ELEC 6740: Electronics Manufacturing Chapter 12: Soldering of

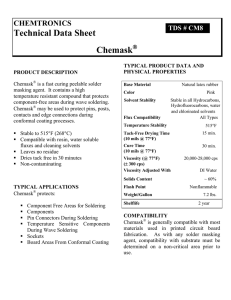

advertisement

ELEC 6740: Electronics Manufacturing Chapter 12: Soldering of Surface Mount Components R. Wayne Johnson Alumni Professor ECE Department, Auburn University 334-844-1880 johnson@eng.auburn.edu Subjects ! ! ! ! ! ! ! Introduction Wave Soldering Vapor Phase Reflow Soldering Infrared Reflow Soldering Convection Reflow Soldering Soldering Defects Alternate Soldering Methods Introduction ! ! ! Soldering - Low temperature Brazing – Medium temperature Welding – High temperature Wave Soldering ! ! ! ! Through hole components SMT resistors, capacitors, diodes, SOTs SOICs more difficult PLCCs and PQFPs should be avoided Wave Solder ! Flux application ! ! ! ! Preheat ! ! ! Foam Spray Jet Minimize thermal shock to board Activate flux Solder wave ! ! Provide solder alloy Form metallurgical connections Wave Solder Flux Spray Pre-heat Molten Solder Wave Wave Soldering Wave Solder Wave Solder Technical Issues Design for Wave Solder ! Outgassing (gas bubbles released from wet flux can cause solder skip or lack of fillet. Design for Wave Solder Design for Wave Solder Board travel direction over the wave Wave Soldering ! Bridges can occur beneath small chips (0805, 0603, 0402, 0201) ! ! Capillary action between glue dots Only liquid photoimageable solder mask is recommended bewteen pads Machine Control Wave Soldering Max. Nom. Minimum 6°C /sec 4°C /sec * ** Temperature Differential Solder Temperature 135°C 120°C 110°C 260°C 240°C ** Dwell Time @ Max. 4 sec. 3 sec. ** N/A 4°C /sec. N/A Ramp up (°C /sec) Ramp Down (°C /sec.) Temperature measured at the component lead area in degrees celcius. Temperature differential between the final preheat stage and the soldering stage. * Will vary depending on board density, geometry and package type. ** Will vary depending on package types and board density Wave Soldering ! Capacitor cracking ! Delta between the wave and the preheat should be 100-120oC Temperature Profile Dual Wave Removes excess solder Forces solder into narrow regions Dual Wave Vibrating Wave 50 or 60Hz vibrations Vibrating Wave Vibration said to be more effective in filling holes and eliminating solder skips than the dual wave. Dual wave and vibrating wave lead to more Sn loss (reaction with atmopshere). Need to replenish Sn. Modified Wave ! ! To reduce bridging and iclicles Improves top side fillets Inert Atmosphere ! ! Nitrogen cover over wave Compensates for lower flux activity Inert Atmosphere Inert Atmosphere Vapor Phase Reflow ! ! ! ! ! ! Q= hA(Tv – Ts) Q = heat transfer rate h = heat transfer coefficient Tv = saturated vapor temperature Ts = part surface temperature A = product surface temperature In-line Vapor Phase Vapor Phase Soldering Vapor Phase Soldering Profile Vapor Phase Soldering Profile Solder Wicking Solder Wicking ! h is higher for a vertical surface than for a horizontal surface Solder Wicking Infrared Reflow Soldering ! ! ! Class I: Radiant IR dominant system Class II: Convection/IR dominant system Class III: Convection dominant systems Infrared Reflow Soldering Infrared Reflow Soldering Infrared Heat Transfer (Radiation) Q = V × E s × At × K (T ⋅ Tt ) 4 s ! ! ! ! ! ! ! 4 Q = infrared heat transfer rate V = geometric view factor (0-1) Es = emissivity factor of the source (0-1) At =absorption factor of the target (0-1) K = Stefan-Boltmann constant (5.67x10-12 w/cm2/K4) Ts = source temperature Tt = target temperature Solder Wicking Convection Heat Transfer ! ! ! ! Q = H x ∆T Q = heat absorbed per unit area H = convective film coefficient ∆T = temperature difference between fluid (air) and the object Convection Reflow Pro & Con of IR & Convection Nitrogen Reflow Solder Profile Development Profiling Common Reflow Defects ! Tombstoning and Part Movement ! ! ! If heating rate is too high, the volatiles in the solder paste will rapidly evolve, possibly causing tombstoning (standing on end), drawbridging (standing at an angle) or lateral shift. Poor design Poor solder wetting Common Reflow Defects ! Thermal shock ! ! Rapid heating or cooling rates Part surface temperature is higher than interior ! ! Component cracking Solder mask discoloration ! Especially dry film solder masks in IR dominant systems Laser Soldering ! ! Selective heating for temperature sensitive components Heats the solder only and not the component Laser Soldering Laser Soldering Laser Soldering Hot Bar Soldering Hot Bar Soldering Hot Bar Soldering Profile Hot Bar Soldering Profile Soldering Options