Automatic Faucets- Instruction Manual (Letter Size)

0GU3046E 2008.10

INSTRUCTION MANUAL

NOTE TO INSTALLER: PLEASE GIVE THIS MANUAL TO THE

CUSTOMER AFTER INSTALLATION.

AUTOMATIC FAUCET

Important Safeguards........

Precautions........................

Model Numbers and Components................

1-2

3

3-4

Before Use.........................

How to Use........................

How to Adjust.....................

5

5

6-7

Maintenance ......................

Periodical Checking............

7-8

9

NSF/ANSI 61

U P

C

Troubleshooting.............

Specifications.................

10-11

11

Trouble Shooting

Replacement Parts......... 12-18

Warranty ............................ 19

1

Important Safeguards

(For your safety, please follow the instructions below.)

Read these Important Safeguards thoroughly before using your Automatic Faucet, and follow the precautions carefully.

After you read this Instruction Manual, keep it where it can be easily referred to again.

Symbols are shown for safe and proper use of your Automatic Faucet and in order to alert you of possible personal injury and damage to your property. The symbols and their meanings are as follows.

Warning

Ignoring these symbols may cause personal injury or property damage.

The items of observation are classified and described.

Absolutely “Do not”.

Do not install the product in high humidity area such as shower room or sauna.

Do not disassemble.

Do not touch the area specified.

This means “mandatory”.

Some models may have different components as illustrated below.

Do not

Warning

Never splash water on the controller.

The Automatic Faucet is an electrical appliance, this may cause the product to malfunction.

Do not strike or kick the Automatic Faucet.

This may cause the product to malfunction or cause water leakage.

Controller

Do not use the Automatic Faucet at temperatures exceeding what local codes allow.

It may cause product malfunction.

below local code

Warning

Do not use in humid areas

Do not place an item with this symbol displayed in a room with high humidity such as shower room or sauna.

This may cause product malfunction.

Do not disassemble

Never attempt to disassemble, reassemble, repair or modify the Automatic Faucet, unless you are an electrician.

This may cause product malfunction and electric shock.

Don’t touch

Do not touch the stop valve of the controller, the surface may be very hot.

This may cause personal injury.

Ouch!

Controller

For EcoPower® model, disconnect the back-up battery connector, when the Automatic Faucet is not in use for a long period of time.

Disconnect

Always close the stop valve(s) before cleaning the strainer.

Hot or cold water may flow out and cause personal injury or property damage.

(Refer to Pg. 9)

Mandatory

Periodically check the piping for leakage.

Ignoring this may cause property damage.

When the room temperature falls under freezing condition, give proper care to the piping to prevent product malfunction.

If the piping is frozen, the components may suffer damage and leakage. Wrap the piping with heat insulation.

Brrrr

2

3

Precautions

(Observe the following precautions.)

Make sure the power cord does not come in contact with the hot-water supply pipe.

(In case of the thermostatically controlled mixing valve.)

High temperature may damage the product.

Avoid placing any objects within the detection range of the infrared sensor.

May result in faulty operation.

Occasionally turn the temperature control handle of the thermostatically controlled mixing valve to prevent buildup or sticking.

Debris may form from inside of the valve, resulting in impaired performance.

Routine maintenance must be performed.

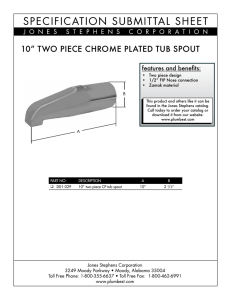

Model Number and Components

Model

Number

Item

Standard

Gooseneck

Helix™

Fordham™

Axiom™

Ryohan™

Duration of

Water Discharge

Single Supply Faucet Thermal Mixing

Valve Faucet

EcoPower® model (1.06 gpm)

TEL3GS10/60 TEL5GS10/60

TEL3GG10/60 TEL5GG10/60

TEL3GC10/60

TEL3GT10/60

TEL3GK10/60

TEL5GC10/60

TEL5GT10/60

TEL5GK10/60

TEL3GM10/60 (0.8 gpm) TEL5GM10/60 (0.8 gpm)

10 Seconds ( TEL5

60 Seconds ( TEL5

□□

10 )

60 )

Single Supply Faucet Thermal Mixing

Valve Faucet

EcoPower® model (0.5 gpm)

TEL3LS10 TEL5LS10

TEL3LG10 TEL5LG10

—

—

—

—

—

—

—

—

# CP = Polished Chrome

Standard sensor part sensor

P. 5-7

Gooseneck sensor part sensor

P. 5-7

Helix™ sensor part sensor

P. 5-7

Fordham™ sensor part sensor

P. 5-7

Axiom™ sensor part sensor

P. 5-7

Spout Spout Spout

Spout

Spout

Spout outlet

Hexagonal nut

Spout connecting hose

Ryohan™ sensor part

Spout outlet

Sensor cord

Hexagonal nut

Spout connecting hose

Sensor cord

Spout outlet

Hexagonal nut

Ryohan™

Sensor cord

Spout outlet

Hexagonal nut

Sensor cord

Spout outlet

Hexagonal nut

Sensor cord

Spout connecting hose Spout connecting hose Spout connecting hose

Optional Accessories (Not included)

4" Plate (TN71V100S) 8" Plate (71244T8CC)

8" Plate sensor

P. 5-7

4" Plate Packing

Spout

Spout outlet

Sensor cord

Hexagonal nut

Spout connecting hose

Packing

Washer

Lock washer

Nut

Base plate

Washer

O-ring

Wing nut

Tie bolt

Packing

Sensor cord

EcoPower ® type

Single Supply Faucet

Spout connecting hose with flexible tube

Sensor cord

EcoPower ®

P.6

Thermal Mixing Valve Faucet

Spout connecting hose with flexible tube

EcoPower ®

P.6

Water inlet bracket with strainer Controller cover

Controller cover

Temperature control handle

P.6

Water inlet bracket with strainer

Required Tools

Adjustable Wrench, Phillips and flat head screwdrivers

4

5

Before Use

Confirmation of connectors

Make sure all connections are made.

• Sensor connector (green)

• Back-up battery connector (white)

<For single supply faucet>

Sensor connector (green)

<For thermal mixing valve faucet>

Cover Back-up battery connector (white)

Pull

Sensor connector (green)

Cover

Pull

Screw Back-up battery connector (white) Screws

How to Use

Normal Operation

1.

Place your hands under the faucet.

The sensor will automatically turn on the water.

2.

Remove your hands.

The sensor will automatically turn off the water.

How to Adjust

Bits of Knowledge About EcoPower

®

Model

Spout Mechanism for Hydropowered generator.

The flow of water causes the turbine in the power generator to rotate, which generates electric power, and enables the Automatic Faucet to operate.

Power generator

Cover

1 A turbine rotates to generate power.

Coil

2 Electric power is stored.

Turbine

3 The Automatic Faucet is using the charged power.

Controller

Solenoid valve

Controller unit

Water supply

Using the faucet 11 times a day for 5 seconds or more will fully recharge the faucet.

How to adjust the temperature

Turn the temperature control handle.

The water temperature has been factory set to 100°F (38°C).

Depending on the conditions of both the cold and hot water supply, adjust the temperature by turning the temperature control handle as necessary.

● Thermostatically controlled mixing valve

Temperature control handle Hot

Cold

Adjustment of the flow rate

TEL

□

GM, 0.5gpm (2L/min.) for TEL

□

L

□

□

G

□

, 0.8gpm (3L/min.) for

, there is no need to adjust the flow rate.

However, if you need to regulate the flow rate because the wash basin is small or that the water supply pressure is too strong, adjust the flow rate by turning the stop valve clockwise.

Close

The EcoPower® type must be used with the stop valve fully opened.

Insufficient flow rate, mentioned on the next page, may cause power shortage resulting in consumption of the built-in back-up battery.

Open

Stop valve

6

Adjustment of the flow rate

●

If you need to regulate the flow rate, make sure that the initial flow rate is more than 0.8gpm (3L/min.) for TEL

TEL

□

□

GM, 0.48gpm (1.8L/min.) for TEL

□

G

L

□

□

, 0.75gpm (2.7L/min.) for

.

●

(For TEL

□

G

□

) The water appears white with a flow rate of more than

0.8gpm (3L/min.)

●

(For TEL

□

GM) If the water pressure is low and the water flow rate is below 0.76gpm (2.7L/min.) the back up battery will run down quickly. To test the water flow rate, run water for 13 seconds cycles into a 20 ounce bottle or container. The faucet should flow at least 20 ounces in

13 second cycles.

●

(For TEL

□

L

□

) If the water pressure is low and the water flow rate is below 0.48gpm (1.8L/min.) the back up battery will run down quickly. To test the water flow rate, run water for 10 seconds cycles into a 20 ounce bottle or container. The faucet should flow at least 20 ounces in

13 second cycles.

The water appears white with a flow rate of more than

0.8gpm (3L/min.)

TEL

□

G

□

20oz.

(591 mL)

TEL

TEL

□

GM

L

□

7

Maintenance

Follow these instructions for daily maintenance.

Use soft cloth for maintenance

●

For general cleaning

Use a damp, soft cloth to clean the spout and sensor.

●

For cleaning dirt

Use a soft cloth with diluted dish washing detergent. Wipe the area using a wet cloth and dry using a soft cloth. If still dirty, wipe the area with a neutral detergent and wet cloth.

Caution

●

Do not scratch the sensor when cleaning.

Sensor part

Outlet

●

Avoid using anything that may scratch the spout surface.

Never use polishing powder, detergent that includes coarse particles, thinner, benzine, acid or alkaline detergent, or a nylon scrub brush. They will damage the surface of the spout.

Maintenance for Drain Cup Unit (Ryohan™ Only)

Remove the drain cup unit

1. Pull the drain cup unit firmly to the drain part then release it.

Pull Firmly Drain cup unit

2. Turn the drain cup unit clockwise (About 45 degrees)

Drain cup part

Main drain body

3. Pull the drain cup upwards and out

Notch

Cross bar

Angle

• If the drain cup unit does not come out, put it back, and while turning it clockwise once again, slowly pull it out.

Install the Drain cup

1. Insert the drain cup into the main drain body

Drain cup unit

3. Pull firmly on the drain cup unit, being careful not to remove it, then release it.

Drain cup unit

Main drain body

2. Turn the drain cup counter-clockwise making the cross-bar align with the notches in the angles.

Drain cup unit

Main drain body

Notch

Cross-bar

Angle

• If the drain cup is accidentally removed, begin the process over from the beginning.

4. Push the drain cup unit in.

Click!

Push the drain cup in until you hear a “Click”.

8

Periodical Checking

Please check your Automatic Faucet at least once a month according to the following instructions.

Leakage

Check the piping to see whether there is any leakage.

Ignoring this may cause property damage.

Water temperature

For thermostatically controlled mix valve, turn the temperature control handle four or five times.

Build up may form inside, resulting in impaired performance if maintenance is not performed.

Loose spout

Check if the spout is loose.

If the spout is loose, tighten the hexagonal nut underneath the spout.

Temperature control handle

Controller

9

Flow rate

Open

Open-close tool

Open

Close

Stop valve

Strainer

Strainer cover

Brush

When the strainer or spout nozzle is clogged, the flow rate will decrease. Make sure to clean the strainer and the spout nozzle.

Pay special attention to the EcoPower® model, since a low flow rate may result in low power generation. (see Pg. 6)

Cleaning the strainer

1. Close the stop valve.

2. Remove the strainer cover with the open-close tool.

3. Pull out the strainer and clean it with a brush.

4. Put the strainer back in its place.

5. Reopen the stop valve fully.

Strainer

Cleaning of the spout nozzle

1. Remove the spout nozzle with the supplied open-close tool.

2. Clean the spout nozzle with a brush to remove dirt from the screen.

3. Set the spout nozzle back in place.

Open

Open-close tool

Spout nozzle

Close

Spout nozzle

Brush

Troubleshooting

Before contacting a repairman, check the following common problems and solutions. If the problem persists contact your dealer.

Problem

Water doesn't run.

Cause

The stop valve is turned off.

EcoPower® model: Backup battery connector is disconnected.

The power generator and sensor connection are not attached.

Water supply is suspended.

Solution

The surface of the sensor is dirty.

Clean the surface of the sensor.

There is an obstruction in front of the sensor. Remove the obstruction.

Turn on the valve.

Connect the backup battery connector.

Securely attach the connector(s).

Wait until water supply is restored.

Ref. page

P.7

P.3

P.6 - 7

P.5

P.5

The strainer or the regulating screen is clogged. Clean the strainer and the regulating screen.

P.9

Water doesn't stop.

Low flow rate.

Water temperature is too high.

Water temperature is too low.

Water temperature is not controlled properly.

The surface of the sensor is dirty.

Clean the surface of the sensor.

There is an obstruction in front of the sensor.

Remove the obstruction.

If water continues to run after attempting above, turn off the stop valve.

Stop valve is not fully opened.

Open the stop valve fully.

The strainer or the regulating screen is clogged. Clean the strainer and the regulating screen.

The temperature control handle is set at "H".

Set the temperature control handle to the middle point.

The stop valve connected to the cold-water supply is not fully opened.

Open the cold-water stop valve fully.

The temperature control handle is set at "C".

Set the temperature control handle to the middle point.

The stop valve connected to the hot- water supply is not fully opened.

The hot-water supply temperature is lower than 120°F.

Open the hot-water stop valve fully.

Set the hot-water supply temperature to 120°F.

One side of the stop valve is not fully opened.

Open the stop valve fully.

P.7

P.3

P.6 - 7

P.9

P.6

P.6 - 7

P.6

P.6 - 7

P.6 - 7

P.9

Short detection range.

The strainer or the regulating screen is clogged.

Clean the strainer and the regulating screen.

The self-adjusting sensor may not work properly when stained or blocked by water droplets.

Clean the sensor surface.

P.7

Trouble Shooting

10

This Automatic Faucet is equipped with a self-adjusting sensor which will automatically adjust its detection range once every 15 seconds. This sensor may exhibit the following phenomena.

Note: These are implemented for safety and conservation purposes, they are not malfunctions.

Phenomenon

After sometime water stops flowing even if your hands are still under the faucet.

After removing hands, water keeps running.

Explanation

The sensor activates by detecting hand movements. If your hands are not moving, it will be regarded as an ordinary object.

Even if your hands are moving, the faucet will only keep running for 60 seconds for safety and conservation purposes.

If the sensor is stained or blocked by water droplets, the water may keep running even after you removed your hands. In such a case, the self-adjusting sensor will stop the water after 15 seconds. Always wipe off all water droplets and stains from the sensor.

Power supply

Battery life

Detection range from the sensor

Water supply pressure

Water supply connection

Ambient temperature

Humidity

Flow rate

Duration time of water discharge

Specifications

EcoPower ®

-

-

5-1/8" ~ 7-7/8" (130~200 mm)

Sensor is self-adjusting

Minimum required water pressure : 14.5 PSI (100kPa) (Flowing)

Maximum water pressure : 125 PSI (862 kPa)

1/2" NPSM

32~104°F (0~40°C)

Max. 90% RH

1.06 gallon per minute (4 L/ min.) (TEL

□

G

□

)

0.8 gallon per minute (3 L/ min.) (TEL

0.5 gallon per minute (2 L/ min.) (TEL

Controlled by governor

□

GM)

L

□

)

10 Seconds

60 Seconds (Not Included: TEL

□

L

□

)

11

Replacement Parts

Gooseneck & Standard Spout

Gooseneck Spout

TEL 3/5 GG10

TEL 3/5 GG60

1

Standard Spout

TEL 3/5 GS10

TEL 3/5 GS60

3

2

5

4

1

6

7

6

5

4

No.

1

2

3

4

5

6

7

Parts Description

Standard Spout Assembly

Sensor

Nozzle Assembly Set

Nut Set

Spout Mounting Kit

Nozzle Bushing Set

Flexible Tube

7

12

13

2

1

Helix™ Spout (TEL 3/5 GC10) & (TEL 3/5 GC60)

3

5

4

No.

1

2

3

4

5

6

7

Parts Description

Helix™ Spout Assembly

Sensor

Nozzle Assembly Set

Nut Set

Spout Mounting Kit

Nozzle Bushing Set

Flexible Tube

6

7

2

Fordham™ Spout (TEL 3/5 GT10) & (TEL 3/5 GT60)

1

3

5

4

6

No.

1

2

3

4

5

6

7

Parts Description

Fordham™ Spout Assembly

Sensor

Nozzle Assembly Set

Nut Set

Spout Mounting Kit

Nozzle Bushing Set

Flexible Tube

7

14

15

2

1

Axiom™ Spout (TEL 3/5 GK10) & (TEL 3/5 GK60)

No.

1

2

3

4

5

6

7

Parts Description

Axiom™ Spout Assembly

Sensor

Nozzle Assembly Set

Nut Set

Spout Mounting Kit

Nozzle Bushing Set

Flexible Tube 3

6

4

5

7

2

Ryohan™ Spout (TEL 3/5 GM10) & (TEL 3/5 GM60)

1

8 6

3

4

5

6

7

8

No.

1

2

3

Parts Description

Ryohan™ Spout Assembly

Sensor

Nozzle Assembly Set

Nut Set

Spout Mounting Kit

Nozzle Bushing Set

Flexible Tube

Drain Assembly

7

4

5

16

5

6

7

8

No.

1

2

3

4

Single Supply Dynamo

Parts Description

Single Dynamo Unit 60 Sec.

Control Cover

Back-Up Battery

Dynamo Hydropower

Generator

Valve Assembly Unit

Solenoid & Diaphragm

Assembly

Mounting Bracket Set

Screws

8

4

2

6

5

8

33

1

7

17

Thermal Supply Dynamo

61

62

66

63

65

64

5

6

7

No.

3

4

1

2

Parts Description

Thermal Dynamo Control Unit 10/60 Sec.

Dynamo & Flow Control Unit

Thermal Mixing Valve

Solenoid & Diaphragm Assembly

Control Cover Set

Mounting Bracket Set

Back-Up Battery

67

18

WARRANTY

1. TOTO warrants its products to be free from manufacturing defects under normal use and service for a period of three (3) years from the date of purchase. This warranty is extended only to the ORIGINAL

PURCHASER and applies only to product purchased and installed in North America.

2. TOTO’s obligations under this warranty are limited to repair or replacement, at TOTO’s option, of products or parts found to be defective, provided that such products were properly installed and used in accordance with OWNER’S MANUAL. TOTO reserves the right to make such inspections as may be necessary in order to determine the cause of the defect. TOTO will not charge for labor or parts in connection with warranty repairs or replacements. TOTO is not responsible for the cost of removal, return and/or reinstallation of products.

3. This warranty does not apply to the following items: a) Damage or loss sustained in a natural calamity such as fire, earthquake, flood, thunder, electrical storm, etc..

b) Damage or loss resulting from any unreasonable use, misuse, abuse, negligence, or improper maintenance of the product.

c) Damage or loss resulting from removal, improper repair, or modification of the product.

d) Damage or loss resulting from sediments or foreign matter contained in a water system.

e) Damage or loss resulting from improper installation or from installation of a unit in a harsh and/or hazardous environment.

f) Damage or loss resulting from acts of animals such as mice and insects.

g) Damage or loss resulting from a use of abnormal power supply.

h) Damage or loss resulting from abrasion of consumable supplies.

i) Damage or loss resulting from frost.

4. This warranty gives you specific legal rights. You may have other rights which vary from State to State or province to province.

5. To obtain warranty repair service under this warranty, you must take the product or deliver it prepaid to a TOTO service facility together with a letter stating the problem, or contact a TOTO distributor or products service contractor, or write directly to TOTO U.S.A., INC., 1155 Southern road, Morrow,

Georgia 30260, (888) 295-8134. If, because of the size of the product or nature of the defect, the product cannot be returned to TOTO, receipt by TOTO of written notice of the defect shall constitute delivery. In such case, TOTO may choose to repair the product at the purchaser’s location or pay to transport the product to a service facility.

THIS WRITTEN WARRANTY IS THE ONLY WARRANTY MADE BY TOTO. REPAIR OR

REPLACEMENT AS PROVIDED UNDER THIS WARRANTY SHALL BE THE EXCLUSIVE REMEDY

AVAILABLE TO THE PURCHASER. TOTO SHALL NOT BE RESPONSIBLE FOR LOSS OF USE OF

THE PRODUCT OR FOR OTHER INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES OR

EXPENSES INCURRED BY PURCHASER, OR FOR LABOR OR OTHER COSTS DUE TO

INSTALLATION OR REMOVAL, OR COSTS OF REPAIRS BY OTHERS, OR FOR ANY OTHER

EXPENSE NOT SPECIFICALLY STATED ABOVE.

EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE LAW, ANY IMPLIED WARRANTIES,

INCLUDING THAT OF MERCHANTABILITY OR FITNESS FOR USE, ARE EXPRESSLY LIMITED TO

THE DURATION OF THIS WARRANTY.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS. OR

THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE

ABOVE LIMITATION AND EXCLUSION MAY NOT APPLY TO YOU.

©2007 TOTO USA, Inc. 1155 Southern Road, Morrow GA 30260

Phone (888)-295-8134 Fax (800)-699-4889 www.totousa.com

TOTO USA, INC. is a wholly owned subsidiary of TOTO Ltd.

Printed in September, 2008

0GU3046E