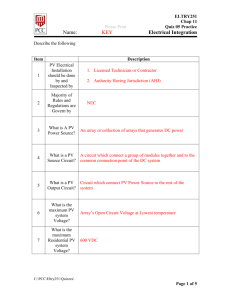

NFPA70-08, National Electric Code

advertisement