheme outer membrane cytochromes serving as reductases (6), small molecular weight compounds that function as electron shuttles (7, 8), or electrically conductive bacterial pili or nanowires (9, 10). Because of their EET abilities, DMRB are commonly used in microbial fuel cells (MFCs) (4, 5), where they are capable of EET to MFC anodes as they anaerobically oxidize organic matter. In particular, model organisms such as Shewanella or Geobacter species have been used in efforts to unravel the biological mechanisms involved with current production (6, 9–14). In such studies it is especially critical to quantify cell numbers as well as describe the depth and architectures of biofilms as they develop on MFC electrodes. However, achieving this knowledge is difficult given typical MFC system designs. Commonly used designs to maximize power generation, cannot be used to accurately quantify the number of cells per electrode surface area or the depth of the biofilm; often this can only be achieved at the terminus of the experiment, which does not provide a direct link between cell colonization/growth and power production. Further, the sampling methods chosen for such quantifications must be delicately employed so that biomass or attachment is not affected by mechanical disruption (15). Destructive single end-point analyses such as total protein (14), and qualitative imaging using various microscopic techniques, render it impossible to study biofilm development, morphology, or architecture through time. Recent mathematical models of electron transfer in biofilms (16) indicate the importance of a conductive biofilm in the transfer of electrons; therefore, biofilm parameters including depth must be measured. Comparative studies of current generation must be directly related to the number of cells on the electrode surface and electron transfer rates. This is germane when using mutant strains, which may be altered in attachment, biofilm formation, and/or rates of EET. To determine the rate of electron transfer per cell it is critical to first obtain an accurate count of the number of cells on the anode. The inability to accurately quantify attached cells and normalize for them inhibits strict standardizations across samples, organisms, and MFC designs among the greater MFC community and even within individual laboratories. One solution to this dilemma is to merge the technology used to measure electron transfer to solid surfaces with the tools for live, noninvasive imaging. A number of studies have used optical flow cells and electrochemically controlled electrode surfaces such as indium tin oxide (17) to investigate how different potentials affect bacterial detachment (17), attachment, and/or growth rates (18). Recently Franks et al. (19) demonstrated the utility of a “mini-stack” MFC that was modified for nondestructive visualization of biofilm growth, a study that focused on changes of pH within anode biofilms. We describe here the construction and application of a parallel plate flow cell with incorporated fuel cell components that accommodates real-time fluorescent microscopic imaging with real-time measurements of current production. With this system, we report for the first time, the electron transfer rates on a per cell basis for Shewanella oneidensis MR-1 interacting with anode electrodes; as well as the changes in anode potential through the development stages of a biofilm from single attached cells to a mature, multicellular, threedimensional structure. VOL. 44, NO. 7, 2010 / ENVIRONMENTAL SCIENCE & TECHNOLOGY 9 2721 Materials and Methods Parallel Plate Flow Anode Chamber with Air Cathode. The optically accessible MFC was a modified, commercially available, biofilm flow cell (model no. FC-81; Biosurface Technologies Inc.). These flow cells were modified by removing the glass slide substrates and replacing them with electrode materials. The anodes were made from superfine isomolded graphite plates (Graphite Store) that were shaped into 5 × 25 × 1 mm electrodes fitted with 0.25 mm platinum wire leads and polished to a final mirror finish with 12000 grit polishing paper. Silicone sealant was used to cover all surfaces of the anodes except the polished top, yielding a total accessible anode surface area of 1.25 cm2. The aircathode consisted of Pt (5 g/m2) coated graphite felt (GDE LT 120E-W, The Fuel Cell Store) coated with Nafion 117 film (Fluka) that was painted on to the surface and allowed to air-dry (20). By placing two anodes side by side in the same compartment, we fit two MFCs into one chamber which allowed us to compare their performances under identical operating conditions. Similar design was used by Dewan et al. (21), to compare power of many MFCs which had multiple anodes. The two anodes were connected to the shared aircathode and cell voltage was measured individually across 100 Ω and 1 MΩ resistors to determine current under operating conditions (Iop) and current density (i) with a digital multimeter (Keithley 2700, Keithley Instruments Inc.). The anode and cathode electrodes were separated from each other by a nonconductive plastic slide. These MFCs were specifically designed to direct the growth medium across the anode surfaces before flowing into the cathode compartment (Supporting Information (SI) Figure 1). At the operating flow rate of 200 µl/min the flow was calculated to be laminar (Reynolds number of 4.3). The chamber volume was 300 µL with a calculated average flow velocity of 16 mm/min translating to a dilution rate of 0.67 min-1 or 1.5 volume changes each minute. Microorganism, Growth Medium, Buffer, and Electrolyte Solution. Shewanella oneidensis strain MR-1 p519nGFP (constitutively expressed green fluorescent protein) was used for all experiments (22). For each experiment, cells from a frozen stock were streaked onto Tryptic-Soy Agar (Difco) plates augmented with Kanamycin and incubated for 18 h at 30 °C. These pregrown cells were transferred to 20 mL of modified M1 minimal medium (6) and incubated for 24 h at 30 °C and at 150 rpm. To ensure an excess of the electron donor lactate in all experiments the M1 medium was supplemented with 60 mM lactate. Measurement of the MFC effluent by high pressure liquid chromatography (HPLC) confirmed the excess of lactate (data not shown). To minimize the concentration of oxygen in the system the influent medium was continuously sparged with ultrahigh purity N2. Fresh medium was delivered into the MFC using a variable speed peristaltic pump (404, Ismatec). Flow Cell Operation. The MFCs where chemically sterilized using a 10% peroxyacetic acid solution and flushed with sterile MFC buffer containing 50 mM PIPES, 100 mM NaCl at pH 7.2. Prior to inoculation, background measurements were taken in MFC buffer solutions, with and without lactate, as well as the minimal growth medium. Inoculation of the MFCs involved injecting the cells immediately upstream of the chamber and allowing them to flow into the chamber and attach to the graphite anodes for 10 min with the flow off (batch mode). Following this, a high flow rate (i.e., 10 min at ∼2 mL/min) was set to flush out any unattached cells. The flow rate was then decreased to the operational level of 200 µL/min. Measurements and Calculations. Potentiodynamic polarizations were used to calculate power curves. These data were used to determine the maximum current (Imax), maximum current density (imax), and maximum power densities 2722 9 ENVIRONMENTAL SCIENCE & TECHNOLOGY / VOL. 44, NO. 7, 2010 (Pmax) of MFCs ((5)) based on the true surface area of the anode. The anode was the limiting electrode and cathodic current was in excess. We used a potentiostat (Reference 600, Gamry Instruments, Inc.) and a three-electrode system with the anode as the working electrode, the cathode as the auxiliary electrode and Ag/AgCl as the reference electrode. The anode potentials were scanned from the open circuit cell voltage (OCV) to a cell potential of 0 mV using a step size of 0.1 mV/s and a sampling time of 1 s. The cathode produced a stable cathodic potential of +230 mVAg/AgCl throughout the experimental period as was measured before and after cell polarization. The resulting increase in cell potential observed at open circuit indicates the anode potential becoming more negative with respect to the cathode over time. A Student’s t test was used for statistical comparisons of anode performance at 120 hrs, assuming a normal distribution and equal variance. The internal resistance of the designed MFCs were measured with active biofilms using the Electrochemical Impedance Spectroscopy (EIS) method described by Dewan et al. (21), and found to be 40 Ω. Microscopy (Epifluorescent, Confocal, Scanning Electron). Epifluorescence. For real time imaging of the cells on the anode surfaces a Zeiss Axio microscope with fluorescence capabilities was used to image 10 random fields-of-view per anode surface at each set time interval to determine the average cell numbers. These counts were typically conducted without disruption of the operation of the MFC or flow rates except for a brief interruption during the removal of the MFC from the microscope after the 18 h time point (Figure 1) resulting in a discharge of anode potential through a short circuit. Image processing was done by means of ImageJ and the biofilm analysis package ISA 3D software (23). The effect of fluorescent imaging on the MFC’s was also conducted with and without cells showing no change in the cell voltage due to any of the excitation wavelengths used. Confocal Microscopy. Microscopic observations were performed on a Leica TCSP5 confocal laser scanning microscope (CLSM) (Leica Microsystems). Image stacks were obtained using a 10× objective. Fluorescence for GFP was collected with 488 nm laser emission. Simulated 3-D images and sections (plan views) were generated using the software Volocity and the plan views with side profile slices using IMARIS (Bitplane AG, Z|Aaurich, CH). Scanning Electron Microscopy. At the termination of each experiment, anodes were fixed in a 2.5% solution of glutaraldehyde, processed through an ethanol dehydration series (i.e., 25, 50, 75, 100% v/v Ethanol, 0.5 h each treatment), then critically point dried (815 Auto-Samdri, Tousimis) (10). The anodes were mounted on aluminum stubs, coated with chromium and imaged in a Phillips XL30 Environmental SEM. 3.1. Results and Discussion Variation in Biomass and Electrochemical Parameters with External Resistance. Using the dual anode real-time imaging compatible MFC we successfully and repeatedly grew biofilms on the anode surface, monitored cell surface growth, quantified biomass and calculated operational current (Iop) with different external resistance. Experiments were very reproducible, and we show here one representative data set from one typical experiment with fluorescent images (Figure 1). The development of current over time followed a general trend for all repeated experiments with a lag in current for several hours followed by an exponential phase and a relatively stable current phase. The corresponding image data, showing how biomass changed during current production, revealed a consistent and striking difference developing between the biomass on the anodes. After 80 h, a thick and highly structured biofilm had formed on the 1 MΩ anode while the biofilm on the 100 Ω remained as a thin layer of cells. Using noninvasive CLSM imaging, the biofilm structure FIGURE 1. Simultaneous monitoring of current generation and biofilm development from single attached cells with epi-fluourescent imaging. Temporal current changes in the imaging compatible MFC for two different anodes with external resistances of 1 MΩ (A) and 100 Ω (B). C) Concurrent image data taken over the course of the experiment for both anodes. Differences in biofilm development were clearly visible by 88 h. Scale bars equal to 10 µm for 0 and 15 h and 100 µm for 18-130 h. FIGURE 2. Representative CLSM and SEM images of the anodes after 5 days of growth. CLSM images collected nondestructively demonstrate the biomass and structural differences between the 1 M Ω (A) and 100 Ω (B) anodes. Representative SEM of the 1 M Ω (C) and 100 Ω (D) processed by critical point drying confirm the structural differences in the biofilms as well as indicate that the 1 M Ω colonies contain a greater amount of extracellular material between the attached cells within these colonies. and thickness were quantified for both anodes. Thicker biofilms with qualitatively more extracellular material were observed on 1 MΩ anode when compared to biofilms that formed on the 100 Ω anode (Figure 2). The biofilms on the 100 Ω anodes appeared as low mounds of cells rising only ∼5 µm from the anode surface (Figure 2b) whereas the 1 MΩ anodes produced a thick base layer with large “towers” (50-80 µm) (Figure 2a). This tower morphology is commonly observed in conventional continuous flow biofilm growth chambers where soluble compounds, such as oxygen or fumarate, serve as the terminal electron acceptor (22, 24). Images collected using SEM were consistent with those obtained using CLSM, despite an observed loss of biofilm biomass during critical point drying for SEM analysis. These VOL. 44, NO. 7, 2010 / ENVIRONMENTAL SCIENCE & TECHNOLOGY 9 2723 FIGURE 3. Representative timecourse measurements of attached cell counts and current density during operation over 24 h on the 1 M Ω and 100 Ω anode. A) Average cell counts per cm2 of anode area (left axis) and the current density during operation (right axis). B) Timecourse plot of the current generated per cell based on direct in situ cell counts and the stable operating current. data demonstrate that higher resistance (lower current flow) maximizes biofilm development or alternatively a lower resistance(highercurrentflow)minimizesbiofilmdevelopment. Current and Cell Density Correlation. Current production and cell counts were monitored from initial attachment through the early stages of biofilm formation on the anode. Initial cell densities on the anodes averaged 2 × 105 cells/ cm2 with virtually no change in numbers during the first 15 h of observation. During this initial period the anodes were covered with only a single layer of cells but the current density under operation increased during this time (Figure 3), indicating an increase in specific anode respiration rate. Between 15 and 18 h, a rapid increase in cell numbers and current was detected for both anodes. By 24 h cell densities reached 1.2 × 106 cells/cm2 with the 1 M Ω, and 8.8 × 105 cells/cm2 with the 100 Ω. Operational current density also increased to 0.09 µA/cm2 (1 M Ω) and 0.08 µA/cm2 (100 Ω) over this period. Specific Electron Transfer Rates. Current generation was calculated on a per cell basis using the electrochemical and microscopic data obtained in real time (Figure 3). The temporal trends in these experiments indicate that the current per cell maximum during operation was reached before the cells went into the rapid growth phase on the anode surface. The 100 Ω anode in the first run (Figure 1) increased initially to a maximum of 200 fA/cell (1.3 × 106 e- cell-1 sec-1) and the 1 MΩ reached 80 fA/cell (0.4 × 106 e- cell-1 sec-1) (Figure 3). These rates decreased to 63 fA/cell and 39 fA/cell, respectively, after the cell growth entered an exponential phase. Replicate runs conducted over a longer time scale (75 h) (SI Figure 2) demonstrated that the trends in cell growth and current generation were very consistent, although the absolute values as well as the time required for rapid increases in cell numbers and current densities showed some variability. To our knowledge, these results represent the first time the absolute values of current per cell over time have been estimated from direct cell counts for a bacteria within an operating MFC. These are also the first estimates of the specific electron transfer rates to an anode surface for Shewanella oneidensis strain MR-1. Previous studies have estimated the current per cell from total protein concentra2724 9 ENVIRONMENTAL SCIENCE & TECHNOLOGY / VOL. 44, NO. 7, 2010 tions at selected time points during a batch operated MFC for Geobacter sulfurreducens with values of 23 fmol/cell/day (14). At the values obtained for MR-1 on the anode operating with a 100 Ω resistor, we obtained ranges from 200 to 63 fA/cell which corresponds to specific electron transfer rates of 179 to 56 fmol/cell/day during continuous operation mode. As noted above, the average cell concentration on the anodes during the first 15 h did not change significantly, whereas the current increased in a linear fashion during this initial period (Figure 3). To determine if, given enough time, the initial cells bound to the surface would produce detectible current without the components in the medium for growth and division, the experiment was modified such that after inoculation and for the following 48 h, MFC buffer augmented with 60 mM lactate was substituted for the M1 growth medium allowing respiration without growth. This experiment showed no observable increase in cell numbers or any detectible increase in current during this time (data not shown). After 48 h the MFC buffer was switched to the standard growth supporting M1 minimal medium and the current and cell numbers began to increase as described above. This suggests that the increased current production is dependent upon growth or perhaps newly synthesized cellular components needed for extracellular electron transfer such as redox active compounds, that is, more redox active compounds per cell. While initial attachment on the two anodes were in similar ranges, consistently more cells attached to the 1 MΩ anode. At later time points, when discrete cells were no longer resolvable on the anode surface, the image analysis software package, ISA 3D (23), was used to quantitatively compare the biomass differences and determine the correlation of colony size (average diffusion distance) with current development (SI Figure 3). Temporal Development of Anode Potential and Maximum Current Density. Polarization measurements were made at several times during the experiment, in an effort to determine how the anode potential and maximum current density (imax) correlated with biofilm development. For these measurements (Figure 4), the system was placed in open circuit for 2 h with uninterrupted flow, and the anode potential monitored against an Ag/AgCl reference electrode (see SI Figure 1) to ensure the anode potential had stabilized. The overall shape of the anode potential vs time curve (Figure 4) was observed to be similar between the two anodes. However, the 1 MΩ anode established a lower anode potential and produced a higher imax more rapidly than the 100 Ω anode. The 100 Ω anode began to rapidly increase after 100 h and reached nearly the same potential as the 1 M Ω. However, neither polarization curve correlated with the timing of the Iop increase trend and the period of exponential cell growth. The anode potential therefore became negative (reducing) and the imax increased in a linear fashion from 20 to 60 h with only a monolayer of cells present on the anodes and did not correlate to the rapid current development period (30 to 60 h). At 20 h of growth with a single layer of cells and before rapid cell growth, the anode potential reached -150 mVAg/AgCl, consistent with the increasing current in the initial growth stages as shown in Figure 3. From 60 to 120 h the Iop of the MFC’s decreased slightly over time whereas the anode potential continued to become more negative and the imaxincreased. The higher cell potential and performance of the MFC at later times is consistent with reported literature for batch studies (6). Interestingly, in the early stages of the experiment, the potential and power densities are higher and are established sooner in the 1 MΩ anode than the 100 Ω anode, but by 120 h the 100 Ω anode approaches this value. Since the 100 Ω anode did not support a thick biofilm by 120 h, the development of its potential and Pmax may not necessary be reliant on a thick biofilm suggesting that a limit on a FIGURE 4. Development of anode potential and performance over the course of biofilm development. Current vs time for (A) 1 M Ω and (B) 100 Ω anodes. The spikes in cell voltage observed in panels A and B represent the times where the fuel cell was in open circuit and when the polarization data were collected. Results from polarization resistance from anodes in A and B over time; (C) development of anode potential. (D) development of maximum current density. MFC’s power is reached prior to the maximum cell density achieved on an anode. Comparing MFC Performance Parameters with Pronounced Biomass Differences. At 120h, when the biofilm thickness differences between anodes were very pronounced, potentiodynamic polarization measurements were performed for five separate experiments (two anodes within each chamber), and the mean of the data were used to quantify the differences in MFC performance with the different external resistance (SI Figure 4). The stable operating current established after 120 h showed the largest measurable difference between the two anodes, even while suffering from high variability in the performance of the 100 Ω anode. The 100 Ω anode statistically outperformed the 1 MΩ anode with mean stable operating currents of 1.2 ( 0.6 µA and 0.3 ( 0.03 µA, respectively. The observed differences are consistent with standard MFC theory that the maximum operating current, or power, is achieved when the fuel cell is operated under conditions where the internal and external resistances are nearly balanced (e.g., 100 Ω external and ∼40 Ω internal in this system) (5). The open circuit potential of the anodes at this later time point, although on average higher in the 1MΩ circuit, was not significantly different (p ) 0.061) at the 5% level (p ) 0.05), despite the clear difference in biofilm thickness (SI Figure 4). The maximum current density however, was significantly higher (p ) 0.027) on the 1 MΩ. The Pmax is on average higher in the 1 MΩ circuit (4.5 ( 1.0 mW/m2) than that of the 100 Ω (3.0 ( 0.9 mW/m2) though not significantly so (p ) 0.084). Overall, the current density and power density values fall into a range of operating values for several reported microbial fuel cells using Shewanella and show our system is operating as well as other designs using similar electrode materials. The most relevant comparison for a power measurement that was believed to be predominately biofilm related was reported by Biffinger et al. (25) at 0.52 mW/m2 for Shewanella strain DSP10. They employed a Pt/C oxygen reduction cathode and attempted to control for a strict biofilm measurement with little influence of planktonic cells. The power densities reported by Biffinger et al. are comparable to those found in this study because both values were calculated using the true surface area of the anode electrode, and not the underestimated “projected” surface area of a porous electrode, which can dramatically increase the calculated power density (26). Discussion The optical compatible dual anode system described here has allowed, for the first time, real time, noninvasive estimates of current per cell collected noninvasively over time in an operating MFC. In the initial phase, the 100 Ω anode increased to a maximum of 200 fA/cell (1.3 × 106 e- cell-1 sec-1) and the 1 MΩ reached 80 fA/cell (0.4 × 106 e- cell-1 sec-1). These rates decreased to 63 fA/cell and 39 fA/cell respectively after the cell growth entered a rapid phase of growth. The average current on a per cell basis over time for both anodes in the initial stages fell within a range of values from 0.007 to 0.2 pA per cell with the 100 Ω, which had a lower cell density on the anode surface, outperforming the 1 M Ω. One hypothesis as to why the current per cell decreases as the cell surface growth enters exponential phase is that some electrons are diverted to building cellular components rather than to respiration via the anode ((5)). As cells were observed to populate the anode surface, a relatively consistent lag phase in current was seen before rapid cell growth began and the stable current was attained. One possible explanation for the observed lag phase in current production could be that initially the cells are not adapted to transferring electrons to solid phase electron acceptors and that upregulation of genes encoding specific proteins and production of new components for this transfer are required. The cells from the liquid grown batch culture used as the inoculum of the fuel cells are from the late exponential phase and most likely the population is not homogeneous and can even include metabolically inactive cells that still maintain fluorescence from the long-lived GFP in this strain. Our cell counts would include the dead or inactive cells that still have intact membranes, which may or may not have enzymatic activity and contribute to the overall current. Bretschger et al. (6) however, have previously shown that membrane fractions of cells alone do not produce current. Overall there are difficulties associated with obtaining a true value for the current per cell and therefore these data represent estimates that are relevant to the specific conditions of our system. Using a different fluorescent construct that harbors a short-lived GFP however, may allow an estimate of anode respiration rates for only the active cell population. Previous studies using noninvasive NMR spectroscopy on live biofilms of S. oneidensis MR-1 under flowing conditions in similar minimal medium, quantified the anaerobic metabolism rates with lactate and various soluble electron acceptors (i.e., fumarate, DMSO, NO3) (22) as well as metabolite profiles within an MR-1 biofilm (27, 28). It was VOL. 44, NO. 7, 2010 / ENVIRONMENTAL SCIENCE & TECHNOLOGY 9 2725 found that even aerobically grown biofilms could immediately reduce fumarate, DMSO or NO3 without prior exposure to these acceptors or adjusting the oxygen concentrations to anaerobic conditions. These reduction studies were conducted under bulk aerobic conditions where oxygen becomes rapidly limited at depth within a metabolically active biofilm. Here we have quantified the electron transfer to solid electron acceptor and the changing potentials from single attached cells though to mature biofilms. Quantification of parameters such as the decreasing anode potential (becoming more negative with respect to the reference electrode) over time indicated that the cells can establish reducing conditions early in the growth phase while still as a single cell layer. For both the thick biofilms on the 1 MΩ anode as well as the thin but active 100 Ω anode biofilm, the anode potential increased rapidly when the circuit was opened, reaching reducing conditions within 2 h. Presumably this is due to the cell’s oxidation of lactate coupled to the reduction of all available redox active compounds within the cells and possibly any extracellular redox components. It is very interesting that current was produced and anode potential was measurable above background under constant flow with only a thin dispersed monolayer on the anode. Given that this was under relatively high laminar flow conditions and high dilution rates, nonadhered soluble redox active compounds, such as electron shuttles, would be of minimal use with single cells on the surface. Of particular note is that the maximum rate of electron transfer to the anode occurred at cell densities that did not completely saturate the available anode surface area. We suspect that a very low level of oxygen is also present in solution since maturation of fluorescent proteins actually requires the presence of molecular oxygen. Fluorescence formation of GFP is prevented by rigorously anoxic conditions (<0.75 µM O2) but is readily detected at 3 µM O2 ((29)). This suggests that the cells (as a single cell layer) on the surface are limited for oxygen as the acceptor and/or prefer the anode as the electron acceptor; an intriguing idea that warrants further investigation. MFC performance parameters, determined from power curves, were averaged for five independent runs. The 120 h time point was chosen for the comparisons since that time showed the most pronounced difference in biomass and stable operating current (SI Figure 4) between the two anodes. These results may be of use in determining whether thick or thin biofilms are optimal for current generation in MFC applications. The averages at 120 h show that the cell potential, imax, and Pmax is higher in the 1MΩ circuit. However, at 120 h, only the imax, was shown to be significantly higher at the 5% level (p ) 0.05). Further study is needed to fully characterize if these parameters are significantly increased when a larger biofilm is present on the anode. Although we have documented that varied external resistance reproducibly results in major biofilm differences, the explanation of these differences remains unknown. Previous work with MR-1 biofilms in flow cells (on inert surfaces) showed their development into complex structures in nutrient rich (24, 30) and in a defined minimal medium (22) grown with oxygen as the major electron acceptor. The development and stability of these structures in MR-1 can vary depending on the availability of a soluble alternative electron acceptor such as fumarate (22). Noninvasive temporal development of MR-1 into biofilms from single attached cells to mature biofilms has not been well documented or previously assessed on an anode of a microbial fuel cell or in correlation with electron transfer rates. It is possible that the availability of an electron acceptor (potential difference between the anode and cathode) or alternatively the rate at which electrons can be passed to an accepting surface (resistance) can drive the building of biomass. Increasing the number of cells or redox active compounds to generate 2726 9 ENVIRONMENTAL SCIENCE & TECHNOLOGY / VOL. 44, NO. 7, 2010 a more reducing environment would be an effective strategy to more quickly reach conditions to enable reduction of solid phase oxides. The observed rapid biomass accumulation and the more negative anode potential observed on the harder to reduce (higher resistance) surface supports this notion. In summary, we have successfully demonstrated a new MFC design to couple imaging technology with microbial fuel cells enabling insights into the physiology of microbial cells as they develop into a biofilm especially as it pertains to the movement of electrons from cells to a solid acceptor. The analogy of these systems to the interaction of microbes in the environment with solid mineral phases should not be overlooked. Microbial fuel cells stand as a technology that can be used to investigate the physiology of the cells on a solid electron accepting surface and as a model system for quantifying cell-mineral electron transfer. Several models have been proposed detailing the mechanisms of electron transport in MR-1 to solid metal oxides such as direct attachment, electron shuttles and, the most recently discovered, microbial nanowires however the exact mechanisms and the relative contributions of each are unclear. Further studies with optical compatible systems may help decipher the role of various mechanisms in solid phase electron transfer. In particular the use of real-time fluorescent gene reporters of the various redox proteins, pili, and electron shuttles would help understand their temporal and spatial (depth) related expression profiles. Acknowledgments This research was supported by the J. Craig Venter Institute; the Legler-Benbough Foundation; and the Office of Science (BER), US Department of Energy with funds from the Environmental Remediation Science Program (grant DEFG02-08ER64560). Appendix A Nomenclature Iop i imax Pmax current under operating conditions (A) current density based on the true anode surface area (A/m2) maximum current density based on the true surface area of the anode (A/m2) maximum power density based on the true surface area of the anode (watts/m2) Supporting Information Available Four figures intended to supplement the material presented in the manuscript. Diagram of the optically compatible MFC, replicate timecourse measurements for current per cell estimates, biofilm structure and current relationships, and 5 day MFC performance parameter comparisons. This material is available free of charge via the Internet at http:// pubs.acs.org. Literature Cited (1) Fredrickson, J. K.; Romine, M. F.; Beliaev, A. S.; Auchtung, J. M.; Driscoll, M. E.; Gardner, T. S.; Nealson, K. H.; Osterman, A. L.; Pinchuk, G.; Reed, J. L.; et al. Towards environmental systems biology of Shewanella. Nat. Rev. Microbiol. 2008, 6 (8), 592–603. (2) Nealson, K. H.; Saffarini, D. Iron and manganese in anaerobic respiration: environmental significance, physiology, and regulation. Annu. Rev. Microbiol. 1994, 48, 311–43. (3) Lovley, D. R.; Coates, J. D. Bioremediation of metal contamination. Curr. Opin. Biotechnol. 1997, 8 (3), 285–9. (4) Logan, B. E. Exoelectrogenic bacteria that power microbial fuel cells. Nat. Rev. Microbiol. 2009, 7 (5), 375–81. (5) Logan, B. E.; Hamelers, B.; Rozendal, R.; Schroder, U.; Keller, J.; Freguia, S.; Aelterman, P.; Verstraete, W.; Rabaey, K. Microbial fuel cells: Methodology and technology. Environ. Sci. Technol. 2006, 40 (17), 5181–92. (6) Bretschger, O.; Obraztsova, A.; Sturm, C. A.; Chang, I. S.; Gorby, Y. A.; Reed, S. B.; Culley, D. E.; Reardon, C. L.; Barua, S.; Romine, M. F.; et al. Current production and metal oxide reduction by Shewanella oneidensis MR-1 wild type and mutants. Appl. Environ. Microbiol. 2007, 73 (21), 7003–12. (7) Marsili, E.; Baron, D. B.; Shikhare, I. D.; Coursolle, D.; Gralnick, J. A.; Bond, D. R. Shewanella secretes flavins that mediate extracellular electron transfer. Proc. Natl. Acad. Sci. U. S. A. 2008, 105 (10), 3968–73. (8) Lies, D. P.; Hernandez, M. E.; Kappler, A.; Mielke, R. E.; Gralnick, J. A.; Newman, D. K. Shewanella oneidensis MR-1 uses overlapping pathways for iron reduction at a distance and by direct contact under conditions relevant for Biofilms. Appl. Environ. Microbiol. 2005, 71 (8), 4414–26. (9) Reguera, G.; McCarthy, K. D.; Mehta, T.; Nicoll, J. S.; Tuominen, M. T.; Lovley, D. R. Extracellular electron transfer via microbial nanowires. Nature 2005, 435 (7045), 1098–101. (10) Gorby, Y. A.; Yanina, S.; McLean, J. S.; Rosso, K. M.; Moyles, D.; Dohnalkova, A.; Beveridge, T. J.; Chang, I. S.; Kim, B. H.; Kim, K. S.; et al. Electrically conductive bacterial nanowires produced by Shewanella oneidensis strain MR-1 and other microorganisms. Proc. Natl. Acad. Sci. U. S. A. 2006, 103 (30), 11358–63. (11) Reguera, G.; Nevin, K. P.; Nicoll, J. S.; Covalla, S. F.; Woodard, T. L.; Lovley, D. R. Biofilm and nanowire production leads to increased current in Geobacter sulfurreducens fuel cells. Appl. Environ. Microbiol. 2006, 72 (11), 7345–8. (12) Bond, D. R.; Lovley, D. R. Electricity production by Geobacter sulfurreducens attached to electrodes. Appl. Environ. Microbiol. 2003, 69 (3), 1548–55. (13) Srikanth, S.; Marsili, E.; Flickinger, M. C.; Bond, D. R. Electrochemical characterization of Geobacter sulfurreducens cells immobilized on graphite paper electrodes. Biotechnol. Bioeng. 2008, 99 (5), 1065–73. (14) Ishii, S.; Watanabe, K.; Yabuki, S.; Logan, B. E.; Sekiguchi, Y. Comparison of electrode reduction activities of Geobacter sulfurreducens and an enriched consortium in an air-cathode microbial fuel cell. Appl. Environ. Microbiol. 2008, 74 (23), 7348– 55. (15) Thormann, K. M.; Saville, R. M.; Shukla, S.; Spormann, A. M. Induction of rapid detachment in Shewanella oneidensis MR-1 biofilms. J. Bacteriol. 2005, 187 (3), 1014–21. (16) Torres, C. I.; Marcus, A. K.; Parameswaran, P.; Rittmann, B. E. Kinetic experiments for evaluating the Nernst-Monod model for anode-respiring bacteria (ARB) in a biofilm anode. Environ. Sci. Technol. 2008, 42 (17), 6593–7. (17) Hong, S. H.; Jeong, J.; Shim, S.; Kang, H.; Kwon, S.; Ahn, K. H.; Yoon, J. Effect of electric currents on bacterial detachment and inactivation. Biotechnol. Bioeng. 2008, 100 (2), 379–86. (18) Busalmen, J. P.; de Sanchez, S. R. Changes in the electrochemical interface as a result of the growth of Pseudomonas fluorescens biofilms on gold. Biotechnol. Bioeng. 2003, 82 (5), 619–24. (19) Franks, A. E.; Nevin, K. P.; Jia, H.; Izallalen, M.; Woodard, T. L.; Lovley, D. R. Novel strategy for three-dimensional real-time imaging of microbial fuel cell communities: monitoring the inhibitory effects of proton accumulation within the anode biofilm. Energy Environ. Sci. 2009, 2, 113–119. (20) HaoYu, E.; Cheng, S.; Scott, K.; Logan, B. Microbial fuel cell performance with non-Pt cathode catalysts. J. Power Sources 2007, 171 (2), 275–281. (21) Dewan, A.; Beyenal, H.; Lewandowski, Z. Scaling up microbial fuel cells. Environ. Sci. Technol. 2008, 42 (20), 7643–8. (22) McLean, J. S.; Majors, P. D.; Reardon, C. L.; Bilskis, C. L.; Reed, S. B.; Romine, M. F.; Fredrickson, J. K. Investigations of structure and metabolism within Shewanella oneidensis MR-1 biofilms. J. Microbiol. Methods 2008, 74 (1), 47–56. (23) Beyenal, H.; Donovan, C.; Lewandowski, Z.; Harkin, G. Threedimensional biofilm structure quantification. J. Microbiol. Methods 2004, 59 (3), 395–413. (24) Thormann, K. M.; Saville, R. M.; Shukla, S.; Pelletier, D. A.; Spormann, A. M. Initial phases of biofilm formation in Shewanella oneidensis MR-1. J. Bacteriol. 2004, 186 (23), 8096– 8104. (25) Biffinger, J. C.; Pietron, J.; Ray, R.; Little, B.; Ringeisen, B. R. A biofilm enhanced miniature microbial fuel cell using Shewanella oneidensis DSP10 and oxygen reduction cathodes. Biosens. Bioelectron. 2007, 22 (8), 1672–9. (26) Ringeisen, B. R.; Henderson, E.; Wu, P. K.; Pietron, J.; Ray, R.; Little, B.; Biffinger, J. C.; Jones-Meehan, J. M. High power density from a miniature microbial fuel cell using Shewanella oneidensis DSP10. Environ. Sci. Technol. 2006, 40 (8), 2629–34. (27) McLean, J. S.; Ona, O. N.; Majors, P. D. Correlated biofilm imaging, transport and metabolism measurements via combined nuclear magnetic resonance and confocal microscopy. ISME J. 2008, 2 (2), 121–31. (28) Majors, P. D.; McLean, J. S.; Fredrickson, J. K.; Wind, R. A. HMR methods for in-situ biofilm metabolism studies: Spatial and temporal resolved measurements. Water Sci. Technol. 2005, 52 (7), 7–12. (29) Shaner, N. C.; Steinbach, P. A.; Tsien, R. Y. A guide to choosing fluorescent proteins. Nat. Methods 2005, 2 (12), 905–909. (30) Teal, T. K.; Lies, D. P.; Wold, B. J.; Newman, D. K. Spatiometabolic stratification of Shewanella oneidensis biofilms. Appl. Environ. Microbiol. 2006, 72 (11), 7324–30. ES903043P VOL. 44, NO. 7, 2010 / ENVIRONMENTAL SCIENCE & TECHNOLOGY 9 2727