Urbane® Modular Carpet Tiles Install Instructions PDF / 146kb

advertisement

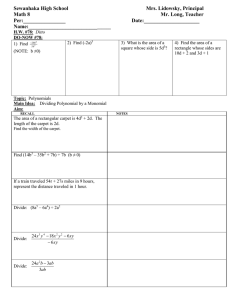

PROCEDURE FOR DOUBLE BOND SYSTEM COMPLETION OF INSTALLATION –– Prime the subfloor and apply adhesive accordingly to the manufacturers instructions. On completion of installing the carpet tiles, the following procedure shall apply: –– Install the underlay. Autex recommend that a double bond underlay, fully supported both sides to be dimensionally stable and a maximum total thickness of 5mm to be used. –– Install the carpet tiles Unless otherwise specified – remove underlay from its packaging and leave fully unrolled for a period of not less than 3 hours, for conditioning purposes. The underlay should be of a commercial grade, dimensionally stable and no thicker than 5mm. Please refer to AS/NZS 2455.2.1996 for additional instruction relating to the double bond installation requirements. Access panel floors – should be true and square and constructed and installed in accordance with AS 4154. NOTE: Attention is drawn to definition of “plane and smooth” in AS/NZS 2455.1.1996. CT1000 - 1 Urbane Installation Instructions August 2011 a. Ensure that no carpet pile is caught between the carpet tile joints and at the perimeters. b. Remove any excess adhesive and nap loose pile. c. Vacuum the total area. d. Ensure that all cut pieces are firmly fixed into position. e. Ensure that the whole work area is cleared of tools and waste. f. Installer to conduct a visual test of installation appearance before leaving the site. g. Where required, for commercial installations, the installed carpet tiles shall be protected by a suitable material. Further Information All queries with regards to the installation or the Urbane Modular Carpet Tiles should be directed to Autex Industries Ltd. ISO 9001 AND ISO 14001 CERTIFIED INSTALLATION INSTRUCTIONS GA400, GA400S, GA4OORS INSTALLATION INSTRUCTIONS PRE-LAYING REQUIREMENTS SETTING UP PLACEMENT OF CARPET TILES: General General Pre-laying shall be in accordance with AS/NZS 2455.1.1996: In setting up, a point in the room shall be determined from which the carpet tiles can be installed to ensure that they are laid a. Carpet Tiles should be fitted in a stair method as shown in Fig. 2. Prior to commencement, the installer should confirm carpet tiles, type, colour, batch numbers, tops and bottoms (if applicable) and arrow/ pile direction are all in accordance with the manufacturer’s specifications and the customer’s requirements. –– Parallel to the longest wall, unless specified otherwise. –– With not less than one-third of a carpet tile width at perimeter walls; and on access floors, with the edge of the modular carpet tile not corresponding with access floor joints. –– Subfloor Condition and Preparation Where practical there should be full tiles in doorways and high traffic areas. Subfloor preparation shall be in accordance with AS/NZS 2455.1.1996: The subfloor shall be rigid, clean, dry and be free of deleterious materials that may have an affect on the installation. The subfloor shall be tested for moisture and alkalinity. Refer to Fig. 1. NOTE: The porosity and absorption of adhesive varies with differing subfloor conditions. It is the responsibility of the installer to ensure the application rate of product, for each specific installation is sufficient to achieve the adhesive manufacturer’s recommended spread rates. Where there is a cable trunking, the finished surface shall be level with the subfloor. X ADHESION METHOD: DIRECT STICK SYSTEM F E d. When installing the carpet tiles, ensure that they are abutted. To ensure abutment is correct, measure the carpet tiles after every 10 modules are fitted. 2. Divide in half to find point X which provides the centre of the room. Prime the subfloor in accordance with subfloor preparation in AS/NZS 2455.1.1996 and spread pressure sensitive adhesive to 100% of the floor area by trowel, roller, brush or spray in accordance with adhesive manufacturers recommendations. CUTTING AND INSTALLATION OF PERIMETER TILES: Perimeter carpet tiles shall be cut and installed as shown in Fig. 3, and as follows: G a. Lay carpet tile C directly on top of B with pile uppermost, and edge of carpet tile C hard against the wall. e. Install carpet tile C, and install cut piece of carpet tile B with cut edge to the wall and the factory edge abutted to carpet tile C. us Rad i Waste --- E Longest Wall 3m F --- m 3m J2 d. Remove carpet tile C and waste from carpet tile B and apply primer and manufacturers recommended adhesive to the full width of the cut tile B from the perimeter wall. C --- s5 c. Using a straight edge, cut from the back face of the carpet tile B to obtain a cut piece to be the perimeter tile. 90° X Fig. 3. b. Using a sharp knife place nicks in the carpet tile B at edges. iu Rad 5m K J1 90° H 5. Draw a line 90˚ to line EG - through K and X. Fig. 1. H c. The carpet tile manufacturers instructions or directional arrow on the carpet tile should be followed for laying direction, unless agreed otherwise by the contractor and the purchaser. NOTE: Ensure that there is no peaking or gapping. 4. From J1 and J2 mark an arc 5 metres to complete point K, where they meet. G b. Lay carpet tiles in the sequence shown in Fig. 2. Lay GXF first, then proceed to lay tiles in the other quadrants in the same sequence commencing at access point X. 1. Measure H - F provides the measurement along the longest wall. 3. Mark points J1 and J2 at a distance of 3 metres each side of X. Fig. 2. Cut Edge B inlay Factory Edge NOTE: If pressure sensitive adhesive is used, ensure that the adhesive has become tacked up before installing the cut piece of the carpet tile.