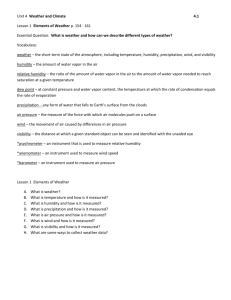

RELATIVE HUMIDITY, PRESSURE AND TEMPERATURE

advertisement