Estimation of Partial Discharge Inception Voltages due to

advertisement

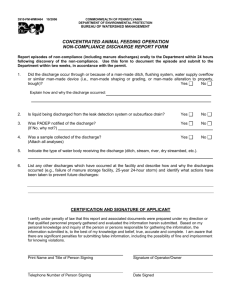

3rd IASME/WSEAS Int. Conf. on Energy & Environment, University of Cambridge, UK, February 23-25, 2008 Estimation of Partial Discharge Inception Voltages due to Voids in Power Cables M.U. Zuberi, A. Masood, M.F. Khan, Ekram Husain & A. Anwar Department of Electrical Engineering, Z.H. College of Engineering and Technology Aligarh Muslim University, Aligarh 202002 India Abstract - In this paper we report a technique for estimating the Partial Discharge (PD) inception voltages in case of discharges occurring at in voids in power cables in the ambient medium of air. Since occurrence of PD is a phenomenon dependent on upon many factors such as the type of gas in the void, the gas pressure, surface properties of the void, size and shape of the void, location of the void, dielectric constant of the surrounding medium etc; these parameters have to be taken into account. The computed values are valid in the pressure range of 0.067 kPa to 101.333 kPa and for gaps ranging from 0.001 cm to 11.0 cm. Computations are accurate to ± 3.5 % in the pt′ range of 0.0133 – 1400 kPa-cm. Keywords - Partial Discharge, Electrical Insulation, Void Discharges, Inception Voltage, Power Cables. 1. Introduction Quality of insulation is essential for successful and reliable operation of any power apparatus. Minor flaws and irregularities such as voids, surface imperfections in the insulation are however inevitable and lead to partial discharge which are characterized by an electrical breakdown at localized regions of the electrical insulation. [1]-[3]. The localization of the discharge may be the consequence of an electric field enhancement restricted to region that is relatively small compared with the dimensions of the space or gap between the conductors. The field enhancement can be associated with abrupt changes in the nature of the insulating medium that may be caused by voids in solid dielectrics or gas filled spaces at dielectric or gas filled spaces at dielectric-conductor or dielectric-dielectric interface. Discharges within cavities (voids) in solid insulating system [4] have long been associated with gradual degradation and dielectric failure. The correlation between cavity discharge and degradation has been established for rotating machines [5], power cables [6] encapsulated transformers and many other solid dielectric systems so that the correlation between cavity discharge and degradation is now well established. Gas filled cavities can originate in a wide range of solid dielectric systems through many mechanism including differential thermal expansion(composite systems) incomplete impregnation or excessive mechanical stress(fiber reinforced systems) or improper process control (epoxy castings).Cavities can also originate over a lifetime of operation as a result of environmental stresses. For PD tests, some existing standards have already evolved from the ‘representation of the worst working ISSN: 1790-5095 Page 345 conditions’ to the requirement of a ‘quality of the insulation system’. This procedure requires a high quality for the design and construction of the insulating structures by controlling their electric field strength at any point. However, in most of the cases it is in fact impossible to estimate the real dimensions of the PD source and of the cavity where it has been produced. Even more difficult is the evaluation of the chemical or physical deterioration that it will produce during long operating times. Since it has not been possible to establish a definite relationship between the discharge intensity and the in-service life of electrical insulating systems employed in cables and power apparatus, the conventional wisdom has always been to insist on the total absence of PD under operating conditions, which in turn favored the establishment and universal acceptance of standardized go/no-go PD tests. In an attempt to quantify the use of partial discharges in evaluating the quality of any insulation system, the lowest voltage at which such events is detected, the partial discharge inception voltage (PDIV) is proposed in [7]. The question arises as to how the PDIV depends on pressure as the pressure in the void decreases to near the Paschen minimum or below [8]. In the present work a technique has been developed to evaluate the partial discharge inception voltages in case of discharges occurring in voids in single core power cables. The estimation of partial discharge voltages is based on the analysis of Townsend breakdown criterion and is valid for the whole range of Paschen’s curve available. These formulations can be applied for estimating the PD inception voltages in case of discharges occurring in voids with sufficient accuracy for various cable sizes and pressures. ISBN: 978-960-6766-43-5 3rd IASME/WSEAS Int. Conf. on Energy & Environment, University of Cambridge, UK, February 23-25, 2008 2. Present Approach On the basis of the Townsend breakdown criterion γ[exp (αt′) – 1] = 1, breakdown voltage Vb is given as: Vb = Bpt ' ln[ Apt ' / ln(1 + 1 / γ )] (1) where p is pressure, t′ is gap spacing and γ is the secondary ionization coefficient. The constants A and B can be evaluated from the Townsend equation [9], [10] for the primary ionization coefficient, α = A p exp [–Bp/E] (2) where A is the saturation ionization in the gas at a particular E/p (electric stress/pressure) and B is related to the excitation and ionization energies [10] ,[11]. In the absence of secondary ionization coefficientγ, for the whole range of E/p, equation (1) is of little use for the evaluation of sparking potentials for the whole pt′ range. It is this drawback in Townsend’s equation which prevents the use of equation (1) for practical applications. Since, reasonably accurate breakdown voltages for the gas under consideration in our case are available [12] for a wide range of pt′ values; it is possible to use these values. Equation (1) can be written as: Vb = Bpt ' ln (pt ' ) + k (3) where k = ln[A / ln(1 + 1/γ)] (4) The values of A and B in equation (2) for air [9], [10] are given in Table 1. Table 1 Values of Constants A and B for Air A B Gas Ionisation /kPa-cm V /kPa-cm Air 112.50 2737.50 Using breakdown voltages Vb from [11] and the values of A and B from Table 1, k is computed and obtained [12] as a function of pt′ as shown in Table 2. Table 2 Computed k as a function of pt′ pt′ Gas k kPa-cm Air 0.0133 -0.2 2.0583(pt′)-0.1724 0.20 - 100 3.5134(pt′)0.0599 100 - 1400 4.6295[corresponding to pt′ = 100 kPa-cm in k=3.5134 (pt′)0.0599] Equation (3) is re-written as: Eg = Vb t ' = Bp ln( pt ' ) + k ISSN: 1790-5095 (5) Page 346 3. Estimation of Pd-Inception Voltages in Voids in a Single Core Cable The schematic of a single-core cable of conductor and sheath radii of Rc and Rs respectively with a cavity of thickness t′ located at a distance d from the conductor center is shown in Fig. 1. Fig 1: Cross section of a Coaxial Cable The expression for the inception voltage inside the gas filled cavity [13] is given as. Vi = S −1 Eg R ⎡ ⎡⎛ Rs ⎞⎛ t' ⎞ ⎤⎤ ⎢ln ⎢⎜⎜ ⎟⎟⎜1 + ⎟ ⎥ ⎥ . S ⎣⎢ ⎣⎢⎝ Rc ⎠⎝ R ⎠ ⎦⎥ ⎦⎥ (6) In the above equations Eg is the breakdown strength of the gas inside the void. The value of S depends upon the shape of the cavity. For a cylindrical void having a large radius to depth ratio, (7) S = ξr whereas for spherical voids [14] S is given by 3ξ r (8) S= 1 + 2ξ r ξ r denotes the relative permittivity of the dielectric sample. Substituting Eg from equation (5) into equation (6), Vi is written as: ⎧ ⎫ R ⎡ ⎡⎛ Rs ⎞⎛ Bp t' ⎞ Vi = ⎨ ⎬ ⎢ln ⎢⎜⎜ ⎟⎟⎜1 + ⎟ ⎩ ln( pt ') + k ⎭ S ⎢⎣ ⎢⎣⎝ Rc ⎠⎝ R ⎠ S −1 ⎤⎤ ⎥⎥ ⎥⎦ ⎥⎦ (8) where k = M (pt′) N, M and N are constants as given in Table 2 for different p t′ ranges. For obtaining critical t′ for minimum inception voltage, equation (8) can be differentiated with respect to t′ and equated to zero. The value of t′ thus obtained can be used in equation (8) to compute the critical inception voltage Vic. ISBN: 978-960-6766-43-5 3rd IASME/WSEAS Int. Conf. on Energy & Environment, University of Cambridge, UK, February 23-25, 2008 4. Discussion & Conclusions Inception Voltage Vi, kV-peak 10 0 0 0 10 0 0 10 0 S phe ric a l C ylindric a l 10 1 0 .0 0 0 1 0 .0 0 1 0 .0 1 0 .1 Cavity thickness t', cm Fig. 2: Variation in computed values of PDIV with cavity thickness for discharges in cavities of various shapes Inception Voltage, kV-peak 10 0 0 0 10 0 0 t' = 0.0005 c m t' = 0.001 c m 10 0 t' = 0.005 c m 10 1 1 10 10 0 10 0 0 Pressure, kPa Fig. 3: Variation in computed values of PDIV with pressure for discharges in cylindrical cavities of various thicknesses Inception Voltage Vi, kV-peak 10 0 10 R = 1.5 c m R = 2.5 c m R = 3.5 c m 1 0 .1 0 .0 1 0 .1 1 10 10 0 10 0 0 Pressure x cavity thickness pt', kPa-cm On the basis of Paschen’s curve and analysis of Townsend breakdown equation it is possible to compute PD inception voltage for discharges occurring in voids in power cables at different pressure and thickness of insulation. This approach is of great use to researchers in deciding their experimental parameters and help in deciding safe working stress for longer life. Fig. 2 gives a plot of the variation of PDIV with cavity size for spherical and cylindrical shaped cavities while other parameters are held constant. It is seen that the PDIV occurs at lower values as the cavity size increases. Furthermore, spherical cavities have a higher PDIV as compared to cylindrical cavities for the same cavity size. For a given cavity size, shape and location, the PDIV can be expressed a s function of pressure. The computed values of Vi with pressure for cylindrical cavities of various thickness are plotted in Fig. 3. It is seen that Vi exhibits a minimum which is the critical inception voltage Vic for a given t′. It is also observed that the minimum is occurring at lower and lower pressures as the thickness of the cavity is increased. Fig.4 illustrates the variation of PDIV with pt’ as the location of the void is changed in the cable insulation. The PDIV curves are found to follow the shape of the Paschen’s curve. It is also obvious from the figure that PDIV is minimum for voids located at the conductor surface where the stress is maximum and increases as the void location is moved towards the sheath. In a practical system, the cavity thickness at sheath surface are expected to be much larger than the cavity thickness at or near the conductor surface and correspondingly may have a lower inception voltage as given in Fig 2. In actual insulation, a number of voids of different shape and dimension are present at random and the critical discharges start at the most favorable site i.e. where stress concentration is maximum. The analysis presented does not address the surface roughness condition, which may exist in voids. Also deviations may exist because the values of breakdown voltages obtained from Paschen’s curve are valid for stress between metal-metal surfaces, whereas in case of partial discharge occurrence the electric stress is between dielectric-dielectric surfaces. It may suggest the Paschen’s breakdown voltage value is obtained from [15]. This method of estimation may be used for predicting PDIV in case of discharges occurring at interface as well as voids under uniform field conditions with sufficient accuracy and has been utilized for predicting PDIV in the ambient medium of air [16] and N2 [17]. Fig. 4: Variation in computed values of PDIV with cavity location for discharges in cylindrical cavities ISSN: 1790-5095 Page 347 ISBN: 978-960-6766-43-5 3rd IASME/WSEAS Int. Conf. on Energy & Environment, University of Cambridge, UK, February 23-25, 2008 References [1] J.H. Mason, “The deterioration and breakdown of dielectrics resulting from internal discharges”, Proc. IEE, 98, (I), pp. 44-59, 1951 [2] J.H. Mason, "Discharges", IEEE Trans.EI-13, No.4, pp 211-238, 1978. [3] C. Mayoux, C. Laurent, "Contribution of Partial Discharges to Electrical Breakdown of Solid Insulating Materials", IEEE Trans. on Dielectrics and Electrical Insulation Vol.2, No.4, pp 641-652, August 1995. [4] S.A. Boggs, “Partial Discharge: Cavity Induced PD in Solid Dielectrics ”, IEEE Electrical Insulation Magazine, 6, No.6, Nov-Dec 1990 [5] Hirabayashi, S.Y. Shibuya, T. Hasegawa and Y. Inuishi, “Estimation of the size of voids in coil insulation of rotation machines”, IEEE Trans. EI-9, No.4, pp.129-136, December 1974. [6] EPRI workshop Proceedings: “Morphology of PE and XLPE”, EPRI Contract TPS 81 184, November 1981. [7] E.O. FORSTER, “Partial discharges & streamers in liquid dielectrics - the significance of the inception voltage”, IEEE Trans. Electr. Insul., 28, (6), pp. 941-946, 1993. [8] D. R. James, I. Sauers, A. R. Ellis, M. O. Pace and DJ. Deschenes, “Effect of gas pressure on partial discharge in voids in epoxy”, in Proc. IEEE 2003 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, pp 628-632 [9] J.S. Townsend, "Electrons in Gases", Hutchinson’s London, 1947. [10] L.B. Loeb, "Basic processes of gaseous electronics", University Press, Berkeley 1955. [11] T.W. Dakin, G. Luxa, G. Oppermann, J. Vigreux, G. Wind, H. Winkelnkemper, "Breakdown of gases in uniform fields-Paschen's curves for air, N2 and SF6," Electra, No. 32, pp 61-82, 1974. [12] Ekram Husain and R.S. Nema, "Analysis of Paschen curves for Air, N2 and SF6 using the Townsend Breakdown Equation," IEEE Transactions on Electrical Insulation Vol. EI-17 No.4, August 1982. [13] N. H. Malik, A. A. Al-Arainy, A. M. Kailani and M. J. Khan, " Discharge Inception Voltages due to Voids in Power Cables," IEEE Transactions on Electrical Insulation Vol. EI-22 No.6, December 1987. [14] J.D. Jackson, "Classical Electrodynamics". John Wiley, 1962. [15] Ekram Husain and R.S. Nema, "Surface discharge studies with uniform field electrodes at low pressures", IEEE Trans. EI-16, No. 2, pp 128133, April 1980. ISSN: 1790-5095 Page 348 [16] E. Husain, A. Anwar, M. U. Zuberi & A. Masood “A Mathematical Technique for Estimation of Partial Discharge Inception Voltage at Different Pressures”, Proc. 2003 IASTED International Conference on Transmission, Distribution & Automation, pp 509-513. [17] M. U. Zuberi, A. Masood, E. Husain & A. Anwar “Estimation of Discharge Inception Voltages at Different Pressures in the Ambient Medium of N2”, Accepted for publication at IEEE PES Transmission & Distribution Conference and Exposition, Chicago, USA from April 21-24, 2008. ISBN: 978-960-6766-43-5