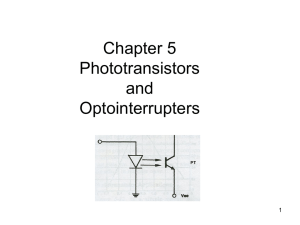

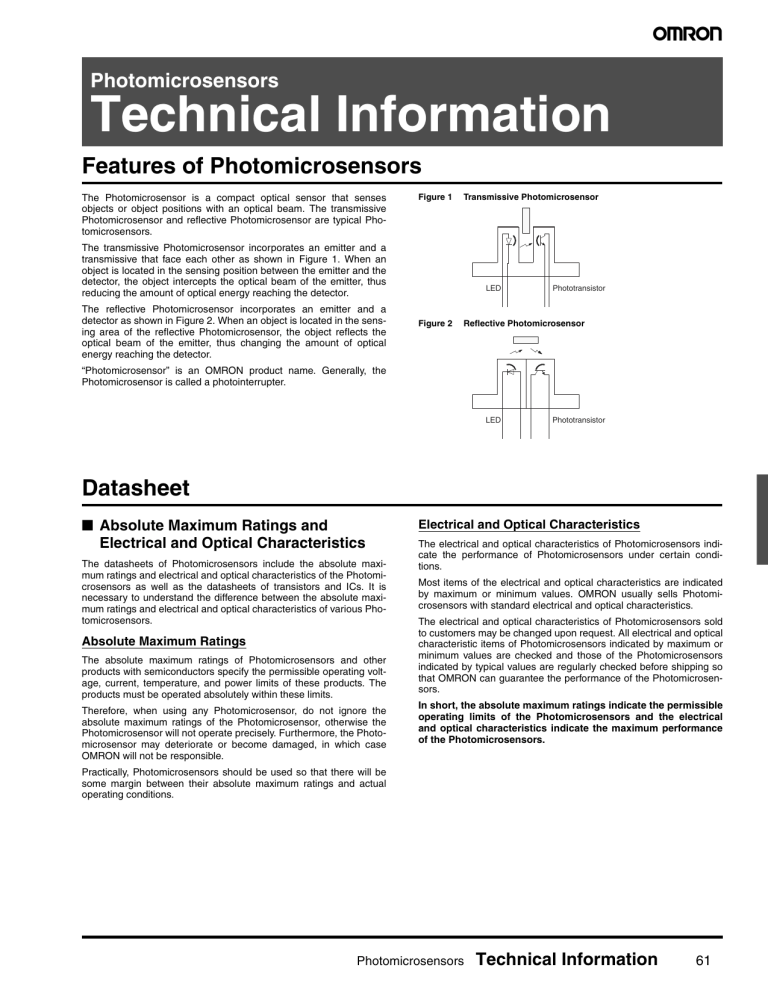

Photomicrosensors Technical Information

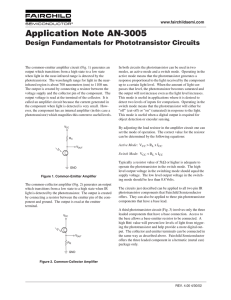

advertisement