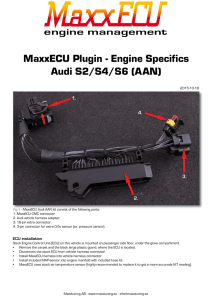

Engine management Molded electronic control unit

advertisement

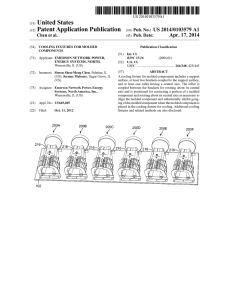

Engine management Molded electronic control unit 1 2 3 6 4 5 Product benefits ff Low weight and small size 1 Direct plug connector with ≤44 pins ff Fast and easy calibration 2 DMC (data matrix code) ff Easy to maintain 3 Sealing ff Good thermal conductivity and temperature stability 4 Guiding ff Vibration resistance 5 Lever area 6 Molded housing Vehicle segments Engine management Molded electronic control unit direct connection Direct plug connector technology, suitable for mounting conditions specific to two-wheelers reliable The molded ECU works reliably and independently of ambient conditions (vibration, temperature, tightness). scalable Hardware and sofware scalable for different markets and system requirements Task The electronic control unit (ECU) collects all necessary information for the engine, for example sensor signals, prioritizes them, and then goes about implementing them. Furthermore rider demands and exhaust-system requirements related to the mixture composition are computed. Torque is the key factor in implementing these requests. For instance, the air-fuel ratio is adjusted in such a way that torque is provided as economically and cleanly as possible. Doing so also allows active safety systems such as ABS and motorcycle stability control (MSC) to affect engine torque. Technical characteristics Function The electronic control unit is realized as a printed circuit with various types of housing possible; in this case, molded housing. It is also able to manage upcoming features such as on-board diagnostics (OBD), a start-stop function, ISO 26262 (Road vehicles – Functional safety), knock control, connectivity, and enhanced user experience, enabled by Bluetooth-compatible communication. Technology inductive or Hall Microcontroller 32 bit Housing molded Thermal concept proper heat dissipation Connector ≤ 44 pins Possible applications 1 cyl. with electronic throttle control (ETC) or 2 cyl. with idle speed actuator (ISA) Emissions legislation up to Euro 5 and comparable Software specific SW platform covering complete two-wheeler functionality Optional software features digital knock control, flex fuel Fault handling with service interface End-of-line (EoL) programming possible, including data variant handling Bosch Corporation | Two-Wheeler & Powersports | 3-9-1, Ushikubo | Tsuzuki-ku, Yokohama | Kanagawa 224-8501 | Japan | www.bosch-motorcycle.com Printed in Germany 292000P1HW-C/CCA-201510-En © Robert Bosch GmbH 2015. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.