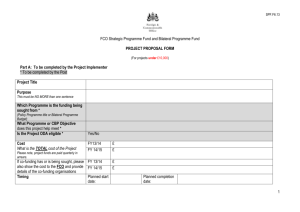

Commercial Applications

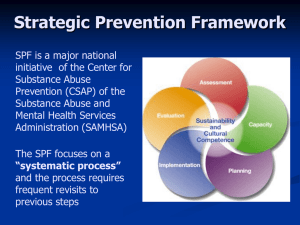

advertisement

The Benefits of Spray Polyurethane Foam in Commercial Applications INTRODUCTION ............................................................................1 KNOwING whAT Type Of Spf TO ChOOSe................................2 Choosing Closed Cell SPF Choosing Open Cell SPF VIAble COmmeRCIAl USeS ........................................................3 why ARChITeCTS ARe ChOOSING Spf......................................3 SPF as a Thermal Control Layer SPF as an Air Control Layer SPF Meeting the ASHRAE and IECC Building Codes why GeNeRAl CONTRACTORS ARe USING Spf ........................6 bUIlDING TypeS ThAT beNefIT fROm Spf ................................7 SPF in Schools SPF in Healthcare Facilities SPF in Offices SPF in Hotels Spf USeS IN exTeRIOR ApplICATIONS......................................10 SPF in Exterior Walls SPF in Roofs Spf USeS IN INTeRIOR ApplICATIONS ......................................13 SPF in Interior Walls SPF in Floors beNefITS wheN USING Spf......................................................14 Overall Energy Savings When Using SPF Reduced Construction Costs with SPF Energy Savings with SPF hURRICANe wINDS AND The beNefITS Of Spf ......................15 RACKING STReNGTh..................................................................16 Spf AND hVAC CONSIDeRATIONS ............................................17 ClASSIfICATIONS AND CODeS fOR Spf ..................................17 Construction Specifications Institute (CSI) ICC Evaluation Service Report (ESR) Certified Applicators 2012 International Building Code and SPF 2012 International Energy Conservation Code (2012 IECC) and SPF ASHRAE 90.1-2010 and SPF California Title 24 and SPF SUSTAINAble bUIlDING pRACTICeS AND Spf..........................20 CONClUSION..............................................................................20 lINKS AND ReSOURCeS ....................................Inside back cover INTRODUCTION W hen it comes to usefulness, not many building materials can compare to spray polyurethane foam (SPF) insulation. SPF is an ideal insulation material for architects when energy efficiency and code compliance related to air tightness and thermal performance are important. Spray polyurethane foam, available in open cell and closed cell, provides an effective thermal and air control layer around a building’s envelope. The air sealing properties and thermal insulation rating, as well as the design flexibility aspects make SPF the all-in-one solution for architects and builders insulating both standard and unconventional residential, commercial, institutional, military and industrial buildings. The benefits of Spray polyurethane foam in Commercial Applications • page 1 Open cell SPF has an R-value of 3.6 per inch. Closed cell SPF has an R-value of 6 per inch. KNOwING whAT Type Of Spf TO ChOOSe There are two basic types of SPF commonly used in commercial construction today, and depending on the type of commercial construction project you are tasked with, it is important to know which type of SPF will work best in each application. Although both open cell SPF and closed cell SPF offer superior insulation performance, the two types are not interchangeable. Choosing Closed Cell SPF S ometimes called two-pound or medium density foam (2lb/ft3 or 32kg/m3) closed cell SPF has a thermal conductivity of less than 24 mW/mK. It has a high R-value of around 6 per inch. Closed cell SPF is an excellent air control layer, bulk water barrier and moisture vapor retarder. It provides structural enhancements to buildings and is effective in all climates. It is typically installed in wall cavities, attics, basements, crawl spaces or on a building’s exterior walls. Choosing Open Cell SPF A lthough open cell SPF has a lower R-value (3.6) than closed cell SPF, it is an effective thermal control layer option for wall cavities, attics and crawl spaces. Usually called low density or half-pound foam (0.5lb/ft3 or 8kg/m3). Open cell SPF has a thermal conductivity of less than 39mW/mK and acts as both an air control layer and noise absorber. Open cell SPF is softer and more flexible than rigid closed cell foams. In general, it is best suited for mixed or warm climates. It can be used in colder climates, when installed in combination with a vapor retarder. To create spray foam insulation, liquid polyurethane precursors (an A-side — MDI and a B-side — polyol blend) are combined to produce a foamed material structurally composed of small bubbles or cells. The two components are mixed under pressure in a spray nozzle from which they are applied directly onto wall, roof or foundation building assemblies. Once applied, SPF immediately adheres to the surface and then expands 20 to 120 times its original size, filling gaps and acting as an adhesive to bond materials. When properly installed, SPF can be an ideal air control material because it forms a continuous air control layer around penetrations like pipes, door assemblies and windows. Additionally, it is structurally strong enough to withstand significant air pressure from inside and outside the structure, and is very durable during and after construction. Closed cell SPF has been accepted by the highly aggressive Miami-Dade Florida Building Codes for High Velocity Hurricane Zone (HVHZ), passing rigorous evaluation for wind resistance properties in uniform static air pressure and also cyclic wind pressure loading. When applied under roof decks, closed cell SPF can reduce uplift and protect the structure — something critical in areas where hurricane wind speeds can reach 185 miles per hour. In addition to thermal and air control layer performance, closed cell SPF offers unique attributes in storm-prone areas by adding structural strength. It can also be used in commercial roof replacement as a simple, effective way to replace an old roof, while adding energy efficiency and water durability. Relative to closed cell spray foam insulation, open cell spray foam insulation has a higher vapor permeability and higher thermal conductivity, but offers different advantages than closed cell spray foam insulation. Open cell SPF is a far more economical choice for builders and remodelers, often costing 30% less to purchase and install. Also, water is the primary blowing agent for open cell SPF, which makes it attractive to building owners interested in environmentally-friendly products. page 2 • The benefits of Spray polyurethane foam in Commercial Applications VIAble COmmeRCIAl USeS why ARChITeCTS ARe ChOOSING Spf While much emphasis has been placed on improving energy efficiency, indoor air quality and structural durability in residential construction, commercial construction should not be overlooked. When designing a commercial building, architects must both satisfy the requirements of all adopted building codes and also satisfy the requirements (and budget) of the project developer. In addition, architects must design a structure that complies with any building energy codes or green building standards the project hopes to meet. This challenge affects the entire design of the structure, including building envelope design, heating, cooling and ventilation systems and lighting. Complying with energy codes also impacts the materials selected for the building by requiring proper window glazing, enhanced insulation levels and lighting design that will reduce energy use, while providing a comfortable environment for the occupants. It is a common assumption that commercial buildings have less air leakage than residential structures; however, according to Tom Kearns, Detailing Manager, The Facade Group, LLC, “air infiltration in commercial buildings is similar to residential structures even though the construction may be different.” Infiltration in commercial buildings can have many negative consequences, including reduced thermal comfort, interference with the proper operation of mechanical ventilation systems, degraded indoor air quality, moisture damage of building envelope components and increased energy consumption. Commercial buildings have unique needs that are different than typical single-family or multi-unit residential structures. Heavy usage by retail clients, high turnover of occupants, large utility costs and liability concerns related to structural integrity can impact the economic viability of the commercial building. A better-built structure that has superior durability and reduced operating costs is highly attractive to owners and occupants of commercial spaces. For these reasons, attention has been given to methods of improving air tightness both in existing buildings and new construction. Builders, engineers and architects are more often opting to utilize the benefits of SPF in commercial buildings today because when properly installed, SPF can actually improve building durability, structural strength and resistance to water and moisture. SPF is one of the leading materials that meets and often exceeds building code requirements, including air barrier and insulation or R-value. More specific information about how SPF can help achieve or surpass locally adopted building codes is noted later in this white paper. R-Value of Common Materials Brick 0.2 0.3 Concrete Plywood 1.3 Open Cell SPF 3.6 Fiberglass 3.6 Rockwool 3.6 Cellulose 3.6 Polystyrene 4.7 6.0 Closed Cell SPF 0 Source: Huntsman 1 2 3 4 R-Value/Inch 5 6 In addition, commercial construction often includes design elements that are non-typical. Architects are often called upon to create large entryways, unique features and specific design elements for commercial buildings. Because SPF can be used for a multitude of purposes, it is often an ideal material for insulating, creating an air control layer or serving as a structural support material in unique building design situations. When evaluating different building materials, design attributes and energy performance expectations, SPF is often a valuable asset in the architect’s material selection process for three main reasons: 1. SPF provides exceptional thermal resistance 2. A separate air barrier is not needed when specifying SPF 3. Specifying SPF in buildings will facilitate code compliance with ASHRAE (formerly the American Society of Heating, Refrigerating and Air Conditioning Engineers) and International Energy Conservation Code (IECC) 1. SPF as a Thermal Control Layer T he thermal control layer keeps building occupants comfortable and energy costs low. Traditionally, the thermal control layer was simply thought to be the insulation used, or specifically the thickness or R-value of the insulation installed in the structure. Today, we understand that the thermal control layer is more complicated than simply putting a few inches of fibrous insulation between the studs. A successful thermal control layer must offer complete coverage without gaps, spaces or compression that can reduce insulation effectiveness. The thermal barrier must also address thermal bridging and heat loss through conductivity. Finally, the thermal control layer must work in conjunction with the rest of the architectural design, integrate with the building envelope and support heating and cooling expectations. The benefits of Spray polyurethane foam in Commercial Applications • page 3 Another benefit of using SPF as a thermal control layer is that the material can provide complete and continuous coverage around the building envelope (e.g., foundation and slab, walls and roof). The monolithic and continuous coverage means SPF can minimize thermal bridging caused by fasteners, joint cracks, load shifts and penetrations into the structure. Thermal bridging is especially important to address in commercial construction where steel framing is more common. Brackets and fasteners used to support traditional insulating materials act as thermal bridges to the metal framing assembly and transfer heat from the exterior to the interior. Because SPF offers complete coverage without the need of fasteners, thermal bridging is almost completely eliminated when it is used as a thermal control layer. Finally, SPF as a thermal control layer integrates well with the air control layer, penetrations, plumbing and mechanical ventilation system and the overall building design. Unlike other insulating materials which are installed as individual pieces that need to be secured or fastened in place, SPF is not an independent material but instead bonds to the structure and becomes an integral part of the building. By adhering directly to the building, closed cell SPF can more easily accommodate unique design features while providing a superior thermal barrier to ensure that comfort and energy efficiency goals are met. There are four key attributes to a well-designed and successfully installed air barrier system: • Air tightness • Durability • Continuous coverage • Structural integrity Architects select closed cell SPF because it can satisfy all four basic requirements of a successful air barrier. A successful air barrier must be impermeable to airflow, and closed cell SPF has an almost zero air permeable rating, meaning that airflow through the material is virtually non-existent. An air barrier must also have sufficient durability over the building’s expected life, without being easily damaged or compromised during construction. Once sprayed, closed cell SPF hardens into a monolithic material that is structurally strong enough to maintain integrity during the construction process and for years after. 2. SPF as an Air Control Layer I n simple terms, an air barrier is a material (e.g., film, sheet, coating or membrane) that controls or stops airflow from the outside of the building to the inside. It can be made from many different materials, but to be an effective an air barrier, it must be properly installed and provide a complete shield around all sides of the building. When installed in a structure, the air barrier material becomes part of an air barrier assembly, which combines with the building’s windows, doors, and design features to form an air barrier system. The primary objective of the system is to block the random air movement into and out of a building and its walls and roof assemblies. A facility with unchecked air movement can have a host of problems, including higher energy use and costs, water intrusion, moisture issues and poor indoor air quality. A unique feature of SPF is that architects can specify it as both a building’s thermal control layer and air control layer. This “two-for-one” benefit reduces construction time and material costs, and can help eliminate the challenge of integrating an air barrier and thermal insulation to create an effective wall assembly. Spray foam sprayed into the stud cavities seals the gaps, cracks, and transitions creating an air tight space. A well-designed and well-installed air control layer will provide continuous coverage around the entire building from the roofing to the below-grade structure. If any part of the air barrier system fails to control air movement, the entire system is considered a failure. When properly installed, closed cell SPF can be an ideal air control layer material because it forms a continuous barrier around penetrations such as pipes, door assemblies and windows, expanding and filling gaps that normally would require taping or caulking if other air barrier materials were used. The final requirement of a successful air barrier is that the materials used have sufficient structural integrity to resist wind loads, stack pressure and other pressure loads without deforming or failing. This is especially important when using page 4 • The benefits of Spray polyurethane foam in Commercial Applications building wraps or other materials that require mechanical fasteners. The long-term durability of closed cell SPF allows it to maintain structural integrity and resist wind loads and stack pressure without becoming detached from the building envelope and failing. For more information, please refer to Controlling Air Flow and Water Movement with Spray Polyurethane Foam. To request a copy of this brochure, please email sprayfoam@huntsman.com. Understanding the term continuous insulation or “CI” The building envelope includes the roof, wall and floor systems that surround the space being heated and cooled. The code provisions require the selection of either building materials or assemblies that do not exceed the maximum air leakage requirements (CFM/ft2). The 2012 IECC also allows the building envelope to be tested to not exceed a maximum air leakage rate as a method for demonstrating compliance with the code. Both ASHRAE 90.1-2010 and the 2012 IECC require that all seams, penetrations and transitions between approved building materials or assemblies are sealed. Many green building standards and local building codes may suggest continuous insulation in the building envelope to improve the thermal control layer and reduce energy loss. But what is CI? ASHRAE standard 90.1 defines continuous insulation as “insulation that is continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior, exterior, or is integral to any opaque surface of the building envelope.” The key to CI is that it covers all areas of the building envelope, whereas traditional insulation materials installed in stud bays leave gaps in the thermal control layer. Considering all insulation options which qualify as “CI,” SPF provide the unique ability to expand during the installation to fill gaps and voids in the building envelope. 3. SPF Meeting the ASHRAE and IECC Building Codes O The commercial building codes, ASHRAE/IES Standard 90.1-2010 (90.1-2010) and the commercial provisions of the 2012 International Energy Conservation Code (2012 IECC) require that the building envelope be carefully designed to limit uncontrolled infiltration and exfiltration. Controlling air movement is especially important in humid regions of the country as humidity can increase the latent load inside the building, requiring the additional use of the building's cooling system to bring the level of humidity down to acceptable levels. ne of the primary concerns for an architect is to ensure that the project they are working on will meet the adopted local building codes, as well as any additional energy building codes that may apply. A building that can’t pass a code inspection because of poor design can be an embarrassing, expensive mistake. For the architect, the key is to select materials that will meet or exceed the 2012 IECC and ASHRAE 90.1-2010 requirements. SPF is on the list of pre-approved materials that are deemed to comply with the maximum air leakage requirement. Specifically, closed cell SPF can be installed with a minimum density of 1.5pcf (24kg/m3) and a thickness of no less than 1.5 inches (38mm). Also, open cell SPF with a density between 0.4 and 1.5pcf (6 and 24kg/m3) and having a thickness of no less than 4.5 inches (114mm) can be used. Knowing that SPF is on the approved list for the latest building codes and energy standards means that architects specifying SPF can rest assured that their choice of material will make the entire building process easier, and the end product will satisfy the energy efficiency and expectations of the owner and occupants. Example of 2012 IECC Prescriptive R-value Requirements for Commercial Building Walls Source: Jay Crandell, P.E., Ares Consulting, www.aresconsulting.biz, jcrandell@aresconsulting.biz Climate Zone Wood Frame Metal Frame Metal Building Mass 1 R13+R3.8ci or R-20 R13+R5ci R13+R6.5ci R5.7ci 2 R13+R3.8ci or R-21 R13+R5ci R13+R6.5ci R5.7ci 3 R13+R3.8ci or R-22 R13+R7.55ci R13+R6.5ci R7.6ci 4 R13+R3.8ci or R-23 R13+R7.5ci R13+R13ci R9.5ci 5/4 Marine R13+R3.8ci or R-24 R13+R7.5ci R13+R13ci R11.4ci 6 R13+R7.5ci or R20+R3.8ci R13+R7.5ci R13+R13ci R13.3ci 7 R13+R7.5ci or R20+R3.8ci R13+R7.5ci R13+R13ci R15.2ci 8 R13+R15.6ci or R20+R10ci R13+R7.5ci R13+R13ci R25ci NOTES: 1. IECC = International Energy Conservation Code published by the International Code Council Inc. Refer to ASHRAE 90.1 for alternative codecompliant wall R-values. 2. Wall R-values are shown as cavity insulation alone or as X + Y, where the first number is the cavity insulation R-value and the second is for continuous insulation. 3. The commercial wall R-values are based on all commercial building groups, except R (residential), which may require additional continuous insulation R-value depending on climate zone. The benefits of Spray polyurethane foam in Commercial Applications • page 5 why GeNeRAl CONTRACTORS ARe USING Spf General contractors are finding that SPF can be an ideal material to choose for commercial building projects for a number of reasons. The general contractor, like the architect, must satisfy building code requirements and the expectations of the client, but there are other considerations that are unique to the general contractor. Time is money for the general contractor, and project delays, cost overruns or long punch-lists can quickly turn a profitable project into a financial loss. When watching the budget of a commercial building project, the general contractor may select SPF for two reasons: • • Reduced construction time Reduced initial building costs Because SPF can be applied as a layer of insulation in a single operation, it does not require large crews for installation of mechanical fasteners, glue, netting or any of the other installation requirements encountered when using traditional insulation types. This means that SPF can be quicker and easier to install in most commercial construction settings. Once sprayed, SPF immediately bonds to the surface it is sprayed on and rapidly expands into hard-toreach places, filling all the gaps and voids. This means that subcontractors won’t have to spend time revisiting the installation area and making sure that all joints, seams and penetrations are caulked and sealed. The other financial advantage of using SPF in commercial buildings is that the single application of SPF can serve as both the air control layer and the insulation. What this means to the general contractor is that fewer subcontractors are needed on the job site. With fewer people to manage and less interruption to the building cycle, closing times can be reduced on projects without sacrificing quality. In fact, closed cell SPF is a superior air control layer product because the expanding foam seals and also provides a barrier for water vapor as well. Because general contractors are financially responsible for bringing projects to completion on time and on budget, selecting SPF offers a product that will help them meet or beat their deadlines. page 6 • The benefits of Spray polyurethane foam in Commercial Applications bUIlDING TypeS ThAT beNefIT fROm Spf With nearly 5 million commercial buildings and 115 million residential households in the United States, buildings account for almost 40 percent of the nation’s total primary energy use and 70 percent of the electricity used annually. Much of the energy wasted in commercial and residential buildings is a result of poor air sealing and insufficient thermal insulation. Air sealing is one of the least expensive and most cost-effective measures available to improve a building’s energy performance, comfort and durability. By sealing uncontrolled air leaks, occupants can expect to see savings of 10 to 20 percent on heating and cooling bills, and even more in older structures that generally are poorly insulated or were built without continuous air barriers. In commercial buildings, a well-designed and properly installed air barrier assembly can result in an even greater energy savings potential. According to simulations by the National Institute of Standards and Technology (NIST), air barrier systems in commercial buildings are estimated to reduce air leakage by up to 83 percent and can reduce natural gas consumption by more than 40 percent and electrical use by more than 25 percent. The U.S. Department of Energy (DOE), in conjunction with the National Renewable Energy Laboratory (NREL), published a report that determined that there are 16 building types that represent approximately 70 percent of the commercial buildings in the United States. Although SPF can provide benefits to all styles of commercial buildings, there are several types where SPF can provide exceptional value, including: 1. Schools and education facilities 2. Healthcare facilities 3. Offices 4. Hotels 16 Reference Building Types Building Type Name Floor Area (ft2) Large Office 498,588 12 54,628 3 Small Office 5,500 1 Warehouse 52,045 1 Stand-alone Retail 24,962 1 Strip Mall 22,500 1 Primary School 73,960 1 210,887 2 45,000 1 Quick Service Restaurant 2,500 1 Full Service Restaurant 2,500 1 241,351 5 Outpatient Health Care 40,946 3 Small Hotel 43,200 4 Large Hotel 120,122 6 33,740 4 Medium Office Secondary School Supermarket Hospital Midrise Apartment Number of Floors DOE developed 16 reference building types that represent most commercial buildings across 16 locations, which represent all U.S. climate zones. (Image source U.S. DOE, http://www1.eere.energy.gov/buildings/ commercial/ref_buildings.html) Example of closed cell SPF applied to the exterior of a church. Photo courtesy of West Roofing Systems, Inc. The benefits of Spray polyurethane foam in Commercial Applications • page 7 Closed cell SPF applied to the exterior walls at Crieve Elementary. Using SPF can help reduce sound, making recovery rooms in hospitals quieter and less stressful for patients. 1. SPF in Schools 2. SPF in Healthcare Facilities P H ublic and private education campuses can greatly benefit from SPF, whether the project involves new construction or retrofitting and updating an existing building. Schools often are on fixed budgets with utilities, and for public education settings, they have to choose between upgrades to the physical building and additional educational programs for students. SPF reduces energy consumption and can help to save on heating and cooling costs. Some universities understand this well; for instance, Texas A&M has installed SPF on over 90 percent of the 10 million square feet of roofs on campus. According to Gerald Scott, Director of Energy at Texas A&M University, the typical payback for this size of investment is 4.5 years. Some types of closed cell SPF are GREENGUARD Indoor Air Quality Certified® and GREENGUARD Children and SchoolsSM Certified. GREENGUARD tests products intended for use in schools, daycares or other environments, where children spend significant periods of time, and is referenced by both The Collaborative for High Performance Schools (CHPS) and the Leadership in Energy and Environmental Design (LEED) Building Rating System. ospitals are enormously complex buildings with many unique requirements. Architects, designers, contractors, developers, owners and lessees of large hospitals sometimes overlook energy usage because they are so focused on meeting the hospital’s numerous other requirements. However, a study conducted by NREL on behalf of the DOE found that 50 percent energy savings is achievable with conventional technologies, while still maintaining all of the requirements necessary for safe and accredited hospital operation. One of the main elements of the energy savings involved replacing the heating and cooling system and properly sizing the mechanical equipment after air sealing exterior walls and properly insulating roof systems. By reducing the infiltration rates of the building and upgrading the heating, cooling and ventilation system, hospitals in all climate zones could reduce energy loads related to climate control by at least 50 percent. For this simulation, air barrier requirements and R-value expectations were met or exceeded when using SPF. Another important contribution SPF can make to health care facilities involves restricting moisture, outdoor allergens and pollutants. The water barrier qualities of SPF help reduce the chance of condensation and mold growth. SPF is also an excellent sound barrier, adding extra value by making recovery rooms in hospitals quieter and less stressful for patients. page 8 • The benefits of Spray polyurethane foam in Commercial Applications Insufficient insulation can account for up to 40 percent of a building’s heating and cooling costs. Closed cell SPF being applied to a hotel in Washington, D.C. 3. SPF in Offices 4. SPF in Hotels A H ccording to a study conducted by the U.S. DOE, as the temperature rises, productivity decreases an average of 2 percent for every degree over 77 degrees Fahrenheit. In practical terms, this means that keeping cool can make both the worker and the bottom line happy. While mechanical ventilation can help regulate the room temperature, heat loss through poor air barriers and insufficient insulation can account for up to 40 percent of a building’s heating and cooling costs. Also, office buildings are usually steel frame construction, which makes them vulnerable to thermal bridging. In steel stud walls, thermal bridging happens most frequently when mechanical fasteners are used to secure insulation materials, and these fasteners come in contact with the metal frame. According to the article Improving Energy Performance of Steel Stud Walls by Jan Kosny, Jeffrey E. Christian, and André O. Desjarlais, Oak Ridge National Laboratory, Buildings Technology Center, “the result is that thermal bridging can reduce the thermal performance of insulation materials by up to 55 percent.” Because SPF does not require metal fasteners and can continuously cover existing thermal bridges, most if not all incidents of thermal bridging can be eliminated. otel room comfort is largely left to the occupants, which can lead to high energy costs as guests adjust heating and cooling demands at will. However, the more consistent the air temperature inside the room, the lower the utility bills will be for the building operator and owner. Often hotels are constructed with only the minimum amount of insulation and air tightness required by building code at the time of construction. By using SPF to create a complete and continuous air control layer, hotels can reduce air infiltration and help maintain a more comfortable space for guests. In a recent renovation of the Gaylord Opryland Resort and Convention Center, SPF was used to insulate a number of guest room walls. The project required the removal of both the fiberglass insulation and the exterior fiberglass-mat faced gypsum board sheathing, leaving exposed brick. Replacing the exterior sheathing would have required removal and replacement of the brick, an expensive proposition. Rather, the general contractor developed the idea to use closed cell SPF with a baffle system. The baffle system provided an air gap for the drainage plane, while serving as a surface for spraying and transferring loads on the brick back to the studs. The baffle was testsprayed prior to installation to ensure it would have good adhesion. Two inches of closed cell SPF were then applied directly onto the baffle system. The adhesion and structural rigidity of the foam solidified the wall system and added strength. SPF provided an R-13 thermal insulation layer and served as the air control layer. Finally, the wall system was finished on the interior with drywall. The benefits of Spray polyurethane foam in Commercial Applications • page 9 Spf USeS IN exTeRIOR ApplICATIONS When applied to the exterior of commercial buildings, in either new or retrofit situations, SPF can greatly reduce energy use, air infiltration and water intrusion. The two primary areas where SPF is used on the exterior of buildings are walls and roofing applications. fiberglass insulated wall assemblies at low and high temperatures with induced air infiltration (Source: ATI ASTM C 1363-05 THERMAL PERFORMANCE TEST REPORT). Because SPF allows very little air permeation, there is almost no measurable movement of air through the insulation material as is common in fiberglass or cellulose insulation. This helps reduce the negative effects of air movement within the building envelope, such as “wind washing” and the stack effect. SPF in Roofs R Closed cell SPF being applied to the exterior of a building. SPF in Exterior Walls O ne of the positive attributes of SPF is that it is a very versatile building material. SPF is compatible with many wall types and can be sprayed onto the exterior sheathing in new construction projects, or assimilated between stud cavities in retrofit situations. SPF-insulated buildings have superior thermal performance due to the air barrier properties SPF provides, as well as reduced thermal bridging through the studs. In addition, studies have found that SPF can improve the structural integrity of the building in areas of high wind events by increasing the “racking strength” of the walls. One of the most important attributes of closed cell SPF in external wall applications is that it is an effective water barrier, as well as an air control layer. Moisture intrusion is one of the biggest threats to the structural integrity and durability of commercial buildings, accounting for up to 89 percent of damage to the building envelope (Source: Bomberg, M.T. and Brown, W.C. (1993), “Building Envelope and Environmental Control: Part 1-Heat, Air and Moisture Interactions” Construction Canada 35 (1), 15-18). Reducing moisture intrusion through the wall, whether in vapor or liquid water form, is critically important for the long-term durability of the structure and health of the occupants. Another benefit of using SPF in exterior walls is that it can mitigate some of the natural air pressure forces that can impact energy efficiency. Testing of wall assemblies by Architectural Testing Inc. demonstrated SPF with its air infiltration reduction characteristics performed better than oof failure is a primary cause for water intrusion into the building, and traditional methods of removing and replacing roofing material can be expensive and expose the structure to additional damage. SPF can be used as a re-roofing material, applied directly on the existing roof structure. It provides two important benefits to a building through waterproofing and increased insulation value. Further, the application of SPF to an existing roof structure is simple and fast. The expanding foam is simply applied directly over the existing metal, wood, concrete, membrane or built-up roofing material. Once the SPF has been applied to the proper thickness, a protective layer of elastomeric coating or gravel is applied over the insulation. This combination of foam insulation and protective layer produces a durable, weather-resistant surface that is strong enough to walk on. In new construction, SPF is ideal for flat commercial roofs because it is lightweight, durable, and requires less maintenance compared to traditional roofing systems. Once applied, SPF can help make roofs weather-proof and has a 30 year expected service life. Additionally, as a roofing material, SPF also increases the structural strength of the building by providing wind uplift resistance which can be critical in hurricane-prone regions. SPF applied to the roof of two commercial buildings. Photos courtesy of West Roofing Systems, Inc. page 10 • The benefits of Spray polyurethane foam in Commercial Applications Typical examples of Spf Usage in Commercial wall Assemblies Concrete Masonry Unit se d C Cell SP F el lS PF Interior Gypsum Board lo Concrete Masonry Unit Flashing Drainage Plane Drainage Plane (Between Brick and Closed Cell SPF) (Between Brick and Closed Cell SPF) Wood Wall Studs Metal Wall Studs Interior Gypsum Board Closed Cell SPF Closed Cell SPF Drainage Plane (Drainage Plane line between Closed Cell SPF and Brick) Brick Oriented Strand Board Fiberglass Interior Gypsum Board Fiberglass Oriented Strand Board Brick Closed C Brick Interior Gypsum Board Brick Drainage Plane (Drainage Plane line between Closed Cell SPF and Brick) The benefits of Spray polyurethane foam in Commercial Applications • page 11 Typical examples of Spf Usage in Commercial wall Assemblies Metal Wall Studs* Closed Cell SPF Interior Gypsum Board Concrete Masonry Units Stucco Drainage Plane (Drainage Plane line between Closed Cell SPF and Maonry Units) Metal Wall Studs* Closed Cell SPF Interior Gypsum Board Concrete Masonry Units Drainage Plane (Drainage Plane line between Closed Cell SPF and Maonry Units) page 12 • The benefits of Spray polyurethane foam in Commercial Applications * Can also be wood wall Studs Spf USeS IN INTeRIOR ApplICATIONS When installed on the interior of walls or as part of the floor system, SPF is an integral part of the overall design strategy to improve comfort, indoor air quality and durability, and to reduce energy bills. Both walls and floors can be places of air infiltration, especially in industrial settings, and have the potential of water intrusion, especially in the form of vapor. SPF in these areas can help promote a healthier and more durable space for the occupants. SPF in Interior Walls I nterior walls in commercial buildings can benefit from SPF in a number of ways, including noise reduction and isolating specific areas of the building from adjacent work spaces. Air infiltration through floors is also a concern if they are above crawl spaces. Using SPF as an air and water vapor control layer will reduce energy use and also protect the structure from mold and rot due to water damage. An additional benefit of closed cell SPF installed in floors above crawl spaces is that the material qualifies as an “air impermeable material,” which is required in areas of unacceptable radon levels. When installed above crawl spaces as a continuous air control layer, commercial buildings can employ closed cell SPF as part of their radon mitigation strategy. Conference rooms, executive offices and human resource departments are all areas in commercial office buildings where sound mitigation is critical in order to maintain a professional atmosphere. Open cell spray foam has strong sound reduction properties, often employed in recording studios to mitigate sound intrusion. Reducing sound transmission within a commercial building is also important in manufacturing facilities, like book binderies, that operate noise-generating machinery. Other buildings that could benefit from noise reduction between interior walls include: • • • Hospitals Hotels Schools Another successful application for SPF in interior walls of commercial buildings is in industrial settings, where air quality issues can impact adjacent work spaces. Manufacturing facilities that generate airborne toxins or pollutants need to be isolated from the administrative areas of the building. This can include automotive repair, paint and body shops, chemical companies and printing facilities where paper dust is generated. SPF in Floors S imilar to the challenges of interior walls, floors can benefit from reduced noise transmission and air infiltration when SPF is applied. This is especially true in office buildings and hotels, where sound transmission through the floor can be especially disruptive. Closed cell SPF being applied to the floor of a building. The benefits of Spray polyurethane foam in Commercial Applications • page 13 The renovation of the Gaylord Opryland’s Cascade Atrium features closed cell SPF. The new bar and lounge, known as The Falls Bar, presented some unique challenges. In designing this area, the general contractor found the existing concrete foundation would be unable to support the bar’s weight. Polystyrene was considered, but there were concerns over it settling under the weight of the structure. The foundation was designed as a waffle grid of concrete channels with SPF in between. To form the channels for the concrete, expanded polystyrene (EPS) boards were covered with polyethylene sheeting, one of the few materials SPF will not adhere to. The boards were cut to form the grid in the foundation, into which concrete was poured. This process required significant detailed labor work to deal with the curved structure and all the pipes and conduit running in the foundation. Once the EPS board grid was formed, 14 inches of closed cell SPF was sprayed — into the grid pattern in multiple passes of two to two-and-a half inches each. Once satisfied that the foam was of acceptable quality, the polyethylene sheeting-covered EPS boards were removed leaving a waffle grid of channels. Concrete was then poured into the channels to complete the structure. The result was a lighter weight foundation for the new bar and lounge that did not require the existing concrete base to be replaced. The Falls Bar during the construction phase with the use of SPF. beNefITS wheN USING Spf Overall Energy Savings When Using SPF T he financial benefits of using SPF in commercial construction are primarily recognized in two specific areas: overall construction cost savings and annual savings through energy conservation. Other financial benefits of selecting SPF as an air control layer and insulation material include increased productivity through a more comfortable work environment, improved air quality, and the increased property value of a more durable and energy efficient building. Reduced Construction Costs with SPF F or the builder or general contractor associated with new or retrofit construction, SPF can offer financial value to a project in three ways. First, because SPF can act as an air control layer and thermal control layer, fewer trades or subcontractors are needed to complete a project. This can be especially important in areas experiencing a high volume of construction starts. Finding qualified subcontractors who are skilled in proper installation of air barrier systems and insulation can be a challenge for a builder or general contractor. Scheduling the preferred trades can be difficult and delay the project while waiting for preferred installers to be available. Reducing the number of trades required to complete a project not only reduces the number of days the project takes to complete, but also reduces the likelihood of delays due to scheduling challenges. “I have heard many reports from builders who say they can’t hire enough people, they can’t find subcontractors, they’re unable to get the labor necessary to build homes that they do have on order — even at the low level of building that’s occurring right now.” — DAVID CROWE, chief economist for the National Association of Home Builders The Falls Bar close up of waffle grid using SPF. Air leakage at the roof/wall transition. Photo courtesy of PIE Forensic Consultants. Source: Article “Homebuilding is Booming but Workers are Scarce,” National Public Radio. http://www.npr.org/2013/01/17/169611619/ homebuilding-is-booming-but-skilled-workers-are-scarce page 14 • The benefits of Spray polyurethane foam in Commercial Applications Another way that SPF helps reduce construction costs is that from a material standpoint, closed cell SPF is the insulation material, air control layer and water barrier in one. By themselves, each of these materials would require sourcing, delivery, storage and then either glue or mechanical fasteners to install. In contrast, SPF is installed by trained and certified professionals who bring to the jobsite all the equipment, tools and materials necessary to complete the task. By not having to manage, store and protect air barrier and insulation materials prior to installation, the builder or general contractor can reduce their liability concerns related to damage or theft of building materials. Finally, SPF is often a more economical for builders and contractors because it can be installed faster and easier than other air barrier and insulation materials. Using more traditional insulation materials and air sealing techniques would require several passes over the same area to install each separate component of the building envelope. Each time an area is revisited, whether for air barrier installation, insulation installation or air sealing cracks, seams and voids, it lengthens the overall building schedule of the project. In contrast, installation of SPF only requires a single pass to manage air infiltration, the thermal boundary and air tightness. This savings in time can be significant, especially in large construction projects such as hospitals and multi-story office buildings. Energy Savings with SPF B esides water mitigation, probably the most well-known benefit of SPF is its ability to be a superior air control layer and insulation material. These attributes result in a host of benefits to the building, but the financial savings through reduced energy consumption are especially attractive to occupants and owners. Buildings insulated with SPF typically require less energy to heat and cool. Side-by-side energy efficiency comparisons have shown up to 40 percent energy savings by using SPF over commonly specified insulation materials. Source: MM reviews the sustainability characteristics of SPF roofing and insulations systems by Mason Knowles. reenbuildingsolutions.org http://www.greenbuildingsolutions.org/Main-Menu/Home/ModernMaterials-Archive/Energy-Efficiency/Spray-Can.html hURRICANe wINDS AND The beNefITS Of Spf According to Honeywell’s white paper, Severe Weather and Closed-Cell Spray Foam: A Better Building Technology, “The material [closed cell SPF] has been shown to increase the ability of homes to withstand the effects of flooding, storm surge and high winds. Longstanding endorsements for closed cell foams by such groups as the Federal Emergency Management Agency (FEMA), coupled with newer research by the University of Florida, highlight the effectiveness of these products in resisting flood and wind forces as well as structural damage.” Hurricane winds are unique and pose a specific threat to wooden frame built commercial buildings and traditional roof systems. First, the sustained winds from a hurricane can last for hours with occasional gusts up to 50 percent greater than sustained air speed. This means that a category 2 hurricane with winds at 100 mph could have gusts that exceed 150 mph, which is equal to category 4 strength. Also, because hurricanes move slowly, wind direction changes slowly as the storm passes. This means that any weakness in the roof system will eventually have to face the brunt of the storm. The benefits of Spray polyurethane foam in Commercial Applications • page 15 Wind uplift is the most common cause of roof damage in hurricanes. Uplift is a naturally occurring vacuum created in strong wind events that results in a rapid and sustained loss of air pressure due to high winds moving around the building. Higher wind speeds, in general, can cause a reduction in air pressure as they flow over objects, and during a hurricane, air speed on the roof can be two times the sustained wind speed on the ground. During strong gusts, on relatively flat roof surfaces where the wind is flowing more than striking, air pressure can quickly drop as air speed increases. This loss of air pressure can act as a vacuum and start to pull roofing materials into the air stream, where the direct force of the wind can immediately sweep them away. The dynamics of simple air pressure against the exterior of the house can create incredible pressure and uplift on a roof and result in extensive damage. Additionally, internal pressures cause roof failures in hurricanes as well. In 2007, Dr. David O. Prevatt conducted a study at the University of Florida’s Department of Civil and Coastal Engineering to determine how closed cell SPF could be used to increase the structural integrity of roof assemblies during severe weather events like hurricanes. Specifically, the research focused on evaluating how the spray-on adhesive could protect the roof from uplift and reduce the chance of water intrusion during storm events. To test the material, two approaches were taken. First, a continuous three-inch thick blanket of closed cell SPF was applied between the 2” x 4” roof rafters to evaluate the effectiveness of a full, monolithic covering of closed cell SPF in the roof assembly. The next approach was to apply closed cell SPF as a three-inch fillet to the junction of the roof plywood deck and the roof rafter/truss top chords. The study found that using closed cell SPF either in a continuous three-inch blanket or in fillets increased the roof panel wind uplift. Additionally, the study found that the fillets of SPF increased wind uplift resistance an average of 2 times, while the 3 inch fill increased it 3 times the uplift capacity of roof panels fastened using conventional mechanical fasteners and nailing patterns. In fact, roofing sections with closed cell SPF applied as an adhesive were able to withstand air pressures in excess of 153 psf or roughly the wind speed found in a category 4 hurricane. RACKING STReNGTh In 1992 the Polyurethane Foam Contractors Division (PFCD) of the Society of the Plastics Industry contracted with NAHB Research Center to test rack and shear strength of SPF insulated wood stud wall panels. In 1996, the PFCD contracted again with National Association of Home Builders (NAHB) Research Center to test the racking strength of SPF insulated metal stud wall panels. The SPF assemblies were compared to “standard constructed” wall assemblies. The purpose of the study was to compare the relative structural strength of most common “baseline wall assemblies” to SPF installed to the similarly constructed wall assemblies. In the 1992 study, SPF insulated wall panels were tested with 16, 24, 32 and 48 inch on-center (OC) stud spacing. In the 1996 study, the walls were tested at a 16-inch OC stud spacing. This study was conducted in accordance with ASTM E-72 Standard Methods of Conducting Strength Tests of Panels for Building Construction. A follow-up study was conducted in 2005 at Architectural Testing Inc. on SPF installed to polyiso sheathing as an exterior covering to wall with wood stud spacing at 16-inch OC. Results R acking performance tests performed at the NAHB Research Center in 1992 and 1996 and at Architectural Testing Inc. (ATI) in 2005 demonstrated medium-density sprayed polyurethane foam increases racking strength 70 to 200 percent to wall assemblies sheathed with various sheathing materials, including oriented strand board (OSB), plywood, gypsum wallboard, vinyl siding and polyiso board. The research demonstrated that SPF significantly increased racking strength in both wood and metal stud construction. In the 1992 study, SPF filled walls achieved similar racking strength at stud spacing of 16, 24, 36 and 48 inches. SPF increased strength of weaker substrates such as gypsum drywall, vinyl siding and polyiso foam insulation at a much greater percentage than stronger substrates such as OSB and plywood. Special bracing for wind resistance would not be required for strength purposes when using SPF in the walls. As a structural material, medium-density SPF can add strength to wall and ceiling assemblies of all sizes and heights, depending on the framing. page 16 • The benefits of Spray polyurethane foam in Commercial Applications SPF installed between metal studs: (3.5 inches) • Increased racking strength of drywall sheathed walls: 2,400 lbs to 5,380 lbs • Increased racking strength of OSB sheathed walls: 4,800 lbs to 6,000 lbs SPF installed between wood studs: (3.5 inches) • Increased racking strength of vinyl sheathed walls: 913 lbs to 2,800 lbs • Increased racking strength of plywood sheathed walls: 2,890 lbs to 5,300 lbs • Increased racking strength of polyiso sheathed walls: 1,109 lbs to 2,159 lbs SPF installed between wood studs: (1.5 inches) • Increased racking strength of polyiso sheathed walls: 1,109 lbs to 2,257 lbs Spf AND hVAC CONSIDeRATIONS When specifying SPF for commercial buildings, architects and mechanical engineers should take into account that the overall heating and cooling load of the building will be significantly less than when using other air barrier and insulation materials. SPF can, in residential settings, reduce the HVAC tonnage requirements by up to 50 percent, meaning a much smaller unit can be installed, which will result in financial savings during the building process and energy savings during the period of occupancy. For more information, please refer to Proper Design of HVAC Systems for Spray Foam Homes, a report written by Doug Garrett, CEM, ACCA Certified Instructor, Building Performance and Comfort Inc. To request a copy, please email sprayfoam@huntsman.com. Also, SPF makes an ideal insulator and air sealer for duct work. Sealing ducts that run through unconditioned spaces can significantly reduce energy loss, and can also prevent additional air pressure within the building envelope. Making sense of the alphabet soup in codes and standards associated with commercial construction can be confusing; however, it is important to understand some of the requirements, certifications and general classifications of building materials in order to discern which materials are best suited for your project or application. This applies to both the materials and also certifications of installers. ClASSIfICATIONS AND CODeS fOR Spf Construction Specifications Institute (CSI) T he Construction Specifications Institute (CSI) was created in 1948 to help improve construction specification quality in the post-war construction boom. Through one of their annual products called MasterFormat, CSI creates a comprehensive list of building products and materials that are defined and organized to help with estimates, creating building specifications and general product data. SPF is classified in the CSI MasterFormat in Division 7, Section 07210 – Building Insulation. Closed cell SPF being applied to the exterior of a building. The benefits of Spray polyurethane foam in Commercial Applications • page 17 ICC Evaluation Service Report (ESR) W hen choosing a brand of SPF to use, it can be helpful to research the product through industry-trusted mechanisms. The International Code Council (ICC) has a subsidiary called the ICC Evaluation Service that evaluates building material products and also vets the materials to see if they are acceptable or within compliance to various industry codes and standards. Generally, the building material manufacturer will request that their product be evaluated and then use the report as a basis for providing technical information and product validation to the industry. When specifying SPF in a building project, it is important that the manufacturer provide an ESR of the SPF so that the architect, engineer and builder will be able to properly install the material in accordance with related codes and industry standards. Certified Applicators T rade organizations often manage certification programs for their members in order to maintain a high level of installation quality in the work force. This is also true for SPF. The Spray Polyurethane Foam Alliance (SPFA) has created a certification program specifically for spray foam applicators. The program was developed in compliance with the American National Standards Institute (ANSI)/ISO 17024 standard, meaning that holders of these certifications have passed a very specific series of required tests in order to validate their expertise in their field. Individual certifications for SPF installers are at four different levels in the two categories of insulation and roofing. To become certified under SPFA’s program, individuals must pass an exam and meet various criteria for the level of certification they would like to achieve. It is a progressive program with each level dependent on the candidate passing the exam for the previous level. Safety, installation practices and proper applications for SPF are all part of the certification program. For more information on the SPFA certification program, please visit www.sprayfoam.org. When choosing SPF for a project, it is important to specify that all trade contractors and SPF installers have the most recent industry-recognized certification. 2012 International Building Code and SPF exterior walls shall provide the building with a weatherresistant exterior wall envelope. The exterior wall envelope shall include flashing and be designed and constructed in such a manner as to prevent the accumulation of water within the wall assembly by providing a water-resistive barrier behind the exterior veneer, and a means for draining water that enters the assembly to the exterior. In addition to this, the WRB must be constructed with a minimum of one layer of No.15 asphalt felt, complying with ASTM D 226 for Type 1 felt or other approved materials, which shall be attached to the studs or sheathing in such a manner as to provide a continuous water-resistive barrier behind the exterior wall veneer. For this code requirement, closed cell SPF is a pre-approved material for commercial building water barriers. Chapter 26 of the IBC, section 2603, refers specifically to foam polyurethane insulation and should also be referenced when specifying SPF for a commercial building project. Also in Chapter 26, in Appendix X, are fire requirements related to SPF. When specifying SPF for a project, it is important to reference the IBC and ensure that the building design and product selected comply with the thermal barrier and ignition barrier requirements in the code. 2012 International Energy Conservation Code (2012 IECC) and SPF T he 2012 International Energy Conservation Code (2012 IECC) requires that the building envelope be carefully designed to limit uncontrolled air movement. The building envelope includes the roof, wall and floor systems that surround the space being heated and cooled. The provisions require that either building materials or assemblies be selected that do not exceed the maximum air leakage requirements (CFM/ft2). SPF is on the list of pre-approved materials that are deemed to comply with the maximum air leakage requirement. Specifically closed cell SPF can be installed with a minimum density of 1.5pcf (24kg/m3) and a thickness of not less than 1.5 inches (38mm). Open cell SPF, with a density between 0.4 and 1.5 pcf (6 and 24kg/m3) and having a thickness of not less than 4.5 inches (114mm), can also be used. C hapter 14 of the 2012 International Building Code (IBC) pertains to exterior walls and specifically addresses water-resistive barriers (WRB) that are meant to protect the building from liquid and vapor water intrusion. Section 1403.2 addresses weather protection and stipulates that page 18 • The benefits of Spray polyurethane foam in Commercial Applications ASHRAE 90.1-2010 and SPF California Title 24 and SPF T T he American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) is a professional organization that works to improve building systems, energy efficiency, indoor air quality, refrigeration and sustainability within the industry through research, standards writing, publishing and continuing education. ASHRAE 90.1-2010 is the energy standard published as a guide to help members design, specify and install buildings to achieve a higher level of energy efficiency. As with the 2012 IECC, SPF is a pre-approved material for use as an air barrier. Spray polyurethane foam being applied to the exterior of army barracks at Fort Drum, N.Y. itle 24 within the California Code of Regulations (CCR) is reserved for state regulations that govern the design and construction of buildings, associated facilities and equipment. These regulations are also known as building standards. Recently the CCR recognized open cell SPF as a viable insulation material, allowing it to be used in new construction and retrofit situations. However, like any building code or standard, CA Title 24 should be reviewed and specifierapproved prior to beginning a project. Spray polyurethane foam applied to the exterior of a dining facility at Fort Bliss, Texas. Climate Zone Map The benefits of Spray polyurethane foam in Commercial Applications • page 19 SUSTAINAble bUIlDING pRACTICeS AND Spf Whether it is “green” building or “sustainable” building, the push to create more durable, energy efficient structures that generate less waste during and after construction remains a priority for many builders, developers and architects. Because of its high R-value and low air permeability rating, SPF can significantly help achieve sustainable goals in commercial building projects. From an energy savings standpoint, SPF is on the front line of conservation of natural resources and reducing greenhouse gasses. Buildings are the largest user of energy in the U.S. today. According to the U.S. DOE, buildings account for more than 40 percent of all energy used in the U.S. annually, and over 40 percent of that energy is used for heating and cooling. Based on current building stock, though, up to 30 percent of the energy used to heat and cool buildings is lost through the building envelope as a result of inefficient air barriers and poor insulation levels. Building with SPF can greatly reduce energy loss through the building envelope while also providing superior insulation to the building. While relatively lower energy bills are an immediate indication that a building material is contributing to a sustainable planet, a more holistic evaluation is achieved by conducting a life cycle assessment (LCA). To determine the true sustainable attributes of SPF, the Spray Polyurethane Foam Alliance (SPFA) initiated an LCA to evaluate the environmental impact of SPF formulations used in residential and commercial building applications. This study is the first comprehensive LCA of spray foam insulation conducted in North America. The entire SPF life cycle consists of cradle-to-end of life phases for making, processing, transporting, installing, using and, finally, disposing of spray foam insulation. For purposes of analysis, the spray foam insulation life cycle was divided into the following five key phases: 1. Raw materials manufacturing and blending 2. Transportation 3. Installation 4. Use phase 5. End of life The results of the study showed that the energy and environmental benefits from SPF use in new commercial roofing retrofits far outweigh the embodied energy and embodied environmental impacts. The study also concluded that the energy and impacts “invested” to make, install, transport and dispose of the insulation at end of life are minimal compared to the substantial use-phase benefits. Besides lowered energy bills and a comprehensive LCA, another indication that SPF is a sustainable building material is to review the associations and green building programs that include SPF as a beneficial contributor to sustainable building and design. As a building material, SPF can contribute to credit or points for programs like LEED,® Green Globes and NAHB National Green Building Standards in the following sections: • • • • • Energy and atmosphere Sustainable sites Material and resource Indoor environmental quality Innovation in design In addition, SPF has also been proven a valuable asset to the military and federal government by helping to improve the energy efficiency of public buildings. By Executive Order 13514, all new federal buildings must be net zero, or consume no more energy than can be generated onsite, by the year 2030. For more information, please refer to Military Standards and Spray Polyurethane Foam (SPF) Insulation. To request a copy, please email sprayfoam@huntsman.com. SPF is also contributing to the American Institute of Architects (AIA) 2030 target that all new buildings, developments and major renovations be designed to meet a fossil fuel, greenhouse gas-emitting, energy consumption performance standard of 60 percent below the regional (or country) average/median for that building type. CONClUSION Whether the objective is to increase energy efficiency, meet or beat sustainability goals, provide sound insulation, create a superior air control layer or improve structural integrity in high wind areas, SPF is a proven asset to any builder or architect’s path to success. By matching the needs of the structure with the benefits of SPF, almost any new or existing commercial building can benefit from SPF. LEED is a registered trademark of U.S. Green Building Council (USGBC). GREENGUARD Indoor Air Quality Certified is a registered trademark of GREENGUARD Environmental Institute. GREENGUARD Children and Schools is a registered service mark of GREENGUARD Environmental Institute. ® page 20 • The benefits of Spray polyurethane foam in Commercial Applications ® SM lINKS AND ReSOURCeS NISTIR 7238 - Investigation of the Impact of Commercial Building Envelope Airtightness on HVAC Energy Use. June 2005. U.S. Department of Commerce, U.S. Department of Energy Office of Building Technologies. http://fire.nist.gov/bfrlpubs/build05/art007.html U.S. Department of Energy Commercial Reference Building Models of the National Building Stock http://www.nrel.gov/docs/fy11osti/46861.pdf Building Energy Codes 101 - An Introduction. DOE EERE PDF found at: http://www.energycodes.gov/sites/default/files/becu/BECU_Codes_101_Intro.pdf Building Envelope Air Leakage Failure in Small Commercial Buildings Related to the Use of Suspended Tile Ceilings http://repository.tamu.edu/bitstream/handle/1969.1/6777/ESL-HH-00-05-10.pdf Building Energy Code Resource Guide: Air Leakage Guide Prepared by Building Energy Codes Program (BECP) for the U.S. Department of Energy, September, 2011 http://www.energycodes.gov/sites/default/files/documents/BECP_Buidling%20Energy%20Code%20Resource% 20Guide%20Air%20Leakage%20Guide_Sept2011_v00_lores.pdf EPA – 2008b. ENERGY STAR Qualified Homes Thermal Bypass Checklist Guide http://www.energystar.gov/ia/partners/bldrs_lenders_raters/downloads/TBC_Guide_062507.pdf Air Sealing Technology Fact Sheet (PDF) EERE, Building America Website http://apps1.eere.energy.gov/buildings/publications/pdfs/building_america/26446.pdf Investigation of the Impact of Commercial Building Envelop/Air tightness on HVAC Energy Use (PDF) Steven J. Emmerich, Tim McDowell, Wagdy Anis Produced by National Institute of Standards and Technology, Technology Administration, U.S. Department of Commerce, June 2005 http://fire.nist.gov/bfrlpubs/build05/PDF/b05007.pdf Improving Energy Performance of Steel Stud Walls, Ornl http://www.ornl.gov/sci/roofs+walls/research/detailed_papers/steel_frame/ Meeting the Commercial Continuous Air Barrier Requirements for ASHRAE 90.1-2010 and the 2012 ICC IECC- Code Notes http://www.energycodes.gov/sites/default/files/documents/cn_meeting_the_commercial_continuous_air_barrier_ requirements_for_ashrae_90.1-2010_and_the_2012_iec_iecc.pdf Large Hospital 50% Energy Savings: Technical Support Document. NREL September 2010 http://www.nrel.gov/docs/fy10osti/47867.pdf Control Of Temperature For Health and Productivity in Offices Olli Seppanen, William J. Fisk, David Faulkner, Lawrence Berkeley National Laboratory Environmental Energy Technologies Division Indoor Environment Department Berkeley, CA June 2004 http://www.osti.gov/bridge/servlets/purl/886957-yDXcC7/886957.pdf Measure Guideline: Hybrid Foundations Insulation Retrofits. K. Ueno and J. Lstiburek, Ph.D., P. Eng. Building Science Corporation (BSC), May 2012 prepared for the U.S. DOE Building America Program http://apps1.eere.energy.gov/buildings/publications/pdfs/building_america/measure_guide_hybrid_found.pdf California Title 24 http://www.energy.ca.gov/title24/ The Florida Building Code http://www.floridabuilding.org/fbc/publications/FBC.pdf Insulation For every insulation challenge, there’s a CertainTeed solution. CertaPro™ Commercial Insulation Machine Works Residential Sustainable Insulation Air & Moisture Management Spray Foam Insulation HVAC / Mechanical Premium Blow-in Insulation IDID#51000229 #510XXX You can Be Certain no other manufacturer offers the depth and breadth of interior and exterior building solutions, knowledge, innovation and sustainability that CertainTeed does. Our advanced, multi-product solutions optimize building efficiency, while creating beautiful, comfortable environments where people can thrive. We continue to shape the future of the building materials industry with a new generation of integrated building solutions. That’s confidence worth building on.™ ASK ABOUT ALL OF OUR OTHER CERTAINTEED® PRODUCTS AND SYSTEMS: ROOFING • SIDING • TRIM • DECKING • RAILING • FENCE GYPSUM • CEILINGS • INSULATION www.certainteed.com/insulation http://blog.certainteed.com CertainTeed Corporation P.O. Box 860 Valley Forge, PA 19482 Professional: 800-233-8990 Consumer: 800-782-8777 © 07/14 CertainTeed Corporation, Printed in the U.S.A. Code No. XX-XX-XXX