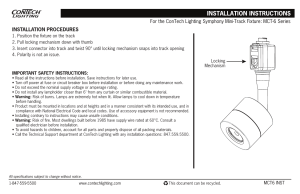

Installation Instructions MX MR16 GU10 Downlight

advertisement

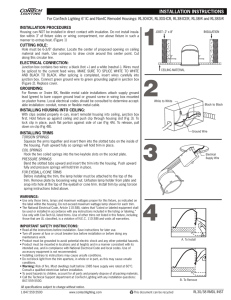

1 OF 5 Installation Instructions MX MR16 GU10 Downlight ! WARNING Risk of electrical shock. Disconnect power before servicing or installing luminaire. ! WARNING Risk of injury or damage. Luminaire will fail if not installed properly. Follow installation instructions. ! WARNING Risk of injury. Wear safety glasses and gloves during installation and servicing. Allow ample time to cool before handling. IS-R1031R5 IMPORTANT SAFETY INSTRUCTIONS –– Read all installation instructions before installing. It is important to save these instructions. –– Connectors on modules and approved housings are keyed for specific voltage combinations; do not force or attempt to bypass connectors. –– Observe and follow all label information and instructions regarding dry, damp and wet location listings, proper Intense LED module, warnings of installation near combustible materials and/or insulation. –– Turn off power at circuit breaker before attempting to install or perform maintenance on the fixtures. –– Be sure to connect ground wire to prevent electric shock or other potential hazards. –– The product must be installed in a manner consistent with the intended use and in compliance with the national electrical codes and local codes. –– Do not block the trim aperture as this may cause unsafe operating conditions. –– WARNING: RISK OF FIRE. Non-IC fixture requires that insulation must be kept at least 3” away from all sides of the fixture. Minimum of 90°C supply conductors. Consult a qualified electrician before installation. WARNING: Use only Intense Lighting trims listed for use with this fixture. Use of trims other than those listed by Intense Lighting is a violation of N.E.C 110-3(B) and voids all warranties. 1 HOUSING INSTALLATION: 1. Mount fixture housing according to ceiling type. -- Universal mounting bracket has slot openings for C-channel, flat bar, and 1/2” EMT; secure to joist or grid using fasteners or wire. C-channel hangers are recommended for T-Bar ceilings, install with notches facing down to engage T-Bar grid. 2 MOUNTING: Bar hanger mounting brackets offer several height choices depending on installation requirements. C-Channel, EMT and other joist bars can be ordered for various ceiling types. Housing lid Universal mounting bracket I100 (C-Channel) I200 (Flat Bar) I400 (Wood Joist) EMT 3 WIRING Metal conduit knockout Junction box cover plate 4 ELECTRICAL CONNECTIONS: 1. Make electrical connections through desired knockout for conduit or romex® cable. Use only UL listed connectors. 2. Connect black wire from fixture to black (HOT) supply wire, white wire from fixture to white (NEUTRAL) supply wire and connect the ground from fixture to green (GROUND) supply wire. Use UL listed connectors or wire nuts to make the connections (provided by others). 3. Close and lock junction box door ensuring all wire connections and wire are contained within. Lamp Note: Insulation detector not present on IC or CP housings Hot Neutral Ground Junction box INSTRUCTIONS L/M-04132016 P-1 Intense Lighting 3340 E La Palma Ave, Anaheim, CA 92806 | tel 714 630-9877 | fax 714 630-9883 ©2016 Intense Lighting, LLC. All rights reserved. Subject to change without notice. 120V connection wires 2 OF 5 IS-R1031R5 HOUSING HEIGHT ADJUSTMENT: Loosen wingnut to make adjustments so that housing collar is flush with ceiling line. 5 6 CEILING THICKNESS: Ceiling thicknesses over 5/8” require custom spring clips on trim. For specific mounting requirements, see submital spec sheet. Wingnut Housing collar Housing collar Ceiling line Ceiling line Flush TRIMLESS INSTALLATION: 1. Screw perforated mud plate to housing with #8 drywall screws (by others). 2. Reinstall plenum cover to prevent paint damage to fixtures. 3. Apply joint compound over perforated mud plate and feather out accordingly. 7 8 TRIMLESS INSTALLATION (B): 1. Screw in mud plate into drywall. Note: Do not remove plenum cover until mud and paint has been applied Mud plate Plenum cover Screws Screw in mud plate into drywall LAMP INSTALLATION/SERVICING: 1. Remove trim, then remove module from channel and disconnect quick connect. 2. Rotate release cap by turning counter clockwise. 3. Set cap aside and change lamp. 4. Align lamp base to socket in module, insert lamp then twist and lock. Module Optic 9 MODULE INSTALLATION: 1. Connect female quick connect from housing to male quick connect on module. 2. Snap module into channel and confirm module sits parallel to ceiling line and is securely fastened into housing. Quick connect Socket Release cap INSTRUCTIONS L/M-04132016 P-2 Intense Lighting 3340 E La Palma Ave, Anaheim, CA 92806 | tel 714 630-9877 | fax 714 630-9883 ©2016 Intense Lighting, LLC. All rights reserved. Subject to change without notice. Channel 10 3 OF 5 IS-R1031R5 11 ADJUSTING HORIZONTAL ADJUSTMENT: 1. Loosen thumb screw to allow fixture to adjust horizontally. 2. Tighten thumb screw to lock horizontal rotation. 12 TRIM INSTALLATION (APPLIES TO ROUND HOUSING ONLY): 1. Position trim label to trim location label in the housing collar. 2. Snap trim into the housing. Trim label Trim label Thumb screw (Horizontal locking) TRIM INSTALLATION (APPLIES TO SQUARE HOUSING ONLY): 1. Position trim label to trim location label on the housing collar. 2. To install trim, rotation plate must be parallel with the housing. Note: Trim will not lineup at any other angle than 90º increments. Rotation plate Trim label Trim label ACCESSORY HOLDER: 1. Rotate release cap by turning counter clockwise. 2. Install accessories into accessory holder and replace accessory holder’s retaining clip. 3. Place accessory holder and accessory flush against optic and replace release cap. Module Accessories Accessory holder’s retaining clip Accessory holder Release cap INSTRUCTIONS L/M-04132016 P-3 Intense Lighting 3340 E La Palma Ave, Anaheim, CA 92806 | tel 714 630-9877 | fax 714 630-9883 ©2016 Intense Lighting, LLC. All rights reserved. Subject to change without notice. Housing 4 OF 5 IS-R1031R5 REPLACING ASSEMBLY: 1. Remove module from channel and disconnect quick connect. 2. Unscrew all four 2mm allen key head machine screws on both sides. 3. Remove vertical adjustment assembly by tilting the assembly to assure clearance. Junction box plate Module quick connect Assembly Allen head machine screws Ceiling opening Accessories and Options MECHANISM KIT Converts between Adjustable or Wall Wash MR16 MODULE KIT ITEM NUMBER Consult factory for MR16 modules IP-MXAJ (MX Adjustable Mechanism) IP-MXWW (MX Wall Wash Mechanism) ACCESSORY HOLDER FILTER MEDIA Holds two filter media Requires an accessory holder ITEM NUMBER ITEM NUMBER LH47 (Accessory Holder, Black) PFLMB-47 PFL4-47 PFL2-47 PFL1-47 WET LOCATION KIT Converts downlight trims into wet location trims. SERIES MXL-RD MXL-SD MXL-RP MXL-SP LENS TYPE (Round Downlight) (Square Downlight) (Round Pinhole) (Square Pinhole) -SL (Solite) -CR (Clear Tempered) -FR (Frosted) INSTRUCTIONS L/M-04132016 P-4 Intense Lighting 3340 E La Palma Ave, Anaheim, CA 92806 | tel 714 630-9877 | fax 714 630-9883 ©2016 Intense Lighting, LLC. All rights reserved. Subject to change without notice. (Hex Louver, Black) (Solite Lens) (Linear Spread Lens) (Prismatic Spread Lens) 5 OF 5 INTENSE LIGHTING WARRANTY 1-YEAR LIMITED WARRANTY Intense Lighting warrants its properly installed products to be free of defects in material and workmanship in normal use, for a period of one year from the date of our shipment. Certain products may have a longer warranty period as noted on the product’s specification sheet, Intense Lighting will repair or replace, at its option, any warranted product returned to it that it determines to be defective. This limited warranty does not include installation or removal, nor does it include lamps, transformers and ballasts, which are covered by their respective manufacturers. To receive credit for defective merchandise, product must undergo quality inspection prior to the processing of credit. If the product is found defective, you will be issued a credit. Product in good working condition will not receive a credit. Please inform your accounting department not to short pay or issue any debits to our company regarding a return. Testing and evaluation can take approximately 1-2 weeks based on quantity. At that time you will be notified if credit is granted for your warranty return. THE ABOVE EXPRESS WARRANTY STATES THE FULL AND COMPLETE OBLIGATION OF INTENSE LIGHTING. ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED IN DURATION TO THE TERM OF THE EXPRESS WARRANTY. UNDER NO CIRCUMSTANCES WILL INTENSE LIGHTING ACCEPT LIABILITY FOR ANY CONSEQUENTIAL SPECIAL OR INDIRECT DAMAGES WHETHER ARISING OUT OF CONTRACT, TORT, OR STRICT LIABILITY. 5-Year and 10-Year Limited Warranty applies to select LED products. Contact Intense Lighting for more information. INSTRUCTIONS L/M-04132016 P-5 Intense Lighting 3340 E La Palma Ave, Anaheim, CA 92806 | tel 714 630-9877 | fax 714 630-9883 ©2016 Intense Lighting, LLC. All rights reserved. Subject to change without notice.