Power MOSFET Electrical Characteristics

advertisement

Power MOSFET

Electrical Characteristics

Power MOSFET in Detail

4.

Electrical Characteristics

4.1

Terminology

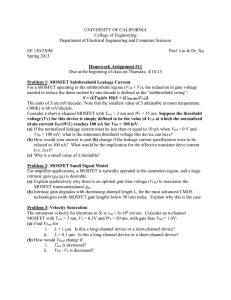

The following is an explanation of main items used to evaluate power MOSFET performance.

(1) |Yfs|: forward transfer admittance

|Yfs| = ΔID/ΔVGS

|Yfs| expresses power MOSFET amplification factor

(2) Vth: gate threshold voltage

If VGS (OFF) is the gate-source voltage in the cut-off state, and VGS (ON) is the gate-source bias

voltage when drain current is flowing, then the following relationship can be established.

VGS (OFF) < Vth < VGS (ON)

(3) RDS (ON): drain-source ON resistance

This is the equivalent of the collector-emitter saturation voltage VCE (sat) of a bipolar

transistor, and is used as a criterion for determining dissipation in the ON status.

(4) VDS (ON): drain-source ON voltage

This is a criterion for determining dissipation in the ON status, as with RDS (ON), and is

expressed as a voltage value.

(5) Ciss, Crss, Coss: capacitances

Ciss, Crss and Coss are input capacitance, reverse transfer capacitance and output capacitance,

respectively. These capacitances restrict the usable frequency and switching speed when a power

MOSFET is used for switching operations.

The index = |Yfs|/Ciss (s−1) is the equivalent of the cutoff frequency fT of a bipolar transistor.

However, normally the following expression is used to define the theoretical cutoff frequency:

f (max) = |Yfs|/2 π {Ciss + (1 + Av) Crss}

4.2

Power MOSFET Temperature Characteristics

The transfer function of power MOSFETs is shown by the differential coefficient of the ID – VGS

curves shown in Figure 4.1.

In the large current area, the temperature coefficient of the transfer function is negative, therefore,

the forward transfer admittance |Yfs| decreases when the internal (channel) temperature increases;

so current concentration and failure due to thermal run-away don’t occur easily even if a large drain

current flows due to the output fluctuates.

Caution must be exercised concerning the temperature dependence of the drain-source ON

resistance. This ON resistance approximately doubles for a temperature increase of 100°C (Figure

4.2). Thus, it is necessary to account for an induced temperature increase to select a heat sink with an

appropiate thermal resistance φf.

1

Power MOSFET in Detail

70

Tc = 100°C

12

Common source

VDS (ON)

−55

VDS = 10 V

10

8

6

4

2

0

1

2

3

4

5

6

Gate-source voltage

7

8

9

15

VGS = 10 V

8

12

6

10

4

5

2

ID = 1 A

0

−60

10

−40

VGS (V)

−20

0

20

40

60

80

100

Case temperature Tc (°C)

Figure 4.1 ID – VGS Characteristics

4.3

10

Drain-source on voltage

Drain current ID (A)

14

25

(V)

12

Common source

Figure 4.2 VDS (ON) – Tc Characteristics

Power MOSFET Electrostatic Capacitance Characteristics

The physical construction of a power MOSFET is such that the gate is completely isolated from the

silicon oxide film; therefore, the capacitances between the drain, gate and source terminals are as

shown in Figure 4.3 (a).

Gate-drain capacitance Cgd and gate-source capacitance Cgs are determined by the gate electrode

construction. In addition, drain-source capacitance Cds is determined by the junction capacitance of

the PN junction based on the double diffusion construction.

Input capacitance Ciss = Cgd + Cgs, output capacitance Coss ∼

− Cds + Cgd, and reverse transfer

capacitance Crss = Cgd are important characteristics for power MOSFETs.

Figure 4.4 shows the dependence of Ciss, Crss and Coss on drain-source voltage VDS.

(a) Power MOSFET capacitance

(b) Simple equivalent circuit including

parasitic devices

rg

Drain (D)

Crss = Cgd

Gate

Drain

Cgs

Cgd

Gate (G)

Cds

gmVG

Cds

r1

Cgs

r3

r2

Source

Source (S)

Input capacitance: Ciss = Cgd + Cgs

rg: gate electrode parasitic resistance

Output capacitance: Coss = Cds + Cgd

r1: equivalent resistance of the source and channel areas

Reverse transfer: Crss = Cgd

r2: equivalent resistance of the high resistance layer

adjacent to the drain

r3: modulated part of the channel resistance

Input capacitance: Cin = Cgs + (1 + AV) Crss

Figure 4.3

2

Power MOSFET in Detail

In the driving of a power MOSFET,

the switching characteristics fluctuate

due to the input capacitance Ciss and

10000

the drive circuit impedance.

6000

4000

Since gate current flows between the

(pF)

gate and source to charge the input

Capacitance C

capacitor, the lower the drive circuit

impedance the faster the switching

speed.

Also, there is almost no temperature

dependence of the capacitors (Ciss, Crss,

2000

Ciss

1000

600

400

Coss

200

Common source

60 f = 1 MHz

Coss).

40 Tc = 25°C

0.3

6

Power MOSFET Switching

1

2

4

6

10

Drain-source voltage

20

40

100

VDS (V)

Characteristics

Since power MOSFETs are majority

Figure 4.4 Capacitance – VDS Characteristics

carrier devices, switching performance

is their main characteristic of interest. The switching speed of a power MOSFET is much faster than

that of a bipolar transistor and its high-speed, high-frequency operation is outstanding.

This characteristic is utilized in switching regulators (f = 1 kHz to 1 MHz) and in motor controls.

As mentioned before, two important features of power MOSFETs are that they have no storage time

dependence, and that their capacitance doesn’t depend on temperature; therefore, their switching

characteristics are not hardly influenced by temperature fluctuations.

Figure 4.5 shows a typical switching time measurement circuit and input/output waveforms.

(a) Measurement circuit

(b) Input/output waveforms

Pulse width

VDD

RL

Pulse

generator

RG

50 Ω

FB

90%

Output

VOUT

Input

Waveform

50%

50%

10%

0

VIN

50 Ω

4.4

Crss

100 VGS = 0

90%

90%

Output

Waveform

10%

0

td (on)

tr

ton

10%

tf

td (off)

toff

Figure 4.5 Switching Time Measurement Circuit and Input/Output Waveforms

3

Power MOSFET in Detail

The definitions of the symbols used for input and output waveforms for switching time are

explained below.

(1) td (on): turn-ON delay time

The charging time required to raise the voltage of input capacitance Ciss to the value of the

threshold voltage Vth.

(2) tr: rise time

The charging time required to raise the gate-source voltage from the value of gate threshold

voltage Vth to the specified VGS level.

(3) td (off): turn-OFF delay time

The discharge time required to lower the gate-source voltage from the drive voltage of the

saturation area to the specified VGS level of the linear area.

(4) tf: fall time

The time required to lower the gate-source voltage from the level of the drive voltage of the

saturation area to the value of the gate threshold voltage level Vth, and to raise the output

voltage to the supply voltage level.

As described above, the switching time can be divided into four different times. In addition, it

should be noted that ton is expressed by adding the turn-ON delay time td (on) to the rise time tr,

and that tOFF is expressed by adding the turn-OFF delay time td (off) to the fall time tf.

td (on) + tr = ton

td (off) + tf = toff

Figure 4.6 shows the switching characteristics (switching time versus drain current ID).

1000

800

10 V

600

0

RL

50 Ω

Switching time (ns)

10 μs

toff

400

Measurement

ID Outcircuit

put

Input

VDD

200

100

80

60

40

Repetitive

Duty <

= 0.5%

tf

ton

tr

Common source

∼ 200 V

VDD −

Tc = 25°C

20

0.3

1

2

4

6 8 10

20

40

Drain current ID (A)

Figure 4.6 Switching Characteristics

4

Power MOSFET in Detail

4.5

Gate Charge

4.5.1

Gate Charge Characteristics

Power MOSFETs are driven by a voltage applied between the gate and source, and the ease with

which a power MOSFET can be driven is expressed by the size of the charge stored in the gate.

td (on) is the time required for an input signal to be applied, the input capacitor to be charged

through the signal and gate resistors, and the gate voltage VGS to exceed the threshold voltage. This

is expressed as

td (on) ∝ Cgs × (rg + RG)

Here RG is the signal resistance and rg is the gate electrode parasitic resistance.

At td (on), the gate charge is expressed as

Qgs (on) ∼

− Cgs・VGS’

During the interval tr, the power MOSFET starts to operate; the input capacitance increases due to

the mirror effect and tr becomes longer than td (on), as follows:

tr∝ {Cgs + (1 + AV) Crss} × (rg + RG)

During the tr interval, the gate charge increases by the amount of reverse transfer capacitance Crss,

as follows:

Qon ∼

− {Cgs + (1 + AV) Crss}・VG

If the transient flow of gate charging current is iG (t), then the total charge Qtotal can be

determined by using the following equation:

Qtotal = ∫ 0t i G (t) dt

5

Power MOSFET in Detail

4.5.2

Calculating the Total Gate Charge

When the power MOSFET is switched ON, the gate current iG (t) flows to charge the gate-source

and gate-drain capacitors.

To determine the total gate charge under the circuit conditions shown in Figure 4.7, consider

allowing a small gate current of iG (t) = 1 mA (constant) to flow for 12 μs and then stopping the flow of

this gate current.

(b) iG (t), VGS (t), VDS (t) waveforms

(a) Total gate charge measurement circuit

Set VGG so that a

certain drain

current flows.

Gate Current

iG (t)

0

VDD = 200 V

1 mA

t’on = 12 μs

Driver FET

VG

Gate-Source

Voltage VGS (t)

VGG

VG

200 V

VDS

Drain-Source

Voltage VDS (t)

Constant-current

power supply

0

Drain-Source ON

Voltage VDS (on)

Figure 4.7 Total Gate Charge

The total gate-source charge Qtotal will be as follows:

t'

Qtotal = ∫ 0 on i G (t) dt

From the constant current iG (t) = 1 mA, the gate current is determined as follows.

−

iG (t) = IG = 1 mA = 1 × 10 3 A

−

Also, if t’on = 12 μs = 12 × 10 6 s, then

t'

Qtotal = ∫ 0 on i G (t) dt = IG ⋅ t'on

−

−

= 1 × 10 3 × 12 × 10 6

−

= 12 × 10 9 (C)

This Qtotal indicates the charge required to switch the MOSFET ON.

6

Power MOSFET in Detail

4.6

Source-Drain Diode

Due to their construction,

double-diffusion-construction power

MOSFETs have a parastic diode between

10

Common source

the source and drain.

(A)

T = 25°C

Drain reverse current IDR

The ratings for the forward current

IDR (Figure 4.8) and the reverse

breakdown voltage for this parastic diode

are the same as for drain current ID and

drain-source voltage VDSS for a power

MOSFET under the ideal heat radiation

D

8

IDR

G

6

S

4

1

VGS = 3 V

2

0

condition.

−1

The reverse recovery time trr for this

0

0

diode is similar to that for a Fast

−0.2

−0.4

−0.6

−0.8

Drain-source voltage

−1.0

−1.2

VDS (V)

Recovery Diode (FRD). Figure 4.9 shows

a reverse recovery time measurement

Figure 4.8 IDR – VDS Characteristics

circuit for the parastic diodes of power

MOSFETs.

(a) Reverse recovery time measurement circuit

D.U.T.

IDR

C2

C1

L1

Rg

P.G.

VGS

(b) Reverse recovery time (trr) and charge (Qrr)

+15 V

VGS: 0

−15 V

di/dt = 50 A/μs

IDR

IDR: 0

IDR: 0

VF

Qrr

10%

Irr

Vrr

*Qrr ∼

−

1

× trr × Irr

2

trr

Figure 4.9 Reverse Recovery Time Measurement Circuit for the Parastic Diodes of Power MOSFETs

7

RESTRICTIONS ON PRODUCT USE

• Toshiba Corporation, and its subsidiaries and affiliates (collectively “TOSHIBA”), reserve the right to make changes to the information

in this document, and related hardware, software and systems (collectively “Product”) without notice.

• This document and any information herein may not be reproduced without prior written permission from TOSHIBA. Even with

TOSHIBA’s written permission, reproduction is permissible only if reproduction is without alteration/omission.

• Though TOSHIBA works continually to improve Product's quality and reliability, Product can malfunction or fail. Customers are

responsible for complying with safety standards and for providing adequate designs and safeguards for their hardware, software and

systems which minimize risk and avoid situations in which a malfunction or failure of Product could cause loss of human life, bodily

injury or damage to property, including data loss or corruption. Before customers use the Product, create designs including the Product,

or incorporate the Product into their own applications, customers must also refer to and comply with (a) the latest versions of all

relevant TOSHIBA information, including without limitation, this document, the specifications, the data sheets and application notes for

Product and the precautions and conditions set forth in the "TOSHIBA Semiconductor Reliability Handbook" and (b) the instructions for

the application with which the Product will be used with or for. Customers are solely responsible for all aspects of their own product

design or applications, including but not limited to (a) determining the appropriateness of the use of this Product in such design or

applications; (b) evaluating and determining the applicability of any information contained in this document, or in charts, diagrams,

programs, algorithms, sample application circuits, or any other referenced documents; and (c) validating all operating parameters for

such designs and applications. TOSHIBA ASSUMES NO LIABILITY FOR CUSTOMERS' PRODUCT DESIGN OR APPLICATIONS.

• Product is intended for use in general electronics applications (e.g., computers, personal equipment, office equipment, measuring

equipment, industrial robots and home electronics appliances) or for specific applications as expressly stated in this document.

Product is neither intended nor warranted for use in equipment or systems that require extraordinarily high levels of quality and/or

reliability and/or a malfunction or failure of which may cause loss of human life, bodily injury, serious property damage or serious public

impact (“Unintended Use”). Unintended Use includes, without limitation, equipment used in nuclear facilities, equipment used in the

aerospace industry, medical equipment, equipment used for automobiles, trains, ships and other transportation, traffic signaling

equipment, equipment used to control combustions or explosions, safety devices, elevators and escalators, devices related to electric

power, and equipment used in finance-related fields. Do not use Product for Unintended Use unless specifically permitted in this

document.

• Do not disassemble, analyze, reverse-engineer, alter, modify, translate or copy Product, whether in whole or in part.

• Product shall not be used for or incorporated into any products or systems whose manufacture, use, or sale is prohibited under any

applicable laws or regulations.

• The information contained herein is presented only as guidance for Product use. No responsibility is assumed by TOSHIBA for any

infringement of patents or any other intellectual property rights of third parties that may result from the use of Product. No license to

any intellectual property right is granted by this document, whether express or implied, by estoppel or otherwise.

• ABSENT A WRITTEN SIGNED AGREEMENT, EXCEPT AS PROVIDED IN THE RELEVANT TERMS AND CONDITIONS OF SALE

FOR PRODUCT, AND TO THE MAXIMUM EXTENT ALLOWABLE BY LAW, TOSHIBA (1) ASSUMES NO LIABILITY

WHATSOEVER, INCLUDING WITHOUT LIMITATION, INDIRECT, CONSEQUENTIAL, SPECIAL, OR INCIDENTAL DAMAGES OR

LOSS, INCLUDING WITHOUT LIMITATION, LOSS OF PROFITS, LOSS OF OPPORTUNITIES, BUSINESS INTERRUPTION AND

LOSS OF DATA, AND (2) DISCLAIMS ANY AND ALL EXPRESS OR IMPLIED WARRANTIES AND CONDITIONS RELATED TO

SALE, USE OF PRODUCT, OR INFORMATION, INCLUDING WARRANTIES OR CONDITIONS OF MERCHANTABILITY, FITNESS

FOR A PARTICULAR PURPOSE, ACCURACY OF INFORMATION, OR NONINFRINGEMENT.

• Do not use or otherwise make available Product or related software or technology for any military purposes, including without limitation,

for the design, development, use, stockpiling or manufacturing of nuclear, chemical, or biological weapons or missile technology

products (mass destruction weapons). Product and related software and technology may be controlled under the Japanese Foreign

Exchange and Foreign Trade Law and the U.S. Export Administration Regulations. Export and re-export of Product or related software

or technology are strictly prohibited except in compliance with all applicable export laws and regulations.

• Product may include products subject to foreign exchange and foreign trade control laws.

• Please contact your TOSHIBA sales representative for details as to environmental matters such as the RoHS compatibility of Product.

Please use Product in compliance with all applicable laws and regulations that regulate the inclusion or use of controlled substances,

including without limitation, the EU RoHS Directive. TOSHIBA assumes no liability for damages or losses occurring as a result of

noncompliance with applicable laws and regulations.